Preparation method of Pt-based multi-component alloy nano electrocatalyst

A technology of alloy nanometers and electrocatalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of affecting the long-term working stability of fuel cells and cumbersome operation steps , metal particle coalescence and other problems, to achieve the effect of being suitable for large-scale production, simple method and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

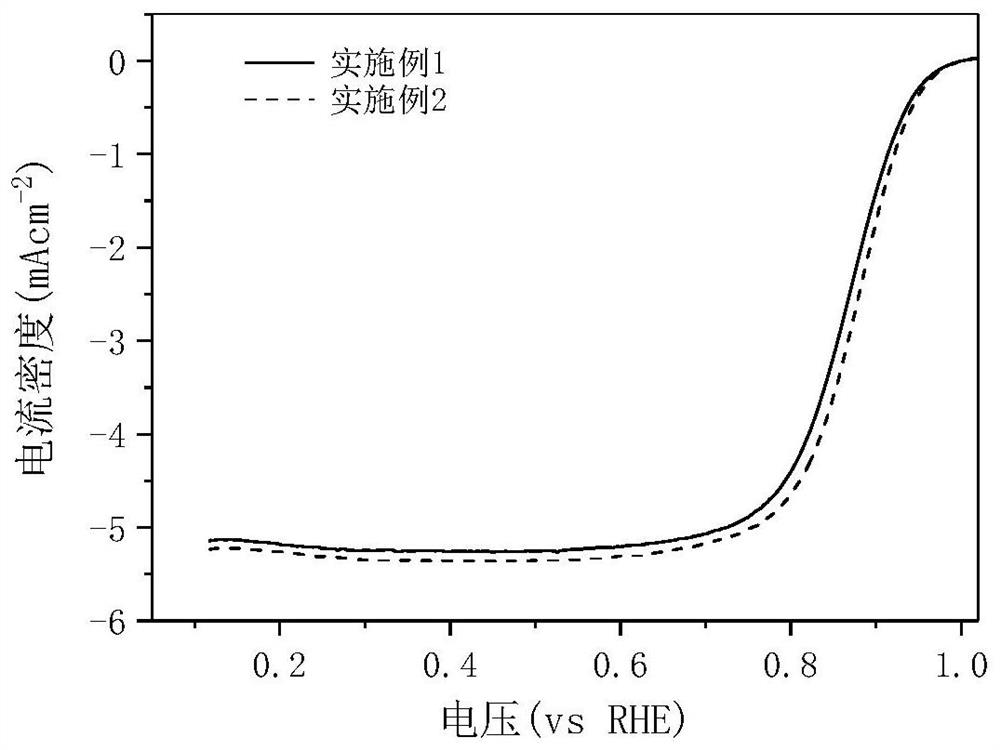

Embodiment 1

[0037] Example 1: 20% wt Pt 2 Preparation of RuCo / C (Pt:Ru:Co=2:1:1) Nano Electrocatalyst

[0038] (1) Raw material mixing: Pt:Ru:Co=2:1:1 by molar ratio, weigh and dissolve sodium chloroplatinate, ruthenium chloride and cobalt chloride in deionized water, stir until completely dissolved; Add an appropriate amount of potassium bicarbonate to the solution with metal ions to adjust the pH of the solution to 7;

[0039] (2) Carbon carrier injection: add a certain amount of carbon black to the solution so that the target metal loading is 20%, and continue stirring to disperse it evenly.

[0040] (3)Pt 2 Preparation of RuCo hydroxide: adjust the temperature of the reaction system to 60°C for 2h, filter and wash, then dry at 60°C for 4h.

[0041] (4) Catalyst heat treatment: Heat the dried product at 200°C under hydrogen for 2 hours and then pass it into N 2 After cooling for 30 minutes, take it out to obtain 20%wt Pt2RuCo / C nanometer electrocatalyst.

Embodiment 2

[0042] Example 2: 20% wt Pt 2 Preparation of RuCo / C (Pt:Ru:Co=2:1:1) Nano Electrocatalyst

[0043] (1) Raw material mixing: Pt:Ru:Co=2:1:1 by molar ratio, weigh and dissolve sodium chloroplatinate, ruthenium chloride and cobalt chloride in deionized water, stir until completely dissolved; Add an appropriate amount of potassium bicarbonate to the solution with metal ions to adjust the pH of the solution to 7;

[0044] (2) Carbon carrier injection: add a certain amount of carbon black to the solution so that the target metal loading is 20%, and continue stirring to disperse it evenly.

[0045] (3)Pt 2 Preparation of RuCo hydroxide: adjust the temperature of the reaction system to 60°C for 2h, filter and wash, then dry at 60°C for 4h.

[0046] (4) Catalyst heat treatment: The dried product was subjected to plasma-assisted heat treatment at 100°C under hydrogen for 2 hours, and then N 2 30min, take out after cooling and it will be 20%wt Pt 2 RuCo / C nano electrocatalyst. The...

Embodiment 3

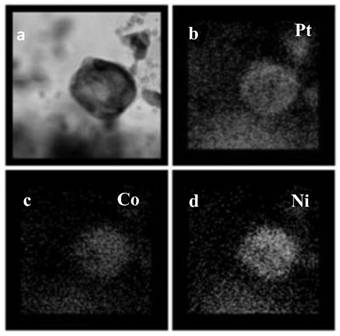

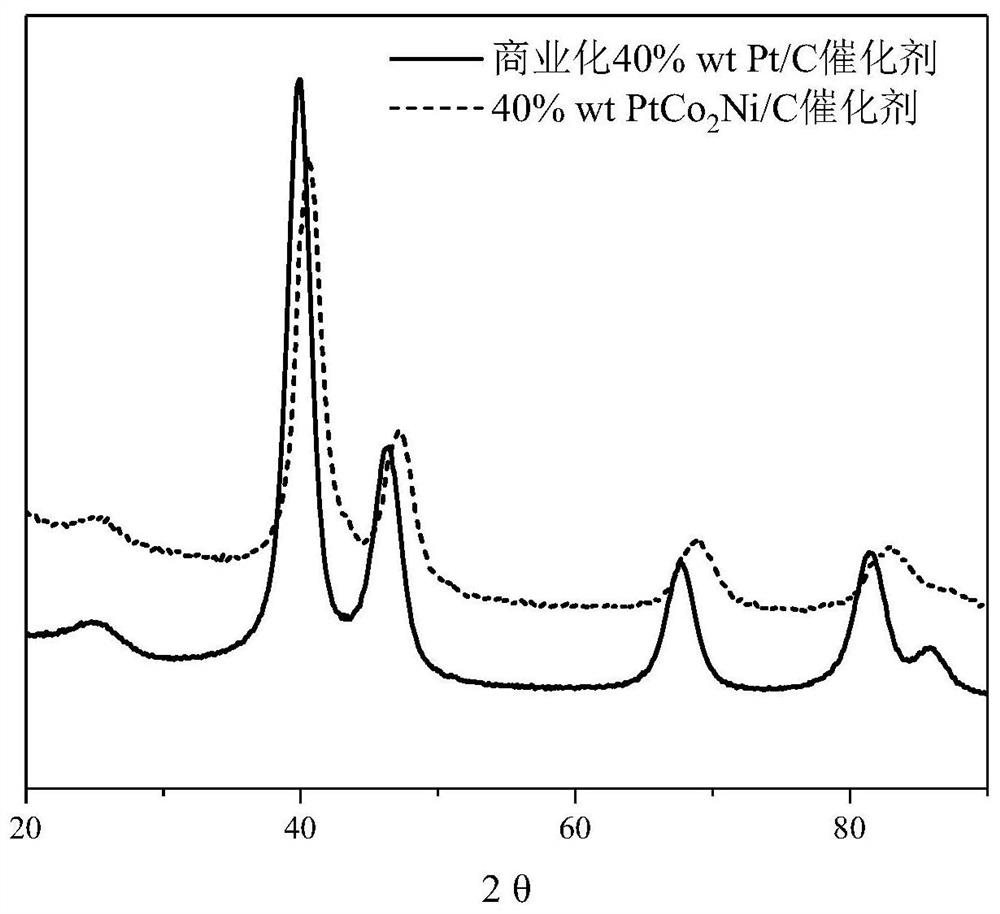

[0049] Example 3: 40% wt PtCo 2 Preparation of Ni / C(Pt:Co:Ni=1:2:1) Nano Electrocatalyst

[0050] (1) Mixing of raw materials: Pt:Pd:Co=1:2:1 ratio is weighed and dissolved in deionized water containing chloroplatinic acid sodium, cobalt chloride and nickel acetate by molar ratio, and stirred until completely dissolved; An appropriate amount of sodium bicarbonate is added to the solution of metal ions to adjust the pH of the solution to 11;

[0051] (2) Injection of carbon carrier: add a certain amount of carbon black to the solution to make the metal loading 40%, and continue to stir to make it uniformly dispersed.

[0052] (3) PtCo 2 Preparation of Ni hydroxide: adjust the temperature of the reaction system to 80°C for 10h, filter and wash, then dry at 60°C for 4h.

[0053] (4) Catalyst heat treatment: After the dried product was subjected to plasma-assisted heat treatment at 200 °C under CO atmosphere for 2 h, N 2 40%wt PtCo after 30min cooling 2 Ni / C nano electrocata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com