Production process of baking base paper

A production process and baking technology, applied in the field of papermaking, can solve the problems of polluted environment, seersucker paper disease, uneven drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

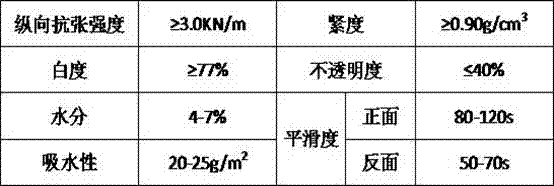

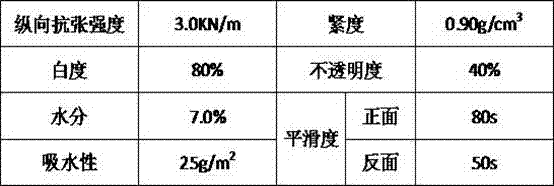

Embodiment 1

[0012] Choose 100% bleached coniferous wood pulp board, and enter the beating process after pulping and heavy slag removal. The beating is divided into two stages. After the first stage of beating, the beating degree of the pulp is controlled to 40°SR. The degree of beating is 65°SR, and the wet weight is 5.5g. After that, the slurry enters the high-level box, and 2.0% PAE relative to the dry pulp is added to the high-level box. After that, the slurry is diluted and heavy slag is removed. Add 0.7% cationic starch relative to absolute dry pulp and 0.05% defoamer relative to absolute dry pulp at the outlet of the pressure sieve. Pressing enters the first stage of drying process. The first stage of drying process includes 10 drying cylinders. The temperature of drying cylinders 1-4# is 80°C, the temperature of drying cylinders 5-9# is 86°C, and the temperature of drying cylinders 10# is 35°C, the first stage of calendering is carried out on the dried paper, the calendering temper...

Embodiment 2

[0016] Choose 100% bleached coniferous wood pulp board, and enter the beating process after pulping and heavy slag removal. The beating is divided into two stages. After the first stage of beating, the beating degree of the pulp is controlled to 40°SR. The degree of beating is 65°SR, and the wet weight is 5.5g. After that, the slurry enters the high-level box, and 3.0% PAE relative to the dry pulp is added to the high-level box. After that, the slurry is diluted and heavy slag is removed. Add 1.1% cationic starch relative to absolute dry pulp and 0.10% defoamer relative to absolute dry pulp at the outlet of the pressure sieve. Pressing enters the first stage of drying process. The first stage of drying process includes 10 drying cylinders. The temperature of drying cylinders 1-4# is 83°C, the temperature of drying cylinders 5-9# is 88°C, and the temperature of drying cylinders 10# is 40°C, the first stage of calendering is carried out on the dried paper, the calendering temper...

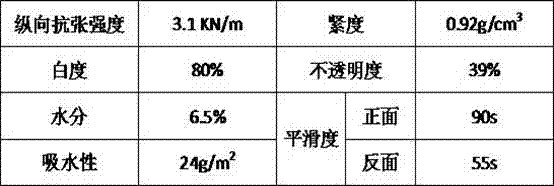

Embodiment 3

[0020]Choose 100% bleached coniferous wood pulp board, and enter the beating process after pulping and heavy slag removal. The beating is divided into two stages. After the first stage of beating, the beating degree of the pulp is controlled to 43°SR. The degree of beating is 68°SR, and the wet weight is 5.0g. After that, the slurry enters the high-level box, and 2.5% PAE relative to the dry pulp is added to the high-level box. After that, the slurry is diluted and heavy slag is removed. Add 1.1% cationic starch relative to absolute dry pulp and 0.10% defoamer relative to absolute dry pulp at the outlet of the pressure screen. Pressing enters the first stage of drying process. The first stage of drying process includes 10 drying cylinders. The temperature of drying cylinders 1-4# is 83°C, the temperature of drying cylinders 5-9# is 88°C, and the temperature of drying cylinders 10# is At 40°C, the first stage of calendering is carried out on the dried paper. The calendering tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com