Novel nickel/sodium alginate inorganic/organic hybrid material and preparation method and application thereof

A technology of sodium alginate and organic hybridization, applied in the direction of organic chemistry, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the complex preparation process, catalyst dispersion, activity and stability There are still problems to be improved to achieve the effect of simple preparation process, inhibition of agglomeration and loss, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

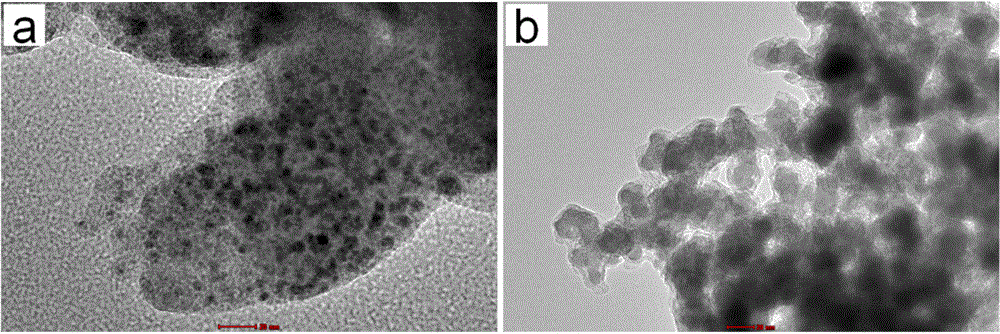

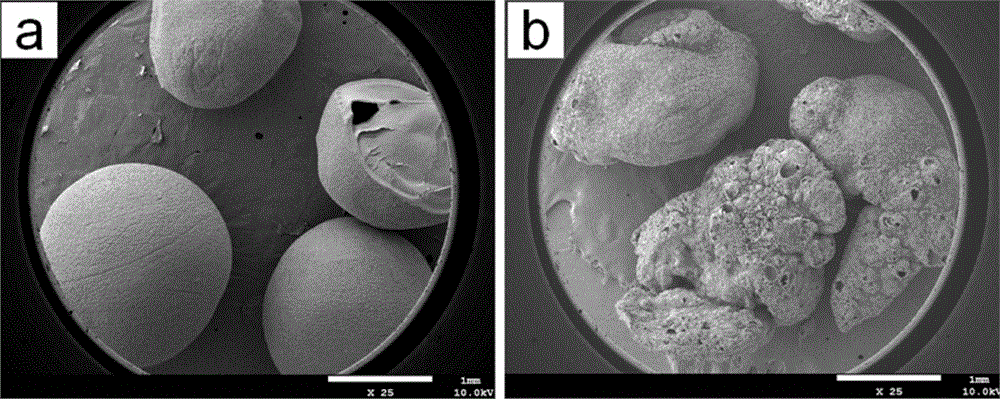

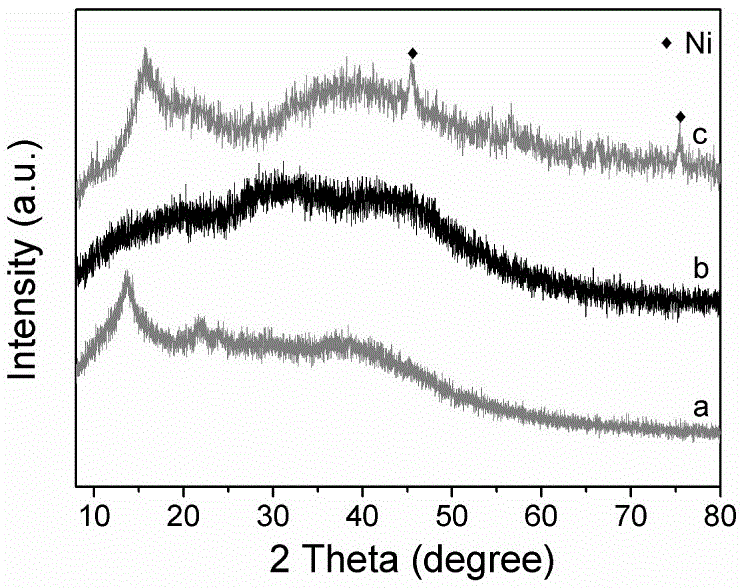

[0035] Prepare the material as follows:

[0036] a. At room temperature, add 2g of sodium alginate powder into 98mL of deionized water to prepare a 2wt% sodium alginate solution, and keep stirring for 12 hours to ensure that the sodium alginate is fully dissolved;

[0037] b. At room temperature, weigh 2.37g NiCl 2 ·6H 2 O in 50mL water, prepare 0.2M NiCl 2 Aqueous solution, dissolved evenly for later use;

[0038] c. Use a syringe to add the sodium alginate aqueous solution drop by drop to NiCl with magnetic stirring 2 In the aqueous solution, cross-link and solidify at room temperature for 12 hours, then perform solvent exchange with 25%, 50% and 100% ethanol solutions in sequence, each exchange time is 6 hours, and finally store the gel balls in ethanol for later use;

[0039] d. Prepare a sodium borohydride solution with a solvent of ethanol and a concentration of 0.26M. Take 40mL of the solution, place the above-mentioned gel balls in the solution for reduction, the r...

Embodiment 2

[0048] Example 2: Preparation and application of nickel / sodium alginate hybrid material.

[0049] The preparation process of the nickel / sodium alginate hybrid material includes steps a, b, c, and d. Wherein, steps a, c and d are correspondingly the same as a, c and d in embodiment 1, the difference is that NiCl 2 The concentration of the aqueous solution is 0.1M, NiCl 2 ·6H 2 O dosage is 1.18g.

[0050] Applications of nickel / sodium alginate hybrid materials are as follows:

[0051] The hydrogenation reaction of styrene was carried out in a 100mL Parr 4598HPHT stainless steel autoclave with a stirring and heating system. The specific experimental process was as follows: 40mL of ethanol, 0.36g of catalyst, and 42mmol of styrene were sequentially added to the stainless steel autoclave, and the autoclave Seal and check the airtightness, and fill with hydrogen for 3 times to replace the air in the kettle. Reaction conditions: pressure 2MPa, temperature 100°C, rotation speed 3...

Embodiment 3

[0052] Example 3: Preparation and application of nickel / sodium alginate hybrid material.

[0053] The preparation process of the nickel / sodium alginate hybrid material includes steps a, b, c, and d. Wherein, steps a, c and d are correspondingly the same as a, c and d in embodiment 1, the difference is that NiCl 2 The concentration of the aqueous solution is 0.3M, NiCl 2 ·6H 2 O dosage is 3.56g.

[0054] Applications of nickel / sodium alginate hybrid materials are as follows:

[0055] The hydrogenation reaction of styrene was carried out in a 100mL Parr 4598HPHT stainless steel autoclave with a stirring and heating system. The specific experimental process was as follows: 40mL of ethanol, 0.36g of catalyst, and 42mmol of styrene were sequentially added to the stainless steel autoclave, and the autoclave Seal and check the airtightness, and fill with hydrogen for 3 times to replace the air in the kettle. Reaction conditions: pressure 2MPa, temperature 100°C, rotation speed 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com