Process for preparing building gypsum powder from phosphogypsum

A technology for building gypsum powder and phosphogypsum, applied in the field of building gypsum powder, can solve the problems of unstable product quality, unsound supporting facilities, need to be optimized, etc. Effects of Thermal Efficiency and Reaction Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

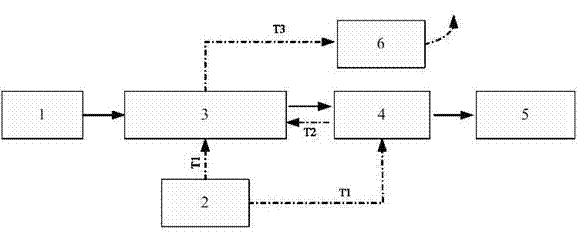

[0028] In order to further explain the technical means adopted by the present invention to achieve the intended purpose of the invention, the process for preparing building gypsum powder from two-step method phosphogypsum according to the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0029] Concrete technical scheme of the present invention is as follows:

[0030] The process system of the present invention operates under negative pressure, and the power comes from the negative pressure difference inside the equipment formed by the induced draft fan. It is composed of feeding device, vertical mill device, suspension dehydration reaction furnace, aging bin and dust collection device, including the following process steps:

[0031] A: Feed of phosphogypsum raw material. The phosphogypsum raw material is quantitatively fed into the feed chute in the C step by a special feeder. According to the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com