Ultra-fine cavitated target type water fluid jet grind

A technology of water jet milling and cavitation, which is applied in the direction of grain processing, etc., can solve the problems of insufficient mixing of material particles and high-speed water jet, low energy efficiency, classification and particle size control, etc., to achieve improved efficiency and high energy utilization , to facilitate the effect of particle size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

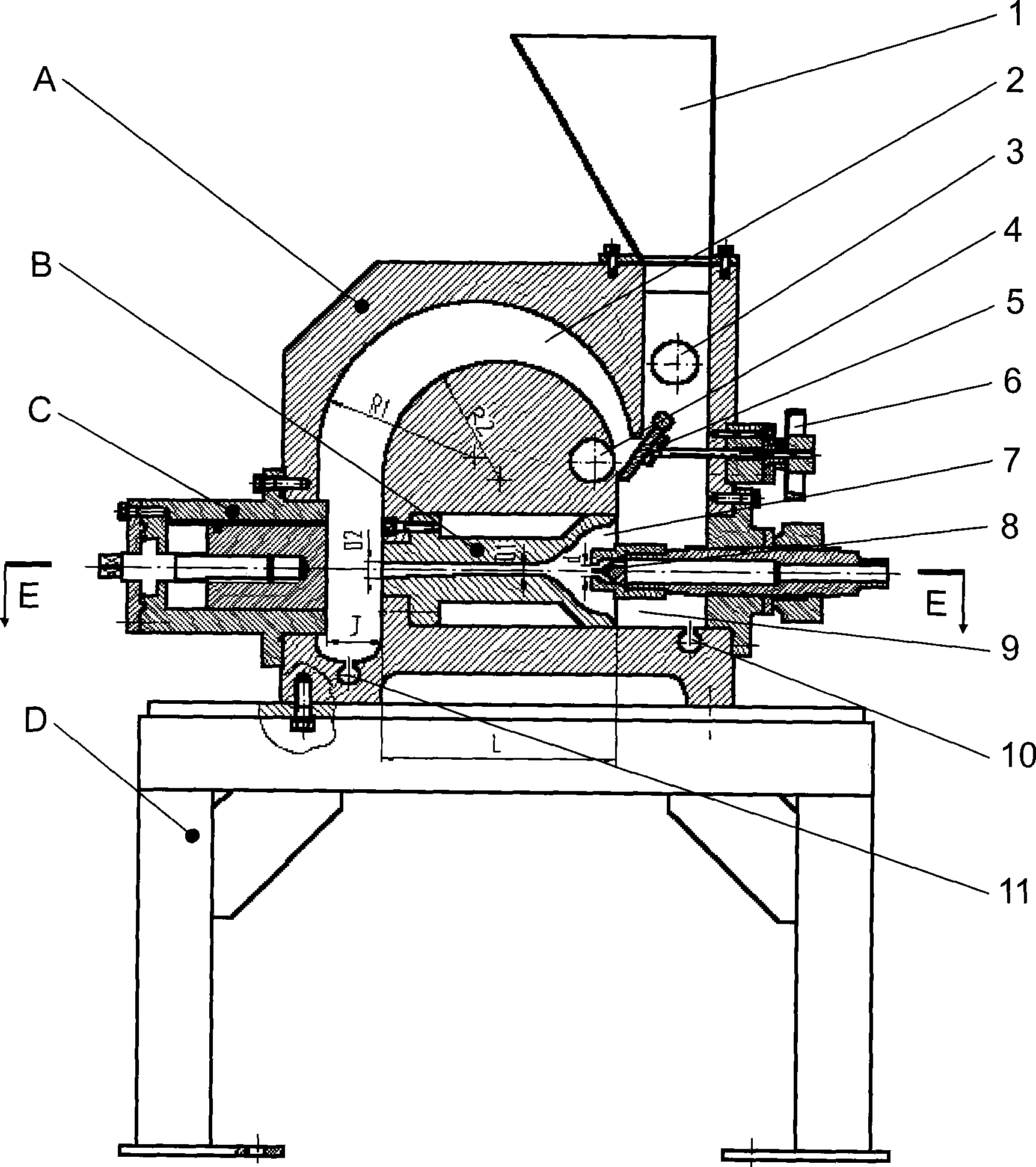

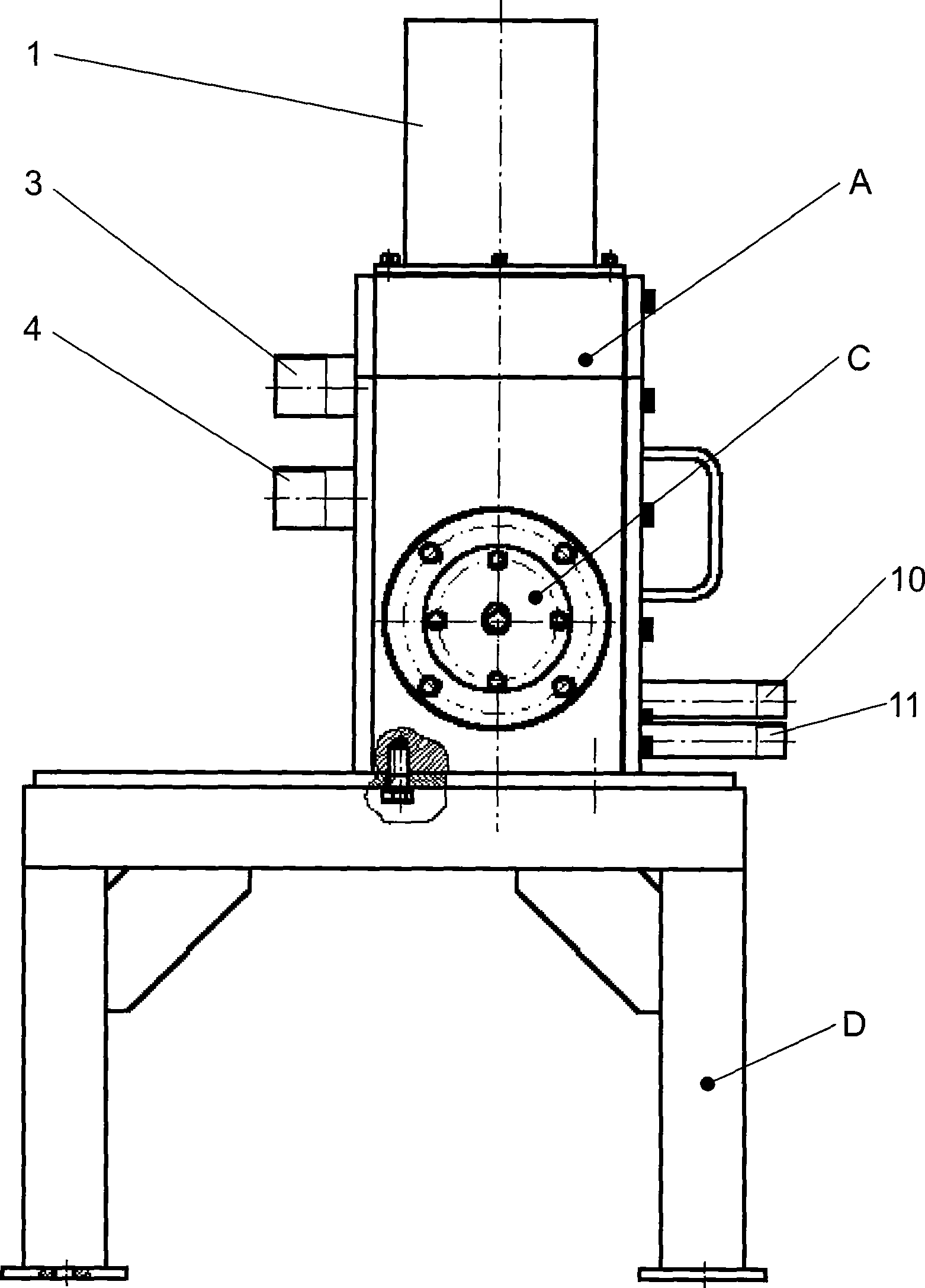

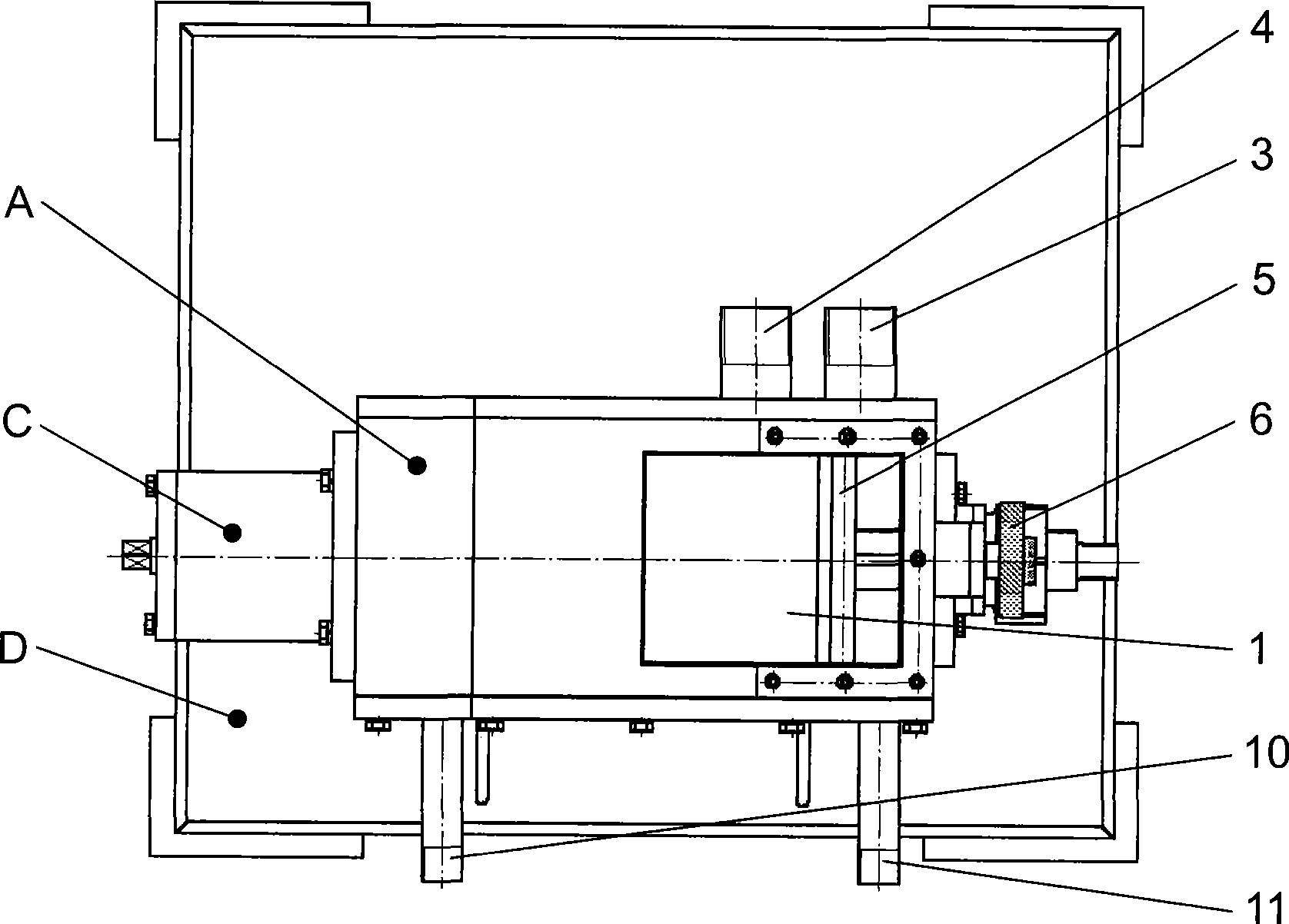

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the ultra-fine cavitation target water jet mill includes a hopper 1, a mill cavity A, a particle size adjustment plate 5, a particle size regulator 6, a primary separation connection 10 for impurities, a secondary separation connection 11 for impurities, and a grinding door 16 , grinding door hinge 17, door handle 18, injection mixing acceleration part B, adjusting impact target body C, machine base D; hopper 1 is fixed on the upper end of mill cavity A (fixed by bolts), and hopper 1 is connected to the mill cavity The injection cavity 9 of the body A is connected; the bottom of the mill cavity A is fixed on the machine base D (fixed by bolts); the impurity primary separation connection 10 and the impurity secondary separation connection 11 are respectively welded on the grinding door 16;

[0040] The output end of the arc-shaped cross-section gradient flow channel 2 of the mill cavity A and the grading di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com