Environmental-friendly coating adhesive and preparation method thereof

An adhesive and environment-friendly technology, applied in coatings, paper coatings, textiles and papermaking, etc., can solve the problems of weak adhesion, poor water resistance, poor dispersibility, etc., to improve film formation, reduce production costs, The effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

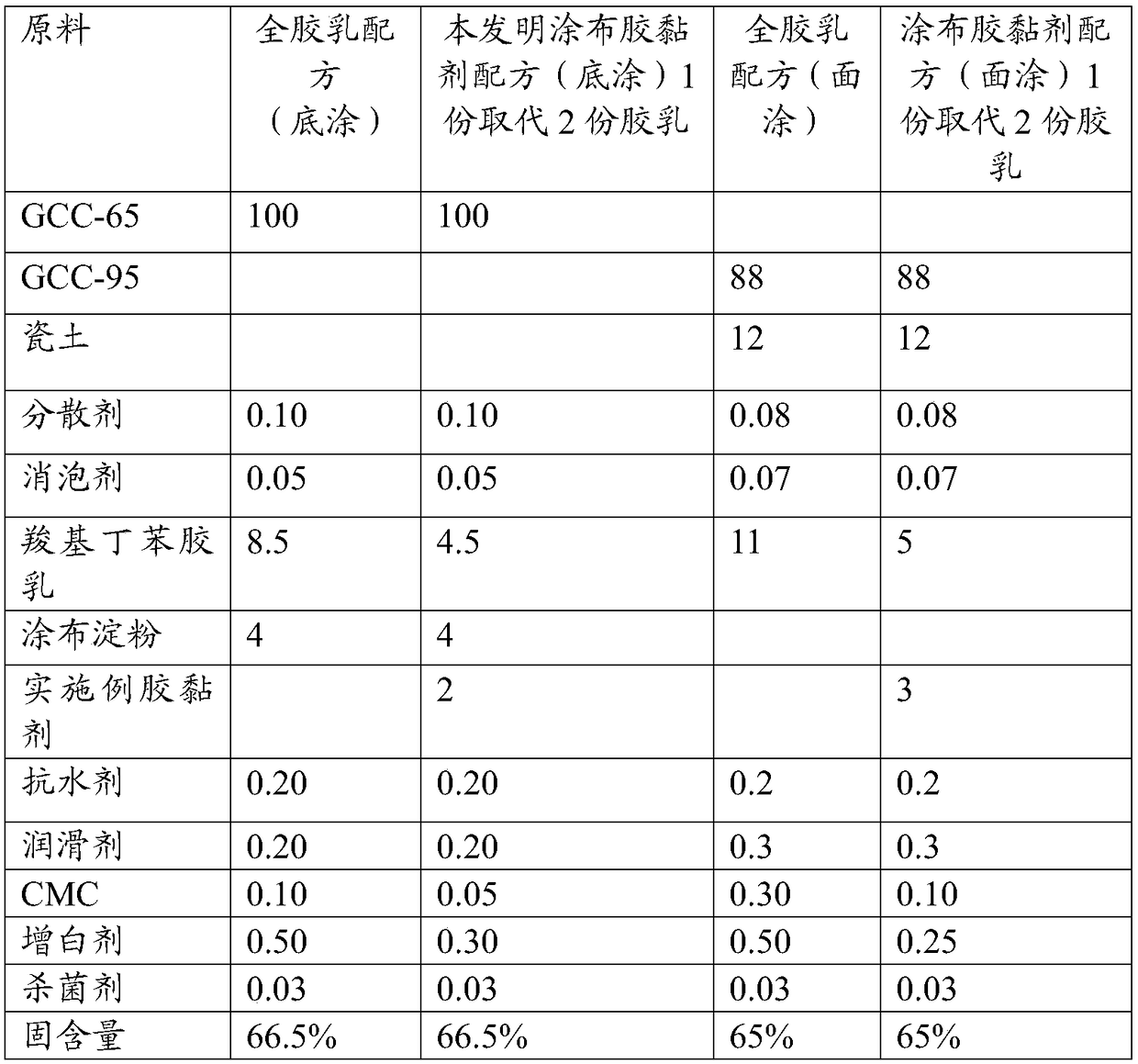

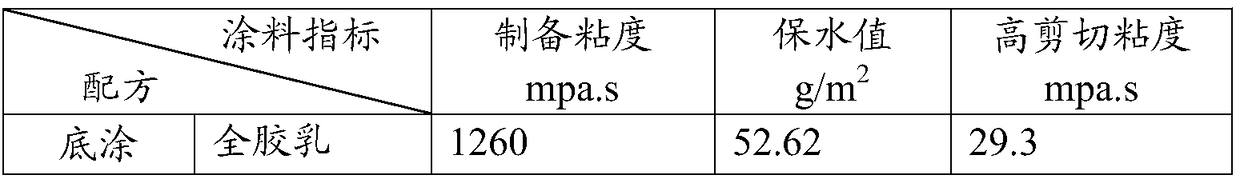

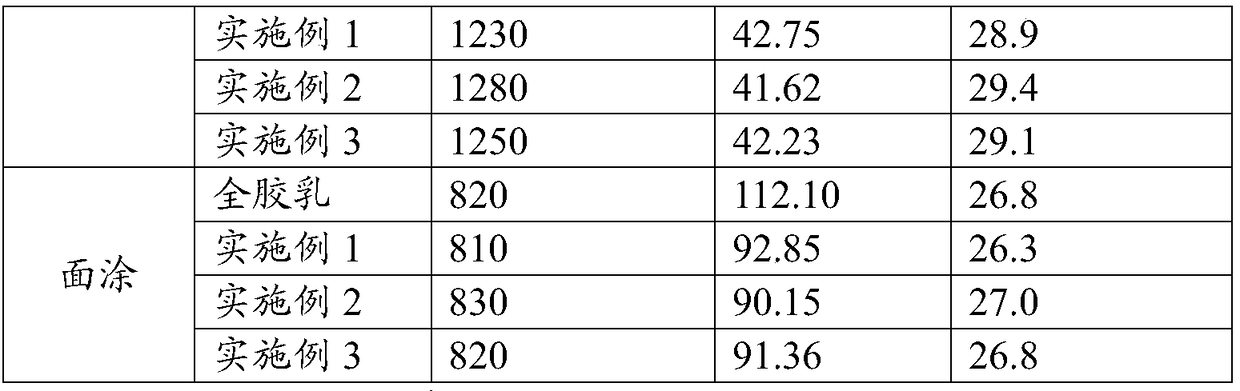

Examples

Embodiment 1

[0026] 1. In a 500ml four-neck flask, add 72g of purified water, start stirring, add 100g of tapioca starch, stir to form an emulsion, slowly add 10g of glycerin into the flask, heat up to 60°C, and keep the reaction for 30min.

[0027] 2. Add 200g of purified water into a 500ml four-neck flask and turn on the stirring, add 55g of PVA, raise the temperature to 90°C, keep it warm for 30min, and prepare a PVA solution.

[0028] 3. Add 100g of the prepared starch solution and 120g of the prepared PVA solution into a 500ml four-neck flask, mix well and add glyoxal dropwise at 60°C for 60 minutes, and keep warm for 60 minutes after the addition is completed; The amount of dialdehyde added is 10% of the total mass of the starch solution and the PVA solution;

[0029] 4. After the heat preservation is completed, the temperature is raised to 70°C, and a mixed monomer composed of 1g of acrylic acid, 10g of butyl acrylate, and 5g of methyl acrylate is added dropwise, and is initiated by...

Embodiment 2

[0032] 1. In a 500ml four-neck flask, add 72g of purified water, start stirring, then add 100g of cornstarch, stir to form an emulsion, slowly add 6g of diethylene glycol into the flask, raise the temperature to 70°C, and keep the reaction for 45min.

[0033] 2. Add 200g of purified water into a 500ml four-neck flask and turn on the stirring, add 60g of PVA, raise the temperature to 95°C, keep it warm for 30min, and prepare a PVA solution.

[0034] 3. Add 100g of the prepared starch solution and 130g of the prepared PVA solution into a 500ml four-neck flask, mix well and add N-methylolacrylamide dropwise at 60°C for 50 minutes. Keep warm for 60 minutes; the amount of glyoxal added is 5% of the total mass of the starch solution and the PVA solution;

[0035] 4. After the heat preservation is completed, the temperature is raised to 80°C, and a mixed monomer composed of 1g of acrylic acid, 2g of sodium styrene sulfonate, 10g of isooctyl acrylate, and 10g of methyl methacrylate is...

Embodiment 3

[0038] 1. In a 500ml four-neck flask, add 72g of purified water, start stirring, then add 100g of tapioca starch, stir to form an emulsion, slowly add 6g of glycerin into the flask, heat up to 80°C, and keep the reaction for 45min.

[0039] 2. Add 200g of purified water into a 500ml four-neck flask and turn on the stirring, add 80g of PVA, raise the temperature to 90°C, keep it warm for 30min, and prepare a PVA solution.

[0040] 3. Add 100g of the prepared starch solution and 100g of the prepared PVA solution into a 500ml four-neck flask, mix well and add zirconium oxychloride dropwise at 60°C for 60 minutes, and keep warm for 30 minutes after the addition is completed; The amount of glyoxal added is 15% of the total mass of the starch solution and the PVA solution;

[0041] 4. After the heat preservation is completed, the temperature is raised to 70°C, and a mixed monomer composed of 1g of methacrylic acid, 5g of butyl acrylate, and 5g of isooctyl acrylate is added dropwise, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com