Fabric core laminated flame retardant conveyor belt cover layer rubber and preparation method thereof

A covering layer and conveyor belt technology, which is applied in the field of flame-retardant covering rubber, can solve the problems of low strength, poor processing performance, and difficult processing, and achieve the effects of easy calendering, good flame-retardant performance, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

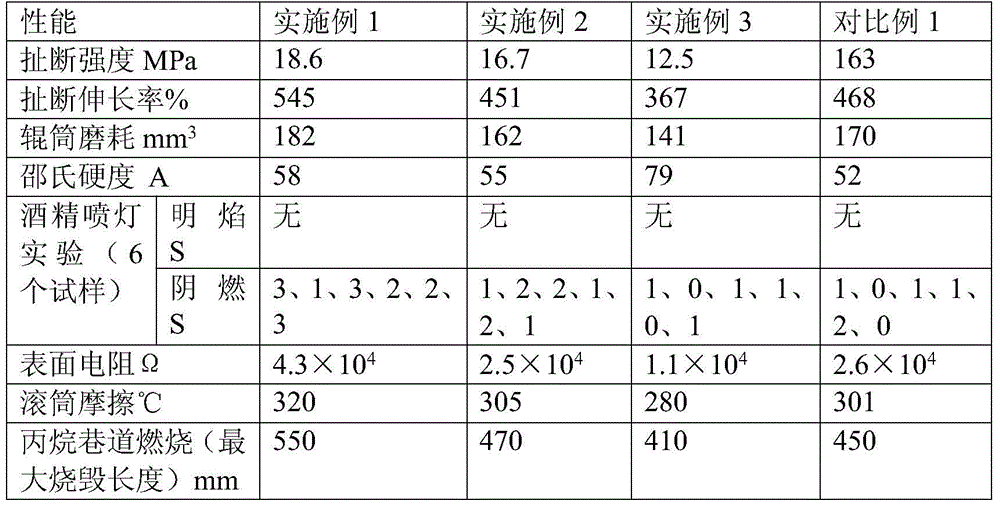

[0021] Add 150g of natural rubber (commercially available 5# standard rubber), 45g of styrene-butadiene rubber (commercially available SBR1502) and 105g of chlorinated polyethylene (commercially available 135A) into the internal mixer or open mixer, and then add the flame retardant in sequence : Chlorinated paraffin 75g, antimony trioxide 15g, ammonium polyphosphate 15g, aluminum hydroxide 30g; metal oxides: nano-zinc oxide 15g, nano-magnesium oxide 9g and stearic acid 3g; antioxidant: 4020 3g, RD 3g; Reinforcing agent: nano-silica 45g, carbon black N115 135g; plasticizer: C5 / C9 copolymer resin 30g; finally add ethylenethiourea (NA-22) 3g and N-cyclohexyl-2-benzothiazolyl Sulfenamide (CZ) 3g, dimorpholine disulfide (DTDM) 6g, vulcanizing agent is sulfur 3g. Mix evenly to obtain a cover layer glue, and then vulcanize the cover layer glue on a vulcanization plate at 155°C for 40 minutes to obtain a finished product, and its properties are shown in Table 1.

Embodiment 2

[0023] Add 105g of natural rubber (commercially available 5# standard rubber), 45g of styrene-butadiene rubber (commercially available SBR1502) and 150g of chlorinated polyethylene (commercially available 135A) into the internal mixer or open mixer, and then add the flame retardant in sequence : chlorinated paraffin 75g, antimony trioxide 15g, ammonium polyphosphate 15g, aluminum hydroxide 30g; activator: nano-zinc oxide 15g, nano-magnesium oxide 9g and stearic acid 3g; antioxidant: 4020 3g, RD 3g; Strong agent: nano-silica 45g, carbon black N115 135g; plasticizer: C5 / C9 copolymer resin 30g; finally add ethylenethiourea (NA-22) 3g and N-cyclohexyl-2-benzothiazolyl Sulfonamide (CZ) 3g, dimorpholine disulfide (DTDM) 6g, vulcanizing agent is sulfur 3g. Mix evenly to obtain a cover layer glue, and then vulcanize the cover layer glue on a vulcanization plate at 155°C for 40 minutes to obtain a finished product, and its properties are shown in Table 1.

Embodiment 3

[0025] In the internal mixer or open mixer, add 75g of natural rubber (commercially available 5# standard rubber), 45g of styrene-butadiene rubber (commercially available SBR1502) and 180g of chlorinated polyethylene (commercially available 135A), and then add flame retardants in sequence : chlorinated paraffin 75g, antimony trioxide 15g, ammonium polyphosphate 15g, aluminum hydroxide 30g; activator: nano-zinc oxide 15g, nano-magnesium oxide 9g and stearic acid 3g; antioxidant: 4020 3g, RD 3g; Strong agent: nano-silica 45g, carbon black N115 135g; plasticizer: C5 / C9 copolymer resin 30g; finally add ethylenethiourea (NA-22) 3g and N-cyclohexyl-2-benzothiazolyl Sulfonamide (CZ) 3g, dimorpholine disulfide (DTDM) 6g, vulcanizing agent is sulfur 3g. Mix evenly to obtain a cover layer glue, and then vulcanize the cover layer glue on a vulcanization plate at 155°C for 40 minutes to obtain a finished product, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com