Material used in ballscrew

A technology of ball screw and element, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., to achieve the effect of improving quenching brittleness and deformation, easy cutting, and improving internal organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

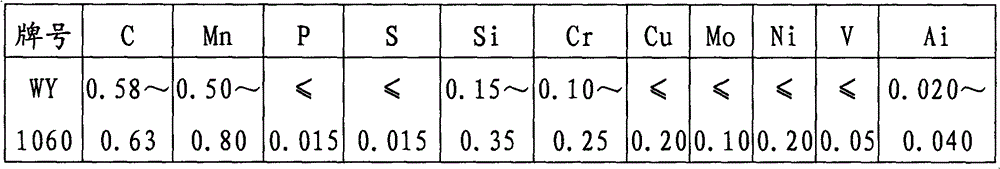

[0038] A material for ball screw according to the present invention, wherein the active ingredients and weight percentage are: 0.58% of carbon element, 0.80% of manganese element, 0.015% of phosphorus element, 0.015% of sulfur element, 0.35% of silicon element, chromium 0.25% element, 0.20% copper element, 0.10% molybdenum element, 0.20% nickel element, 0.05% vanadium element, 0.040% aluminum element, and the balance is iron element. According to the above composition and weight percentage, it is smelted by adopting electric arc furnace plus vacuum refining method, and finally smelted into steel in the state of hot-rolled spheroidizing annealing and peeling.

Embodiment 2

[0040] A material for a ball screw according to the present invention, wherein the active ingredients and weight percentage are: 0.605% of carbon element, 0.65% of manganese element, 0.015% of phosphorus element, 0.015% of sulfur element, 0.35% of silicon element, chromium 0.25% element, 0.20% copper element, 0.10% molybdenum element, 0.20% nickel element, 0.05% vanadium element, 0.040% aluminum element, and the balance is iron element. According to the above composition and weight percentage, it is smelted by adopting electric arc furnace plus vacuum refining method, and finally smelted into steel in the state of hot-rolled spheroidizing annealing and peeling.

Embodiment 3

[0042] A material for ball screw according to the present invention, wherein the active ingredients and weight percentage are: 0.63% of carbon element, 0.50% of manganese element, 0.015% of phosphorus element, 0.015% of sulfur element, 0.35% of silicon element, chromium 0.25% element, 0.20% copper element, 0.10% molybdenum element, 0.20% nickel element, 0.05% vanadium element, 0.040% aluminum element, and the balance is iron element. According to the above composition and weight percentage, smelting is carried out by adopting an electric arc furnace plus a vacuum refining method, and finally smelted into steel products in the state of hot-rolled spheroidizing annealing and peeling.

[0043] Through the above-mentioned technical scheme, the steel smelted from this material by adding alloy elements completely overcomes the weakness of GCr15 steel, improves the internal structure of the steel, and makes it easy to cut and roll on the basis of maintaining the advantages of GCr15 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com