A flame retardant and high temperature resistant cable

A high temperature resistant and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of harsh working environment, high temperature resistance and unsatisfactory flame retardancy, etc., achieve less toxic gas generation, excellent weather resistance and aging resistance , Reduce the effect of reducing the high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

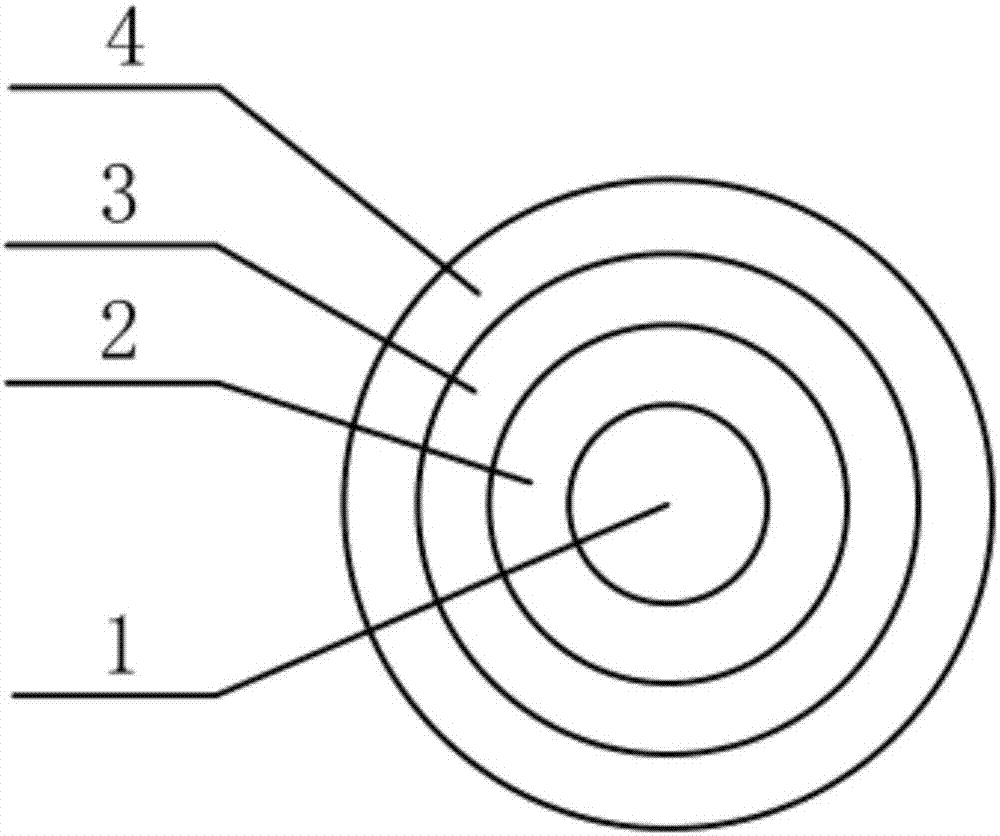

[0017] figure 1 It is a structural schematic diagram of the flame-retardant and high-temperature-resistant cable described in the present invention, referring to figure 1 , a flame-retardant and high-temperature-resistant cable proposed by the present invention, including a copper conductor 1, a fluoroplastic insulating layer 2 is coated on the outer surface of the copper conductor 1, and a silicone rubber inner sheath is coated on the outer surface of the fluoroplastic insulating layer 2. Cover 3, covered with an outer sheath 4 outside the silicone rubber inner sheath 3; wherein, the outer sheath 4 is made of a natural rubber composite material, and the raw materials of the natural rubber composite material include by weight: 100 parts of natural rubber, 20 parts of EPDM rubber, 35 parts of butyl rubber, 10 parts of nylon 66, 25 parts of epoxy resin, 1 part of stearic acid, 5 parts of zinc oxide, 0.5 parts of sulfur, double-tert-butyl peroxide 2.5 parts of cumene oxide, 0.5 ...

Embodiment 2

[0019] refer to figure 1 , a flame-retardant and high-temperature-resistant cable proposed by the present invention, including a copper conductor 1, a fluoroplastic insulating layer 2 is coated on the outer surface of the copper conductor 1, and a silicone rubber inner sheath is coated on the outer surface of the fluoroplastic insulating layer 2. Cover 3, covered with an outer sheath 4 outside the silicone rubber inner sheath 3; wherein, the outer sheath 4 is made of a natural rubber composite material, and the raw materials of the natural rubber composite material include by weight: 100 parts of natural rubber, 35 parts of EPDM rubber, 20 parts of butyl rubber, 25 parts of nylon 66, 10 parts of epoxy resin, 2.5 parts of stearic acid, 2 parts of zinc oxide, 2 parts of sulfur, double-tert-butyl peroxide 1 part of cumene oxide, 1.5 parts of N,N'-m-phenylene bismaleimide, 2 parts of montmorillonite, 12 parts of kaolin, 2 parts of talcum powder, 12 parts of zinc borate, 3 parts of...

Embodiment 3

[0021] refer to figure 1 , a flame-retardant and high-temperature-resistant cable proposed by the present invention, including a copper conductor 1, a fluoroplastic insulating layer 2 is coated on the outer surface of the copper conductor 1, and a silicone rubber inner sheath is coated on the outer surface of the fluoroplastic insulating layer 2. Cover 3, covered with an outer sheath 4 outside the silicone rubber inner sheath 3; wherein, the outer sheath 4 is made of a natural rubber composite material, and the raw materials of the natural rubber composite material include by weight: 100 parts of natural rubber, 31 parts of EPDM rubber, 28 parts of butyl rubber, 22 parts of nylon 66, 18 parts of epoxy resin, 2.2 parts of stearic acid, 3.2 parts of zinc oxide, 1.5 parts of sulfur, bis-tert-butyl peroxide 1.9 parts of cumene oxide, 1.2 parts of N,N'-m-phenylene bismaleimide, 5.8 parts of montmorillonite, 10 parts of kaolin, 6.5 parts of talcum powder, 6.5 parts of zinc borate, 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com