Anti-aging rubber sealing ring material and preparation method thereof

A rubber sealing ring and anti-aging technology, applied in the field of rubber sealing materials, can solve problems such as shortening the service life of equipment, corrosion of mechanical equipment, leakage of materials, etc., to facilitate calendering and extrusion molding operations, prevent corrosion, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

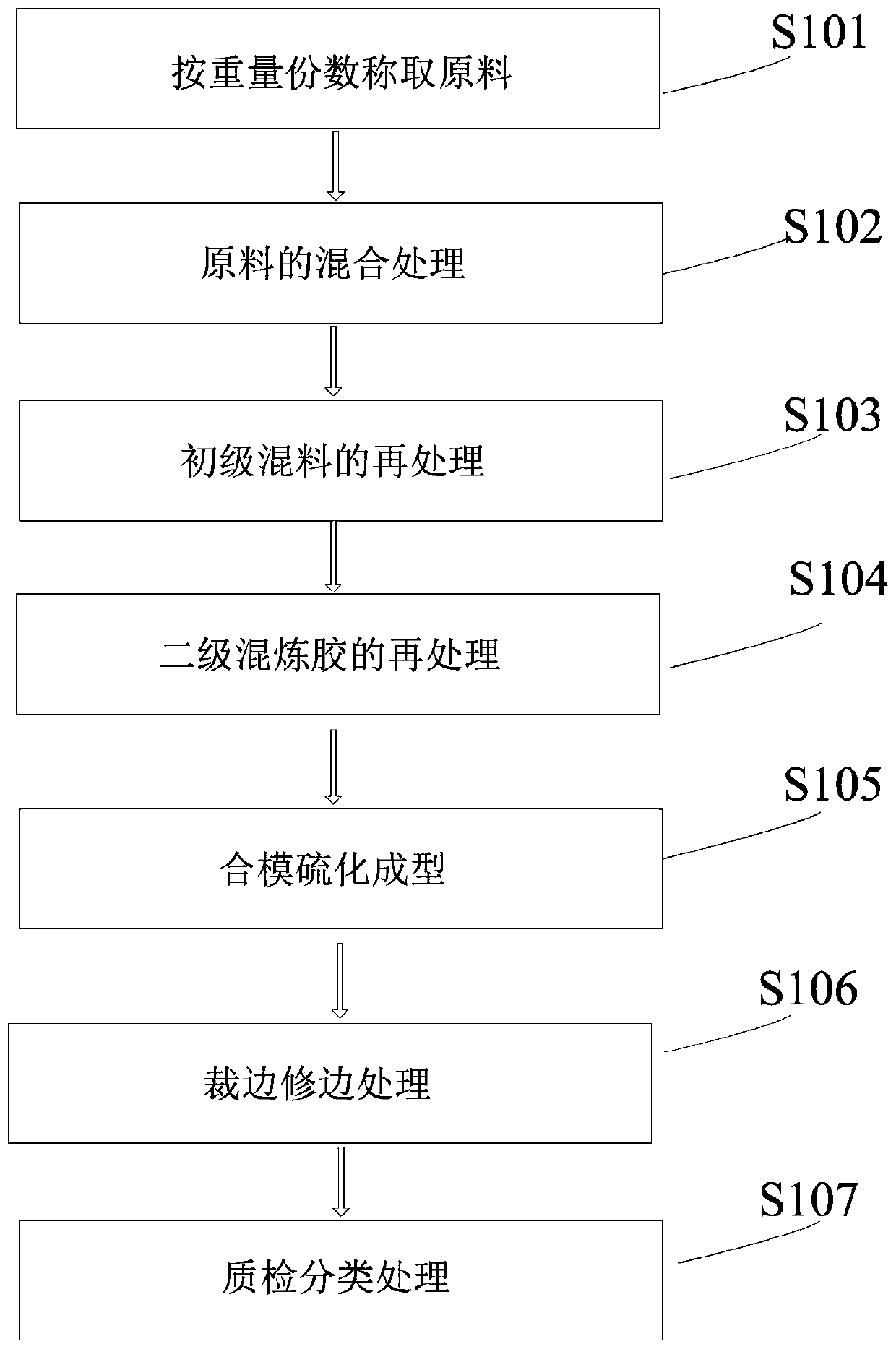

[0046] Preferably, the preparation method of the anti-aging rubber sealing ring material specifically includes the following steps:

[0047] Step 1: Weigh the raw materials by weight;

[0048] Step 2: mixing of raw materials;

[0049] Step 3: Reprocessing of primary mixture;

[0050] Step 4: Reprocessing of secondary rubber compound;

[0051] Step 5: Clamping and vulcanization molding;

[0052] Step 6: Trimming and trimming;

[0053] Step 7: Quality inspection and classification.

[0054] Preferably, in step 1, the raw materials are weighed in the following proportions: 80-90 parts of styrene-butadiene rubber, 20-25 parts of acrylate rubber, 15-20 parts of neoprene rubber, and 25-35 parts of nano-ceramic clay , 10-15 parts of polyurethane rubber, 8-12 parts of polycaprolactone, 15-20 parts of reinforcing filler, 4-8 parts of nano silica, 5-15 parts of quartz fiber, 8-12 parts of nano titanium dioxide, composite antioxidant 2-10 parts, vulcanizing agent 4-8 parts, auxiliary...

Embodiment 1

[0066] The invention discloses an anti-aging rubber sealing ring material and a preparation method thereof. The specific steps are as follows:

[0067] Step 1: Weigh the raw materials in parts by weight: the weighing of the materials is carried out in the following proportions: 80 parts of styrene-butadiene rubber, 20 parts of acrylate rubber, 15 parts of neoprene rubber, 25 parts of nano-ceramic clay, 10 parts of polyurethane rubber, 8 parts of lactone, 15 parts of reinforcing filler, 4 parts of nano silica, 5 parts of quartz fiber, 8 parts of nano titanium dioxide, 2 parts of composite antioxidant, 4 parts of vulcanizing agent, 2.5 parts of auxiliary vulcanizing agent, 4 parts of bauxite powder , 10 parts of plasticizer;

[0068] Step 2: Mixing treatment of raw materials: Add styrene-butadiene rubber and acrylate rubber into the internal mixer, and plasticize on the internal mixer. When the thickness of the plasticized rubber reaches 1mm, add polycaprolactone evenly, and at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com