Preparation method of titanium dioxide slurry with high water dispersibility

A dispersive, titanium dioxide slurry technology, applied in chemical instruments and methods, dyed high molecular organic compound treatment, dyed low molecular organic compound treatment and other directions, can solve the problem of low water dispersibility of titanium dioxide slurry, and achieve particle size control. Excellent, saving manpower and material costs, and isolating the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of high water dispersible titanium dioxide slurry comprises the following steps:

[0033] a. Sieve the sand-milled slurry to control the TiO content in the sieved slurry 2 The concentration is 400-550g / L;

[0034] b. Add the dispersant to the slurry treated in step a, and stir for 30-60min;

[0035] c. The temperature of the slurry treated in step b is raised to 70-100°C, then a silicate solution is added, and an aluminum salt solution is added in parallel to adjust the pH to 9-10, and then mature for 60-120min;

[0036] d. Cool the slurry treated in step c to 30-70°C, add dilute acid solution to adjust pH to 3-6, mature for 30-45min, then add phosphate solution, and add aluminum salt solution to adjust pH to 4- 7, aging for 90-120min;

[0037] e. Add the aluminum salt solution to the slurry treated in step d, adjust the pH to 5-8 with a pH regulator, and age for 90-180min to obtain high water dispersibility titanium dioxide slurry.

[0038] I...

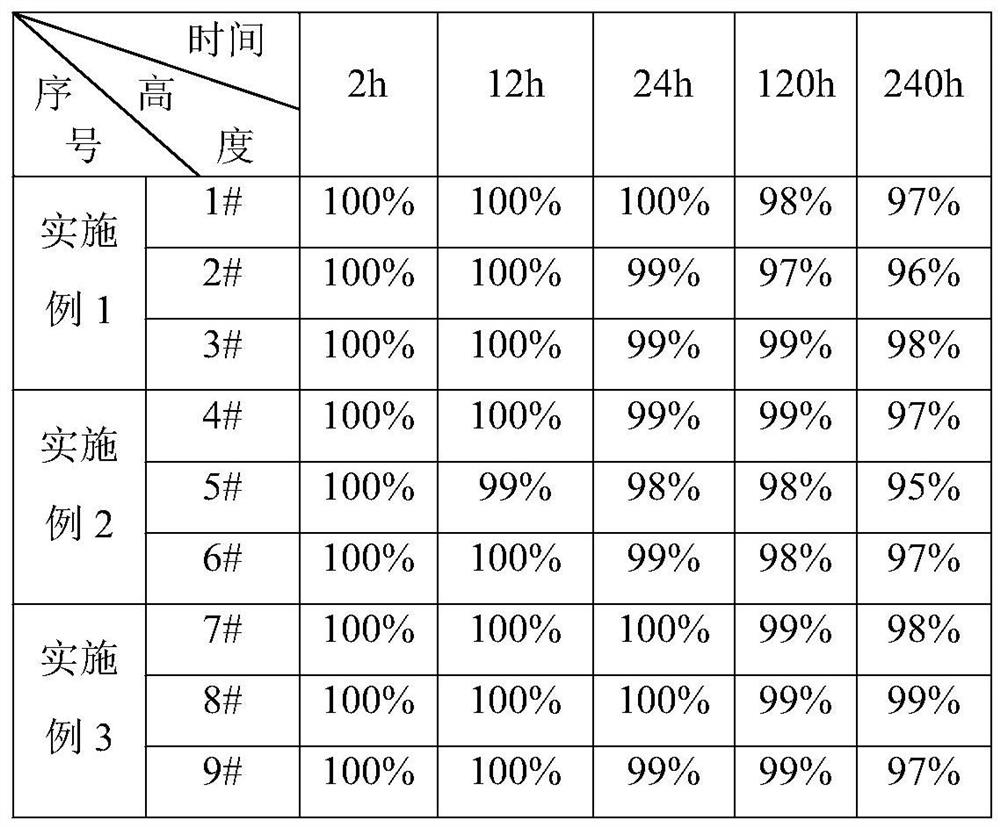

Embodiment 1

[0046] Embodiment 1 concrete experimental procedure is as follows:

[0047] a. After sanding, the slurry passes through a 500-mesh sieve to obtain a ready-to-use slurry, the concentration of the titanium dioxide slurry is 450g / L, the temperature is raised to 55°C, and the initial pH is 10.1;

[0048] b. Add 0.3% potassium nitrate and 0.2% sodium polycarboxylate mixed solution (use TiO 2 total amount), stirring and dispersing for 30 minutes;

[0049] c. Heat up to 80°C, add 2.5% sodium silicate (as TiO 2 total amount), adding aluminum sulfate at the same time, maintaining the pH value between 9-10, and aging for 60 minutes;

[0050] d. Add water to cool down to 55°C, add dilute sulfuric acid, maintain the pH value between 4.5-5.5, ripen for 30 minutes, and add a mixture of 1.5% phosphoric acid and sodium dihydrogen phosphate (using TiO 2 total amount), while adding sodium metaaluminate in parallel to maintain the pH value between 5.0-6.0, and aging for 90 minutes.

[0051] ...

Embodiment 2

[0052] Embodiment 2 Concrete experimental steps are as follows:

[0053] a. After sanding, the slurry passes through a 500-mesh sieve to obtain a ready-to-use slurry, the concentration of the titanium dioxide slurry is 500g / L, the temperature is raised to 50°C, and the initial pH is 10.5;

[0054] b. Add 0.2% potassium nitrate and 0.25% sodium stearate mixed solution within 10min (use TiO 2 total amount), stirring and dispersing for 30 minutes;

[0055] c. Heat up to 85°C, add 3.0% sodium silicate (as TiO 2 total amount), adding aluminum sulfate at the same time, maintaining the pH value between 9-10, and aging for 90min;

[0056] d. Add water to cool down to 50°C, add dilute sulfuric acid, maintain the pH value between 5.0-5.5, ripen for 30 minutes, and add 2.0% sodium phosphate (based on TiO 2 total amount), while adding sodium metaaluminate in parallel to maintain the pH value between 5.0-5.5, and aging for 100 minutes.

[0057] e. keep the temperature constant, add 4.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com