Cohesive target type water fluid jet grind

A water jet mill and target technology, applied in solid separation, wet separation, grain processing, etc., can solve the problems of low energy efficiency, classification and particle size control, insufficient mixing of material particles and high-speed water jet, etc. The effect of high energy utilization, easy particle size control, and convenient gradation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

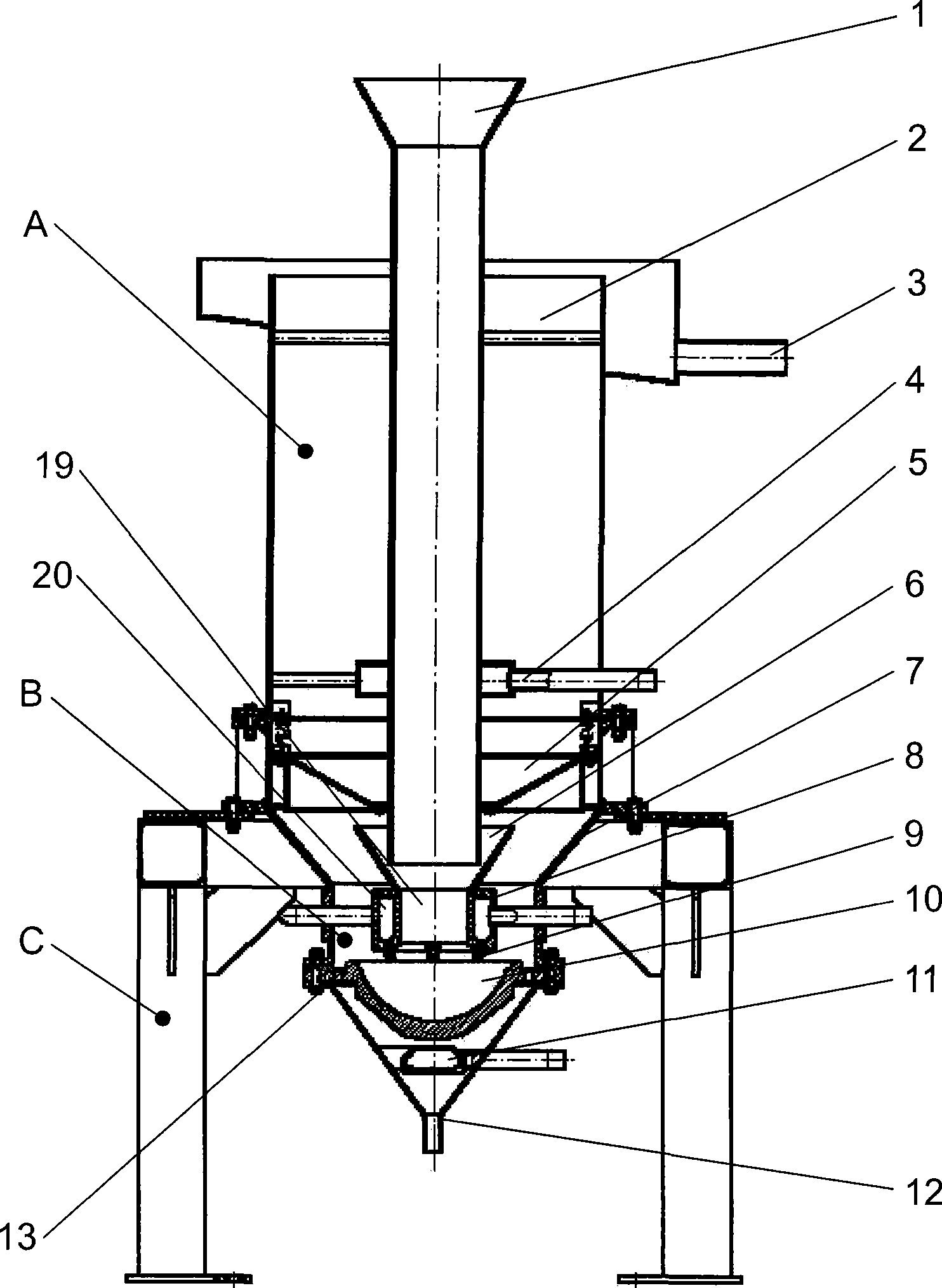

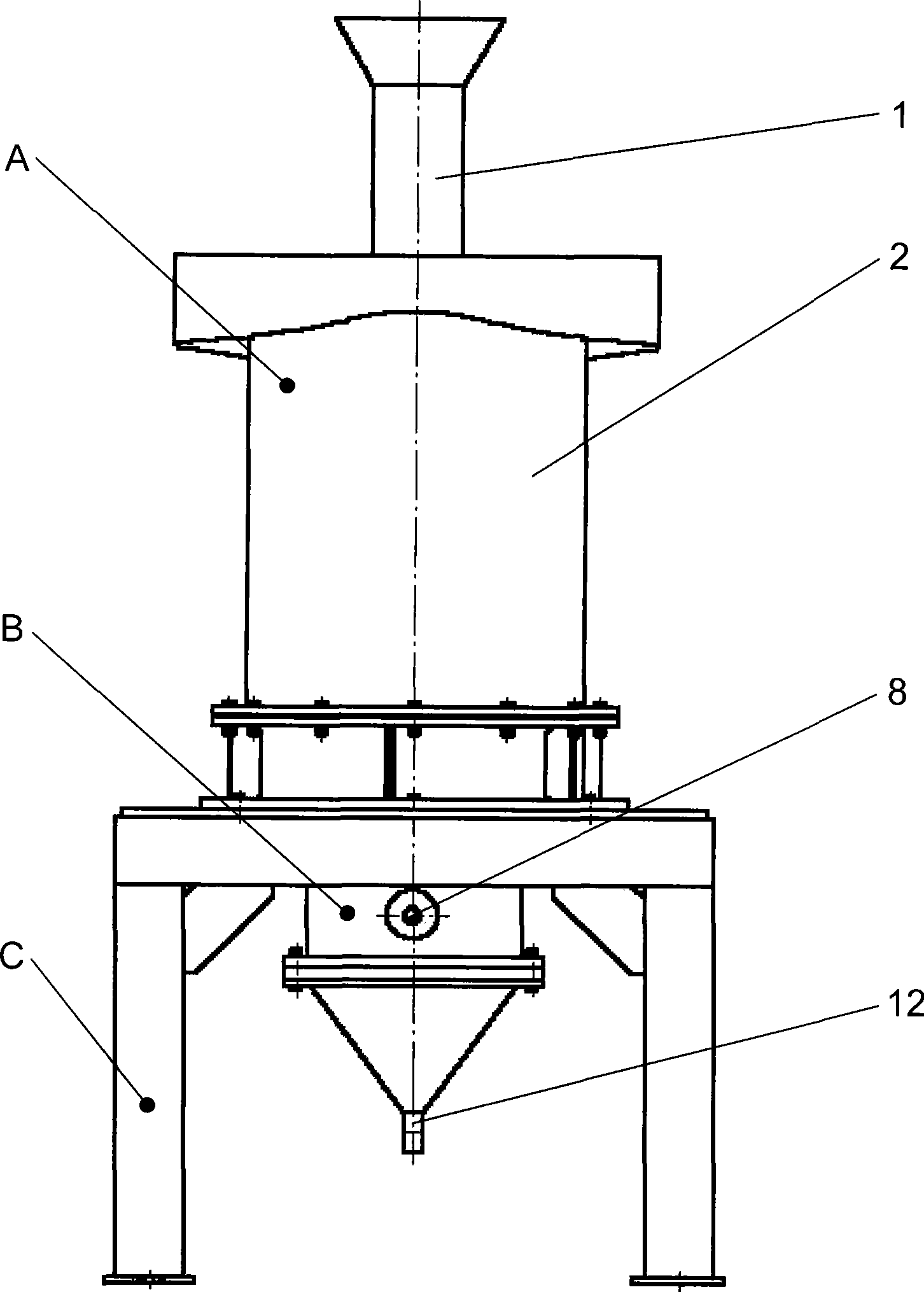

[0041] Such as figure 1 , figure 2 , image 3 As shown, the cohesive target water jet mill includes a material classification part A, a material crushing part B, and a machine base C.

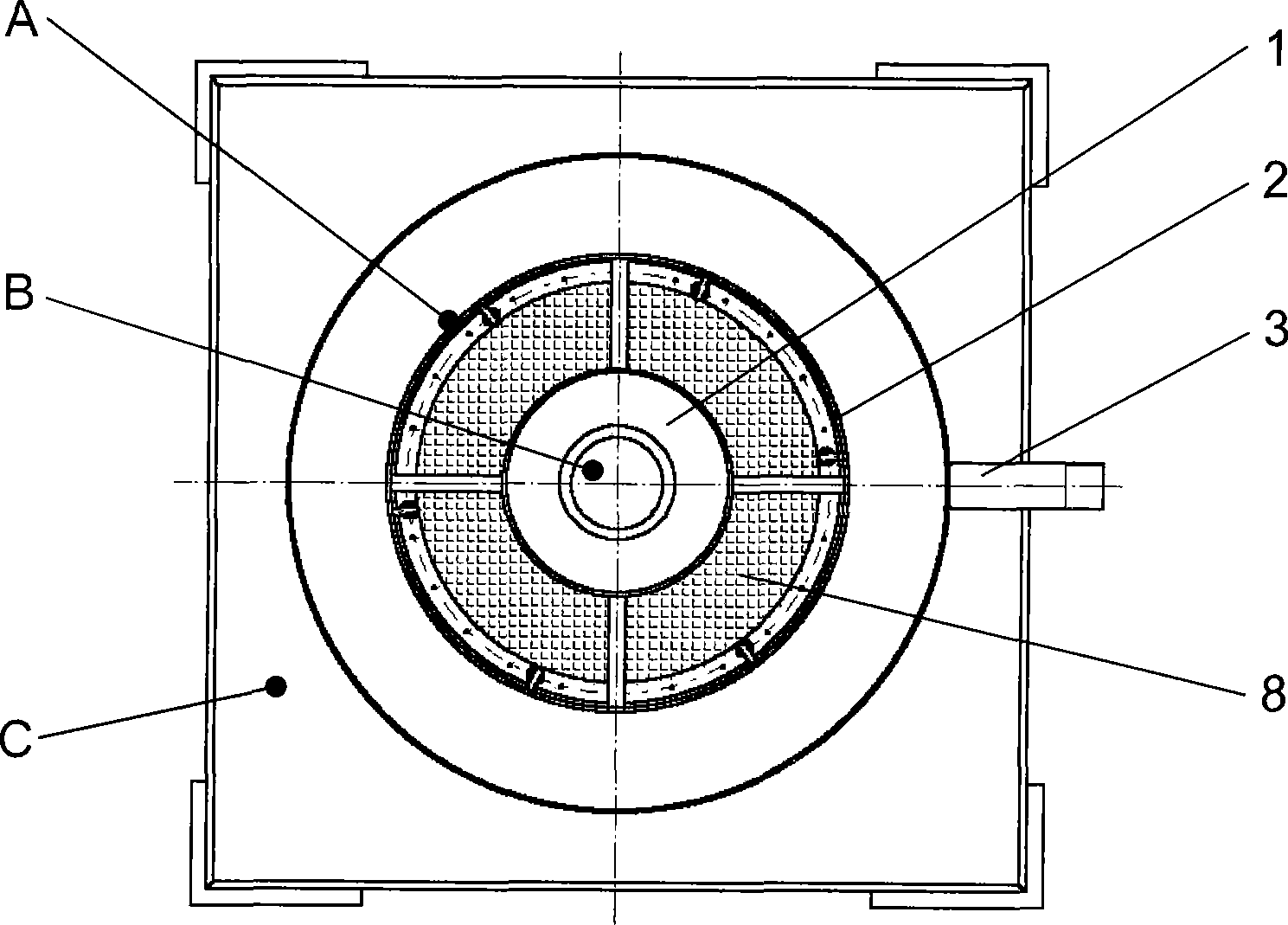

[0042] Such as Figure 4 As shown, the material classification part A includes a central feeding pipe 1, an overflow type suspension classification cylinder 2, an overflow tank 3, an annular water flow uniform distributor 4, and a water-excited conical vibrating screen 5; The lower end passes through the overflow-type suspension classification cylinder 2, and the central feeding pipe 1 is positioned on the central axis of the overflow-type suspension classification cylinder 2 through the welding of the support rod. The upper end of the central feeding pipe 1 is the feeding port; the overflow-type suspension classification cylinder 2 The upper part of the upper part is welded with the overflow tank 3 to form an overflow graded structure, and the overflow tank 3 is provided with a discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com