High-hardness plastic paving material

A pavement material, high hardness technology, applied in decoration, floor covering, application, etc., can solve the problems of PVC floor cost increase, poor dimensional stability, low production efficiency, etc., to increase fluidity, facilitate calendering, hardness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

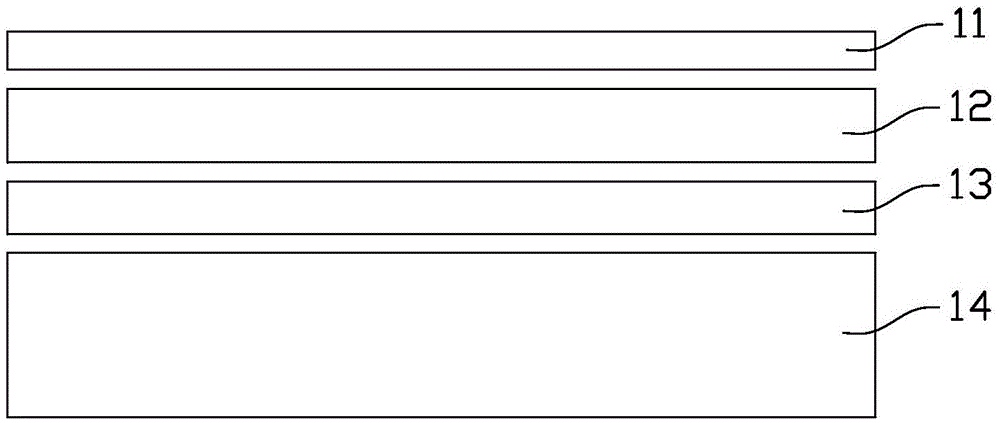

[0038] The high-hardness plastic pavement material of the present invention is a composite material, which can be used not only for laying the ground, but also for laying ceilings, walls, wardrobes and the like. In the present invention, the high-hardness plastic paving material is preferably composite flooring. Such as figure 1 As shown, the high-hardness plastic paving material includes a UV coating 11 , a surface protection layer 12 , a decoration layer 13 and a base layer 14 from top to bottom.

[0039] The UV coating 11 is formed on the surface protection layer 12 . In other embodiments of the present invention, the UV coating 11 may be omitted as appropriate.

[0040] The thickness of the surface protection layer 12 is 0.05-1.5mm, and the surface protection layer 12 can be made of rigid polyvinyl chloride transparent film, rigid polyester transparent film or other suitable materials. The rigid polyvinyl chloride transparent film or the rigid polyester transparent film...

no. 2 example

[0047] The UV coating 11, the surface protection layer 12, and the decorative layer 13 of the high-hardness plastic pavement material of the present embodiment are completely the same as the high-hardness plastic pavement material of the first embodiment, and the differences between the present embodiment and the first embodiment in the base layer 14 . In this embodiment, no liquid plasticizer is added to the material of the base layer 14 . In this embodiment, the mass percentages of the components in the base layer 14 are as follows: PVC resin 100wt%, solid plasticizer 10-60wt% (preferably 30-60wt%), additives 60-510wt% (preferably 150-350wt%, the best is 225-300wt%).

[0048] Among the components of the base layer 14, the additive is a mixture of stone powder and other additives. Other additives in the present invention can be at least one of PVC common additives such as stabilizer, flame retardant, smoke suppressant, antioxidant. The solid plasticizer is a modified envir...

no. 3 example

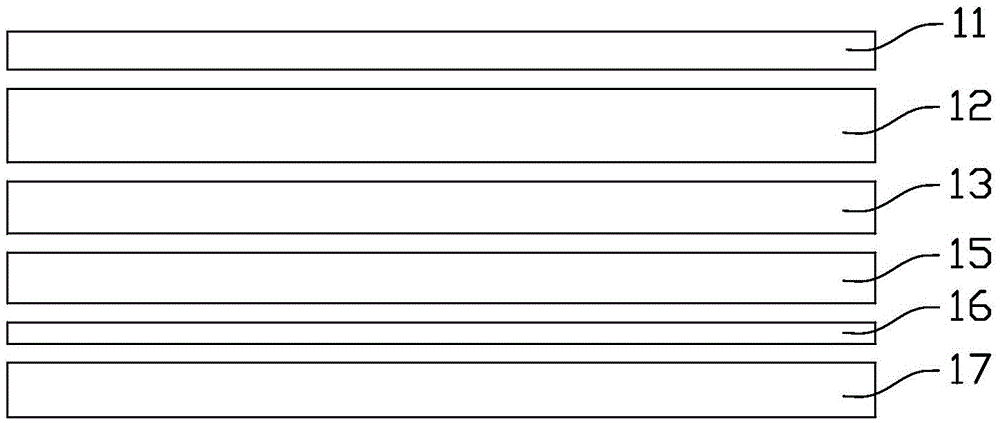

[0051] The UV coating 11, the surface protection layer 12, and the decorative layer 13 of the high-hardness plastic pavement material of the present embodiment are completely the same as the high-hardness plastic pavement material of the first embodiment, and the differences between the present embodiment and the first embodiment in the base layer. In this embodiment, the base layer includes two layers of the middle material layer 15 and the bottom material layer 17, and the components of the middle material layer 15 and the bottom material layer 17 are the same as those of the base layer in the first embodiment, and the difference is only in the composition mass percentage. The mass percent of each component in the middle material layer 15 is as follows: PVC resin 100wt%, solid plasticizer 10~60wt%, liquid plasticizer 0.1~10wt%, additive 125~400wt% (preferably being 150~350wt%, The optimum is 225-300wt%), wherein the additive is a mixture of stone powder and other additives....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com