Steel plate surface blind hole punching die

A stamping die and blind hole technology, which is applied in the field of blind hole stamping dies on the surface of steel plates, can solve the problem of low qualified rate of blind holes in stamped thin steel plates, difficulty in ensuring the overall alignment accuracy of the punch and die, and the time required for adjustment and check Long and other issues, to avoid damage to stamping equipment, to achieve the effect of possibility and reliability, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

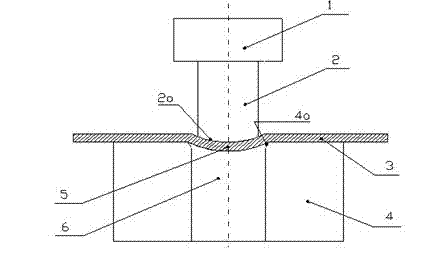

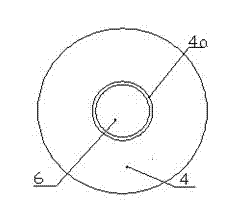

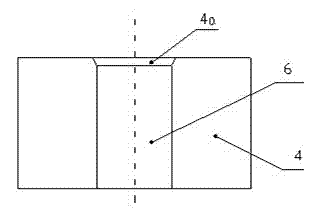

[0021] combine Figure 1 to Figure 4 .

[0022] As shown in the figure, the stamping die for blind holes on the steel plate surface includes a punch 2 installed on the punch of the punch and a die 4 installed on the base of the punch. The center of the die 4 is a through hole 5 . The cylindrical diameter of the punch 2 is smaller than the diameter of the central hole 6 of the die. The cylinder diameter of the punch 2 is equal to the inner diameter of the blind hole 5 minus twice the thickness of the steel plate 3 . The impact surface 2a of the impact head of the punch 2 is arc-shaped.

[0023] combine figure 1 , figure 2 and image 3 , figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com