Method for directly carbonizing calcinated mid and low grade phosphate ore ammonium salt lixivium to prepare calcium magnesium carbonate

A low-grade technology of calcium and magnesium carbonate, applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, chemical instruments and methods, etc., can solve the problems of high water content, difficulty in recycling, and low concentration of the regenerated ammonium salt solution, and achieve The effect of saving raw material costs, increasing production capacity, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

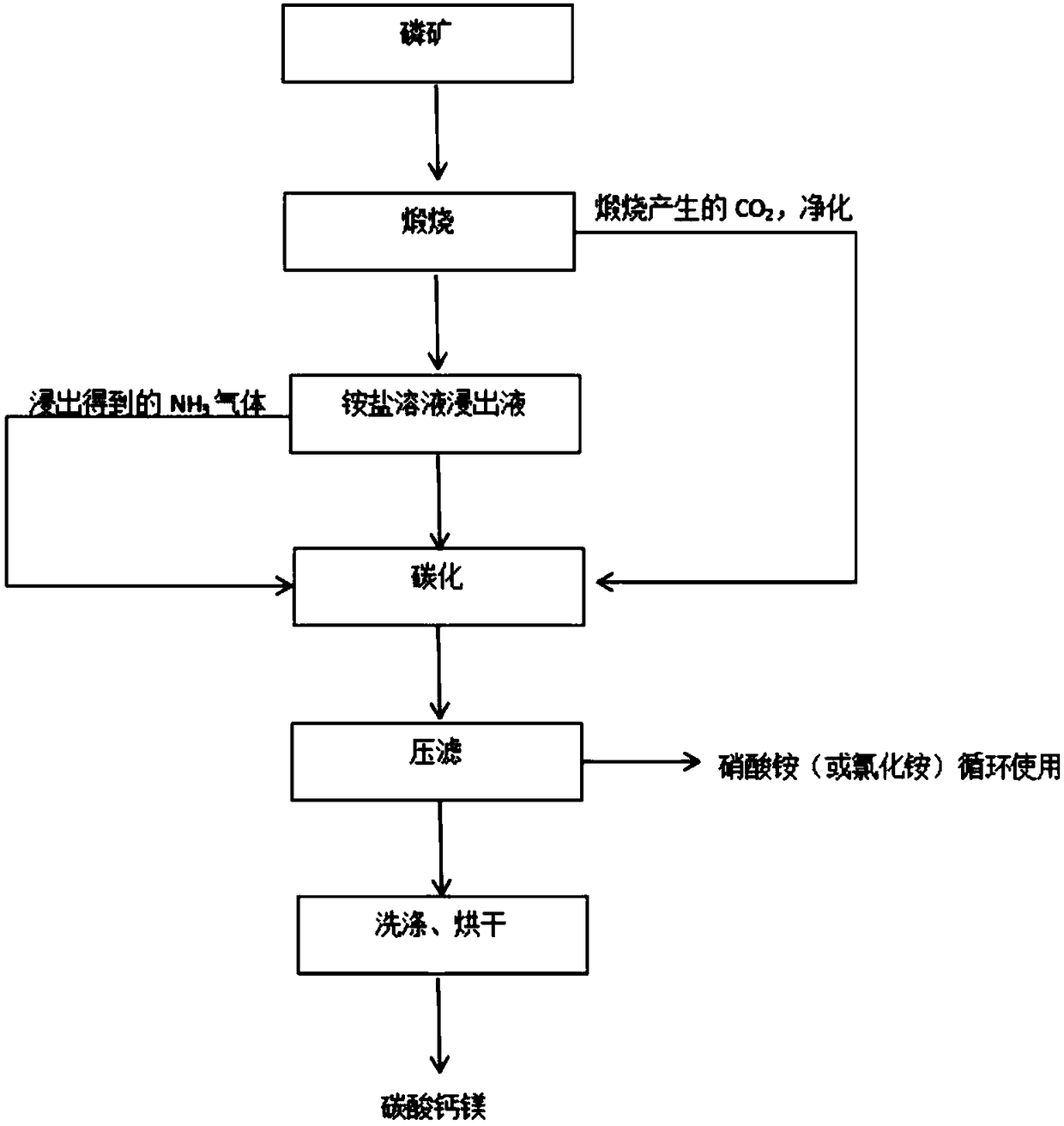

[0024] A method for preparing calcium and magnesium carbonate by direct carbonization of the leaching solution of low-grade phosphate rock ammonium salt in calcined, comprising the steps of:

[0025] (1) Calcining medium and low-grade phosphate rock to obtain pyrolysis products and CO 2 gas;

[0026] (2) Mix and extract the obtained pyrolysis product and ammonium nitrate solution, control the temperature at 45°C, and circulate and absorb the generated NH in the absorption tower 3 Gas, so that the pH value of the leachate is 8.5, to obtain the calcined low-grade phosphate rock ammonium salt leachate containing calcium and magnesium salts and NH 3 gas;

[0027] (3) the low-grade phosphate rock ammonium salt leaching solution obtained by the calcining obtained with the CO obtained by step (1) 2 Gas and the NH obtained in step (2) 3 The gas is passed together into the leaching solution of low-grade phosphate rock ammonium salt for calcining, and the reaction is carried out. Th...

Embodiment 2

[0030] A method for preparing calcium and magnesium carbonate by direct carbonization of the leaching solution of low-grade phosphate rock ammonium salt in calcined, comprising the steps of:

[0031] (1) Calcining medium and low-grade phosphate rock to obtain pyrolysis products and CO 2 gas;

[0032] (2) Mix and extract the obtained pyrolysis product and ammonium nitrate solution, control the temperature at 25°C, and circulate and absorb the generated NH in the absorption tower 3 Gas, so that the pH value of the leachate is 6.5, and the leaching solution of low-grade phosphate rock ammonium salt containing calcium and magnesium salts and NH 3 gas;

[0033] (3) the low-grade phosphate rock ammonium salt leaching solution obtained by the calcining obtained with the CO obtained by step (1) 2 Gas and the NH obtained in step (2) 3 The gas is passed together into the leaching solution of low-grade phosphate rock ammonium salt for calcining, and the reaction is carried out. The r...

Embodiment 3

[0036] A method for preparing calcium and magnesium carbonate by direct carbonization of the leaching solution of low-grade phosphate rock ammonium salt in calcined, comprising the steps of:

[0037] (1) Calcining medium and low-grade phosphate rock to obtain pyrolysis products and CO 2 gas;

[0038] (2) Mix and leaching the obtained pyrolysis product with ammonium nitrate solution, control the temperature at 95°C, and circulate and absorb the generated NH in the absorption tower 3 Gas, so that the pH value of the leachate is 9.5, and the leaching solution of low-grade phosphate rock ammonium salt containing calcium and magnesium salts and NH 3 gas;

[0039] (3) the low-grade phosphate rock ammonium salt leaching solution obtained by the calcining obtained with the CO obtained by step (1) 2 Gas and the NH obtained in step (2) 3The gas is passed together into the leaching solution of low-grade phosphate rock ammonium salt for calcining, and the reaction is carried out. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com