Granularity sorting method for epoxy molding compound powder material

A powder and sorting technology, used in grain processing and other directions, can solve the problems of difficulty in controlling density and weight, heavy environmental pollution at the production site, and large particle size distribution and dispersion, and reduce the generation of large particles and dust. Reasonable and good powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

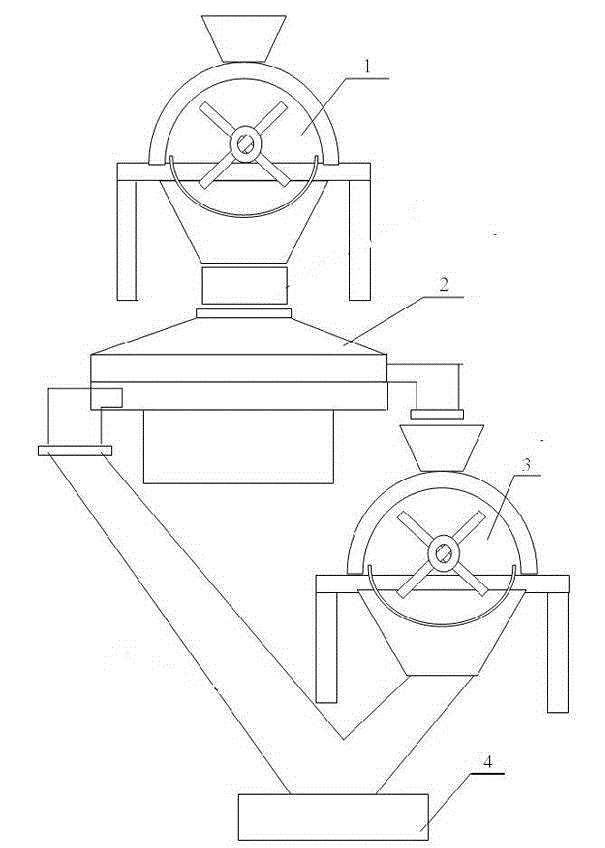

[0017] Embodiment 1, a method for particle size separation of epoxy molding compound powder, the steps are as follows:

[0018] First put the material into the first-stage hammer mill 1 for crushing. The screen aperture of the first-stage hammer mill 1 is 3.5-6 mm, and the speed is 1200-2600 rpm; the crushed material enters the double The mesh size of the double-layer sorting sieve is 8-16 mesh, and the included angle of the vibrating hammer in the double-layer sorting sieve is 30-75°; the fine-grained powder passes through the double-layer sorting The sieved screen enters the collector from the outlet of the lower layer;

[0019] Coarse particle powder is screened out by double-layer sorting, and enters the second-stage hammer mill for re-grinding. The sieve diameter of the second-stage hammer mill is 2-3 mm, and the speed is 1200-2600 rpm. The crushed powder directly enters the collector.

Embodiment 2

[0020] Embodiment 2, a method for particle size separation of epoxy molding compound powder, the steps are as follows:

[0021] First put the material into the first-stage hammer mill 1 for crushing. The screen aperture of the first-stage hammer mill 1 is 3.5 mm, and the speed is 2000 rpm; the crushed material enters the double-layer sorting Sieve 2 is sorted, and the screen mesh number of double-layer sorting sieve 2 is 15 orders, and the included angle of the vibrating hammer in double-layer sorting sieve 2 is 40 °; The screen enters the collector from the outlet of the lower layer;

[0022] Coarse particle powder is selected by double-layer sorting sieve 2, enters in secondary hammer mill 3 and pulverizes again, and the sieve aperture of secondary hammer mill 3 is 2mm, and the rotating speed is 2000 rpm, The pulverized powder directly enters the collector 4.

Embodiment 3

[0023] Embodiment 3, a method for particle size separation of epoxy molding compound powder, the steps are as follows:

[0024] First put the material into the first-stage hammer mill 1 for crushing. The screen aperture of the first-stage hammer mill 1 is 5 mm, and the speed is 2200 rpm; the crushed material enters the double-layer sorting screen 2 for sorting, the mesh number of the double-layer sorting sieve 2 is 10 orders, and the included angle of the vibrating hammer in the double-layer sorting sieve 2 is 50°; The net enters into the collector 4 from its lower floor outlet;

[0025] The coarse particle powder is selected by the double-layer sorting sieve 2, and enters the secondary hammer mill 3 for further pulverization. The screen aperture of the secondary hammer mill 3 is 3 mm, and the rotating speed is 2200 rpm. The pulverized powder directly enters the collector 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com