A kind of flexible graphite paper calendering device

A calendering device and flexible graphite technology, applied to presses, presses using rotating pressure components, manufacturing tools, etc., can solve the problems of unsatisfactory calendering quality of graphite paper, inconsistent adjustment of two ends, unfavorable calendering, extension, etc., to achieve Good use effect, sensitive calendering thickness, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

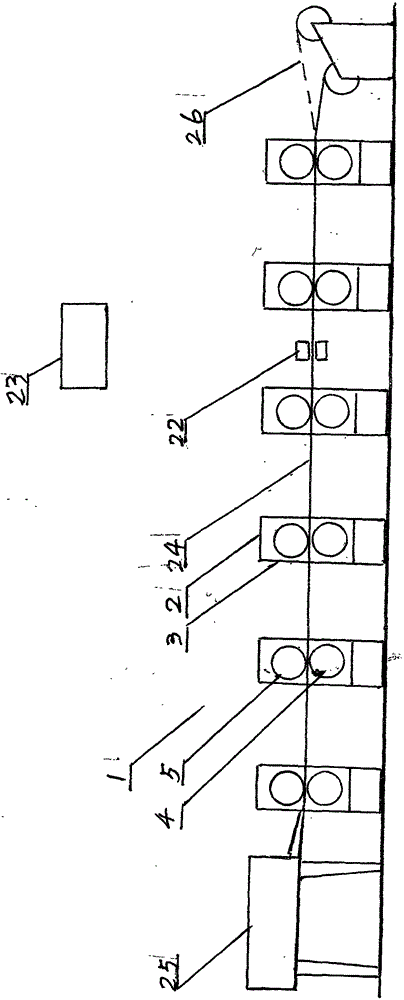

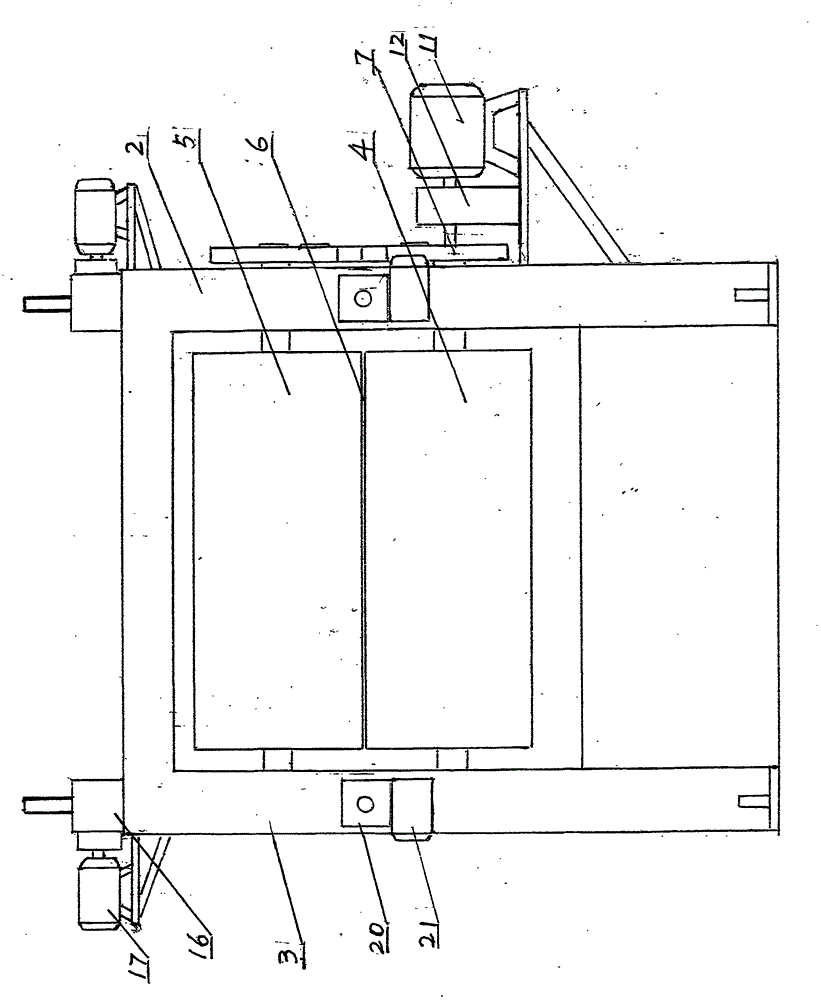

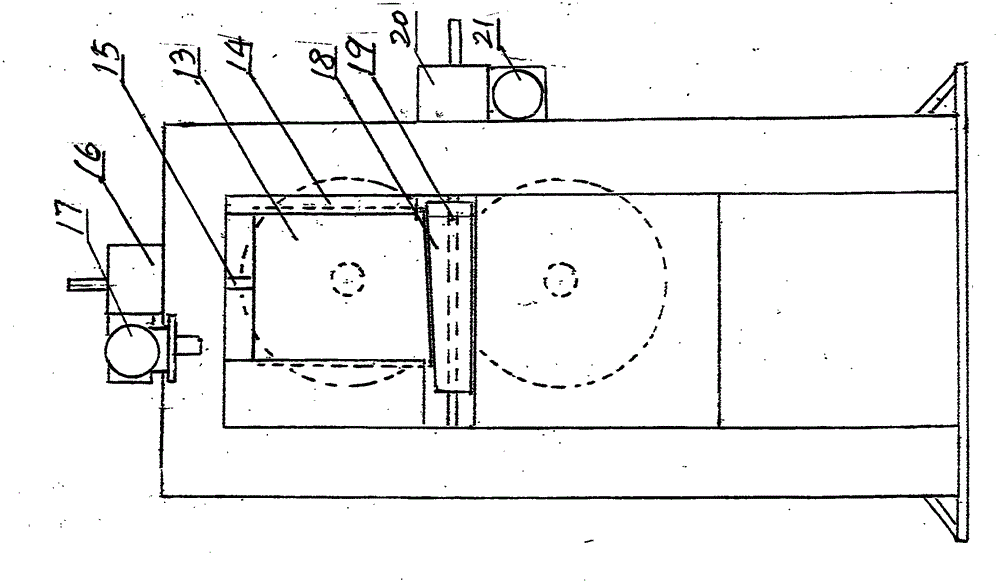

[0014] attached figure 1 , 2 , 3, 4 express a specific embodiment of the present invention. The flexible graphite paper calendering device is composed of a plurality of calenders 2 arranged in sequence, and each calender is composed of a frame 3, a driving roller 4, a driven roller 5, a roller transmission mechanism and a gap between the two rollers. Adjustment mechanism. The transmission mechanism is engaged with the first driven gear 8 by the driving gear 7 installed on the shaft end of the driving pressure roller, the first driven gear 8 is engaged with the second driven gear 9, and the second driven gear 9 is engaged with the The driven gear 10 at the shaft end of the driven pressure roller is formed by meshing with each other. The number of calenders 2 arranged in sequence is 6-10, and this embodiment is 6. The diameters of the rollers of the 6 calenders are divided into two groups of large diameter and small diameter. The 1st, 3rd, and 5th calenders are calenders equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com