Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Easy particle size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

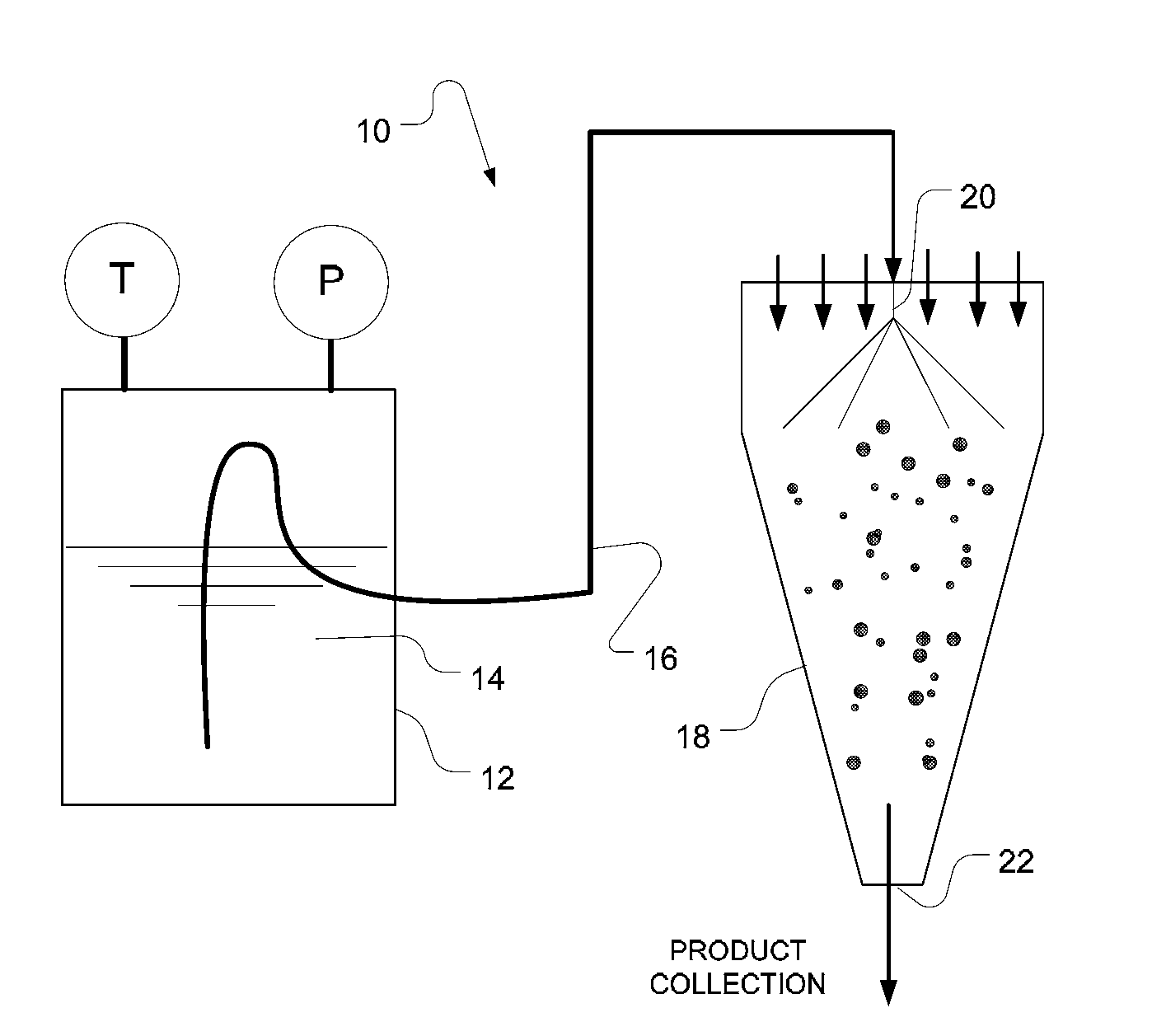

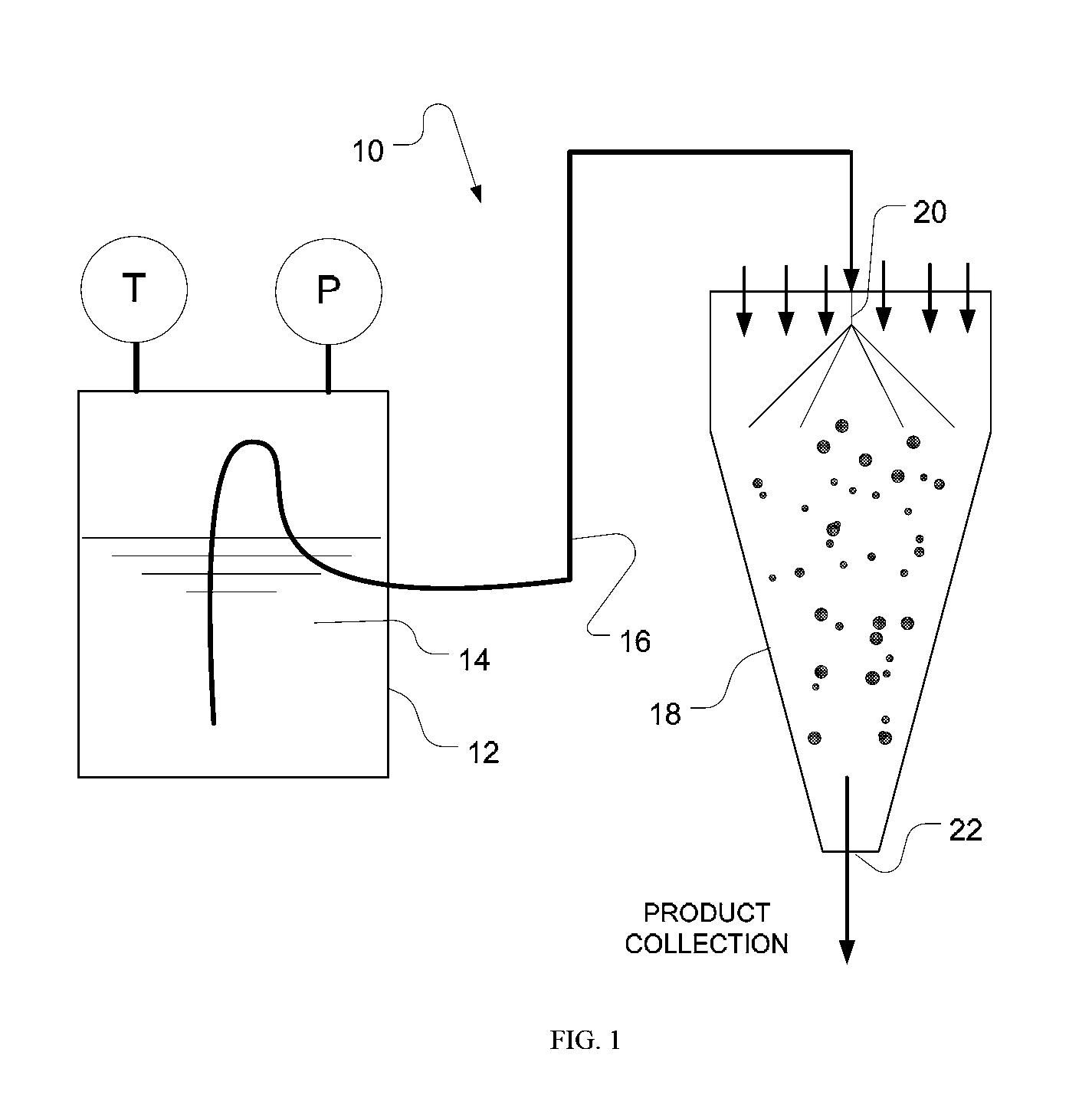

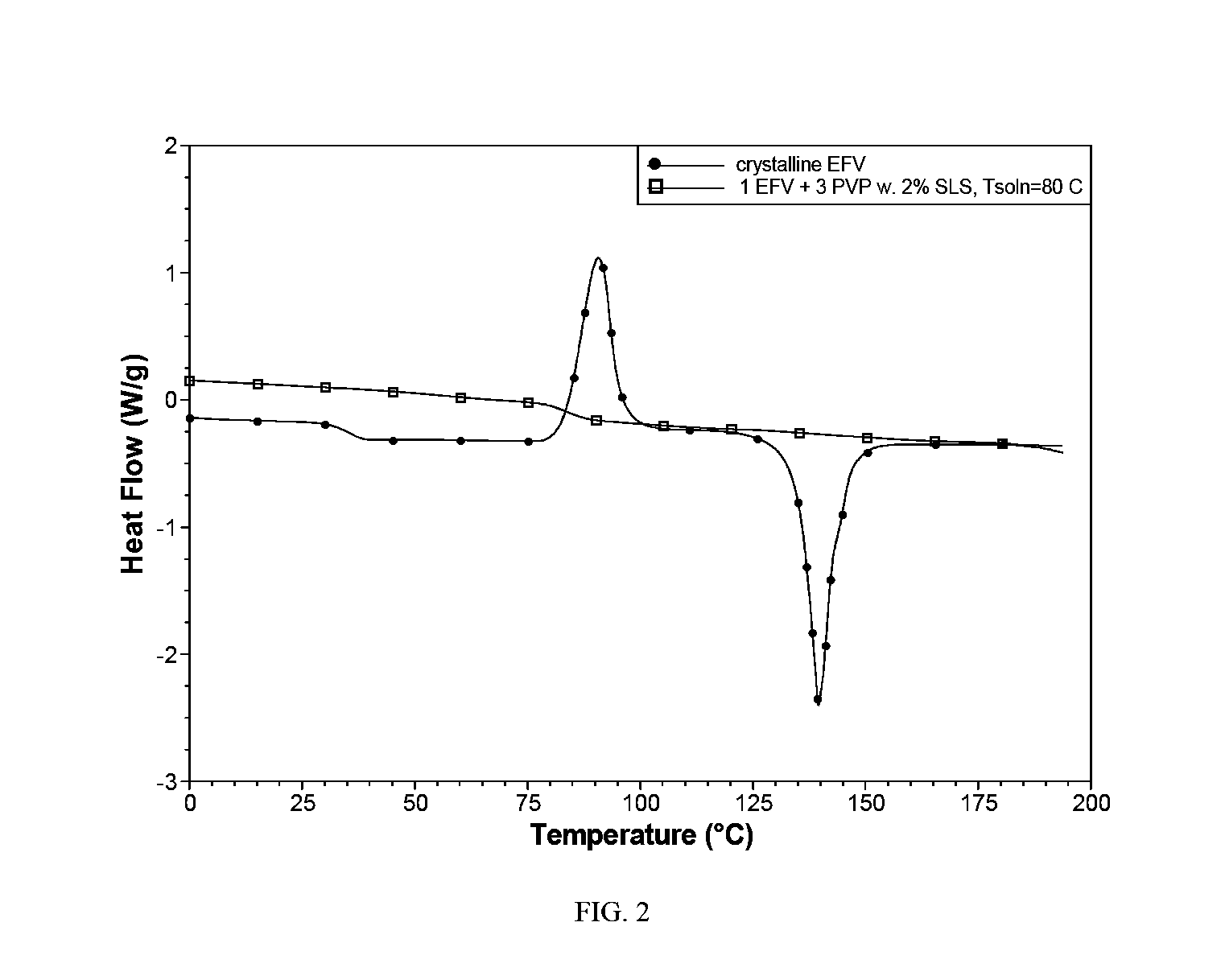

Formulation process method to produce spray dried products

ActiveUS20080181962A1Easy particle size controlImprove propertiesPowder deliveryGranular deliveryNon solventHigh pressure

A method for preparing solid materials is described. One aspect of the method includes the steps of (a) providing a feedstock comprising an organic material(s) in a solvent system containing a non-solvent for the organic material at an elevated temperature and / or pressure above ambient conditions, (b) distributing the feedstock into either droplets or a film, and (d) evaporating the solvent system from the feedstock.

Owner:ISP INVESTMENTS LLC

Process for preparing building gypsum powder from phosphogypsum

The invention discloses a process for preparing building gypsum powder from phosphogypsum. The process comprises the technical links of: phosphogypsum drying, fine grinding and powder sorting; suspended dehydration; proper aging and the like. According to the process system disclosed by the invention, the phosphogypsum fine grinding, drying and dehydration process is divided into two relatively independent links, the negative-pressure operation is adopted, and a hot blast stove, a feeding device, a phosphogypsum fine grinding, drying and powder sorting device, a suspended dehydrator, an aging bunker, a dust collecting device, an induced draft fan and the like are provided in the process. The process is stable in production process, capable of saving energy and realizing large-scale production and high in product quality.

Owner:WENGFU (GRP) CO LTD +1

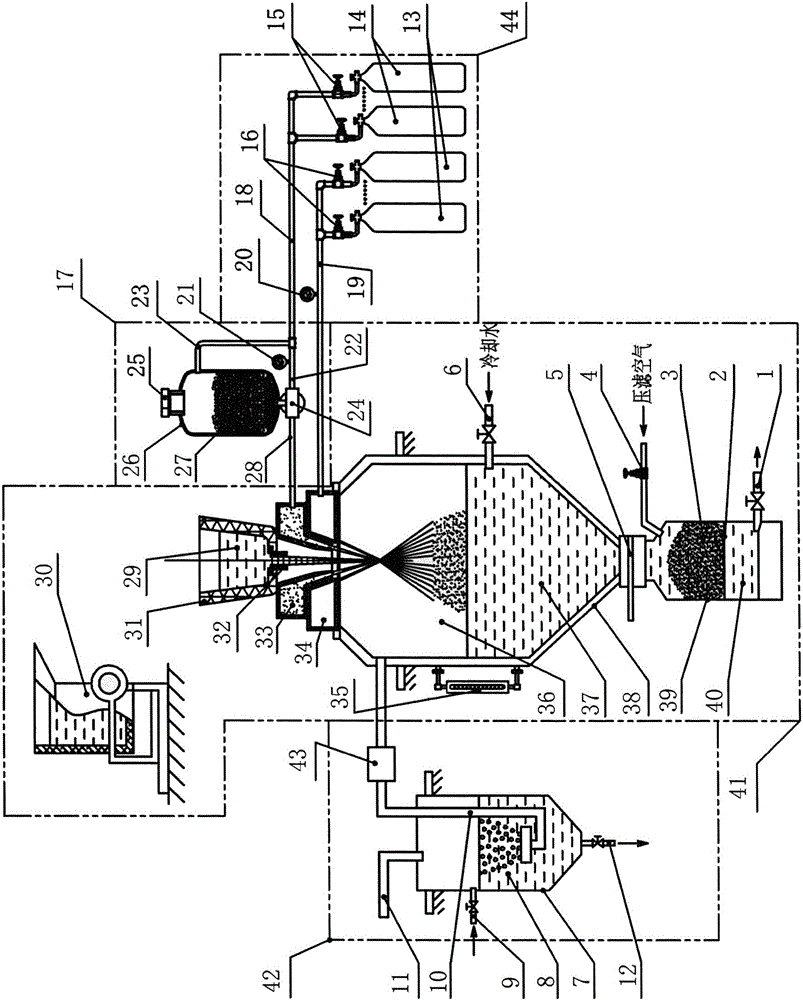

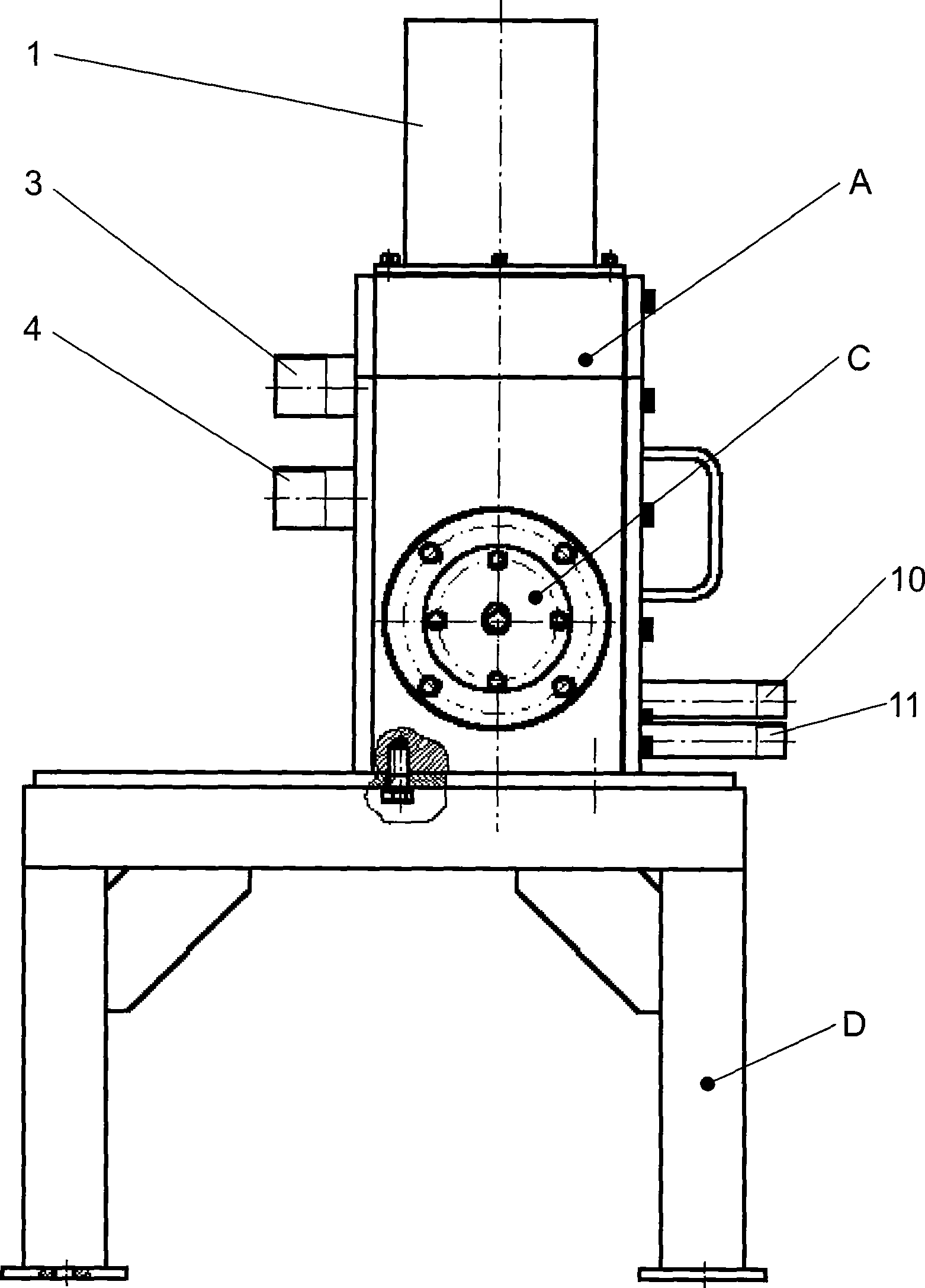

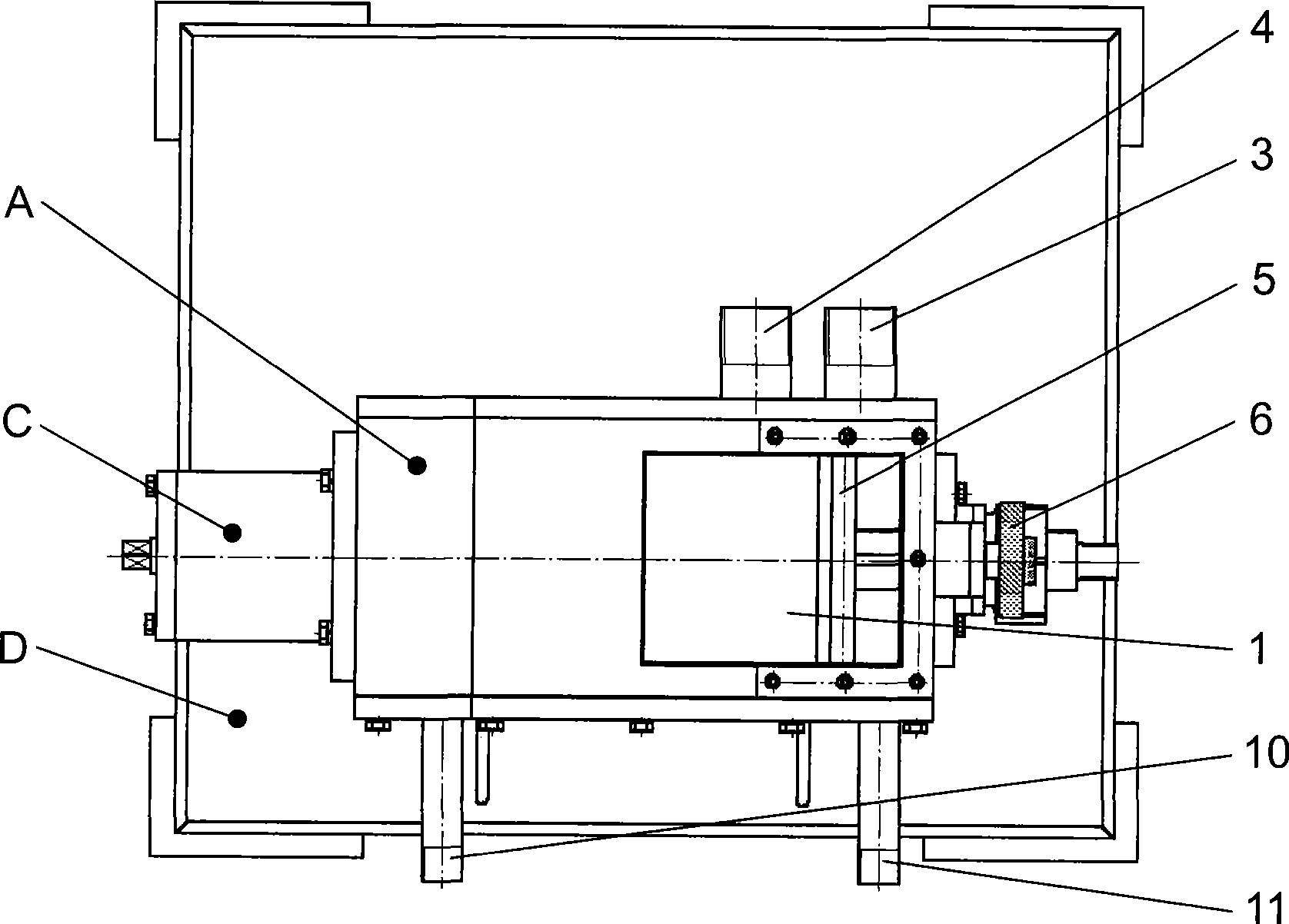

Free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment

The invention provides free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing equipment which comprises a double-nozzle atomizing and water cooling device (41), a spiral mixed powder conveying device (17), a water seal dust removing device (42) and a gas station (44). In the atomizing process, a low-pressure mixed powder jetting nozzle and a high-pressure gas flow nozzle are adopted, and therefore the problem that when a single nozzle is used, erosive wear is caused is solved; a free-falling manner is adopted, and therefore the problems that erosive wear to a molten metal flow guide pipe is caused and molten metal flows back and is sprayed upwards are avoided; a cooling manner of water cooling and fast setting is adopted, the problem that hard abrasive particles drift away from a metal matrix and the problem of control over the depth of distribution are solved, and hard abrasive is controlled to be distributed on a surface shallow layer of the magnetic abrasive; meanwhile, the flight distance of powder mixed molten metal drops is shortened, and the overall height of the free-falling atomizing and condensing chamber and equipment is reduced. The equipment is new equipment provided for realizing a free-falling powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method and preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

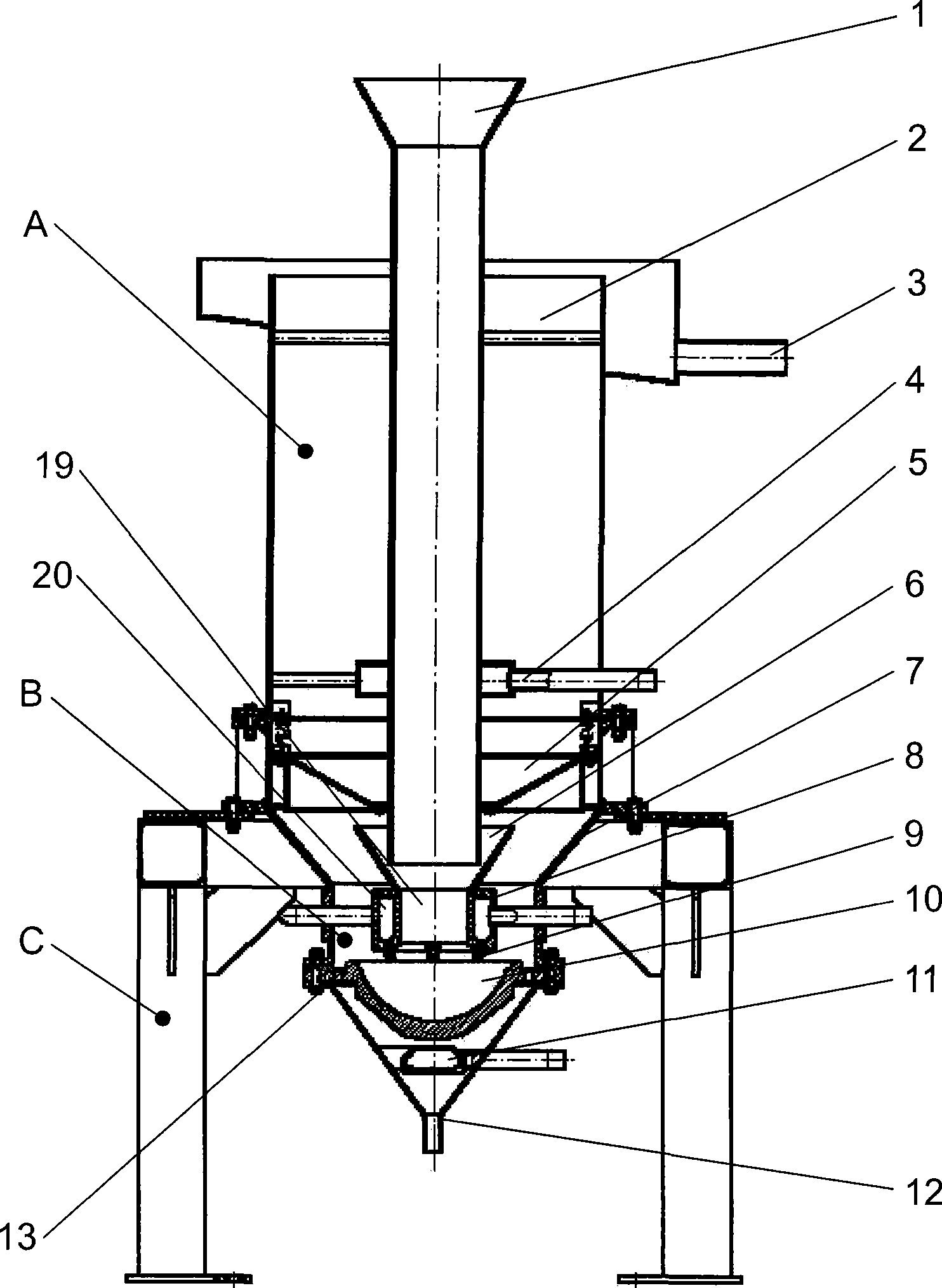

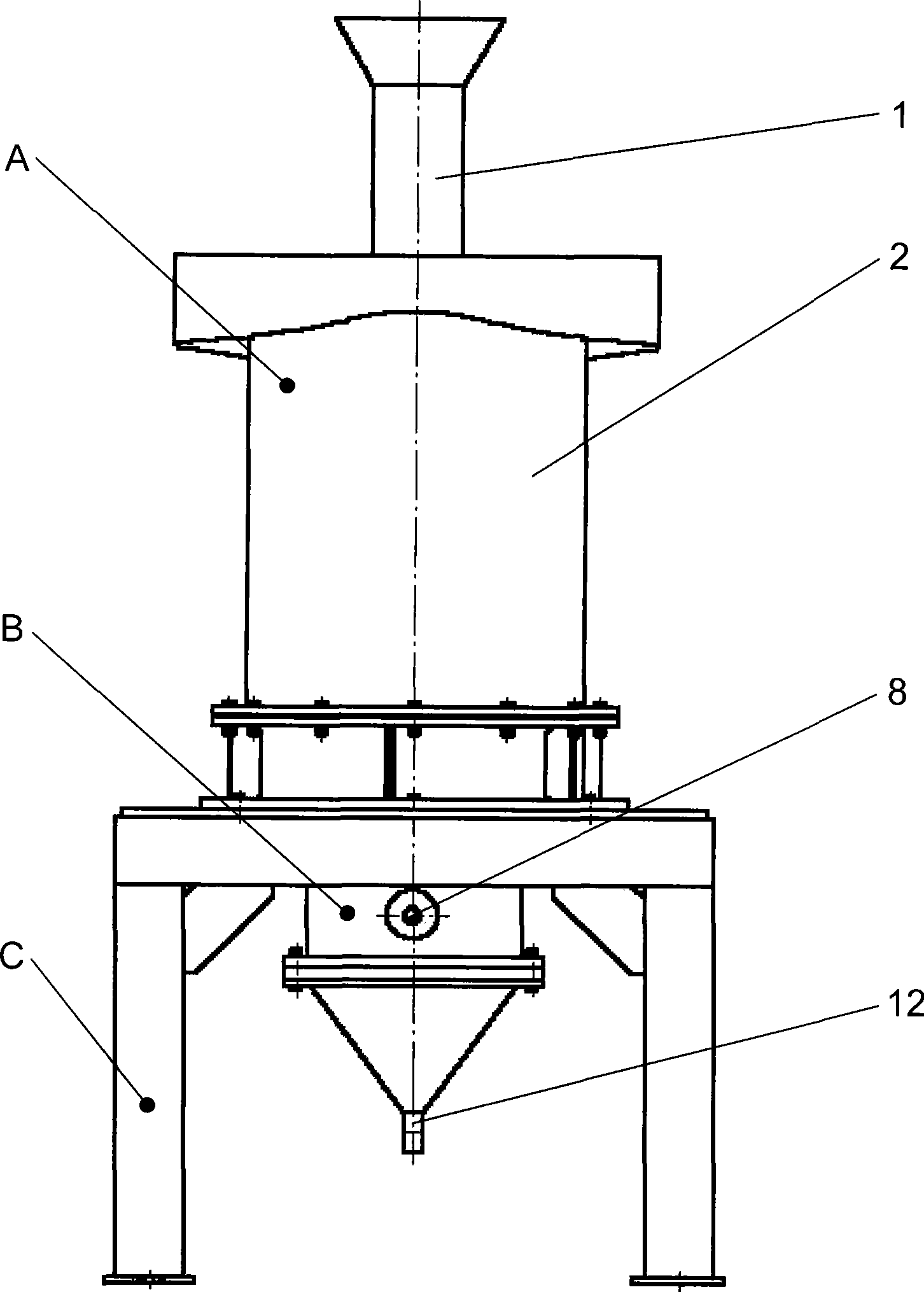

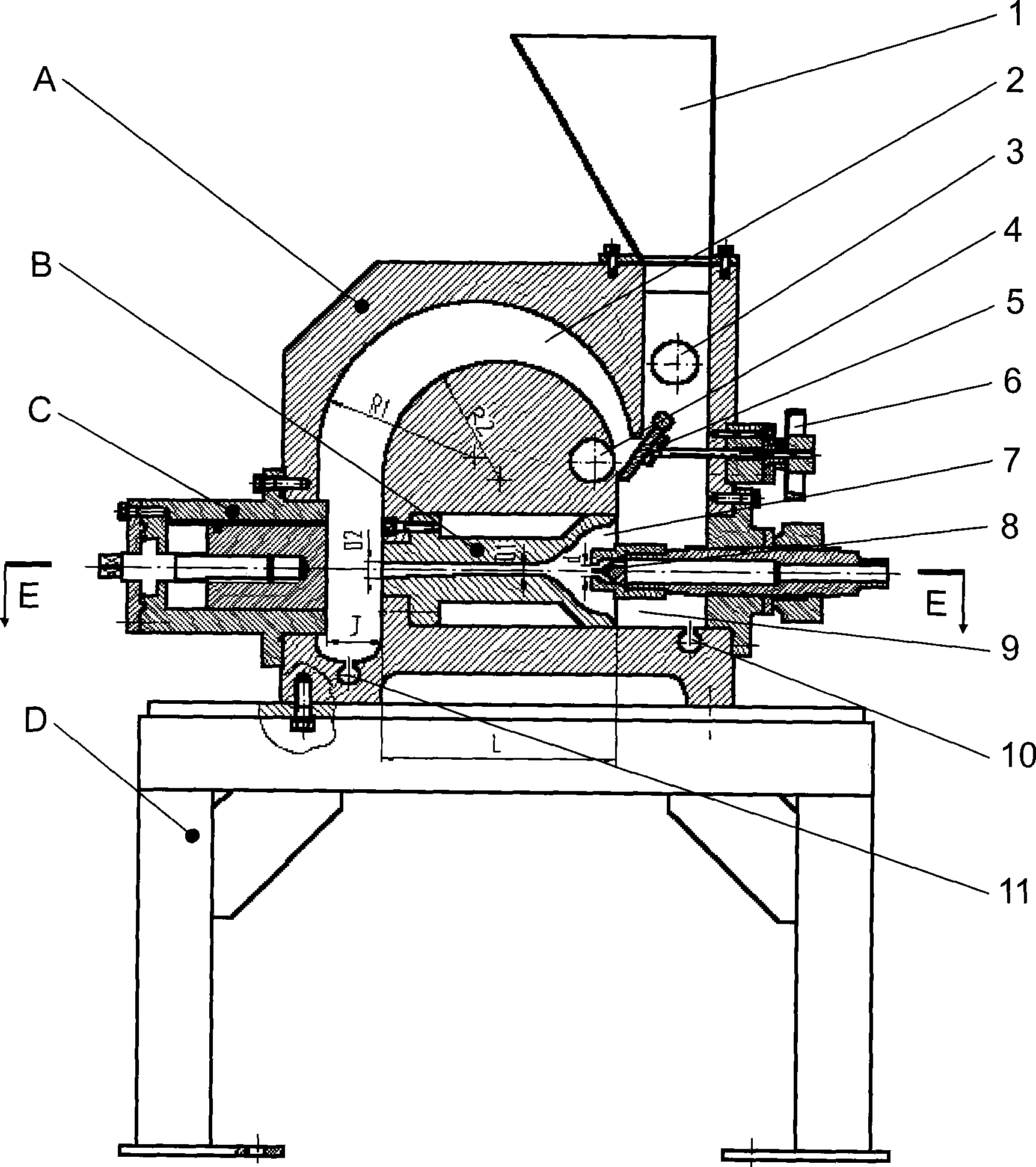

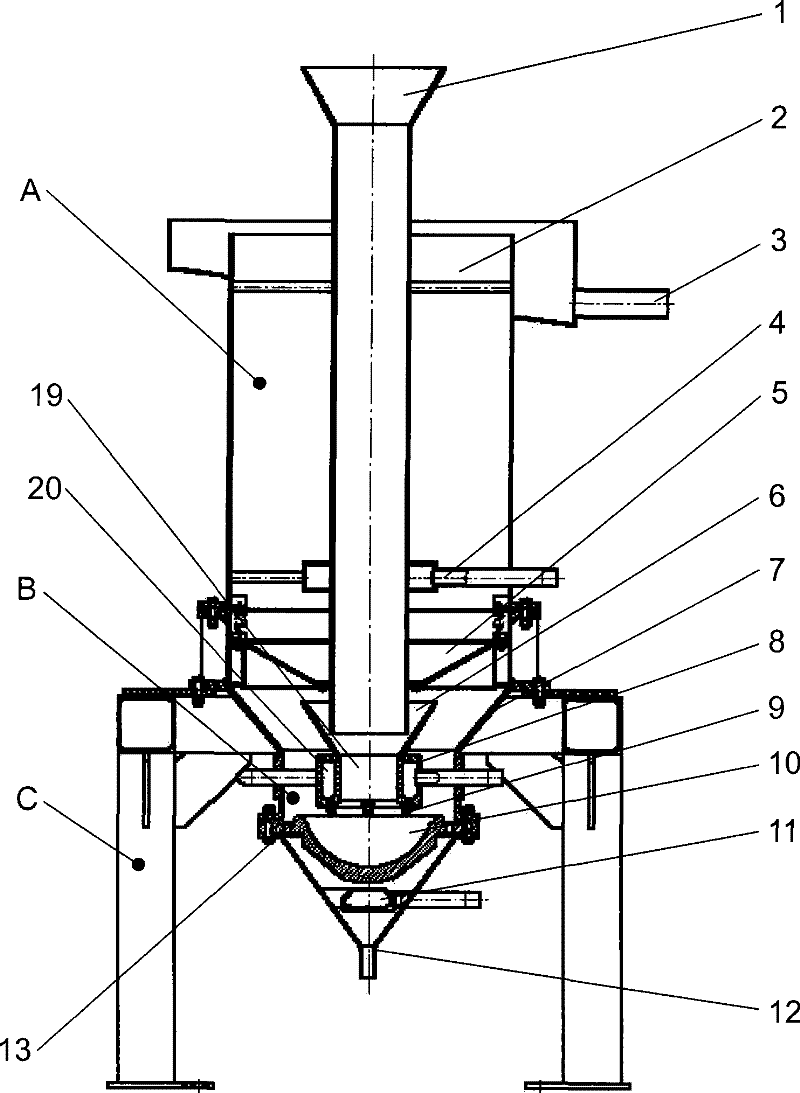

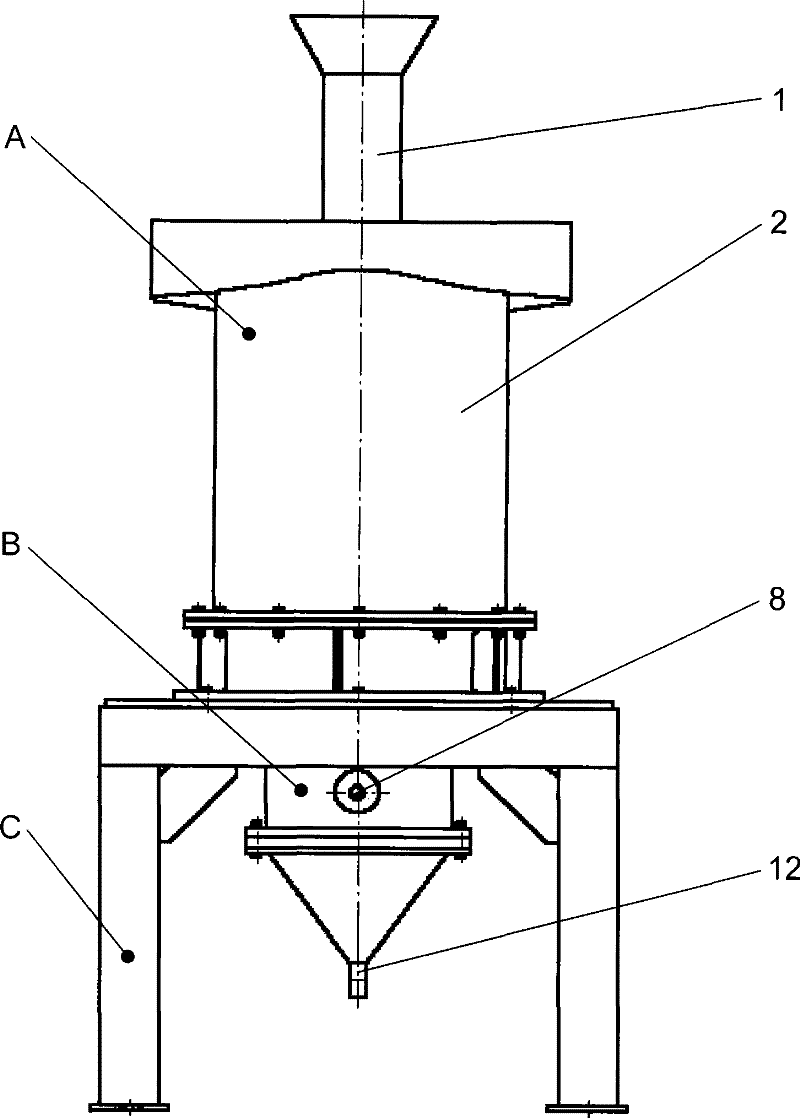

Cohesive target type water fluid jet grind

InactiveCN101367061AReduce consumptionImprove energy utilizationGrain treatmentsWet separationWater flowEngineering

The invention relates to a solid material crushing device, in particular to a cohesion target type water-jet mill which is characterized by comprising a material grading part, a material crushing part and a stand, wherein the material grading part comprises a central feed pipe, an overflow suspension assorting cylinder, an overflow groove, an annular water uniform distributor, and a water shock conical vibration sieve; the upper part of the overflow suspension assorting cylinder is welded with the overflow groove which is provided with a discharge hole; the lower end of the overflow suspension assorting cylinder is connected with the upper end of a cylinder body of a crushing part of the material crushing part through a flange; a feed hole of the central feed pipe is higher than the discharge hole of the overflow groove; the material crushing part comprises a material guide cone, the cylinder body of the crushing part, an annular nozzle holder, a nozzle, a cohesion target body, a conical water injector, a grading hopper and a separating grate sieve; and the cylinder body of the crushing part is fixedly connected with the stand. The cohesion target type water-jet mill has the characteristics of high utilization rate of energy and good effects of cleavage and crushing.

Owner:WUHAN UNIV OF TECH

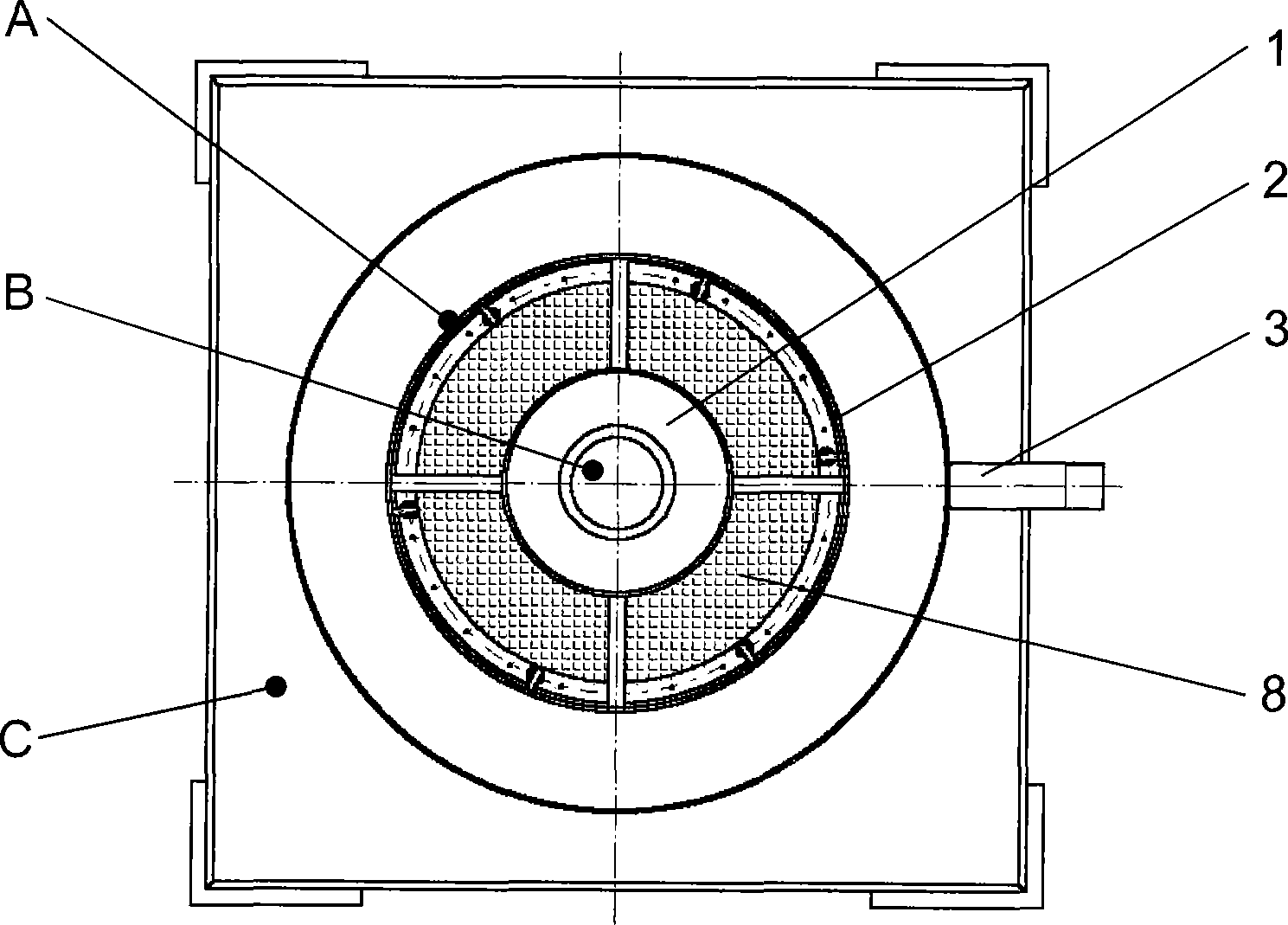

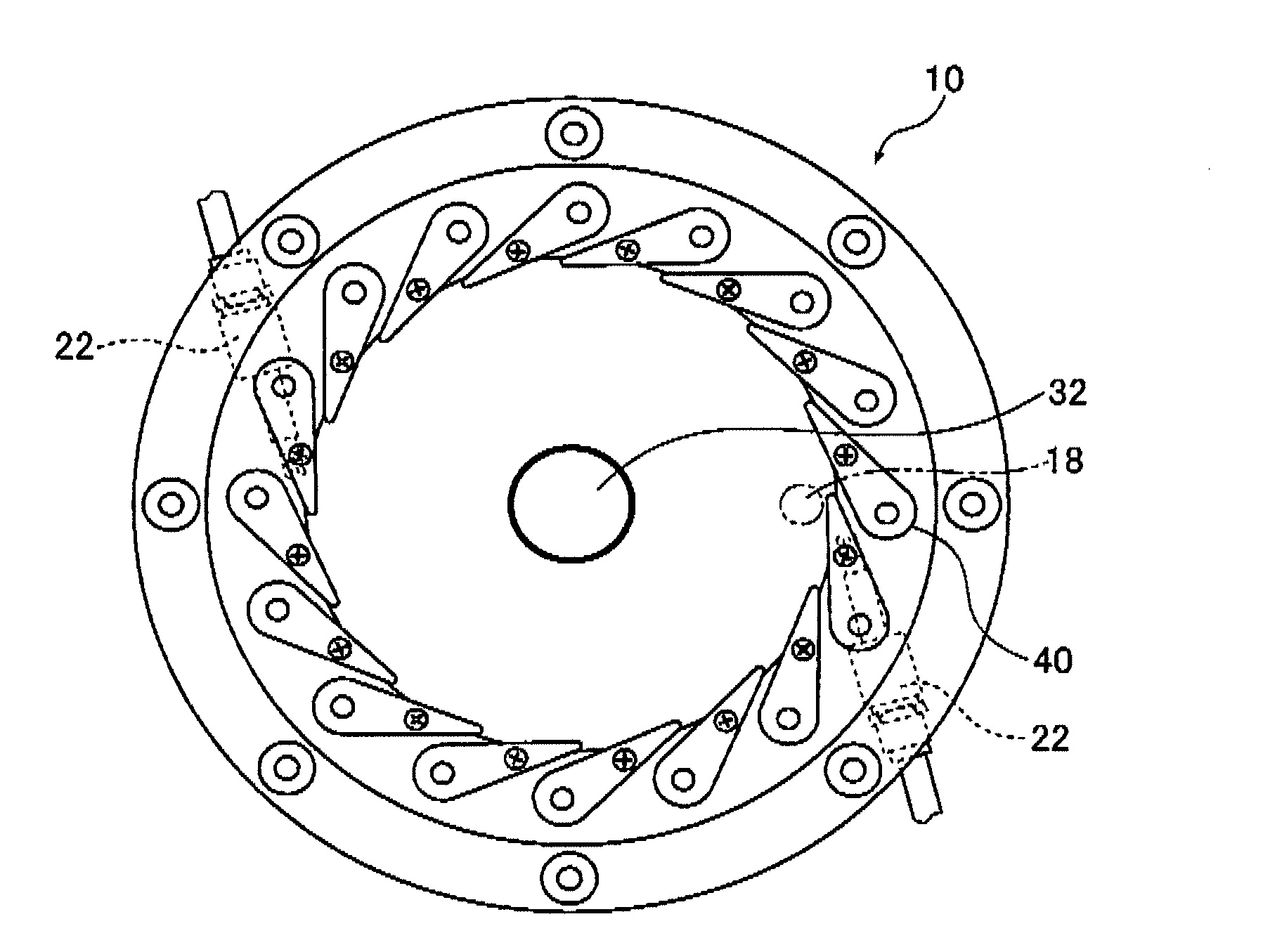

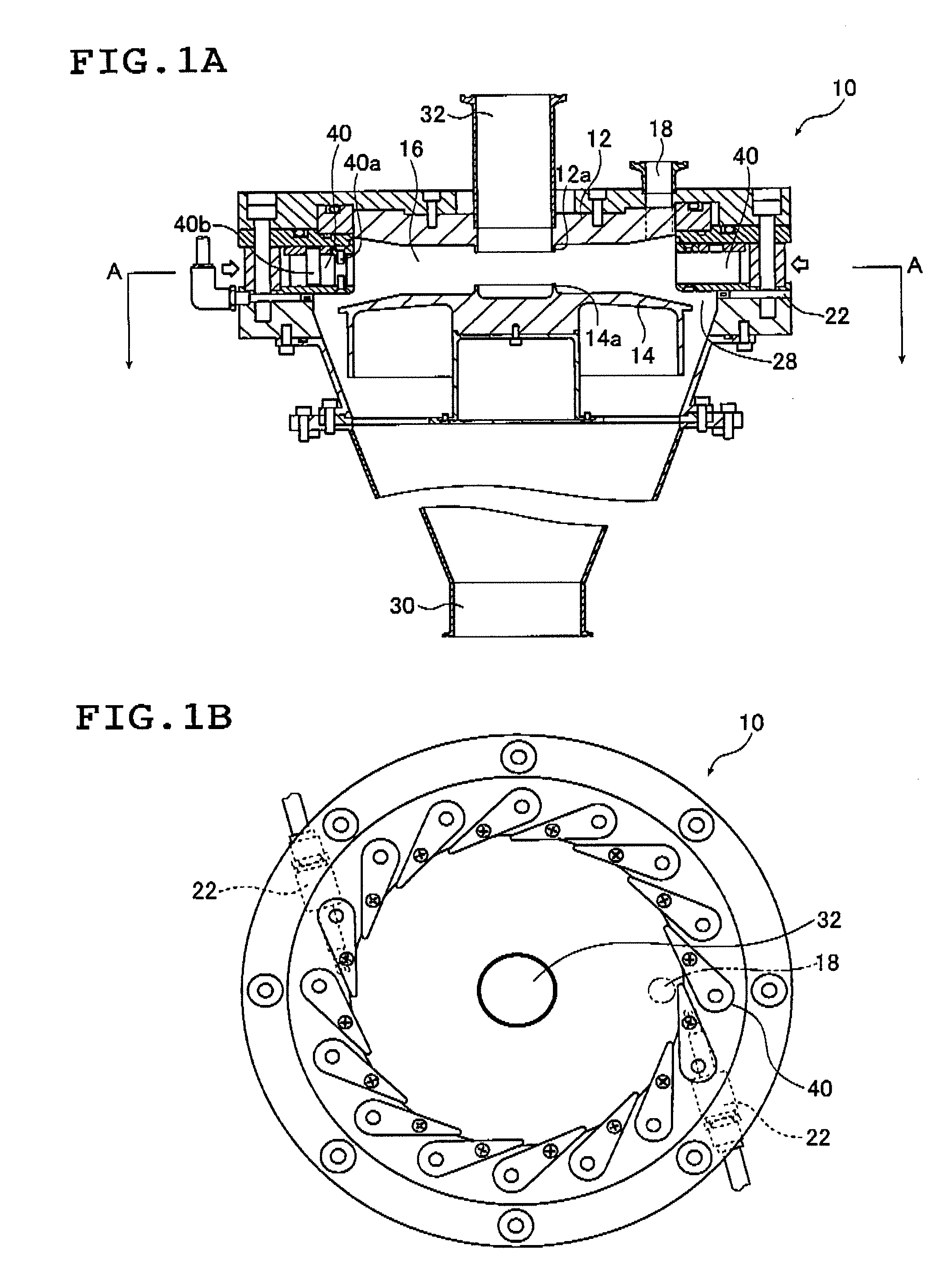

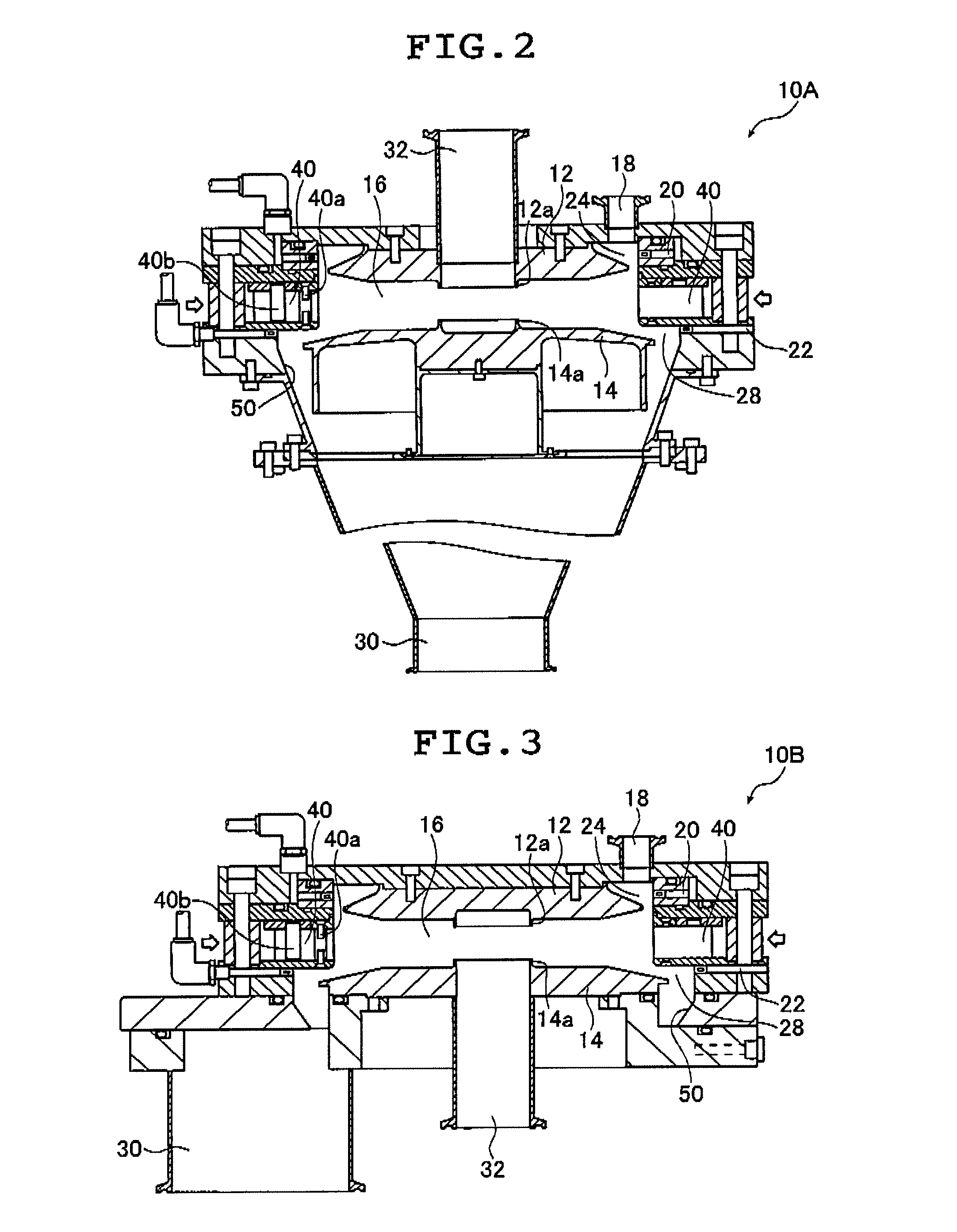

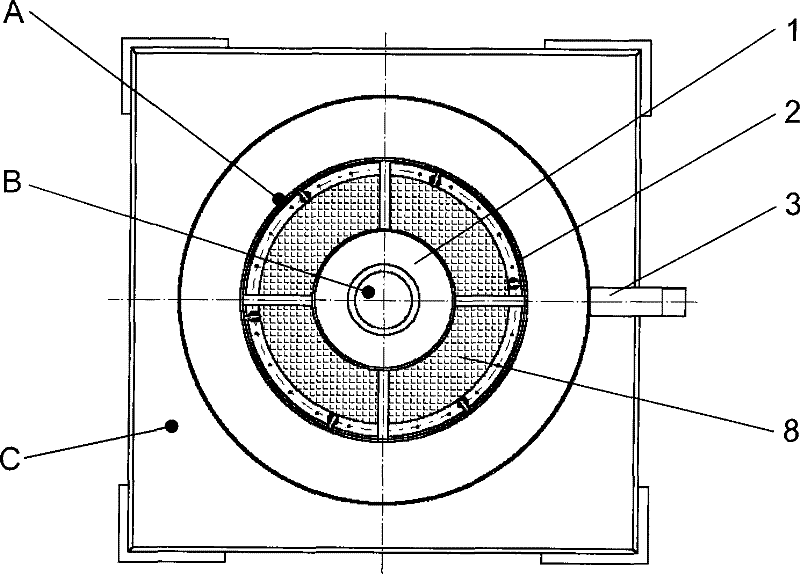

Powder classifying device

ActiveUS20090032443A1High precisionEasy maintenanceGas current separationSingle direction vortexCoarse particleParticle-size distribution

The powder classifying device classifies powder having a particle size distribution and collects the classified powder. The device includes a disc-like cavity to which the powder is supplied and where the supplied powder is classified, a powder supply port for supplying the powder to the cavity, guide vanes arranged so as to extend from an outer periphery of the cavity in an inner direction at a predetermined angle, a discharge unit for air streams including fine particles discharged from the cavity, a collection unit for coarse particles discharged from the cavity and air nozzles arranged below the guide vanes on an outer peripheral wall of the cavity along a tangential direction of the outer peripheral wall and blow compressed air into an inside of the cavity.

Owner:NISSHIN SEIFUN GRP INC

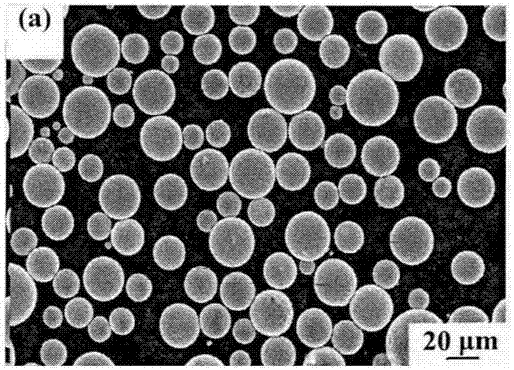

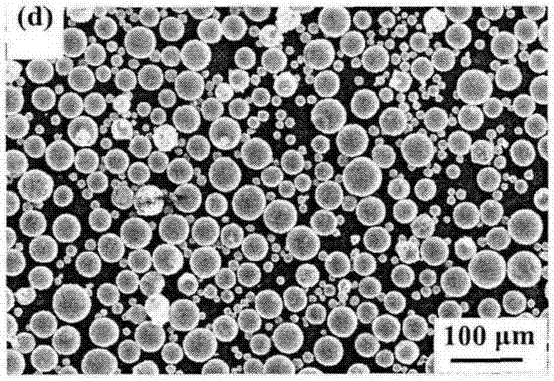

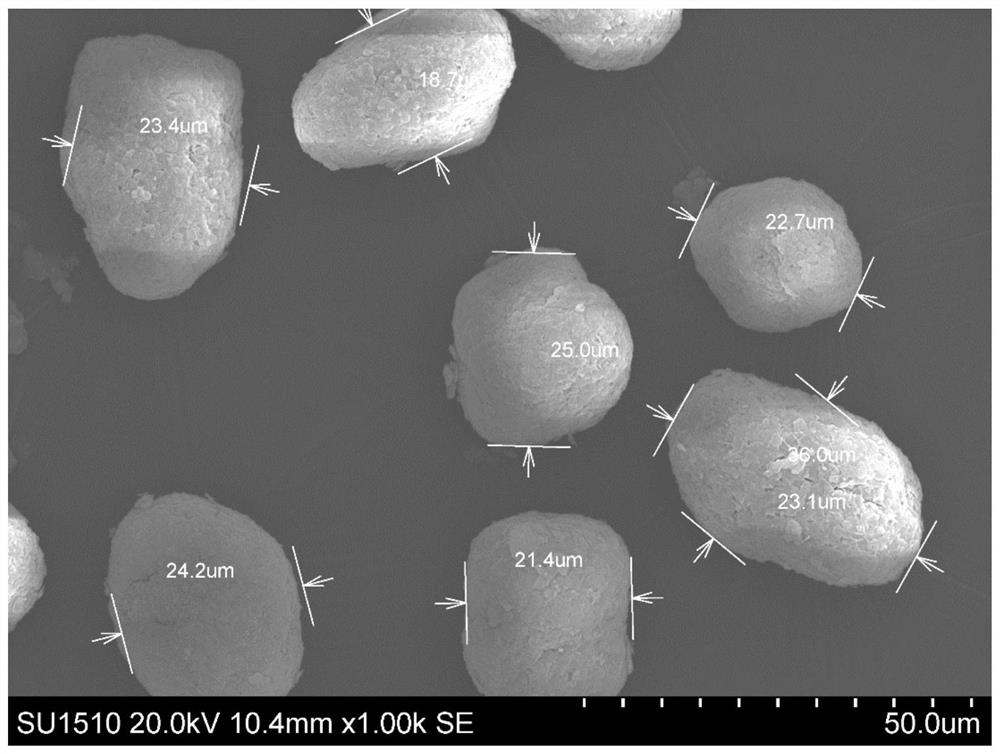

Preparation method and application of high-purity dense spherical molybdenum powder

ActiveCN107309434AHigh purityLow costAdditive manufacturing apparatusMolten spray coatingImpurityParticle-size distribution

The invention provides a preparation method and application of high-purity dense spherical molybdenum powder and belongs to the technical field of spherical metal powder material preparation. Conventional reduction molybdenum powder serves as the raw material, the particle size range of the granulated molybdenum powder is controlled actively by adjusting the granulation process, the molybdenum powder subjected to degumming, impurity removal and sintering is further screened, the particle size of the granulated molybdenum powder before plasma spheroidizing is effectively controlled, and it is beneficial to granularity control over the final granulated molybdenum powder. The particle size distribution of the molybdenum powder subjected to granulation and screening processing is narrow, vaporization and the burning loss of the molybdenum powder in the plasma spheroidizing process can be effectively lowered in cooperation with spherification process parameters, such as the input power, the powder feeding rate and the gas flow, it is beneficial to stability of the production process, and production efficiency and product quality are greatly improved; through introduction of hydrogen gas into the degumming, impurity removal and sintering processes of the molybdenum powder, the impurity content of the molybdenum powder before spherification is effectively lowered; and meanwhile, screening, spherification, cooling and collection of the molybdenum powder are all operated under the protection atmosphere of argon gas, and the oxygen content of a product is effectively lowered.

Owner:云航时代(重庆)科技有限公司

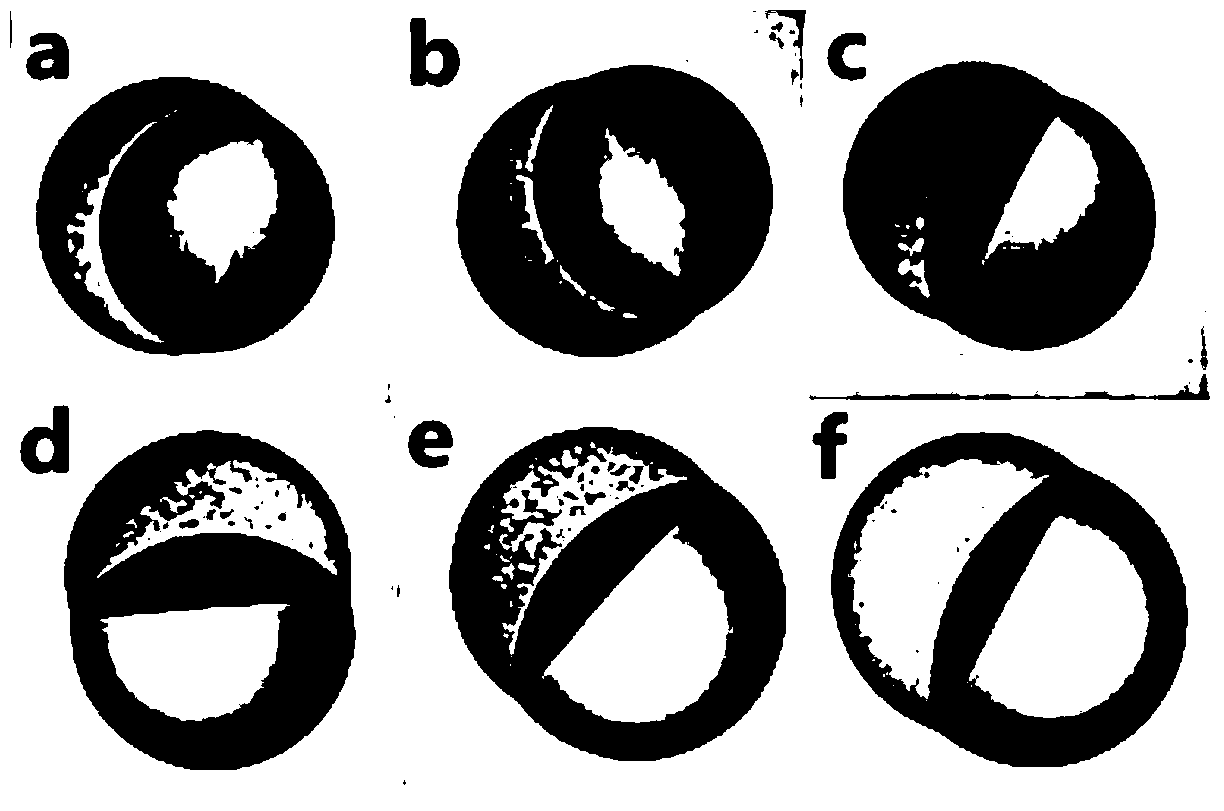

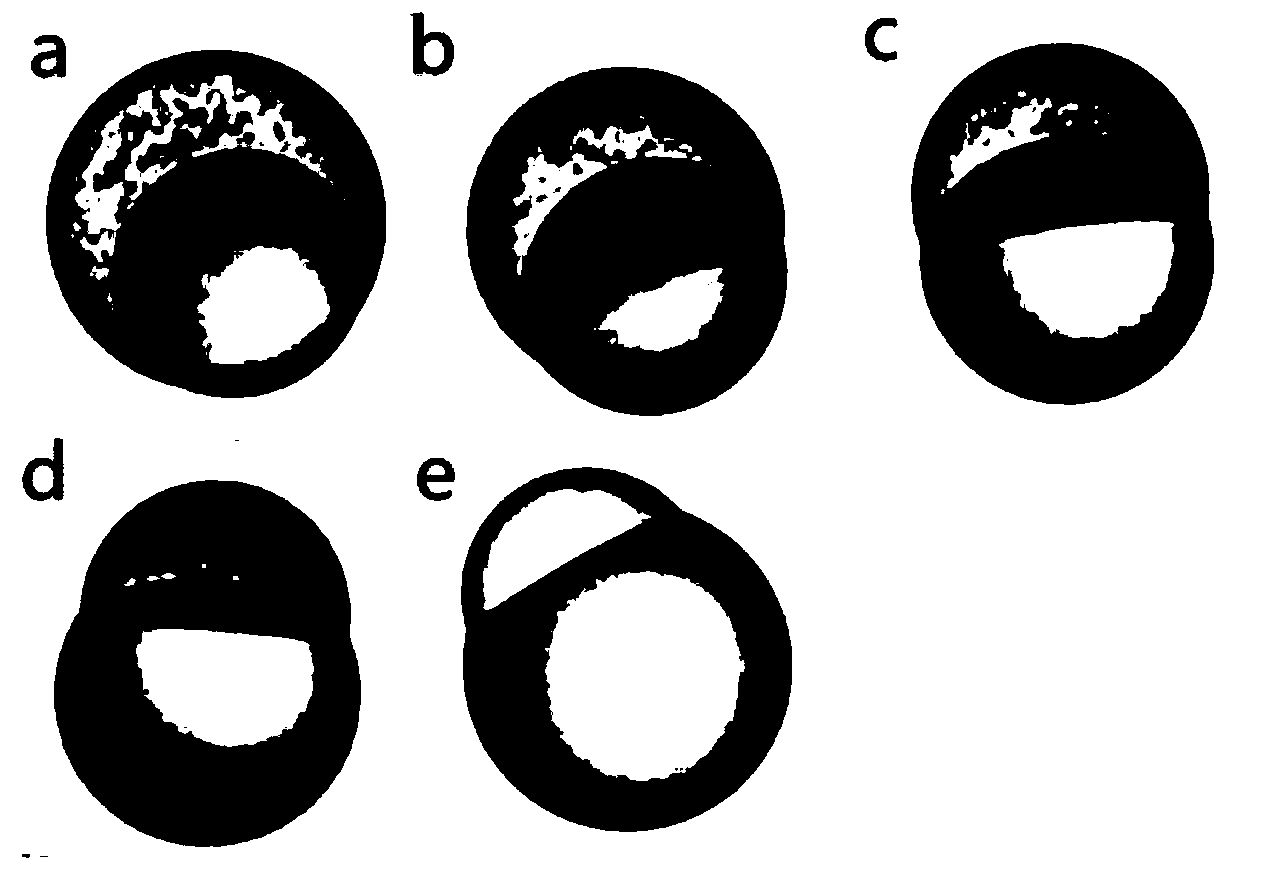

Monodisperse polarity isomerism Janus microsphere with controllable grain diameter and morphology, preparation method of microsphere and microfluid control device used in method

InactiveCN103846068AEasy to shapeUniform particle sizeLaboratory glasswaresMicroballoon preparationMicrosphereIsomerisms

The invention discloses a monodisperse polarity isomerism Janus microsphere with the controllable grain diameter and morphology, a preparation method of the microsphere, and a microfluid control device used in the method. The preparation method is characterized by comprising the following steps: preparing a polar dispersion phase solution, a non-polar dispersion phase solutions and a continuous phase solution; under the shearing action of the continuous phase solution, contacting the two dispersion phase solutions to form Janus liquid drops with different hemispherical polarities; adjusting and controlling the morphologies and the sizes of the Janus liquid drops by adjusting and controlling the concentration of a surface active agent in the polar dispersion phase solution, the flow ratio of the polar dispersion phase solution and the non-polar dispersion phase solution, and the flow rates of the polar dispersion phase solution, the non-polar dispersion phase solution and the continuous phase solution; curing the liquid drops so as to obtain the monodisperse polarity isomerism Janus microspheres, wherein the size range is 200-500 microns, and the coefficient of dispersion CV is smaller than 5%. The microfluid control device is simple in structure and easy and convenient to assemble and disassemble, so that the polarity isomerism Janus microspheres with the different sizes and morphologies can be conveniently obtained.

Owner:UNIV OF SCI & TECH OF CHINA

Free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method

The invention provides a free-falling double-stage powder mixing gas atomizing water-cooling fast-setting magnetic abrasive preparing method. The method is characterized in that double-stage free-falling nozzles are adopted, the first-stage nozzle is a low-pressure mixed powder flow jetting nozzle, the second-stage nozzle is a high-pressure gas flow nozzle, the low-pressure mixed powder flow jetting nozzle is next to the portion above the high-pressure gas flow nozzle, and by adjusting the height of the water level of cooling water in an atomizing and cooling chamber, the cooling speed of powder mixed molten metal drops is controlled, so that the hard abrasive forms the magnetic abrasive distributed on a surface shallow layer of a magnetic abrasive metal matrix. According to the method, the effect of fully mixing the hard abrasive and molten metal before atomization is achieved, waste of the hard abrasive is avoided, the proportion of the hard abrasive in the magnetic abrasive is controlled, erosive wear to a single-stage nozzle is avoided, and control over the depth of distribution of the hard abrasive on the surface shallow layer of the magnetic abrasive metal matrix is achieved; meanwhile, the flight distance of the powder mixed molten metal drops is shortened substantially, and the overall height of the atomizing chamber and equipment is reduced. The method is a new technical method for preparing the high-performance magnetic abrasive.

Owner:SHANDONG UNIV OF TECH

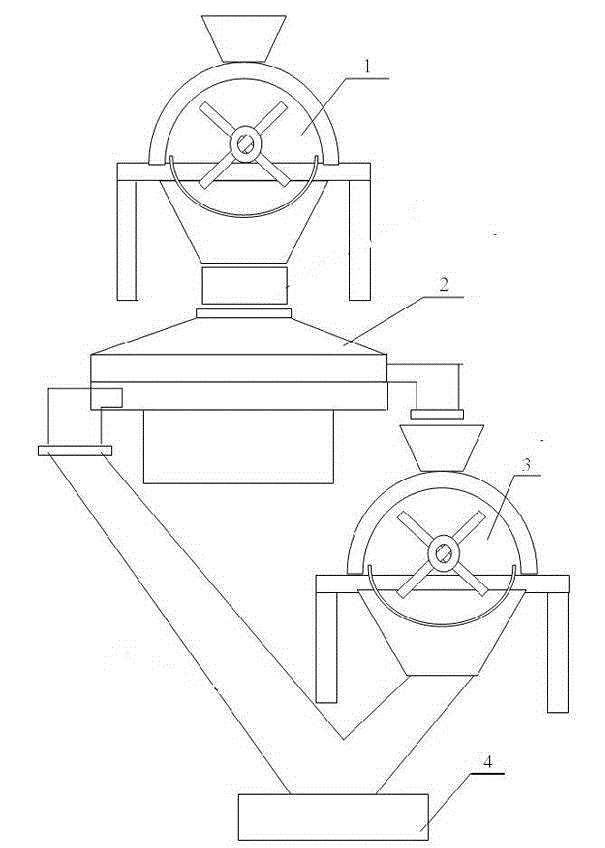

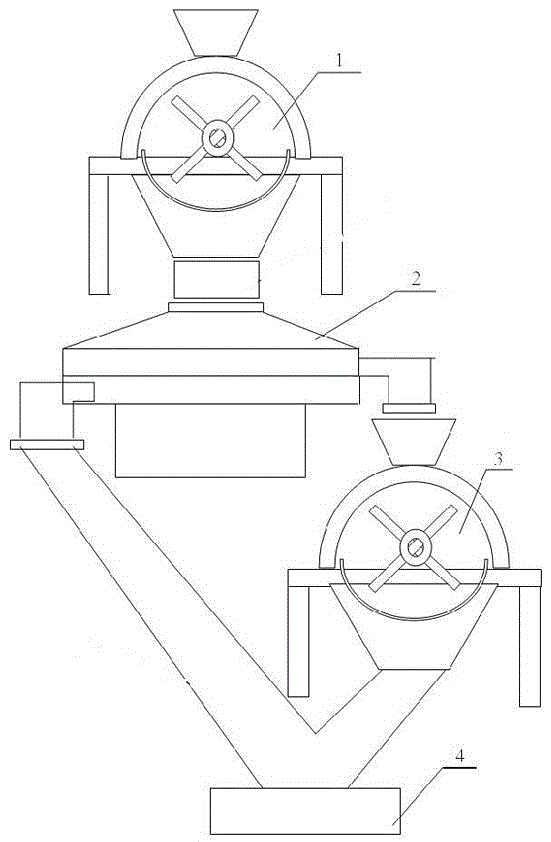

Granularity sorting method for epoxy molding compound powder material

ActiveCN102941140AThe crushing method is reasonableStrong maneuverabilityGrain treatmentsPulverizerSieve

The invention discloses a granularity sorting method for an epoxy molding compound powder material. The method comprises the following steps of: smashing the material through a first-stage hammer type smashing machine, sorting the smashed material in a double-layer sorting sieve, and pouring the fine powder material into a collector from a material outlet at the lower layer through a screen of the double-layer sorting sieve; and screening out rough powder material through the double-layer sorting sieve, smashing the rough powder material again in a two-stage hammer type smashing machine, and directly putting the smashed powder material into the collector. The smashing method is rational and high in operability; the material is smashed twice; moreover, a smashing machine screen and a sorting sieve screen which have different mesh size are adopted, so that powder materials in different granularity distribution ranges can be obtained; the granularity of the powder material is well controlled; the production efficiency is high; the material during production is high in powder flowability, so that a bridge is difficultly formed in a system; large particles and dust can be reduced; and the field working environment is improved.

Owner:灌云县瑞聚电子商务商行

Process for preparing aqueous vinyl polymer dispersions

ActiveUS20140039122A1Good coating performanceLack of transparencyCoatingsFunctional monomerCarboxylic acid

The invention relates to a process for the preparation of aqueous vinyl polymer dispersions having good film forming properties, good stability and in can clarity, to the polymer dispersions obtainable by the process and coating compositions prepared from said polymer dispersions and the use thereof. The process comprising, (1) a first polymerisation step comprising (1a) preparing an emulsion (1A) in water of a first monomer mixture (1a1) comprising carboxylic acid functional monomers, a surfactant (1a2) and water soluble inorganic salt (1a3) wherein surfactant (1a2) is a sulfur based anionic surfactant containing less than 60 wt % ethylene oxide and wherein the salt (1a3) content at the start of polymerization (1b) is between 0.01 and 3 gr / kg water, (1b) emulsion polymerizing the obtained emulsion 1A forming a hydroplasticisable first stage polymer particle dispersion (1B) said first stage polymer having a Tg from 10 to 125°, (2) a second polymerization step comprising (2a) adding to dispersion 1B a second monomer mixture (2a1) wherein carboxylic acid functional monomers is present in an amount such that the acid value of the resulting polymer is less than 23 KOH / g and wherein the amount of monomer mixture (2a1) is between 10 and 90 wt % of the total weight of monomers (1a1) plus (2a1), (2b) polymerizing second monomer mixture (2a1) to form a second stage polymer in the first particle dispersion (1B) to form a multiphase particle dispersion (2B).

Owner:ALLNEX NETHERLANDS BV

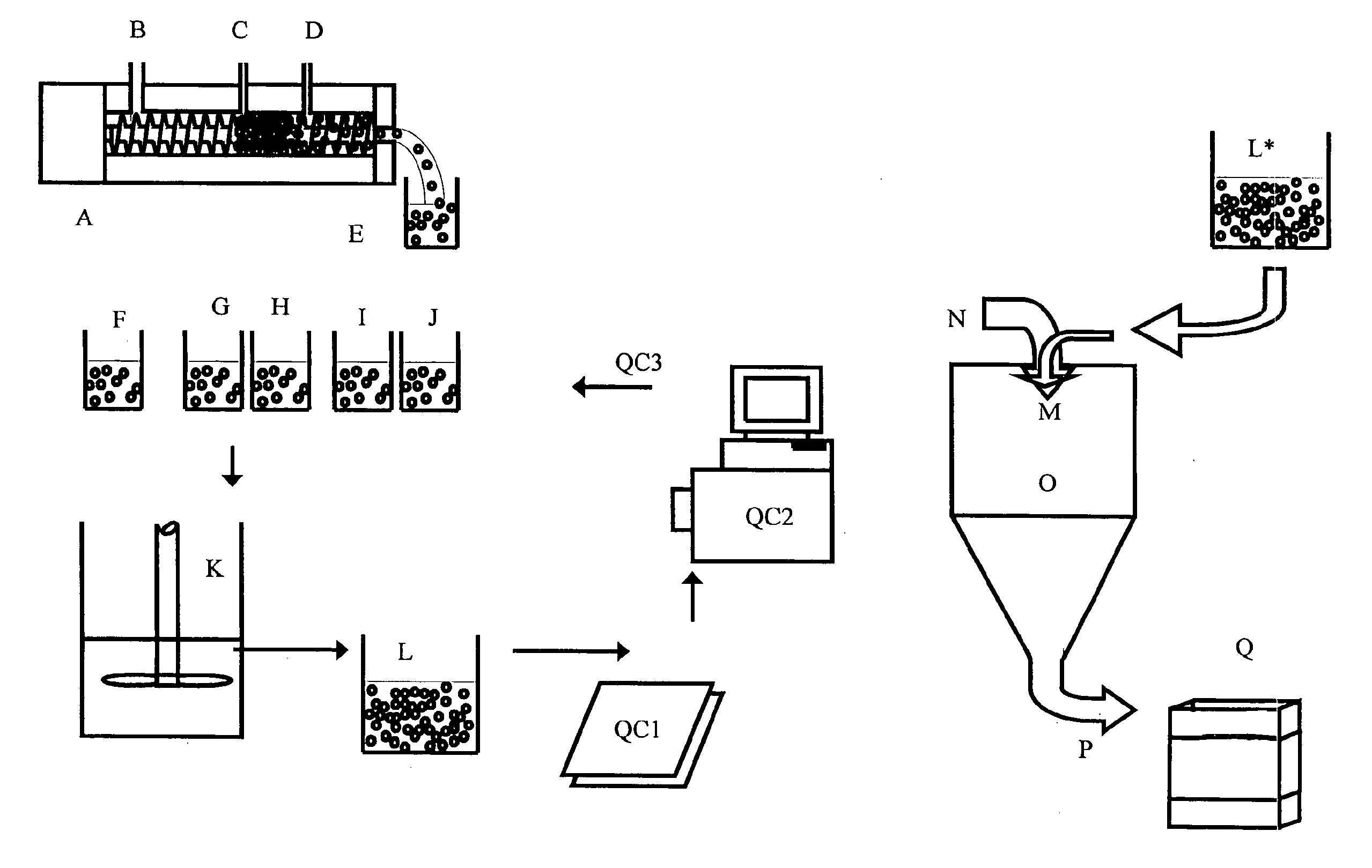

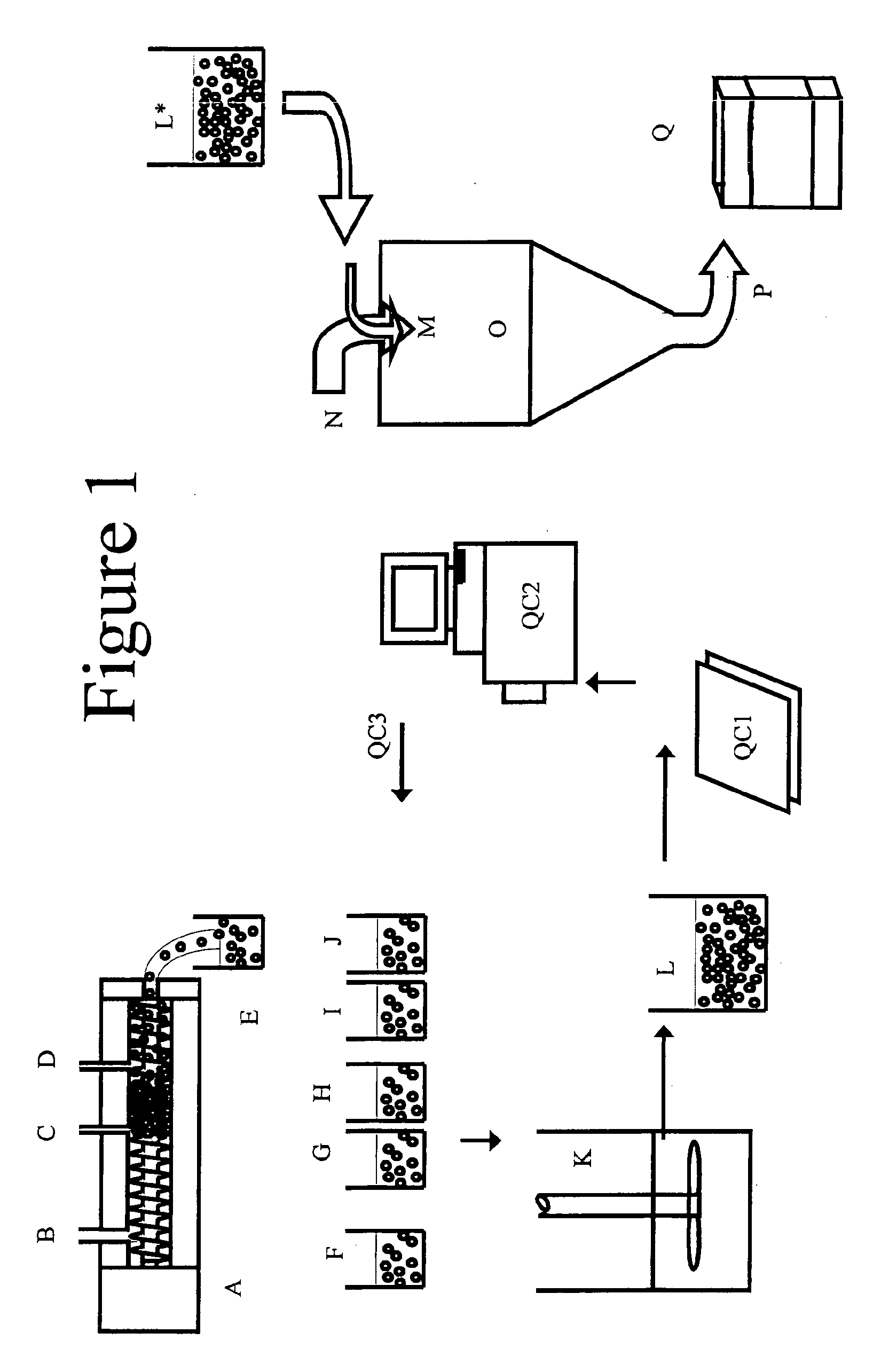

Process for preparing a powder coating composition

InactiveUS20090017209A1Improve quality controlEasy to adjustPowdery paintsSpecial surfacesEmulsionPowder coating

The present invention pertains to a process for preparing a powder coating composition, the process comprising the steps of:a. providing a set of base compositions, each base composition comprising a liquid carrier and one or more constituents responsible for an intended property of the coating product, at least one base composition A being an aqueous dispersion or emulsion of a film-forming material,b. selecting base compositions to be used to obtain the intended end product property, said base compositions comprising at least one base composition A as specified;c. mixing the selected base compositions in a ratio suitable to obtain the intended end product property;d. drying, preferably spray-drying, the mixture of base compositions or otherwise removing the liquid carrier(s), ande. simultaneously or subsequently, combining the particles of the base compositions into larger particles.Preferably, the particles of film-forming material in base composition A have a d(v,50)<5 μm. Preferably, at least one base composition A is prepared by phase inversion emulsification.

Owner:AKZO NOBEL COATINGS INT BV

Ultra-fine cavitated target type water fluid jet grind

InactiveCN101367060AImprove energy utilizationEasy particle size controlGrain treatmentsCavitationGranularity

The invention relates to a solid material crushing device, in particular to a superfine cavitation target type water-jet mill which is characterized by comprising a hopper, a cavity of the mill, a granularity regulating plate, a jet mixing accelerating part, an impact regulating target body and a stand, wherein the hopper is fixed on the upper end of the cavity of the mill and is communicated with an injection cavity of the cavity of the mill; the bottom of the cavity of the mill is fixed on the stand; a diffusion mixing pipe of the jet mixing accelerating part is fixed in a cavity of a diffusion mixing pipe positioning seat in the cavity of the mill; a nozzle mouth of a cavitation nozzle is positioned in an input port of a diffusion mixing pore channel; the impact regulating target body is positioned on the left of an output port of the diffusion mixing pipe of the jet mixing accelerating part; the granularity regulating plate is arranged on the position of an output end of a gradually varied channel with an arc section and a grading discharge hole in the cavity of the mill; and the grading discharge hole of the cavity of the mill is communicated with the output end of the gradually varied channel. The superfine cavitation target type water-jet mill has the characteristics of high utilization rate of crushing energy and easy regulation of granularity.

Owner:WUHAN UNIV OF TECH

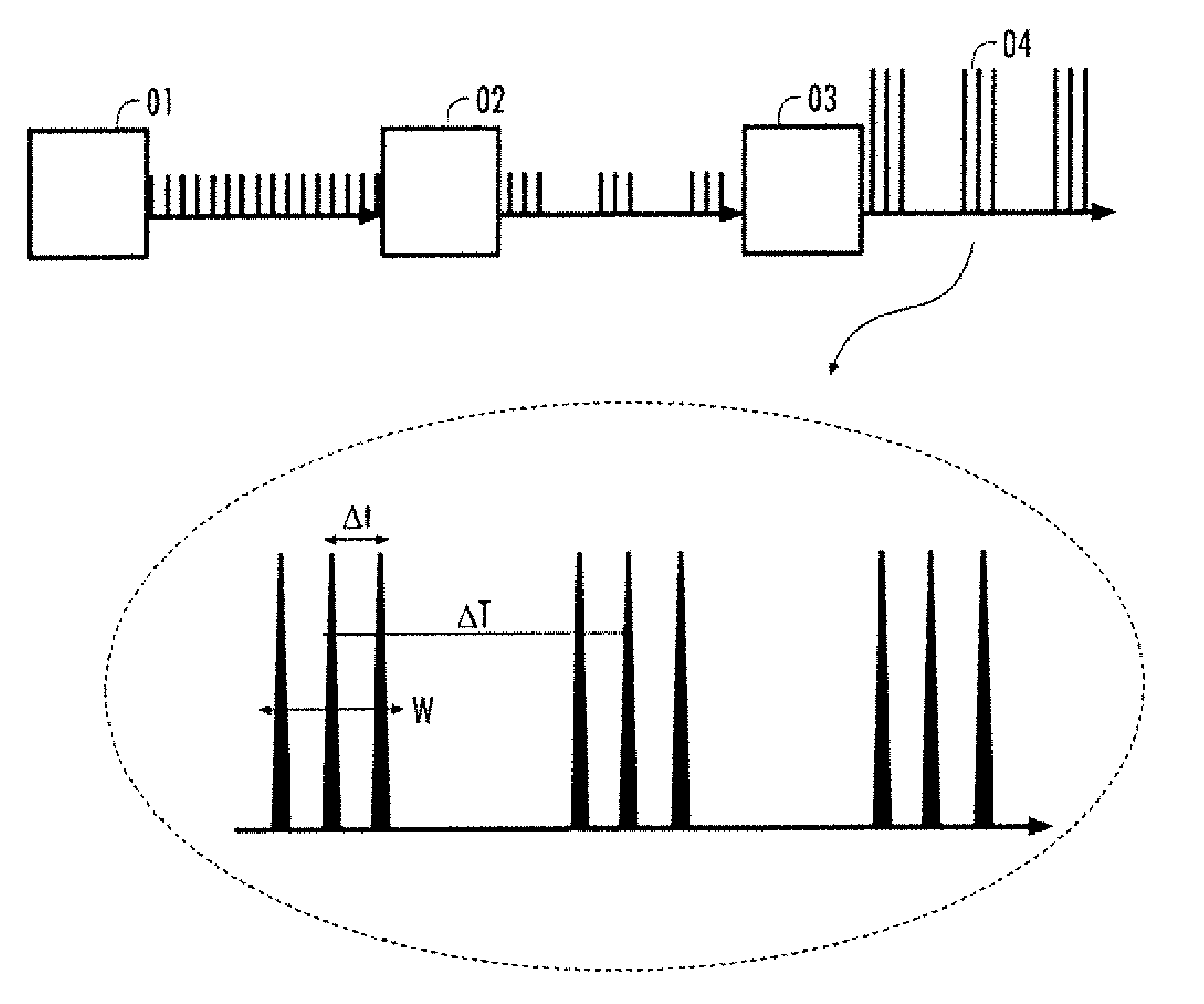

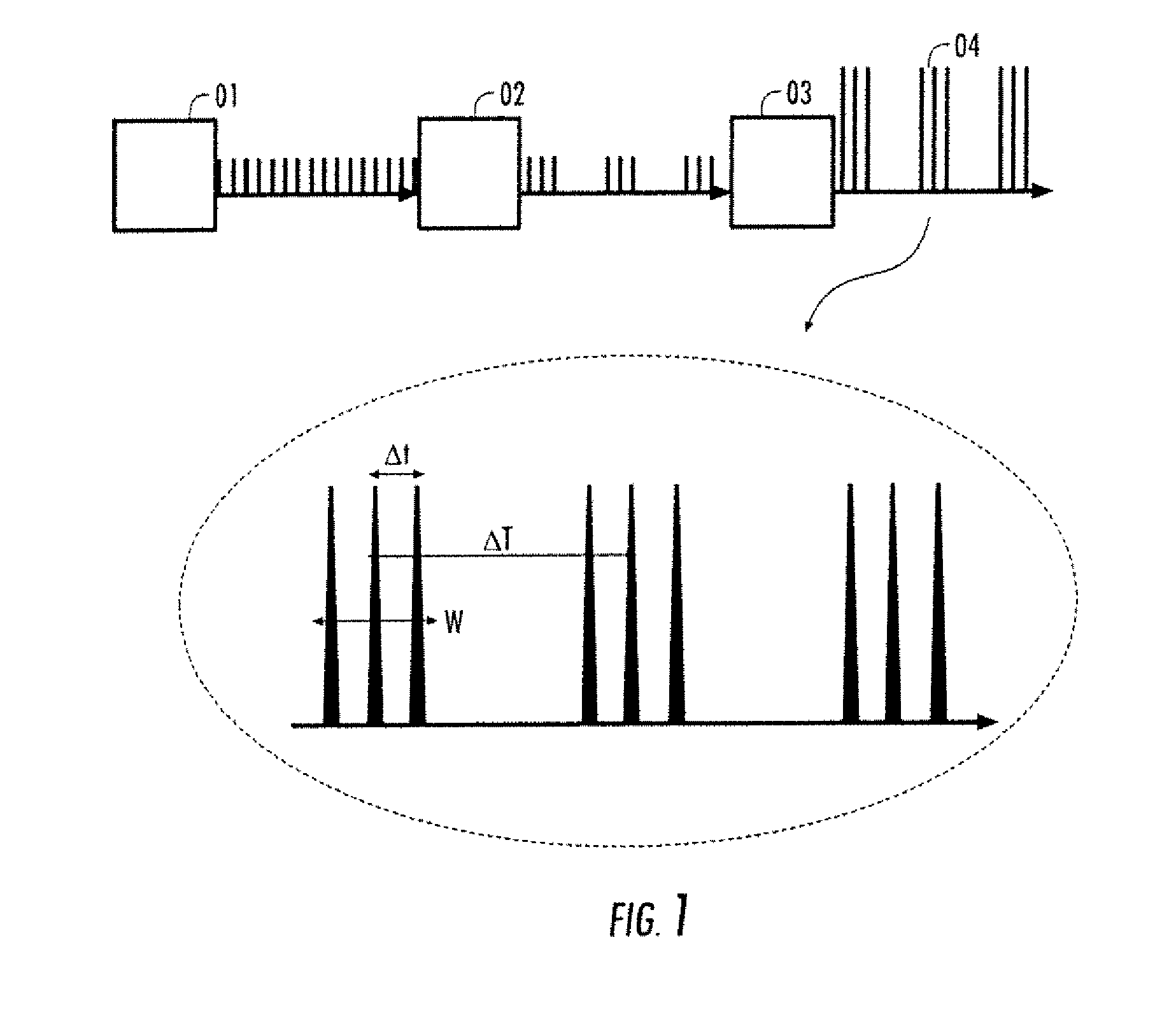

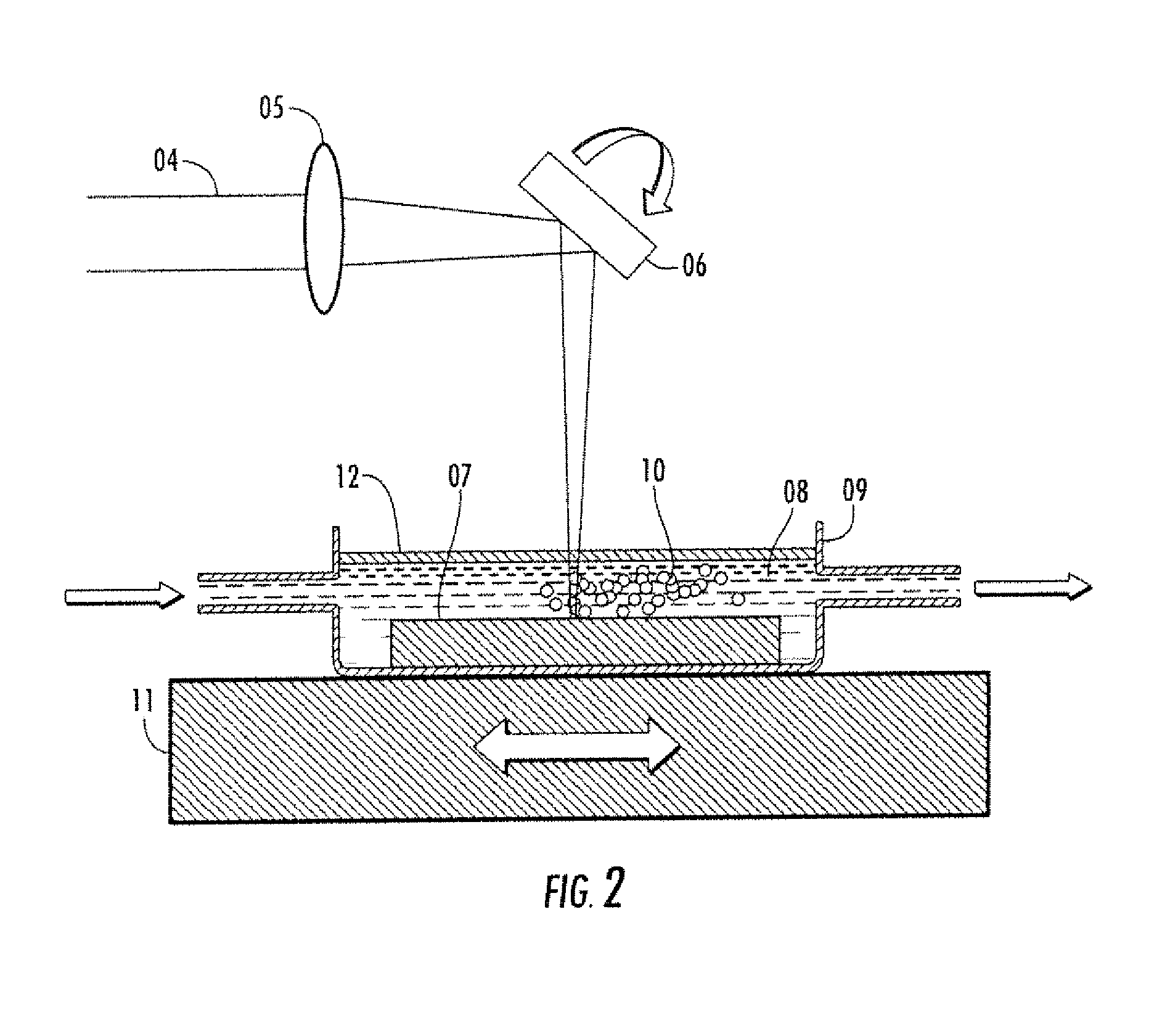

Nanoparticle production in liquid with multiple-pulse ultrafast laser ablation

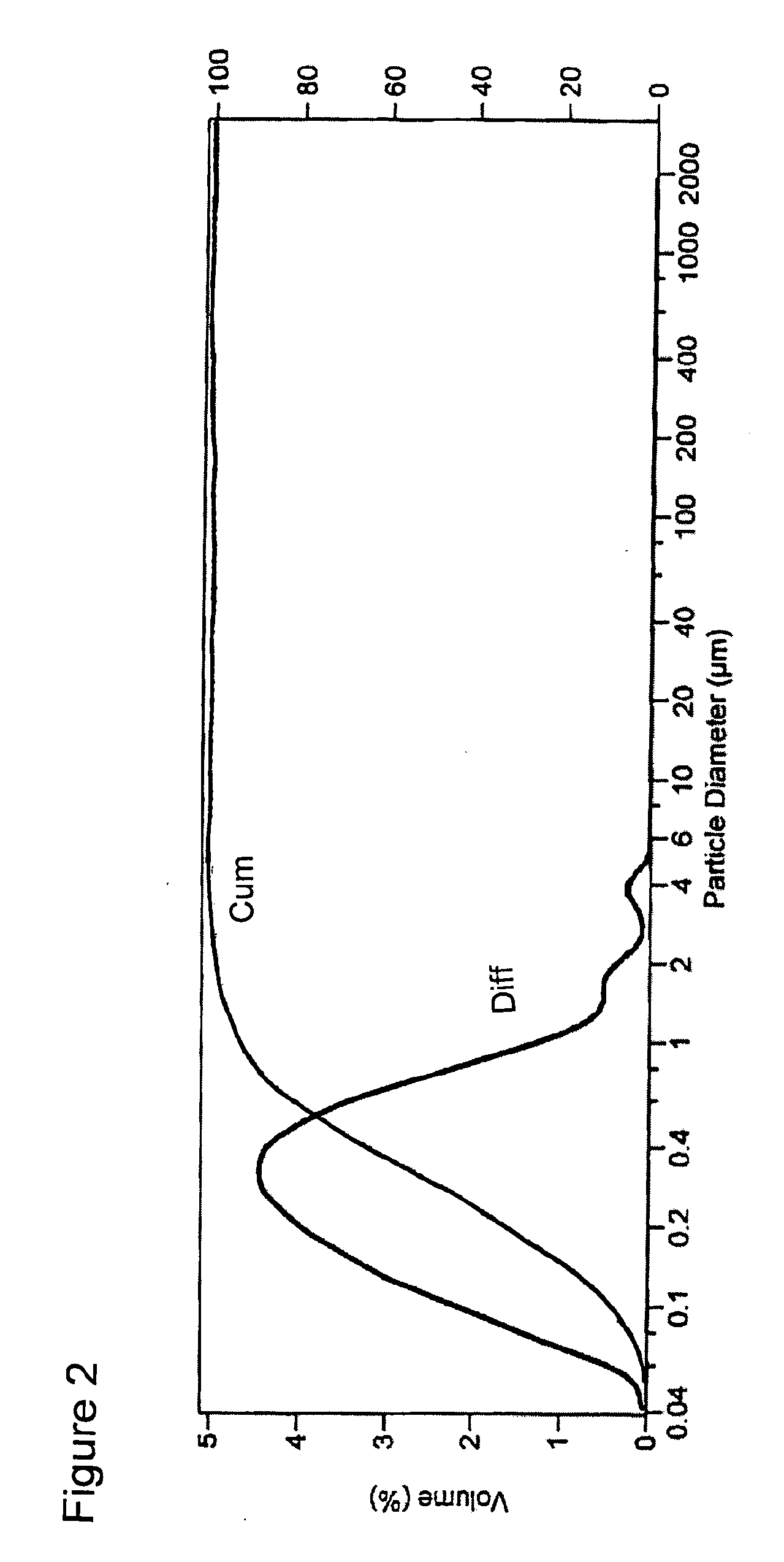

ActiveUS8858676B2Easy particle size controlImprove production efficiencyNanotechTransportation and packagingNanoparticle ProductionNanosecond

A method for generating nanoparticles in a liquid comprises generating groups of ultrafast laser pulses, each pulse in a group having a pulse duration of from 10 femtoseconds to 200 picoseconds, and each group containing a plurality of pulses with a pulse separation of 1 to 100 nanoseconds and directing the groups of pulses at a target material in a liquid to ablate it. The multiple pulse group ablation produces nanoparticles with a reduced average size, a narrow size distribution, and improved production efficiency compared to prior pulsed ablation systems.

Owner:IMRA AMERICA

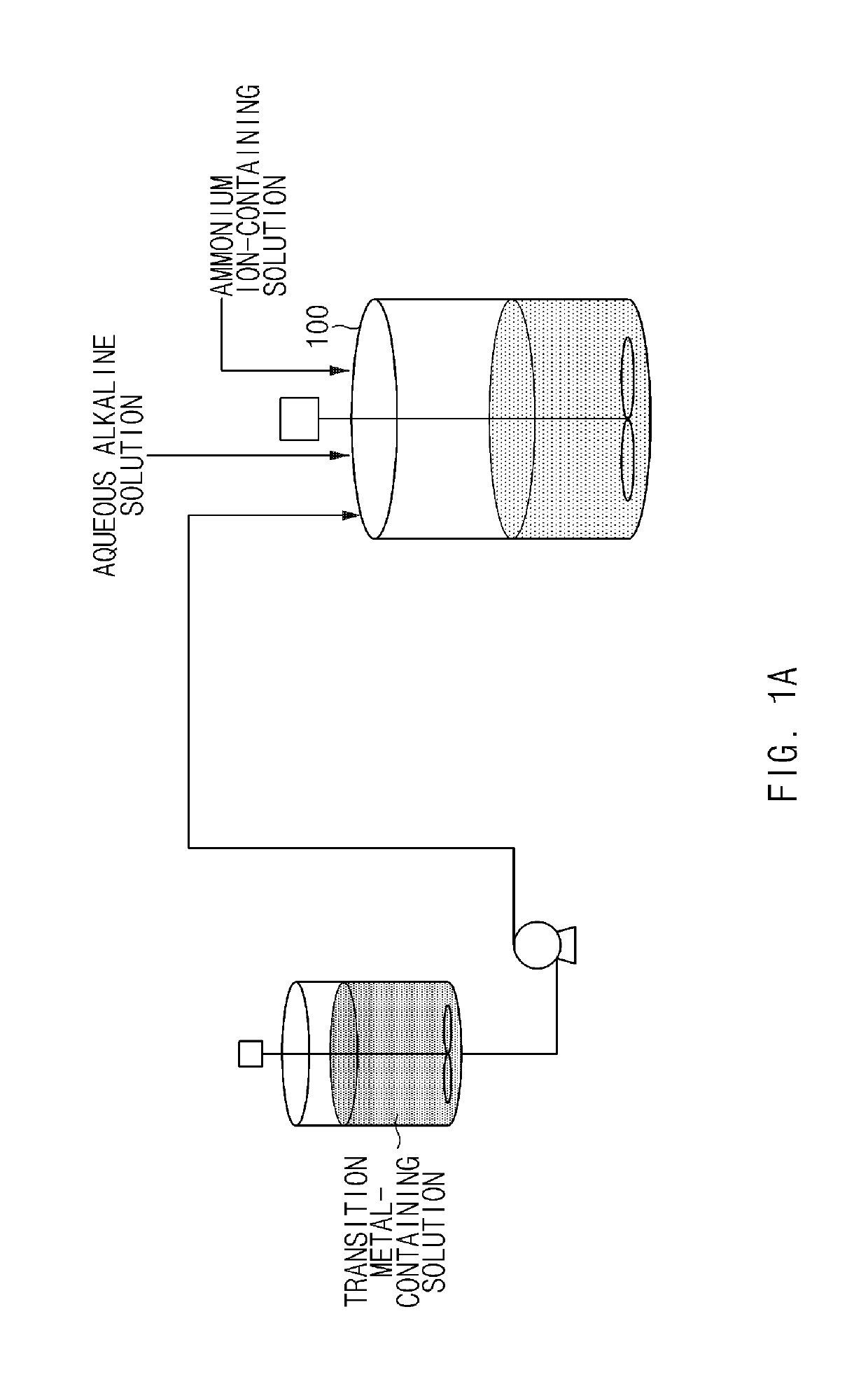

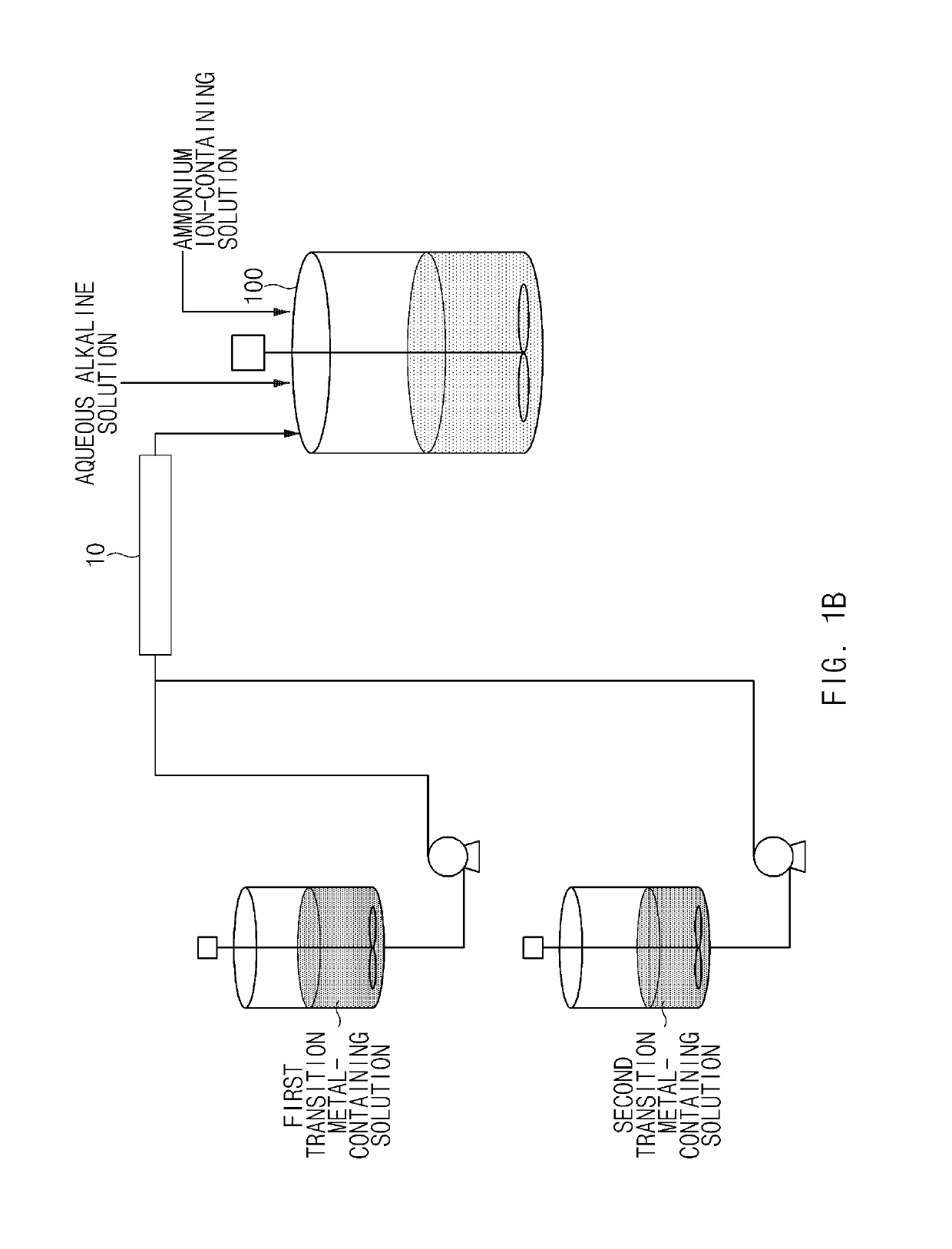

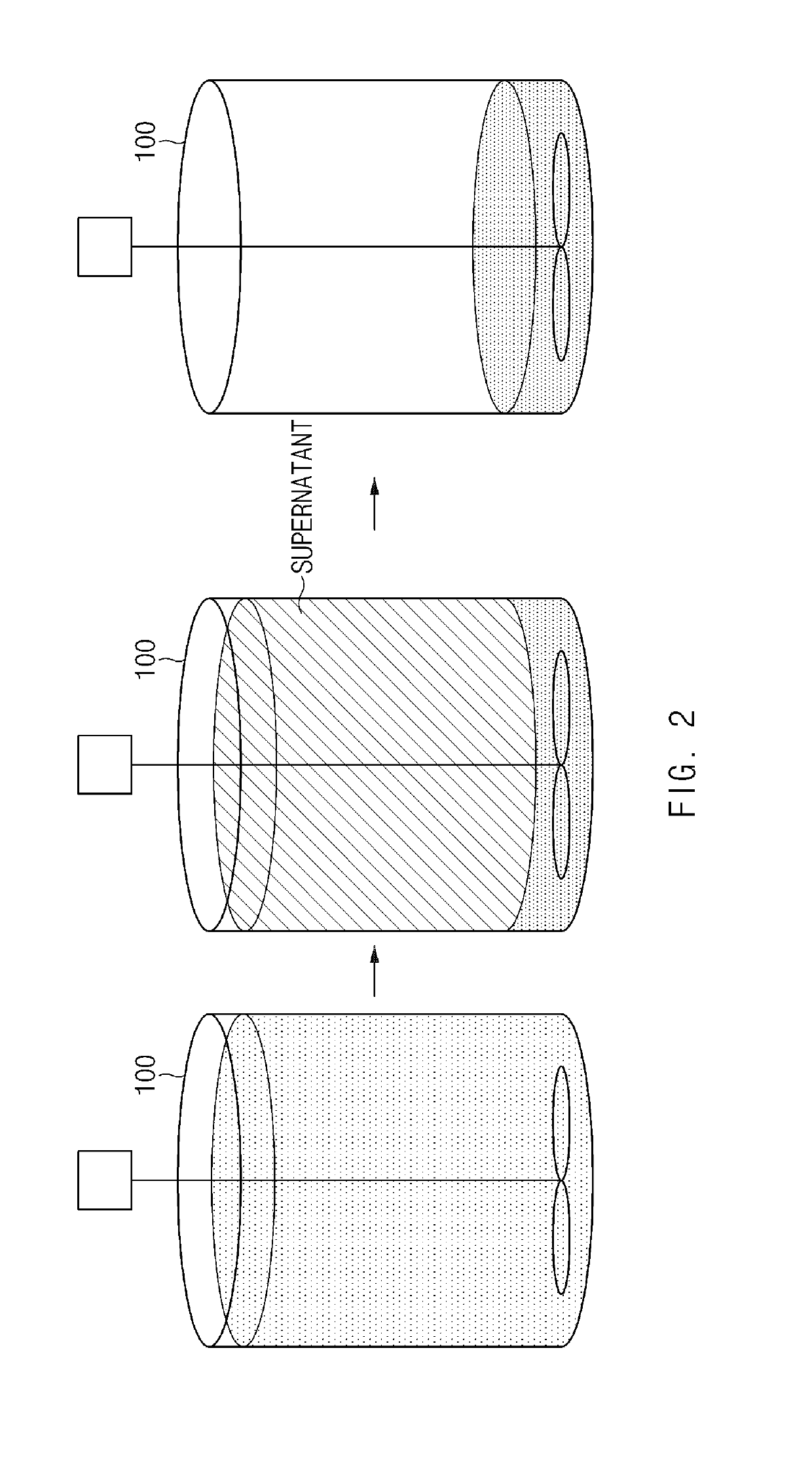

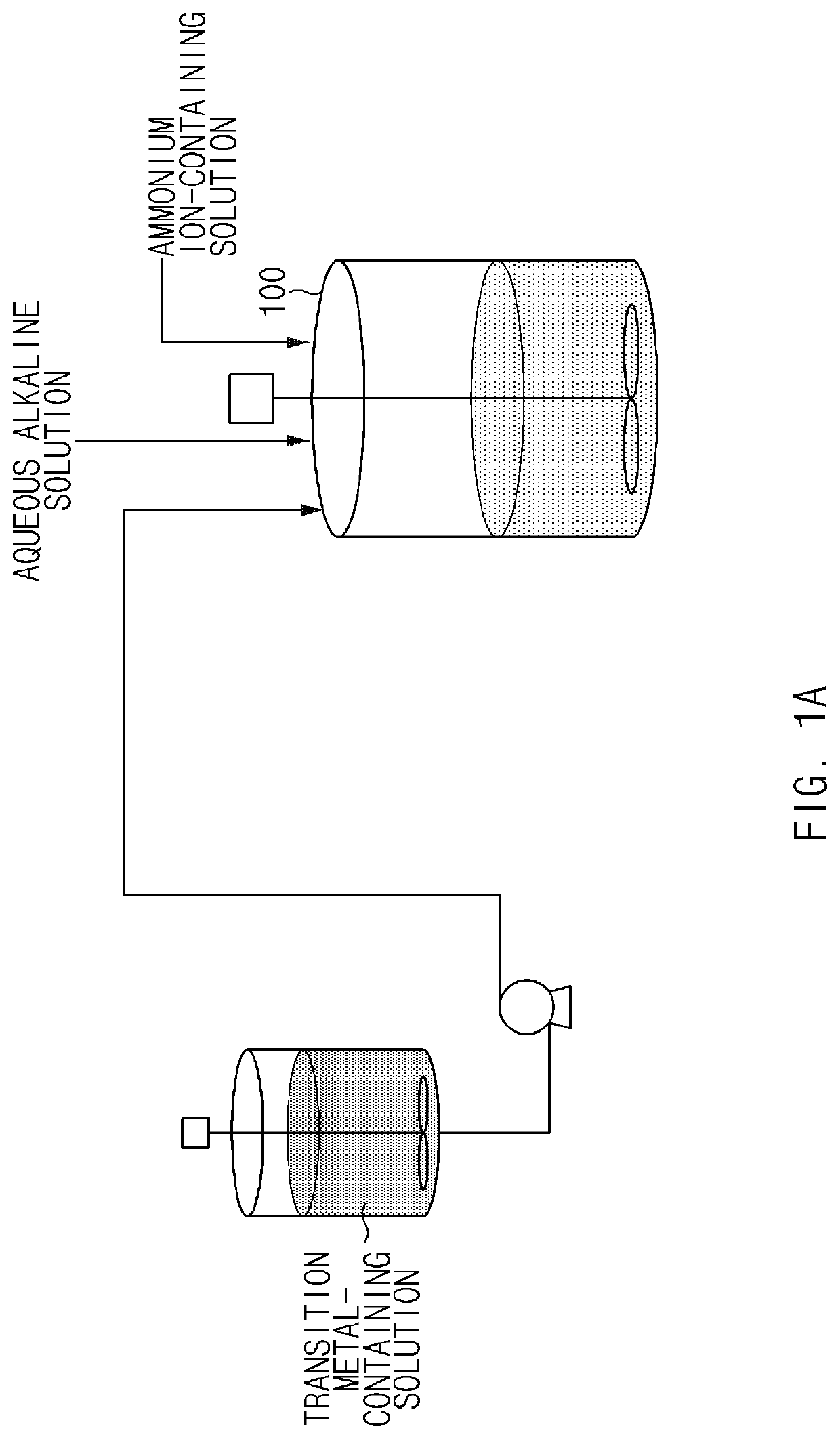

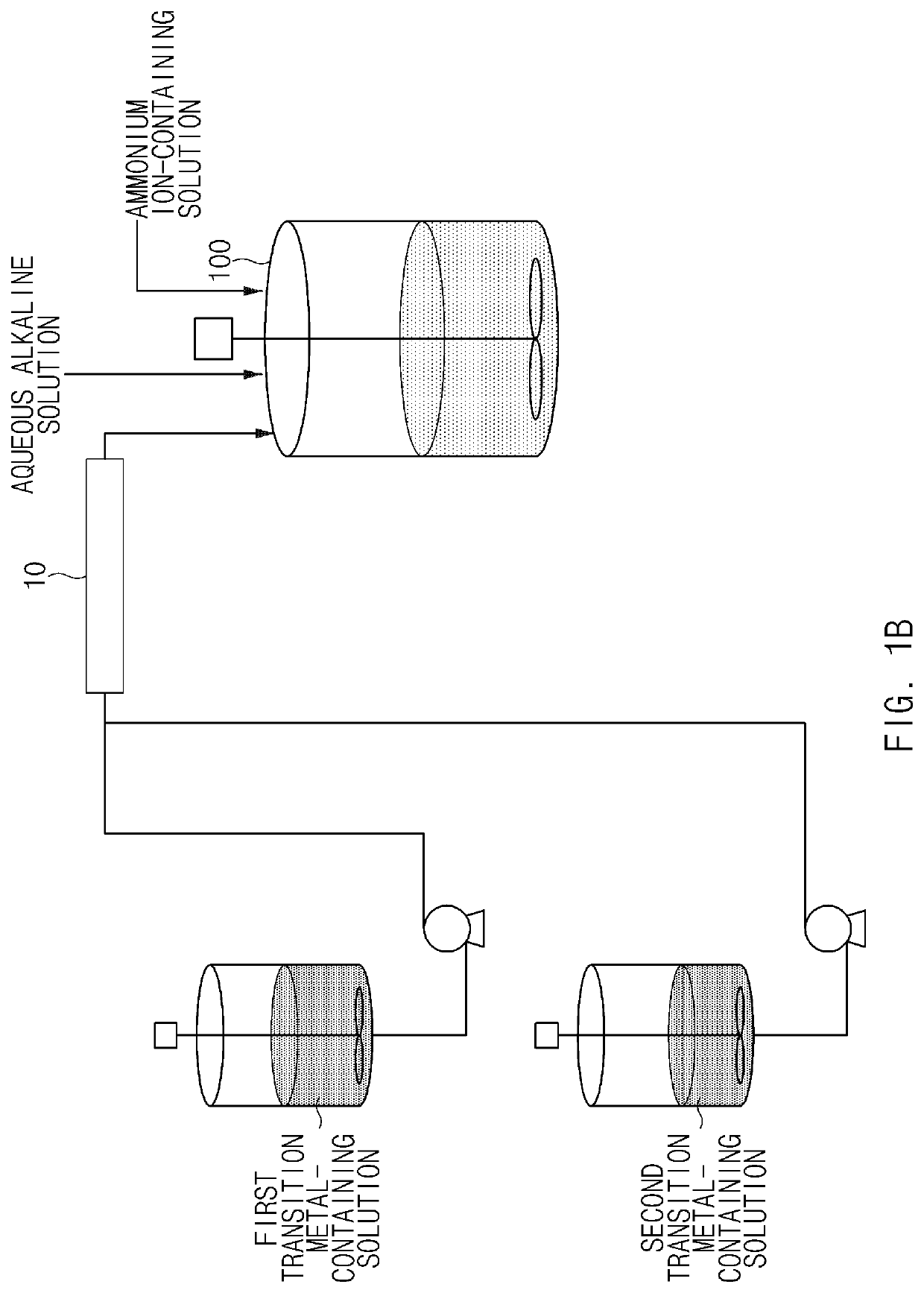

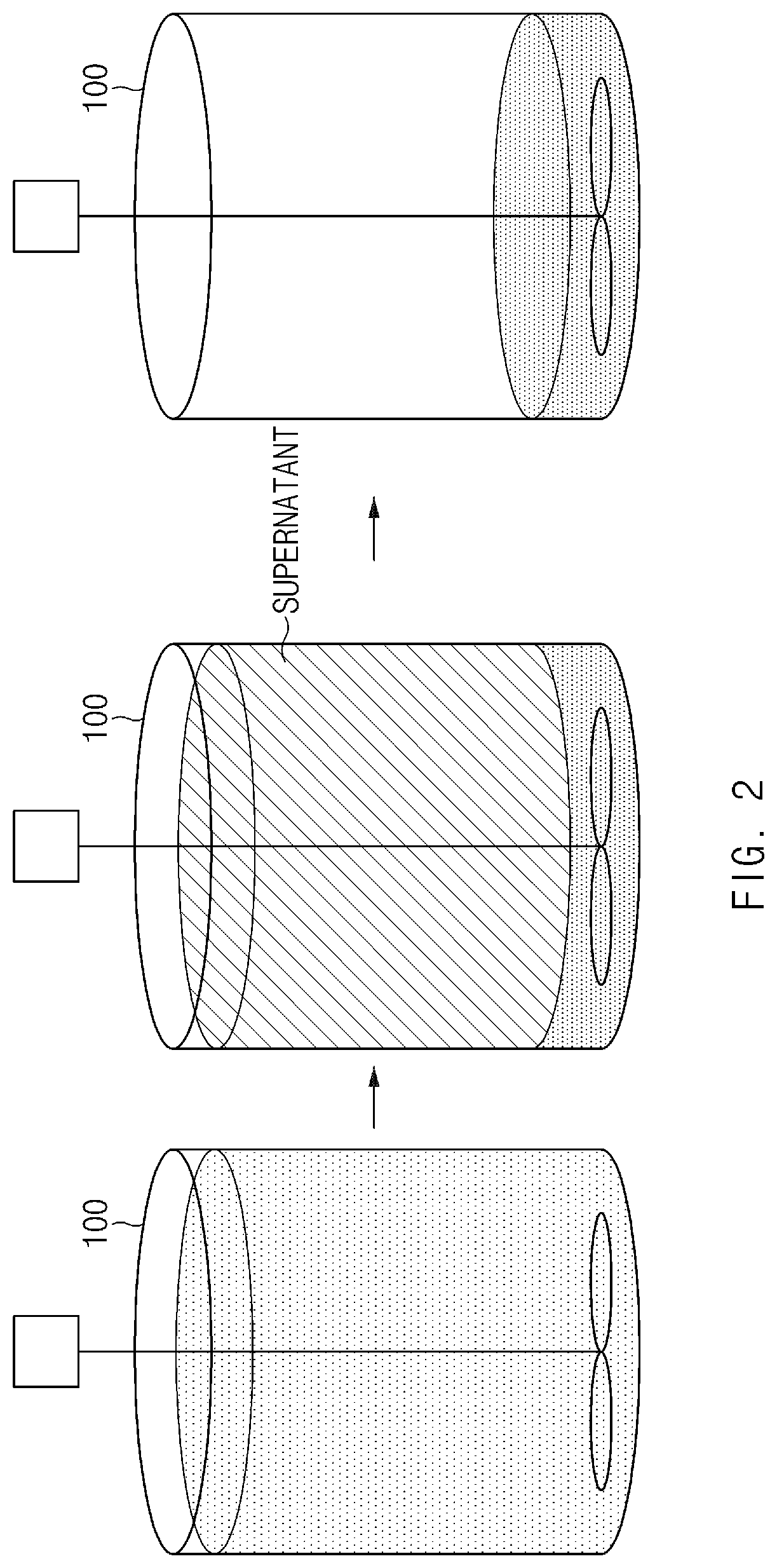

Methods of Preparing Positive Electrode Active Material Precursor For Lithium Secondary Battery And Positive Electrode Active Material

ActiveUS20190214628A1Decrease productivityEasy particle size controlElectrode thermal treatmentSecondary cellsLithiumAqueous solution

A method of preparing a positive electrode active material precursor for a lithium secondary battery by using a batch-type reactor, which includes the steps of 1) forming positive electrode active material precursor particles while continuously adding a transition metal-containing solution including a transition metal cation, an aqueous alkaline solution, and an ammonium ion-containing solution to a batch-type reactor, 2) sedimenting the positive electrode active material precursor particles formed; 3) discharging a supernatant formed after the sedimentation of the positive electrode active material precursor particles to an outside; 4) adjusting a pH to 10 to 12 by adding the ammonium ion-containing solution; and 5) growing the positive electrode active material precursor particles while continuously again adding the transition metal-containing solution to the batch-type reactor, and a method of preparing a positive electrode active material using the same.

Owner:LG CHEM LTD

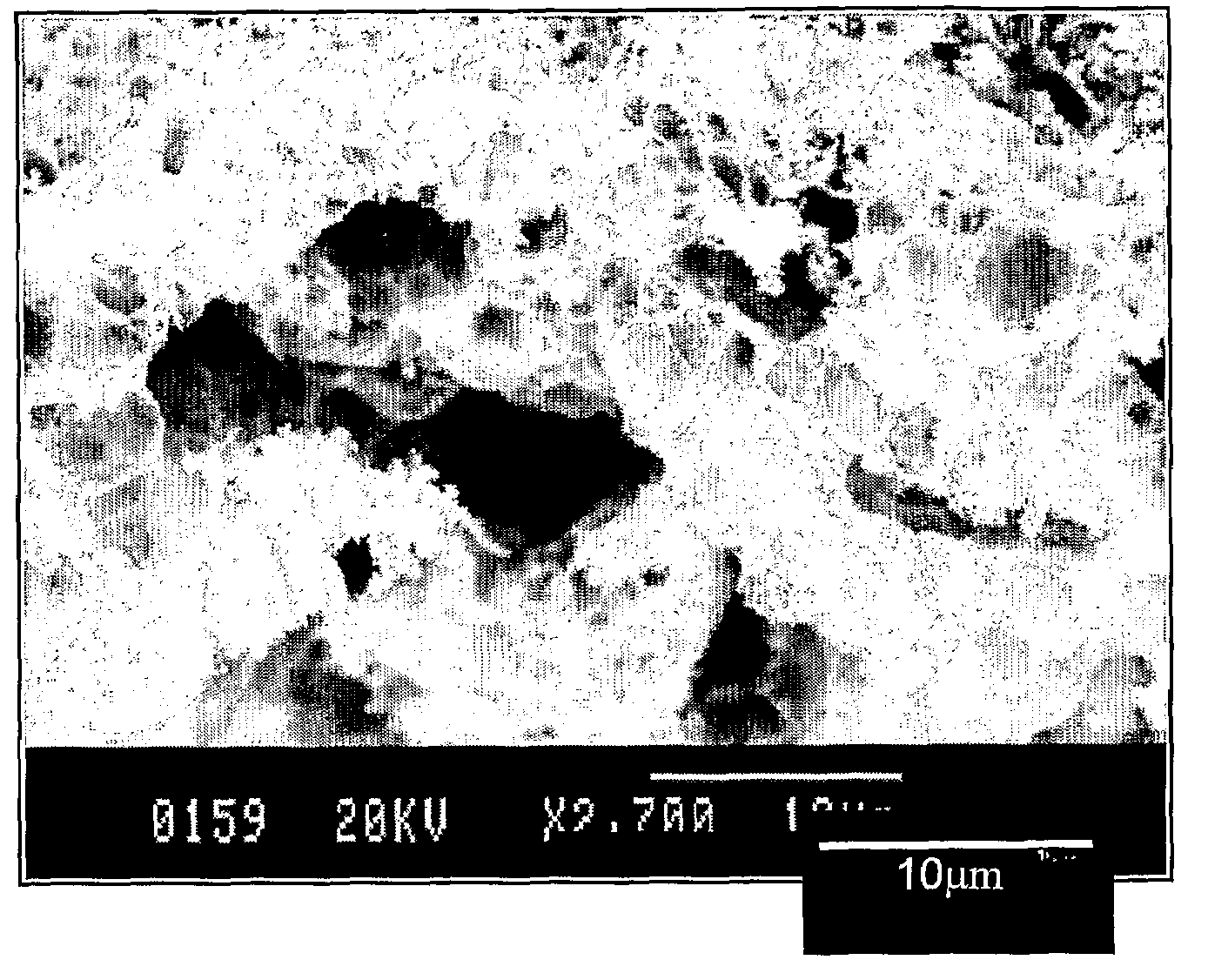

Novel nickel/sodium alginate inorganic/organic hybrid material and preparation method and application thereof

InactiveCN105944758AEvenly dispersedHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationDispersityFiltration

The invention provides a novel nickel / sodium alginate inorganic / organic hybrid material and a preparation method and application thereof. The preparation method includes the steps that 1, a sodium alginate solution is prepared; 2, a NiCl2 aqueous solution with the concentration being 0.05-1.0 M is prepared; 3, the sodium alginate aqueous solution is dropwise added to the NiCl2 aqueous solution in a stirring state, crossing and curing are conducted at the normal temperature, and gel beads are obtained; then the gel beads are preserved in ethyl alcohol for use through solvent exchange; 4, the gel beads are placed in a sodium borohydride solution for reduction, an obtained sample is subjected to suction filtration and washing and activation treatment, and the nickel / sodium alginate inorganic / organic hybrid material is obtained. Nickel nanoparticles in the prepared nickel / sodium alginate hybrid material display better dispersity and a smaller particle size, high action force between nickel and sodium alginate inhibits agglomeration and losing of nickel particles, and a catalyst can have good catalytic activity and stability.

Owner:HEBEI UNIVERSITY

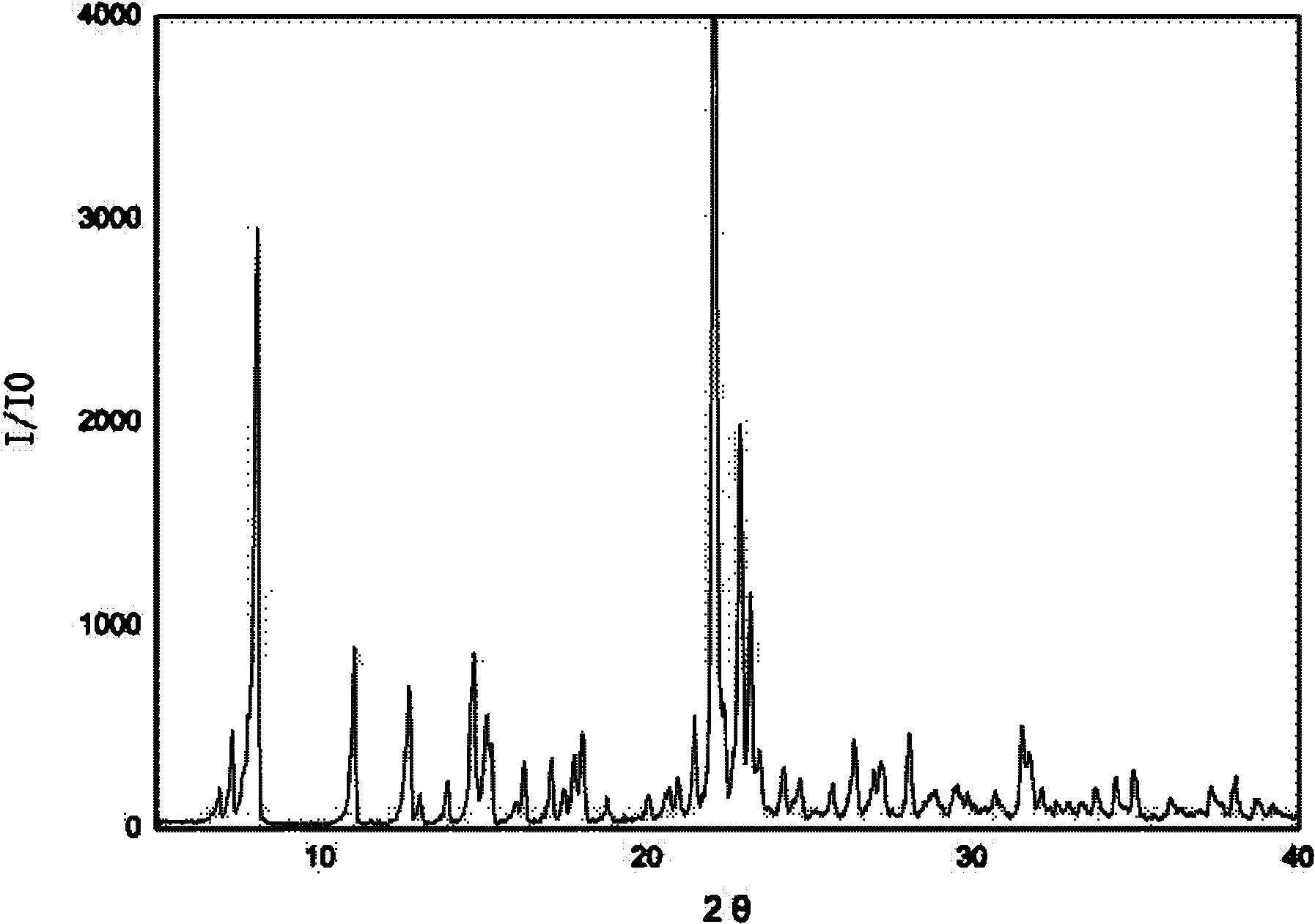

Preparation method of slurry for photoanode of nano TiO2 membrane of dye-sensitized solar cell

ActiveCN103531363AImprove performanceHigh porosityLight-sensitive devicesTitanium dioxideDispersitySlurry

The invention belongs to the field of solar batteries, and particularly relates to a preparation method of slurry for a photoanode of a nano TiO2 membrane of a dye-sensitized solar cell. The method aims at solving the technical problem that the existing preparation method of the slurry required by a nano TiO2 photoanode membrane is higher in cost and complicated in technology. In order to solve the technical problem, the preparation method of the slurry for the photoanode of the nano TiO2 membrane of the dye-sensitized solar cell comprises the following steps of: a, heating commercial titanium liquid for hydrolysis, performing centrifugal settling on a hydrolysis system, removing supernatant, washing and obtaining metatitanic acid, b, adding a dispergator into metatitanic acid for dispergation, obtaining metatitanic acid slurry, and c, adding an additive to allow the metatitanic acid slurry to be dispersed uniformly. The method is simple to implement; performances of the slurry can be flexibly adjusted according to technological parameters; the obtained metatitanic acid slurry is good in dispersity and strong in stability; and a new method is provided for preparing the slurry for the photoanode of the nano TiO2 membrane of the dye-sensitized solar cell.

Owner:PANZHIHUA UNIV

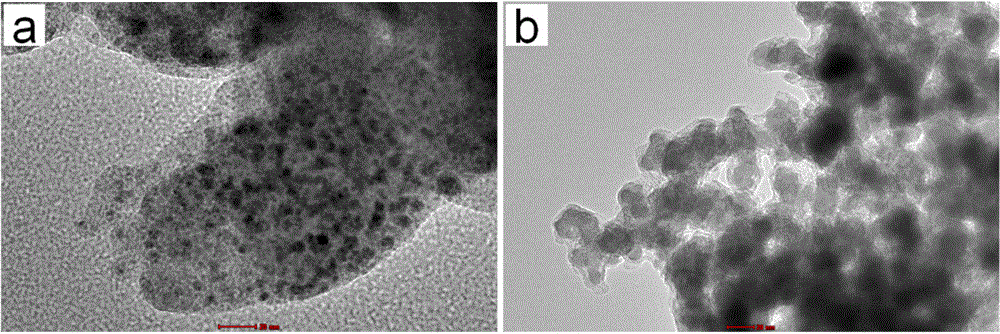

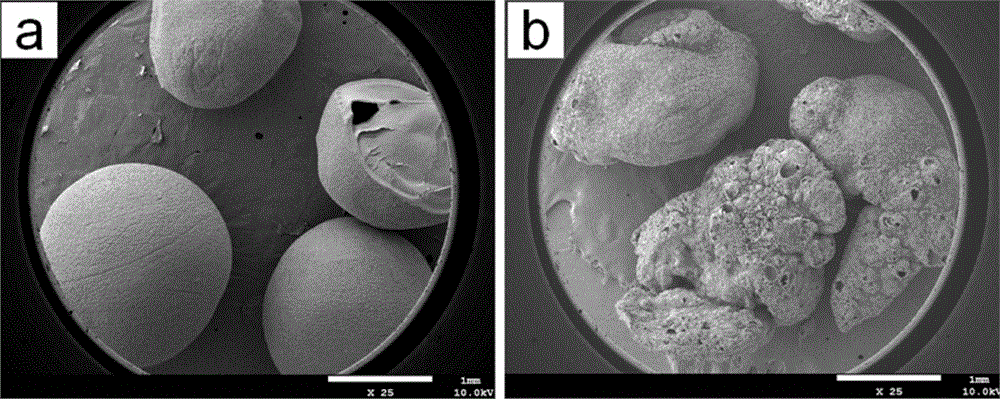

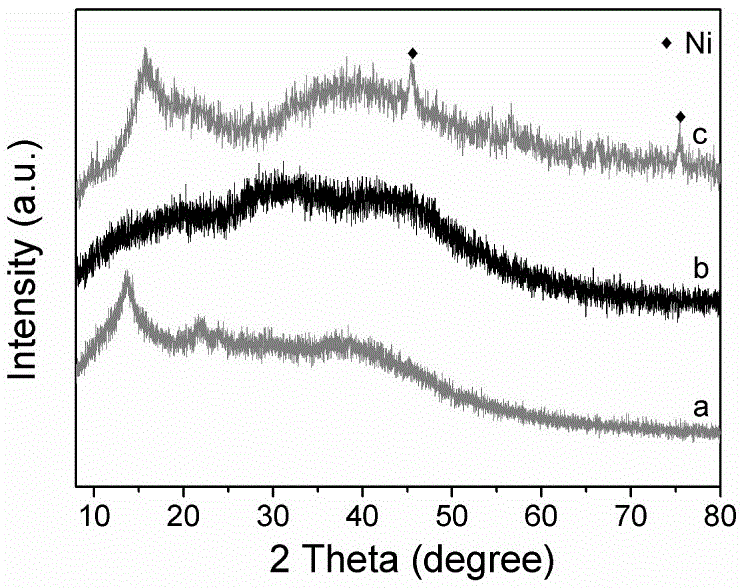

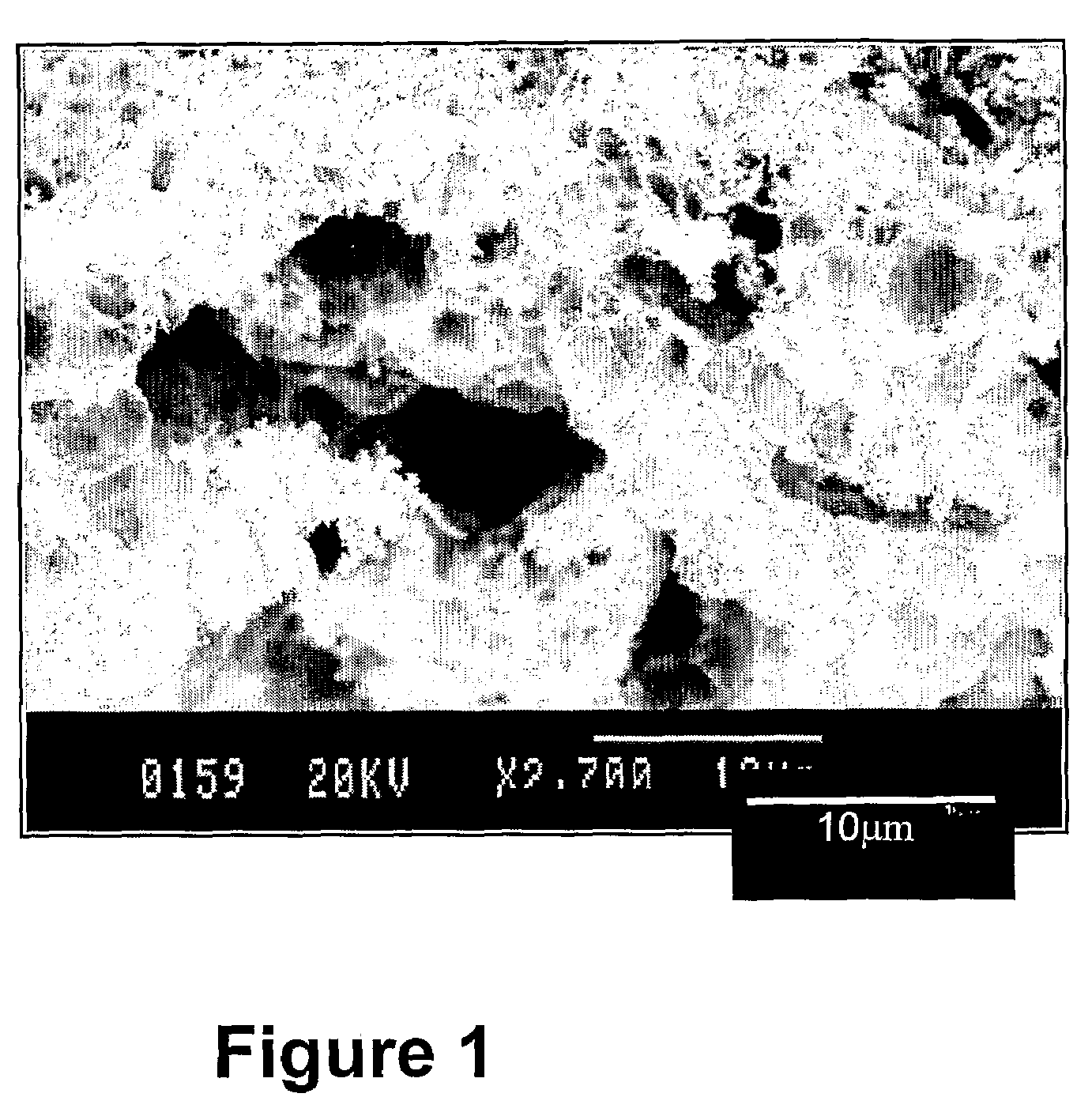

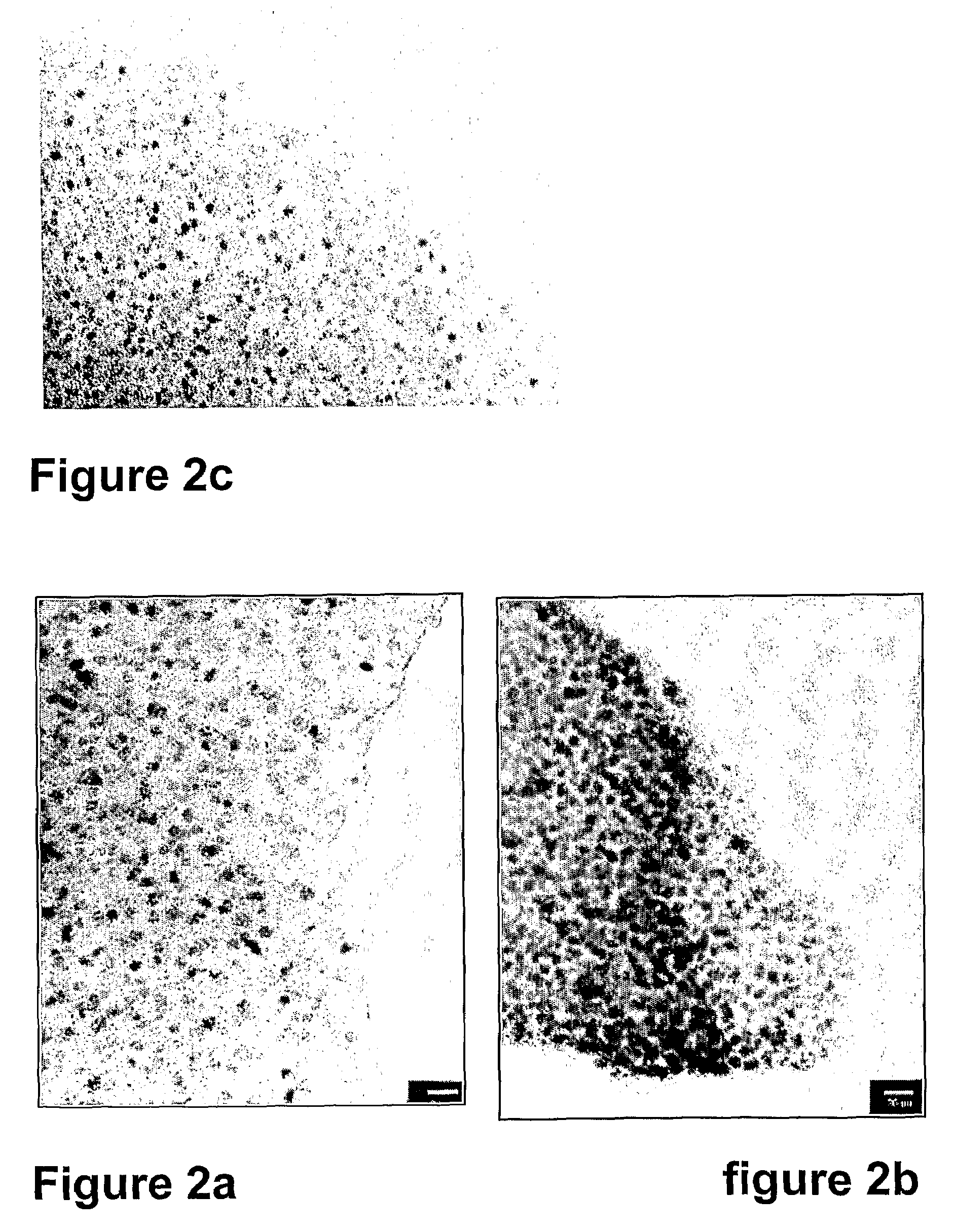

Composite materials and method of its manufacture

ActiveUS7740814B2Excellent propertySuitable for up-scalingSolar heating energySolar heat devicesPtru catalystThin membrane

A novel solution route has been developed that after heat-treatment to 500-600° C. under inert atmosphere, yields highly porous composites of nano-sized metal (Ni) particle inclusions in ceramics (Al2O3). Metal loadings could be made from <1% to >95% Ni. The metal inclusion sizes in the Ni—Al2O3 system with the 10 atom % Ni sample were 4-7 nm, while for the 75 atom % Ni sample they were 5-8 nm. It was shown that the 10 atom % Ni sample could be used as a catalyst for the conversion of CO2 and CH4 in the temperature range 550-700° C., while higher temperatures led to growth of the Ni particles and carbon poisoning over time. The solution routes could also be deposited as thin dense films containing <10 nm Ni particles. Such films with high Ni-particle loadings deposited on aluminium substrates have shown very good solar heat absorber proficiency and provide good substrates for carbon tube growth.

Owner:SUNSTRIP

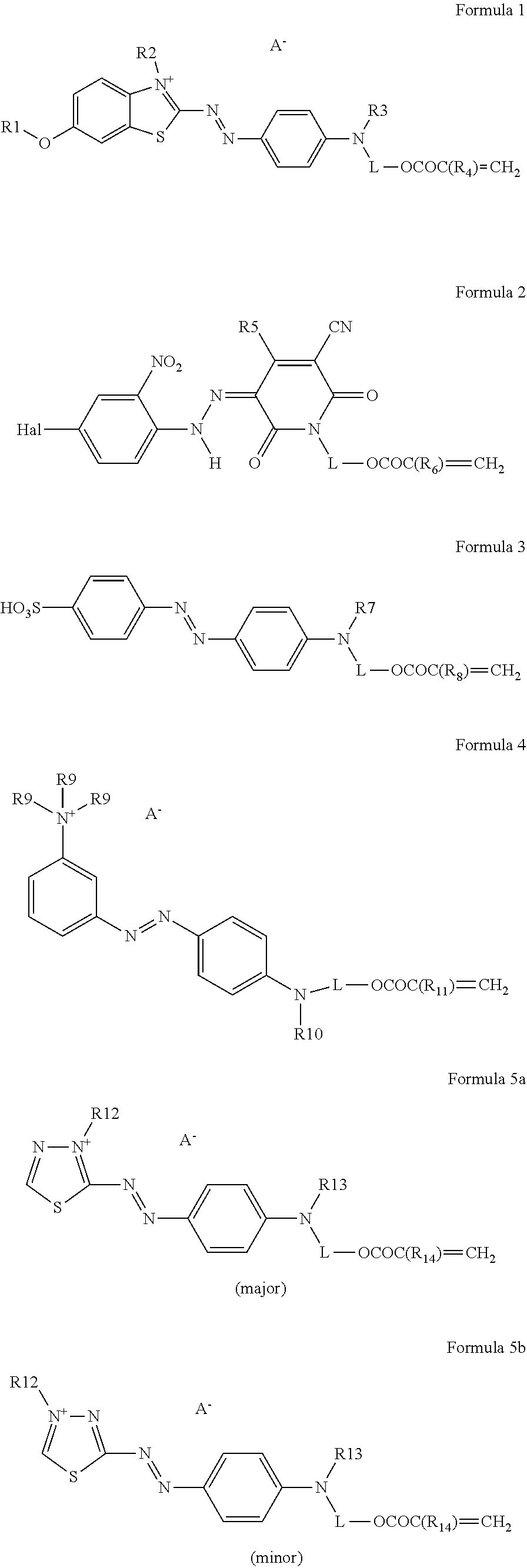

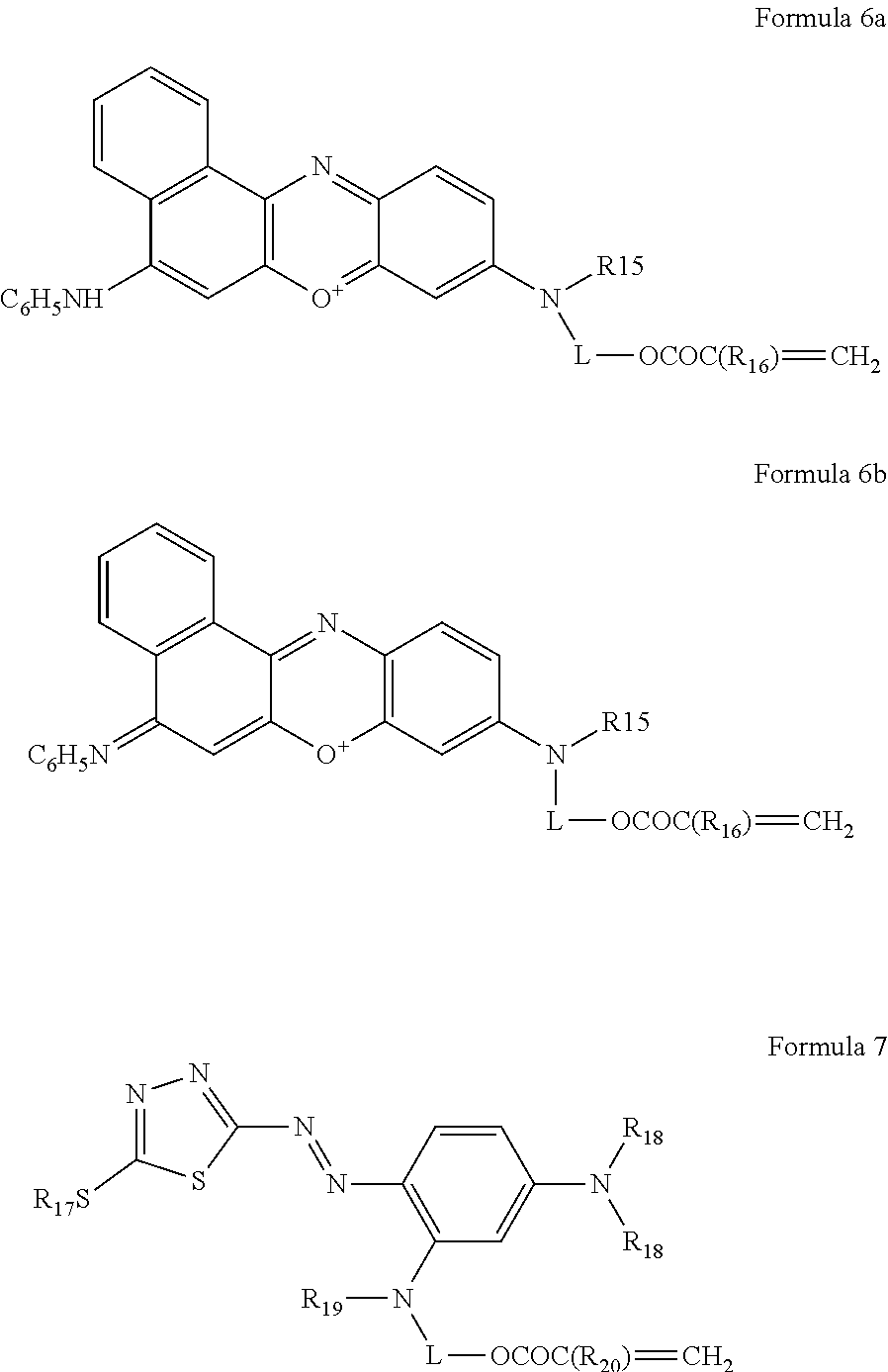

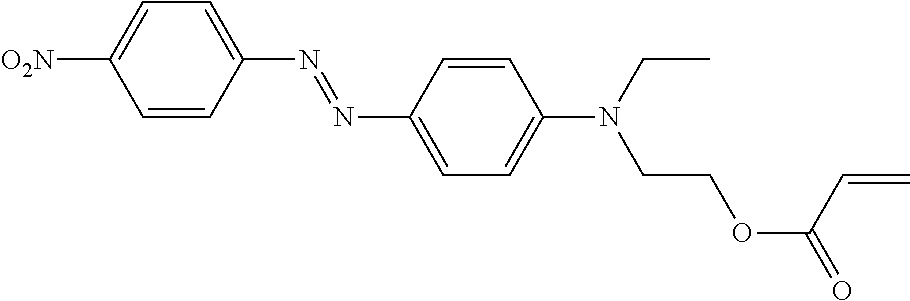

Particles for electrophoretic displays

ActiveUS10435566B2Good monodispersityPromote sportsOrganic chemistryReactive dyesCharge retentionElectrophoresis

This invention relates to polymer particles preferably with surface functionality for charge retention, a process for their preparation, the use of these particles for the preparation of an electrophoretic device, electrophoretic displays comprising such particle, and new polymerizable dyes.

Owner:E INK CORPORATION

Process for recycling waste mortar during solar silicon wafer slicing

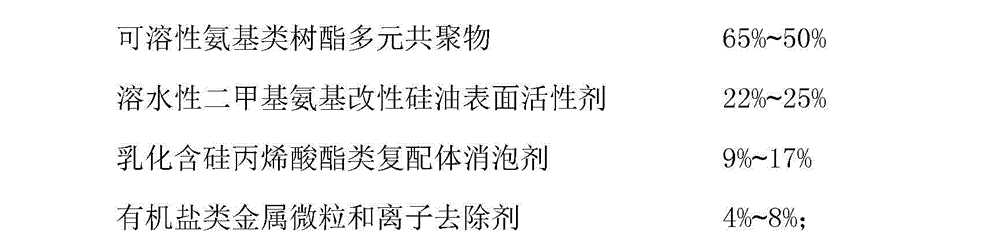

InactiveCN102229849AEasy particle size controlReduce brokenNon-ionic surface-active compoundsOrganic detergent compounding agentsSurface modificationPolyethylene glycol

The invention relates to a process for recycling waste mortar during solar silicon wafer slicing, comprising the following steps of: carrying solid-liquid separation, weighing and adding sand obtained by the solid-liquid separation into a mixed solution of polyethylene glycol containing 2-6% cleaning fluid, stirring for 60-180 minutes according to a program at different mixing speeds, carrying out solid-liquid separation on the mortar, preparing a new cleaning fluid by the separated liquid, adding the separated sand into the mixed solution of polyethylene glycol containing 5-20% surface modifier, fully stirring for 1-2 hours, standing for 6-8 hours in a special storage tank to be subjected to surface modification treatment, packaging with special wet sand packaging bags, and sealing; and carrying out mortar slicing on the separated sand in the packaging bag according to the technological requirement. By adopting the process provided by the invention, the conventional sand washing process is changed, no sewage is discharged, and a green and cyclic regeneration production ideal is met; and the particle size of the recycled separated sand is easy to control, no drying is required, less broken sands are produced in a sorting process, the yield is high, and the application cost is low.

Owner:蒙特集团(香港)有限公司

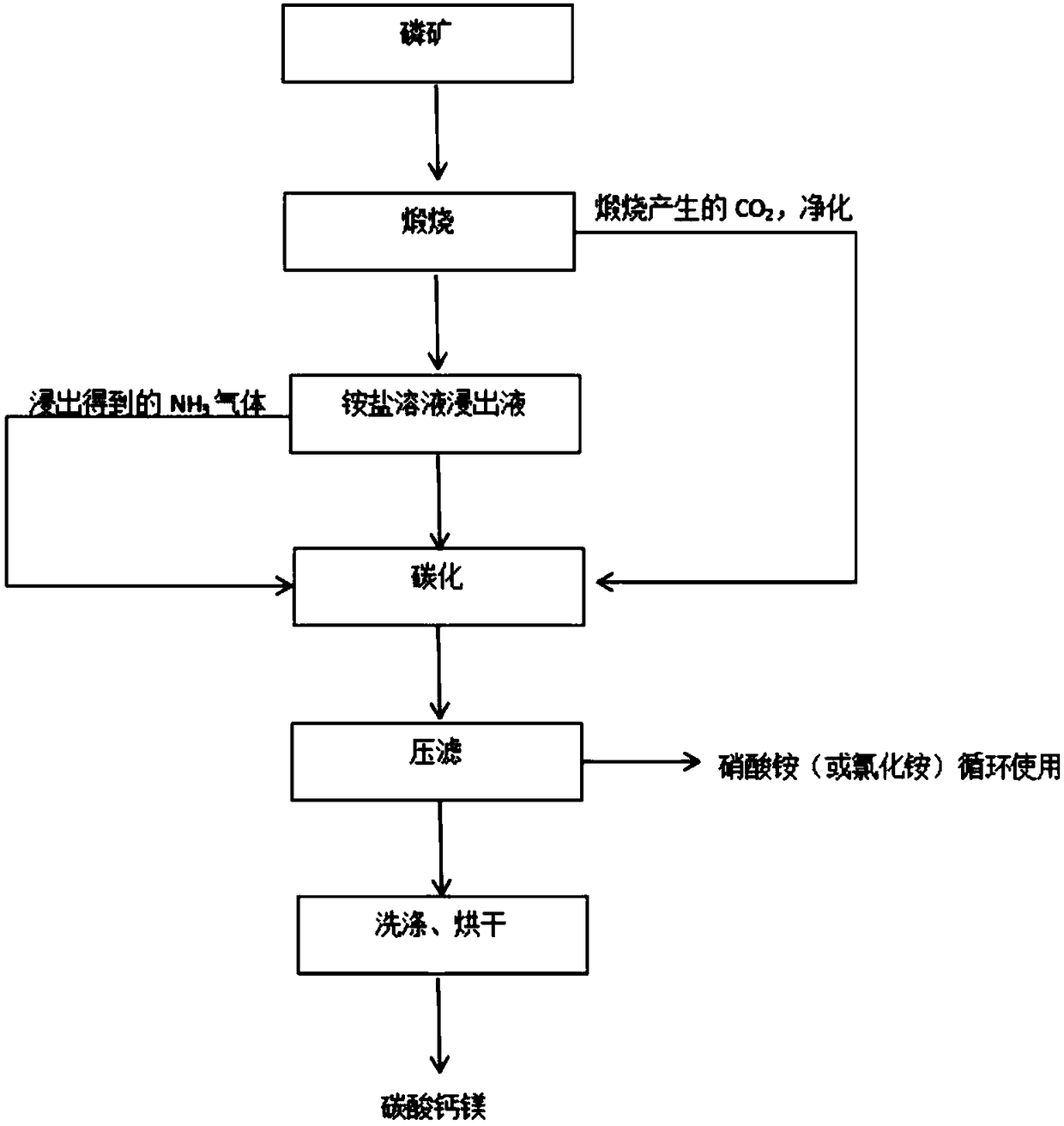

Method for directly carbonizing calcinated mid and low grade phosphate ore ammonium salt lixivium to prepare calcium magnesium carbonate

InactiveCN108358230ANo lossEasy particle size controlCalcium/strontium/barium carbonatesMagnesium carbonatesAmmonium nitrateMoisture

The invention relates to the technical field of inorganic chemical engineering, in particular to a method for directly carbonizing calcinated mid and low grade phosphate ore ammonium salt lixivium toprepare calcium magnesium carbonate. The method utilizes CO2 gas obtained through calcination of phosphate ores, NH3 gas produced in the extracting process of a phosphate ore pyrolysis product to jointly react with the calcinated mid and low grade phosphate ore ammonium salt lixivium, calcium and magnesium in the calcinated mid and low grade phosphate ore ammonium salt lixivium can form calcium magnesium carbonate sediment. The method only uses ammonium nitrate or ammonium chloride solutions to achieve circulation, no loss of ammonium nitrate is caused, and meanwhile, the situation that moisture is newly introduced into a circulation system is avoided; granularity control in the synthesis process of calcium magnesium carbonate is facilitated, and the production capability of filter pressing and washing is improved; the NH3 gas used in the method comes from the reaction of the pyrolysis product and the ammonium nitrate or ammonium chloride solution, CO2 comes from calcinations of the phosphate ores, and the pyrolysis product is obtained, the waste gas needing to be emitted in the original production process is recycled, not only is emission of the waste gas reduced, but also the cost of the raw materials is reduced.

Owner:贵州盛源新材料股份有限公司 +1

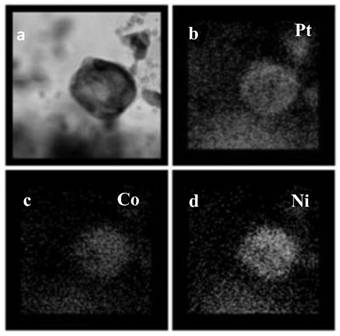

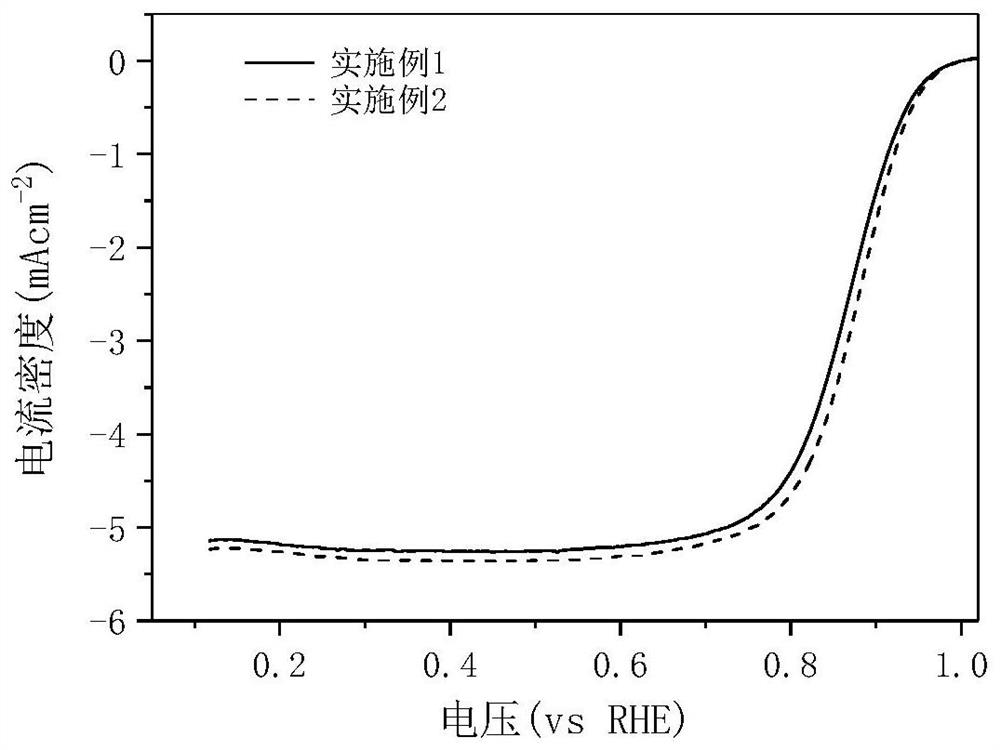

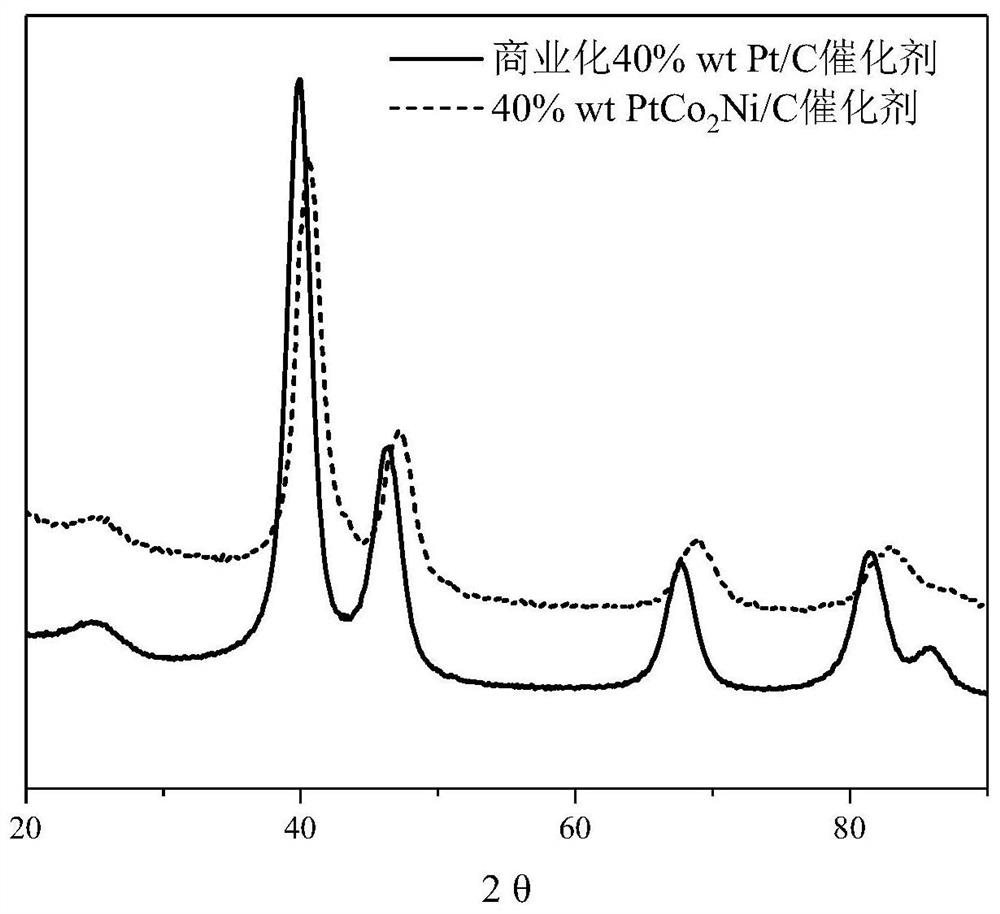

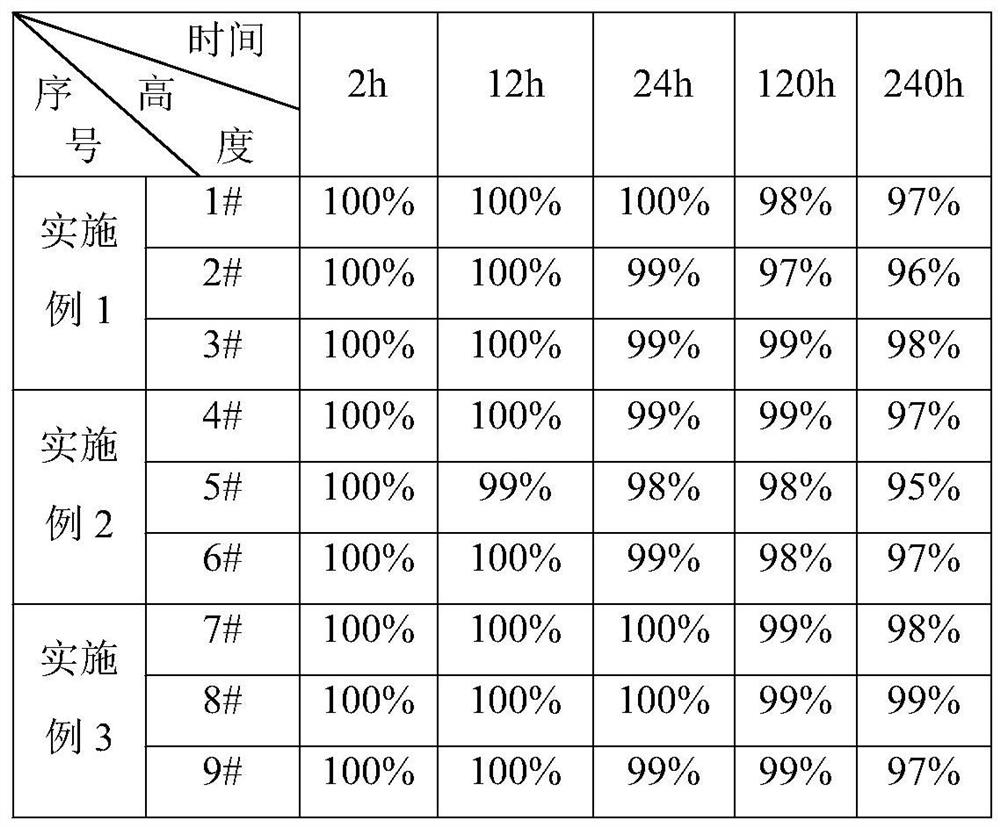

Preparation method of Pt-based multi-component alloy nano electrocatalyst

PendingCN111744473AEasy particle size controlAvoid growing up fastMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlloy catalyst

The invention relates to a preparation method of a Pt-based multi-component alloy nano electrocatalyst, which comprises the following steps: weighing a platinum-containing compound, an X metal salt and a Y metal salt according to the target composition, and dissolving in deionized water to form a solution in which metal ions are dissolved, with X and Y being base metals; adding a proper amount ofweakly alkaline substances into the solution, with the alkalinity of the weakly alkaline substances being smaller than that of ammonia water; adding a carrier or a sacrificial template into the solution, and uniformly dispersing; reacting the solution at a proper temperature for a period of time to form Pt-XY hydroxide, and loading the Pt-XY hydroxide on the carrier or the sacrificial template; and carrying out heat treatment on the Pt-XY hydroxide in a reducing atmosphere to form the Pt-XY alloy catalyst supported on the carrier or the sacrificial template. The dispersity and the performanceof the metal particles are improved.

Owner:宁波中科科创新能源科技有限公司

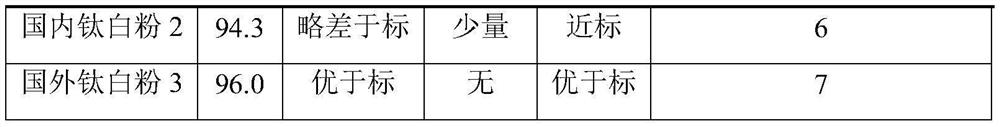

Preparation method of titanium dioxide slurry with high water dispersibility

PendingCN113789067AIsolated migrationReduce photochemical activityCoatings with pigmentsCoatingsPhosphateDioxide titanium

The invention discloses a preparation method of titanium dioxide slurry with high water dispersibility, and belongs to the field of titanium dioxide production. The preparation method of the high-water-dispersibility titanium dioxide slurry comprises the following steps of: a, sieving sanded slurry; b, adding a dispersing agent, stirring and dispersing; c, heating, adding a silicate solution, and adding an aluminum salt solution in a parallel flow manner; d, cooling, and adding a dilute acid solution, a phosphate solution and an aluminum salt solution; and e, adding an aluminum salt solution to adjust the pH value to obtain titanium dioxide slurry with high water dispersibility. The water dispersibility and fluidity of the titanium dioxide slurry can be obviously improved. The preparation method is simple, and the production cost is low. The prepared titanium dioxide slurry can be directly used for a papermaking system in the form of titanium dioxide slurry. The problem that existing titanium dioxide slurry is low in water dispersibility can be effectively solved.

Owner:攀钢集团重庆钒钛科技有限公司

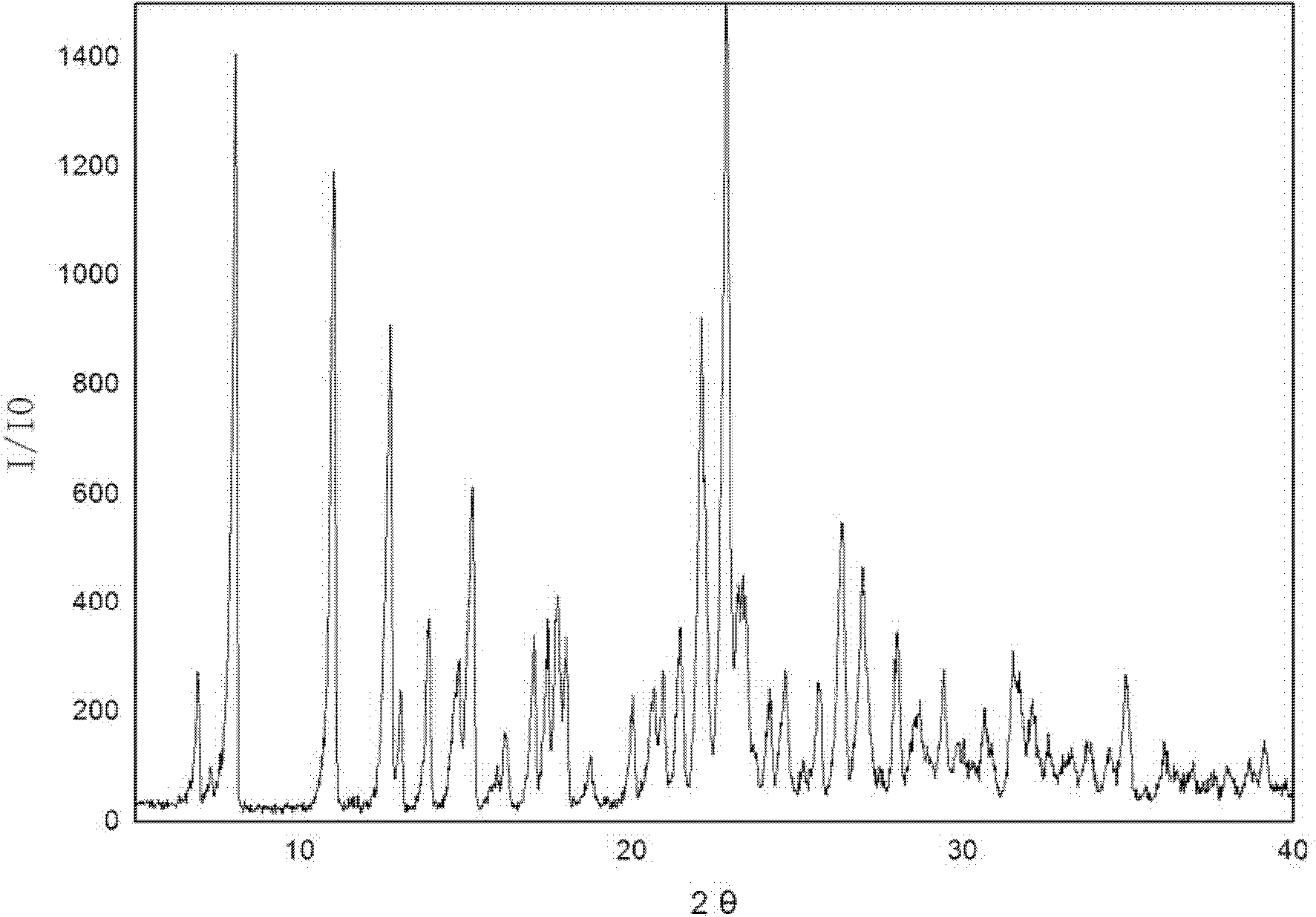

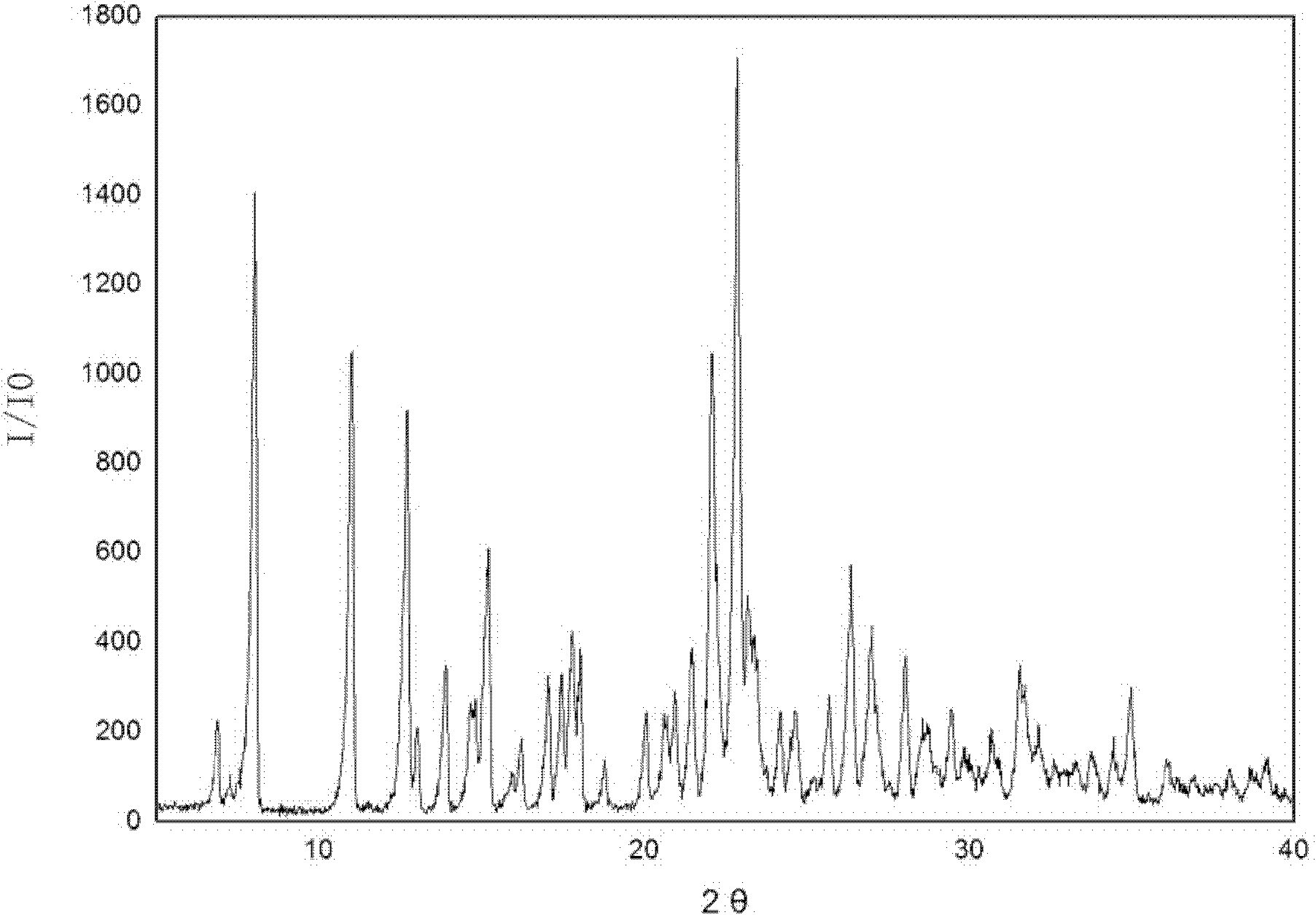

Irbesartan hydrobromide and preparation method thereof

InactiveCN101781287AConcentrated particle size distributionSmooth surfaceOrganic chemistryMetabolism disorderSolventChemistry

The invention relates to irbesartan hydrobromide and a preparation method thereof; irbesartan and solvent are mixed to prepare into solution or suspension liquid, and the mass ratio of the solvent volume and the irbesartan is 1-10mL / g; and then the solution or suspension liquid is mixed with hydrobromic acid solution, and the mass ratio of the hydrobromic acid in the hydrobromic acid solution andthe irbesartan is 1:2.6-5.3; the mixture is stirred continuously, after the solution is settled, elution agent is dropwise added, the volume ratio of the elution agent and the solvent is 1-10:1, seedcrystal is added or crystal growing is carried out after crystal generation is carried out spontaneously, after the elution agent is dropwise added, crystal mush is washed and dried to obtain the irbesartan hydrobromide after solid-liquid separation is carried out. The irbesartan hydrobromide obtained in the invention has adjustable granularity, concentrated granularity distribution, bright and clean surface, good product mobility, high crystallinity and low static electricity property, and is beneficial to industrial operation; in addition, the product has stable performance, is hard to be decomposed and is convenient for storage and transportation and usage.

Owner:TIANJIN UNIV

Cohesive target type water fluid jet grind

InactiveCN101367061BReduce consumptionImprove energy utilizationGrain treatmentsWet separationWater flowPipe

The invention relates to a solid material crushing device, in particular to a cohesion target type water-jet mill which is characterized by comprising a material grading part, a material crushing part and a stand, wherein the material grading part comprises a central feed pipe, an overflow suspension assorting cylinder, an overflow groove, an annular water uniform distributor, and a water shock conical vibration sieve; the upper part of the overflow suspension assorting cylinder is welded with the overflow groove which is provided with a discharge hole; the lower end of the overflow suspension assorting cylinder is connected with the upper end of a cylinder body of a crushing part of the material crushing part through a flange; a feed hole of the central feed pipe is higher than the discharge hole of the overflow groove; the material crushing part comprises a material guide cone, the cylinder body of the crushing part, an annular nozzle holder, a nozzle, a cohesion target body, a conical water injector, a grading hopper and a separating grate sieve; and the cylinder body of the crushing part is fixedly connected with the stand. The cohesion target type water-jet mill has the characteristics of high utilization rate of energy and good effects of cleavage and crushing.

Owner:WUHAN UNIV OF TECH

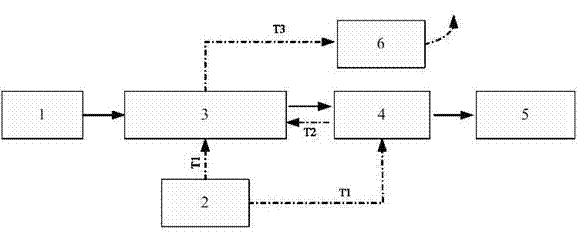

Methods of preparing positive electrode active material precursor for lithium secondary battery and positive electrode active material

ActiveUS10892471B2Granularity controllableDecrease productivityElectrode thermal treatmentSecondary cellsPhysical chemistryBattery cell

A method of preparing a positive electrode active material precursor for a lithium secondary battery by using a batch-type reactor, which includes the steps of 1) forming positive electrode active material precursor particles while continuously adding a transition metal-containing solution including a transition metal cation, an aqueous alkaline solution, and an ammonium ion-containing solution to a batch-type reactor, 2) sedimenting the positive electrode active material precursor particles formed; 3) discharging a supernatant formed after the sedimentation of the positive electrode active material precursor particles to an outside; 4) adjusting a pH to 10 to 12 by adding the ammonium ion-containing solution; and 5) growing the positive electrode active material precursor particles while continuously again adding the transition metal-containing solution to the batch-type reactor, and a method of preparing a positive electrode active material using the same.

Owner:LG CHEM LTD

Process for recycling waste mortar during solar silicon wafer slicing

InactiveCN102229849BEasy particle size controlReduce breakageNon-ionic surface-active compoundsOrganic detergent compounding agentsPolyethylene glycolEngineering

The invention relates to a process for recycling waste mortar during solar silicon wafer slicing, comprising the following steps of: carrying solid-liquid separation, weighing and adding sand obtained by the solid-liquid separation into a mixed solution of polyethylene glycol containing 2-6% cleaning fluid, stirring for 60-180 minutes according to a program at different mixing speeds, carrying out solid-liquid separation on the mortar, preparing a new cleaning fluid by the separated liquid, adding the separated sand into the mixed solution of polyethylene glycol containing 5-20% surface modifier, fully stirring for 1-2 hours, standing for 6-8 hours in a special storage tank to be subjected to surface modification treatment, packaging with special wet sand packaging bags, and sealing; and carrying out mortar slicing on the separated sand in the packaging bag according to the technological requirement. By adopting the process provided by the invention, the conventional sand washing process is changed, no sewage is discharged, and a green and cyclic regeneration production ideal is met; and the particle size of the recycled separated sand is easy to control, no drying is required, less broken sands are produced in a sorting process, the yield is high, and the application cost is low.

Owner:蒙特集团(香港)有限公司

Preparation method of spherical magnesium diethoxylate

ActiveCN112299984AParticle size controllableUniform particle sizeOrganic compound preparationCarboxylic acid salt preparationAlcoholActive agent

The invention provides a method for preparing magnesium diethoxylate, which comprises the following steps of: by using metal spherical magnesium powder and absolute ethyl alcohol as raw materials, adding elemental iodine and a cosolvent to prepare spherical magnesium diethoxylate. The particle size of the obtained spherical magnesium diethoxylate ranges from 1 micron to 200 microns, and the span of particle size distribution is smaller than 3. The cosolvent is added into the reaction system, the particle size of the obtained magnesium diethoxylate can even reach 5 [mu] m to 15 [mu] m, and compared with a traditional method of adding a surfactant, silicone oil or span and the like, the method has the advantages that the cosolvent is easier to remove, impurity residues are avoided, and post-treatment is more convenient. The method has the advantages of low reaction temperature, stable reaction, short reaction time and no discharge of environment-unfriendly substances, and is suitable forlarge-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of particle size sorting method of epoxy molding compound powder

The invention discloses a granularity sorting method for an epoxy molding compound powder material. The method comprises the following steps of: smashing the material through a first-stage hammer type smashing machine, sorting the smashed material in a double-layer sorting sieve, and pouring the fine powder material into a collector from a material outlet at the lower layer through a screen of the double-layer sorting sieve; and screening out rough powder material through the double-layer sorting sieve, smashing the rough powder material again in a two-stage hammer type smashing machine, and directly putting the smashed powder material into the collector. The smashing method is rational and high in operability; the material is smashed twice; moreover, a smashing machine screen and a sorting sieve screen which have different mesh size are adopted, so that powder materials in different granularity distribution ranges can be obtained; the granularity of the powder material is well controlled; the production efficiency is high; the material during production is high in powder flowability, so that a bridge is difficultly formed in a system; large particles and dust can be reduced; and the field working environment is improved.

Owner:江苏旭远新材料有限公司

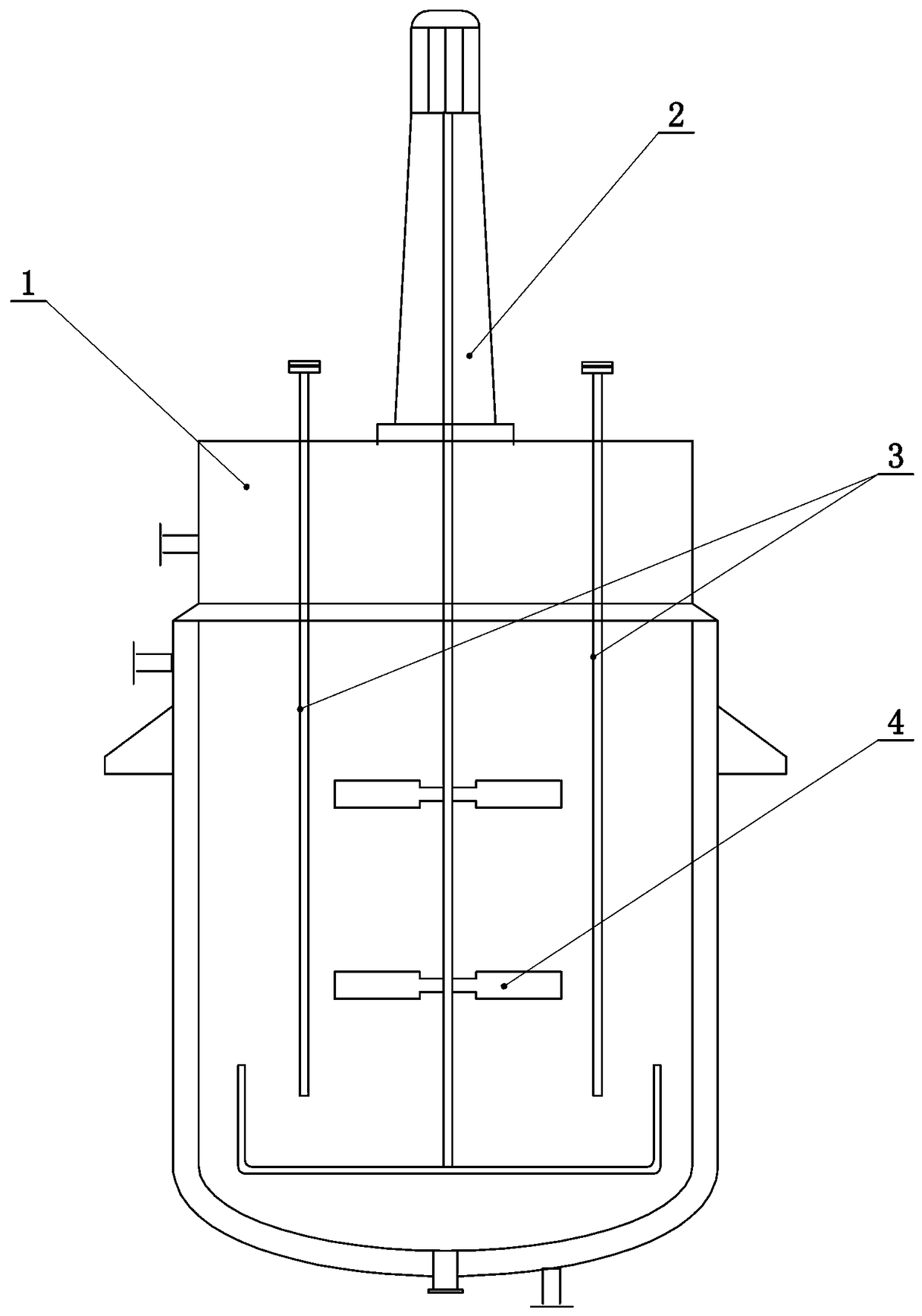

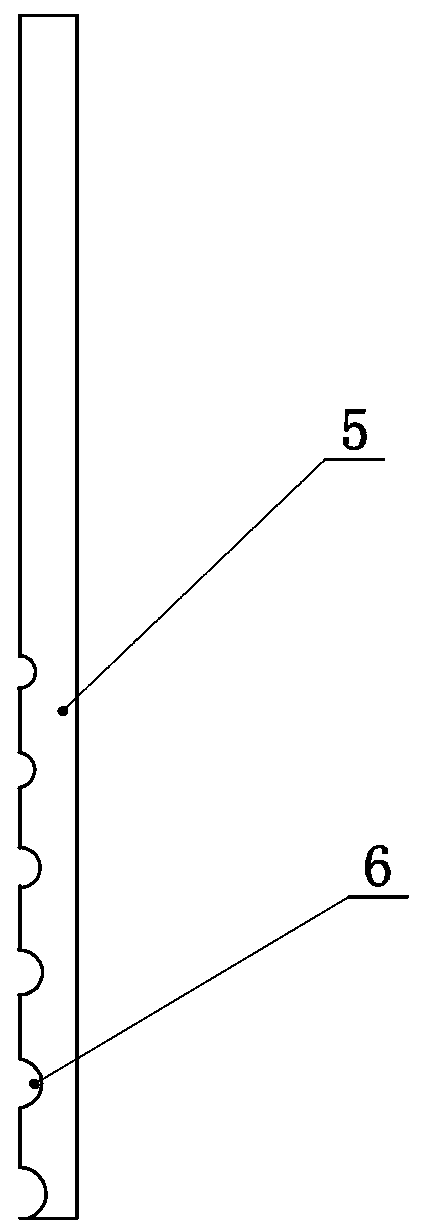

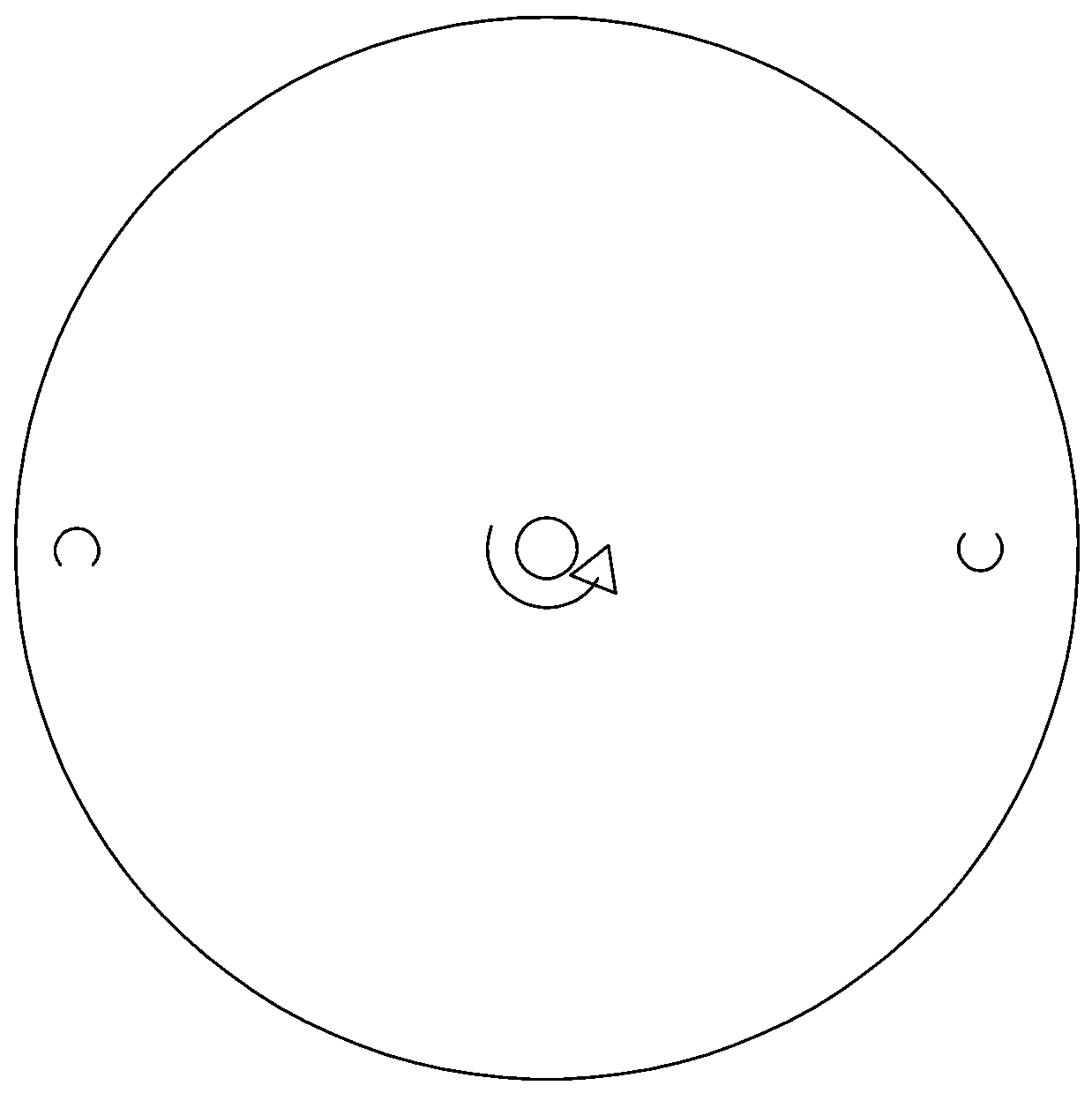

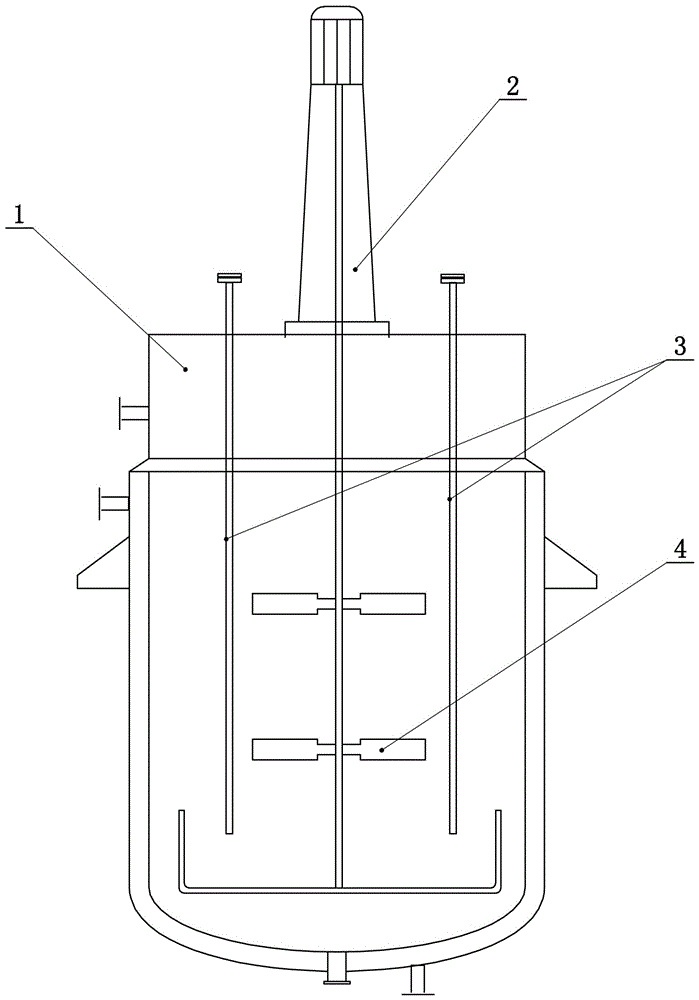

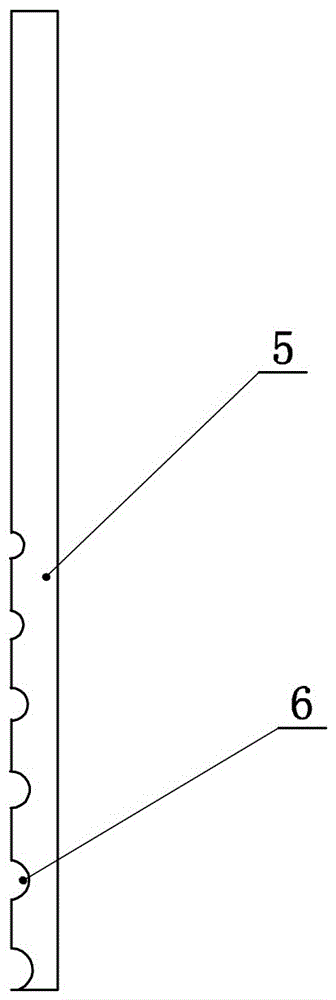

Co-precipitation reactor

ActiveCN106140065BWell mixedDisperse fastChemical/physical/physico-chemical stationary reactorsFeed devicesCoprecipitationEngineering

The invention relates to a co-precipitation reaction kettle. The co-precipitation reaction kettle comprises a kettle body, wherein the kettle body is provided with a stirring apparatus with stirring blades and a feeding apparatus, the feeding apparatus comprises a feeding pipe, and the bottom end of the feeding pipe is disposed on the bottom of the kettle body. In the structure, material inlets are formed in the side wall of the feeding pipe. In the structure, the length of the feeding pipe is 1.8 m. In the structure, 4 to 7 material inlets are provided. In the structure, the number of the material inlets is six. In the structure, the material inlets are successively enlarged from the upper part to the lower part. In the structure, a distance between two material inlets is 50mm.

Owner:宋程

Co-precipitation reaction kettle

ActiveCN106140065AWell mixedDisperse fastChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringPrecipitation

The invention relates to a co-precipitation reaction kettle. The co-precipitation reaction kettle comprises a kettle body, wherein the kettle body is provided with a stirring apparatus with stirring blades and a feeding apparatus, the feeding apparatus comprises a feeding pipe, and the bottom end of the feeding pipe is disposed on the bottom of the kettle body. In the structure, material inlets are formed in the side wall of the feeding pipe. In the structure, the length of the feeding pipe is 1.8 m. In the structure, 4 to 7 material inlets are provided. In the structure, the number of the material inlets is six. In the structure, the material inlets are successively enlarged from the upper part to the lower part. In the structure, a distance between two material inlets is 50mm.

Owner:宋程

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com