Rotary spiral waste organic glass propelling and continuous splitting decomposition method and device

A plexiglass and waste technology, which is applied in the field of waste plexiglass rotary screw propulsion continuous cracking, can solve the problems of easy safety accidents and complex structures, and achieve the effects of reducing pollutant emissions, high safety, and improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

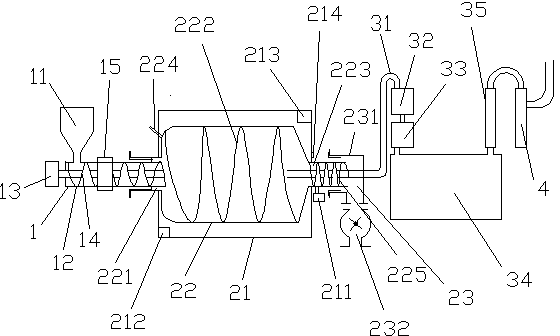

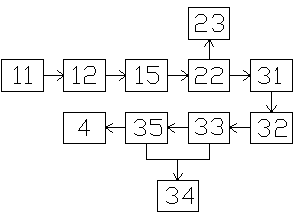

[0030] see figure 1 , this embodiment includes a feed device 1, a cracking device, a condensation device and a waste gas treatment device connected in sequence.

[0031] The feed device 1 in the present embodiment comprises an electric heater 15, a feed funnel 11, a feed pipeline 12, a motor 13 and a screw push rod 14, the screw push rod 14 is movably linked with the feed pipeline 12, and the screw push rod 14 The outer diameter of the screw is slightly smaller than the inner diameter of the feed pipe 12, the motor 13 controls the rotation of the screw push rod 14, and the screw push rod 14 gradually pushes the material particles from the feed funnel 11 end to the cracking device; the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com