Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129results about How to "Contains less impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater

ActiveCN105905933ASolve pollutionAvoid wastingCalcium/strontium/barium fluoridesWater contaminantsHigh concentrationPollution

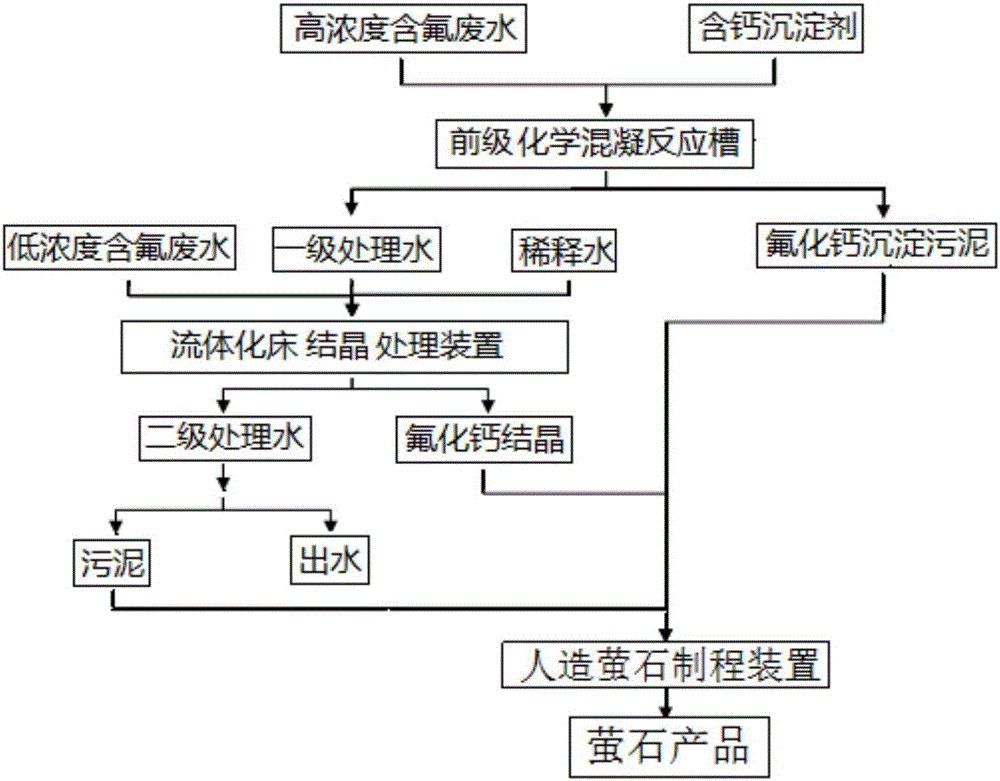

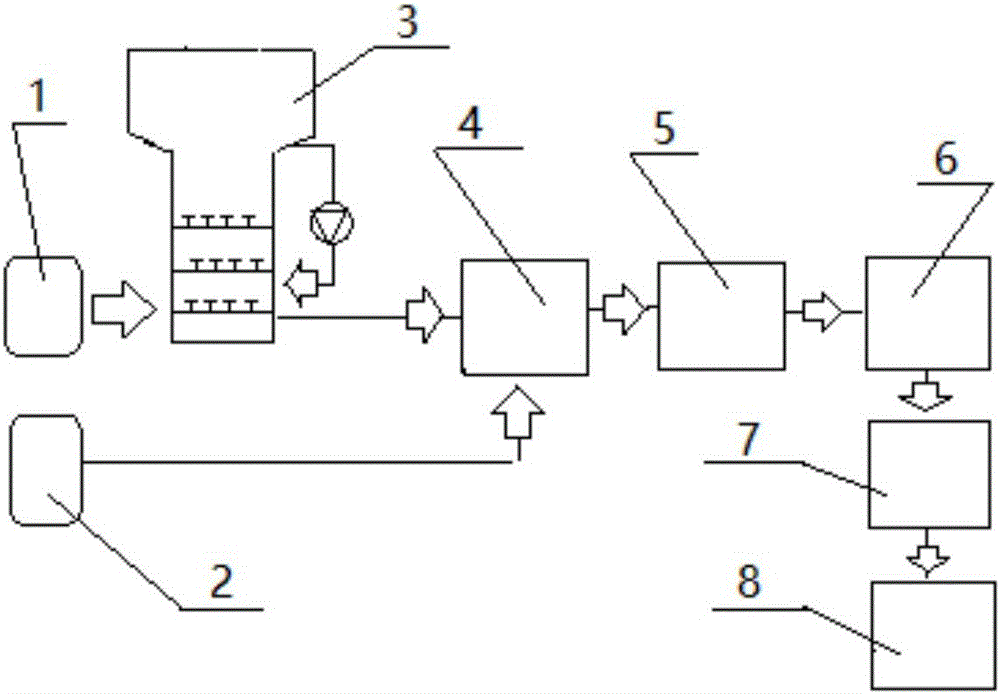

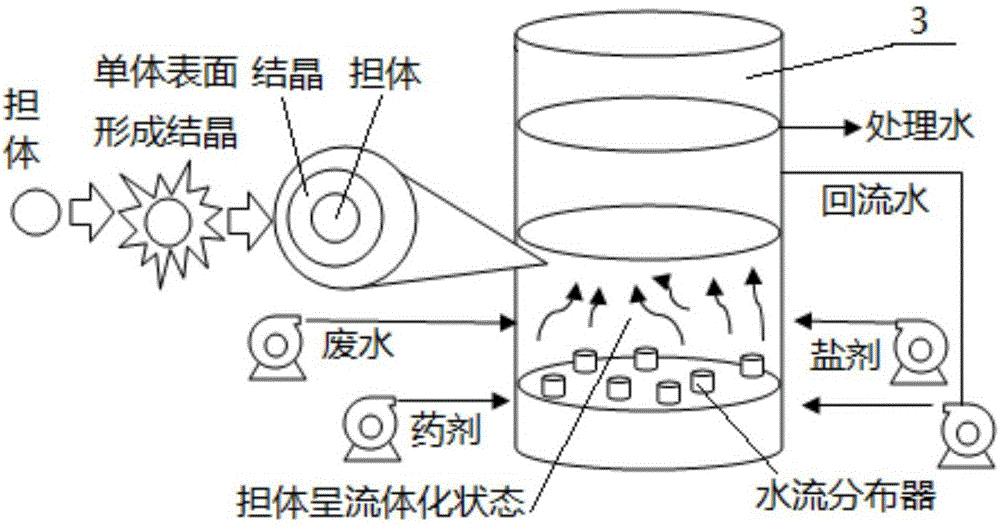

According to a process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater, a fluidized bed serves as a crystallization treatment device, fluoride components in wastewater are efficiently extracted in a supporter crystallization mode, a high-purity calcium fluoride artificial fluorite product is prepared, fluoride-containing wastewater can be treated to reach the standard, no secondary pollution exists, the problems of land occupation and environment pollution of bottom mud produced during treatment of industrial fluoride-containing wastewater are solved, fluoride resources in the bottom mud are effectively used, circulation is short, operation is simple, implementation is easy, fluoride pollution and fluoride resource waste are reduced, and process efficiency is high; good balance can be achieved between making emission not exceed the standard and controlling wastewater treatment cost. Produced calcium fluoride crystals are suitable for preparing artificial fluorite to serve as the substitute of natural fluorite, calcium fluoride crystals produced in the technological process are low in water content, fluoride-containing waste reducing or resourceful using aim is effectively achieved, and the process is an environment-friendly method for treating high-concentration fluoride-containing wastewater and is wide in industrial application prospects.

Owner:KUNSHAN YANGCHENG LANGU ENVIRONMENTAL INST CO LTD

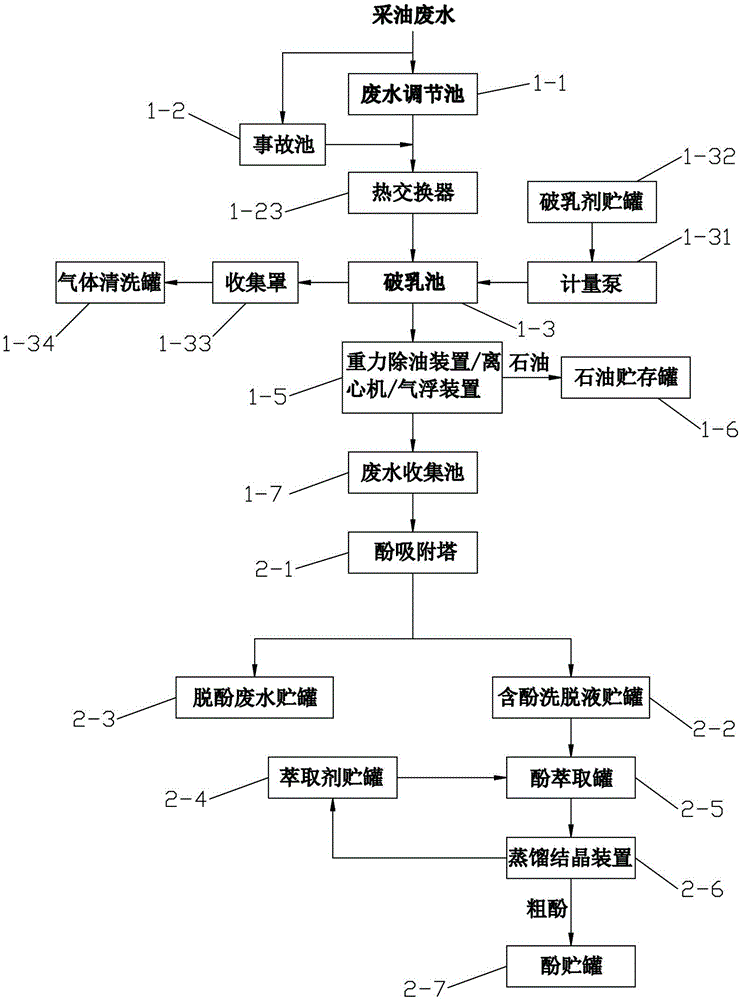

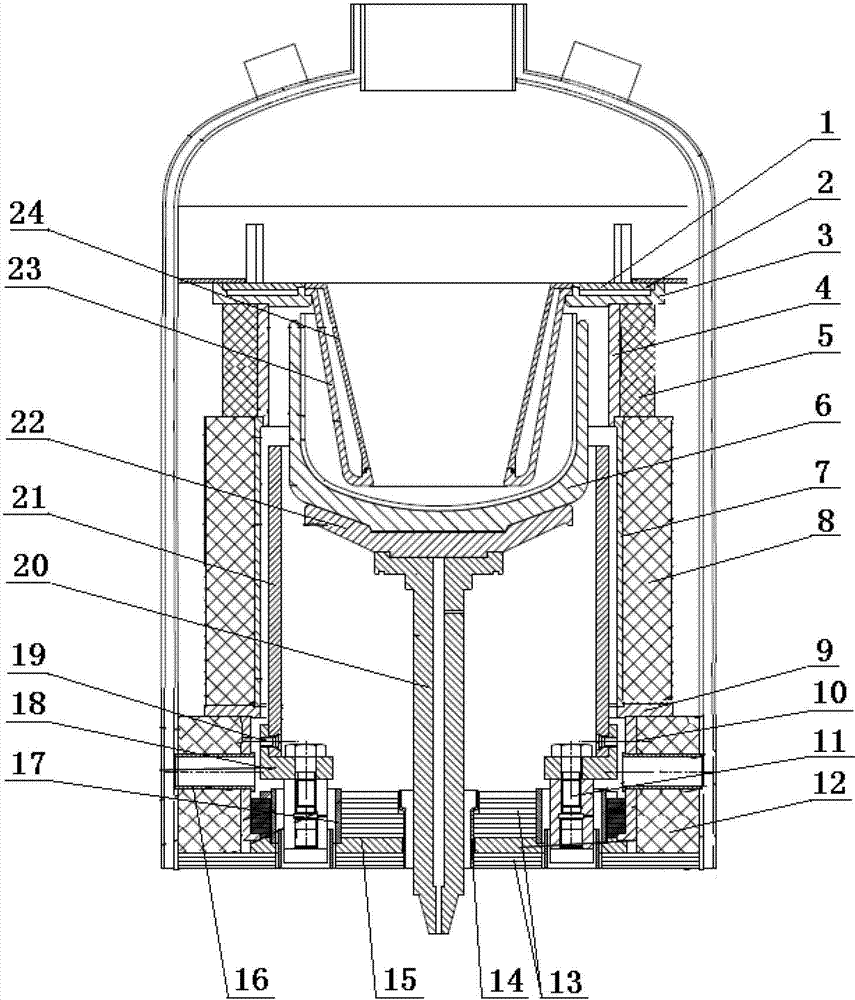

Device and method for recycling petroleum and phenol from oilfield industry wastewater and treating and regenerating wastewater

InactiveCN105399271AContains less impuritiesEasy to processWaste water treatment from quariesWater/sewage treatment by centrifugal separationAnaerobic treatmentReclaimed water

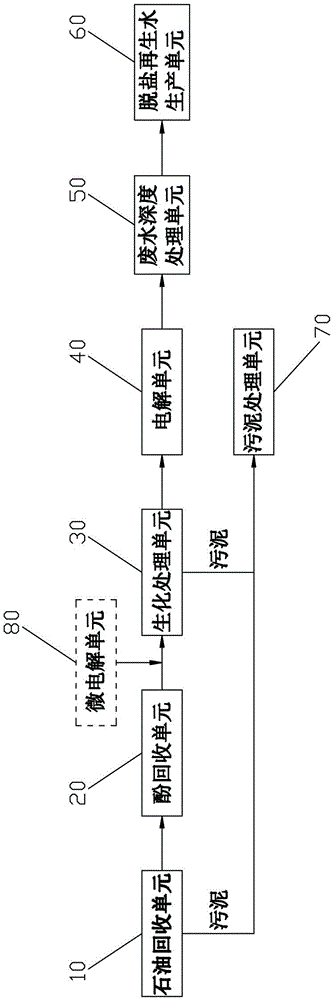

The invention discloses a device for recycling petroleum and phenol from oilfield industry wastewater and treating and regenerating wastewater. The device disclosed by the invention comprises a petroleum recycling unit, a phenol recycling unit, a biochemical treatment unit, an electrolysis unit, a deep wastewater treatment unit, a desalted regenerated water production unit and a sludge treatment unit. A method of the device disclosed by the invention sequentially comprises the following steps: demulsifying, recycling petroleum, recycling phenol, carrying out anaerobic treatment, carrying out aerobic treatment, carrying out electrolysis treatment, carrying out membrane treatment or biochemical treatment by virtue of a biological aerated filter, and desalting. The device and method which are disclosed by the invention have the advantages that petroleum and phenol in the oilfield industry wastewater are recycled, a wax component is recycled, and wastewater is effectively treated, so that resource recycling is realized while oilfield industry wastewater pollution is treated, and wastewater quality can meet emission standards in technical specification for oilfield industry wastewater treatment (HJ2041-2014).

Owner:罗依依

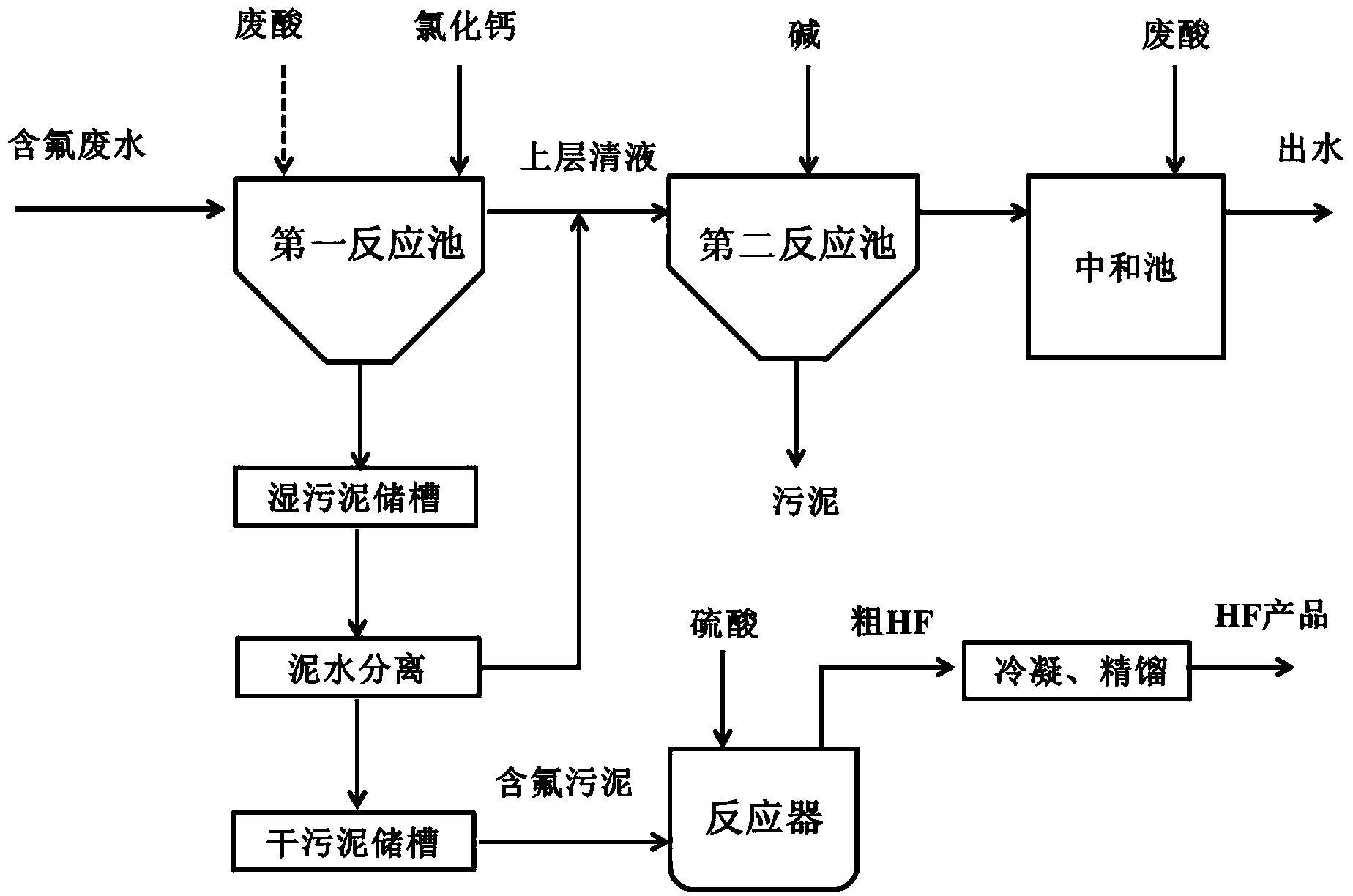

Method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater

ActiveCN103848522ATreatment up to standardReduce dosageSludge treatmentWater contaminantsSludgeImpurity

The invention discloses a method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater. The method comprises the steps of reacting the fluorine-containing wastewater with calcium chloride under the acidic condition formed by adding a waste acid matter, performing crystallization sedimentation to remove most fluorine ions from the wastewater to form high-purity fluorine-containing sludge, removing dissolved calcium fluoride and other impurities from supernate through alkali sedimentation to form a small amount of fluorine-containing sludge with relatively low purity, then neutralizing the supernate, and discharging effluent, wherein the concentration of fluorine ions of the effluent is lower than 10 mg / L and accords with national discharge standards; drying the high-purity fluorine-containing sludge, then adding the dried sludge and excessive sulfuric acid into a reactor with a stirring device, reacting at 150-300 DEG C to prepare hydrogen fluoride, and condensing and rectifying the obtained crude hydrogen fluoride gas to obtain an anhydrous hydrogen fluoride product.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

Method for extracting precious metals from dead catalysts containing precious metals

ActiveCN103451433AContains less impuritiesQuality improvementProcess efficiency improvementPlatinumPre treatment

The invention provides a method for extracting precious metals from dead catalysts containing the precious metals. The method comprises a pretreatment step, an oxygen pressure acid leaching step, a precious metal separation step and a palladium powder and platinum powder recovery step. The method can be used for removing base metals and heavy metal elements in the dead catalysts by combining the acid pressure leaching process and the precious metal enrichment process and has the characteristics of strong selectivity for the precious metal elements in a reaction process, high recovery rate, simplicity and convenience in operation, low energy consumption and the like. The yielded precious metal nanopowder contains few impurities, has high quality and can serve as products to be directly applied to the fields such as catalysts and medicines.

Owner:XINGUANG RECYCLING SHANGHAI

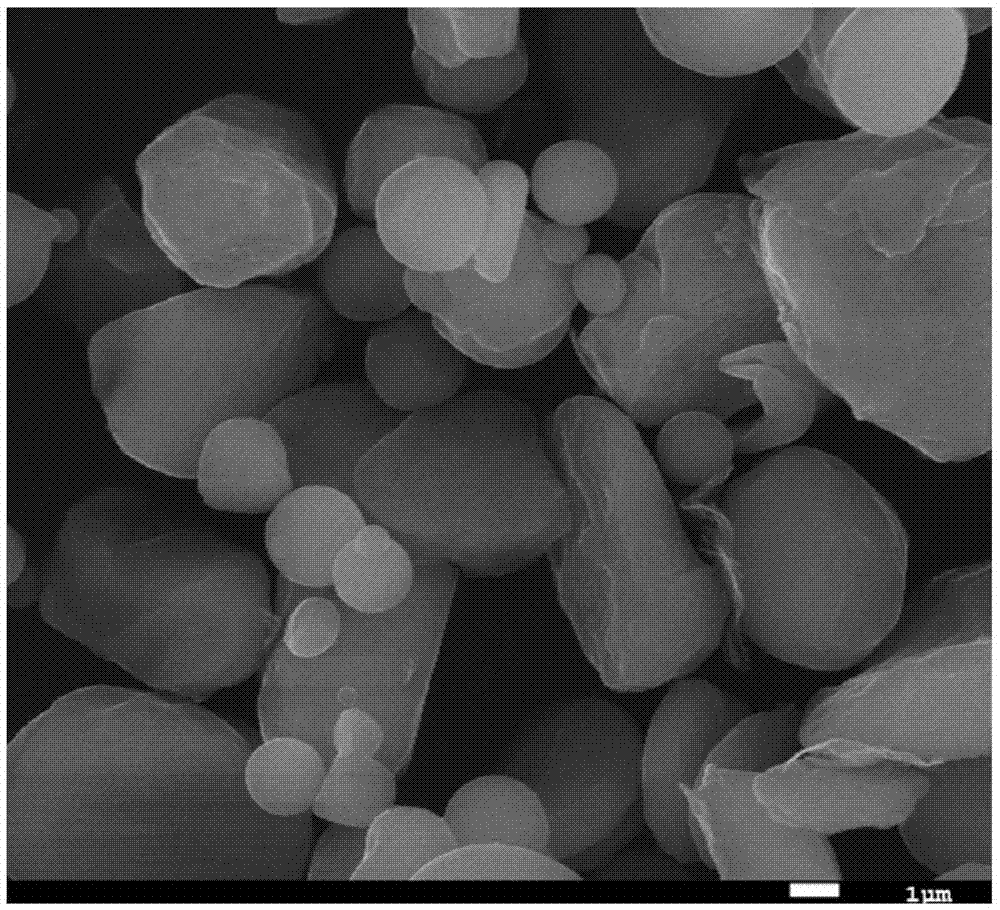

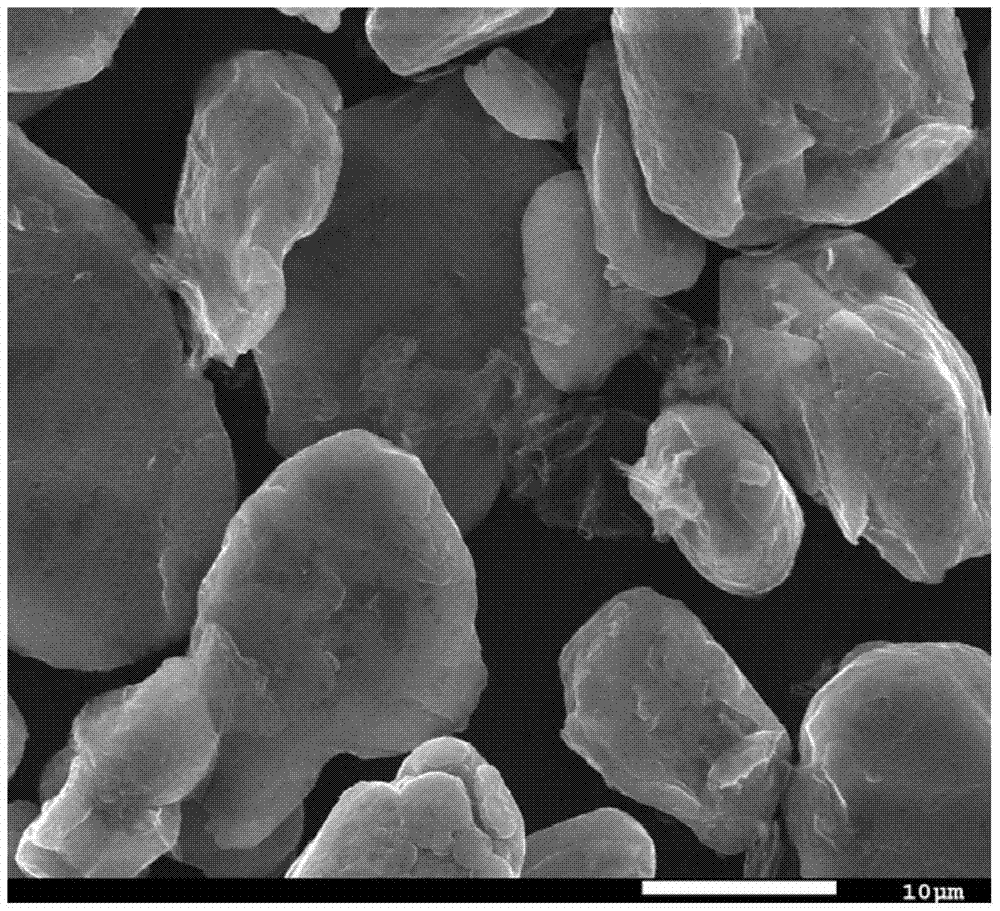

Preparation method for composite powder of graphene and metal aluminum powder

InactiveCN106914611AImproved reunion statusGuaranteed preprocessing effectAluminium powderSpherical shaped

The invention relates to a preparation method for composite powder of graphene and metal aluminum powder, and belongs to the field of nanosheet structure reinforced metal base composite materials. The preparation method comprises the following steps of: taking grapheme and metal aluminum powder as raw materials, and performing pre-dispersing through a mechanical stirring method, an ultrasonic vibrating method and a chemical reagent dispersing method; and then, preparing the composite powder by ball-milling, wherein the composite powder comprises the following components in percentage by weight: 0.3 wt.%-8.5wt.% of graphene and 91.5wt.%-99.7wt.% of aluminum powder. According to the preparation method, aluminum powder generates the laminarization effect, so that the morphology of the aluminum powder is changed into a cake shape or an ellipsoid shape from a spherical shape, dimension deformation percentage of the aluminum powder ranges from (-)200% to 200%, and graphene is uniformly distributed in aluminum powder. The obtained composite powder is low in impurity content, has moisture content lower than 0.01wt.%, and realizes kilogram-level composite powder preparation; and the preparation method is nontoxic and safe.

Owner:GRIMAT ENG INST CO LTD

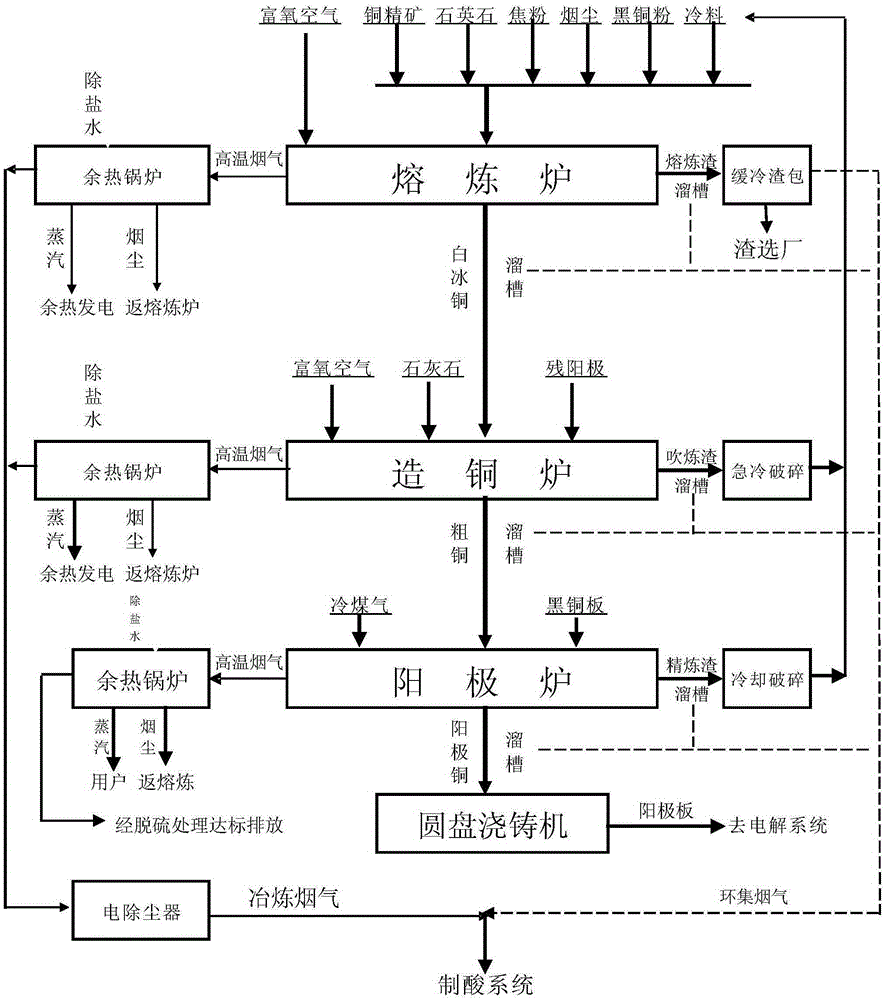

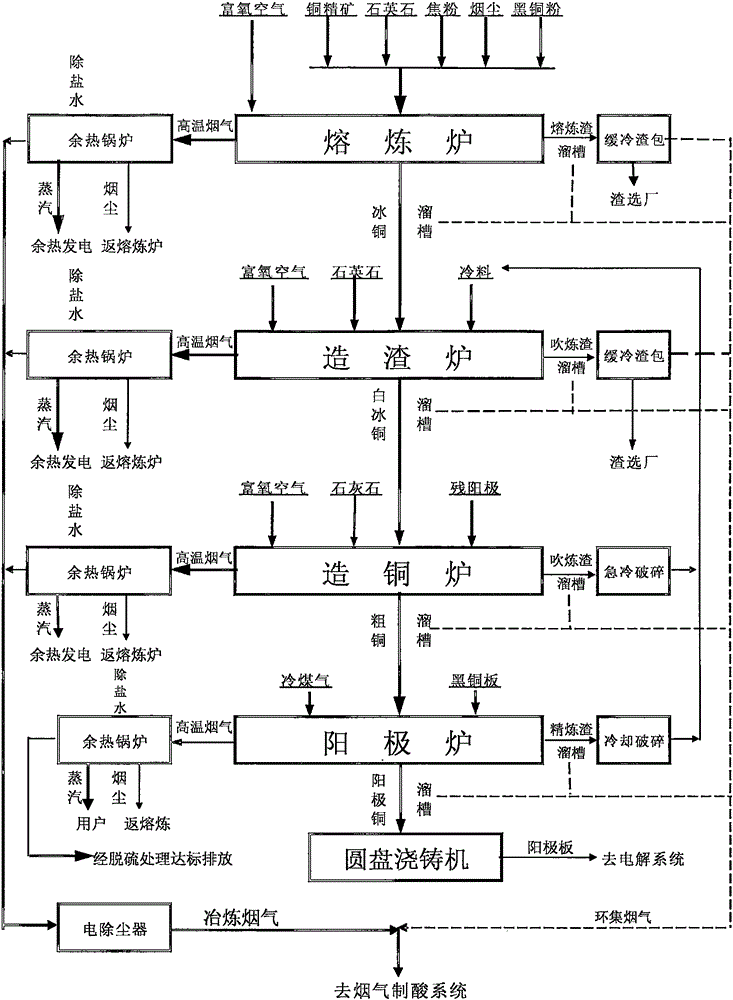

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

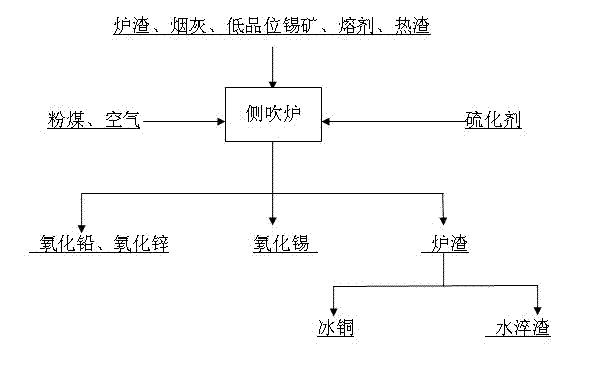

Process for recovering copper and zinc and tin and lead by utilizing side blown converter at the bottom

The invention discloses a process for recovering copper, zinc, tin and lead by utilizing a side blown converter at the bottom. The process is characterized in that materials dosed and mixed from slag, ash, low-grade tin ore and flux are selected for use, the water content of the dosed and mixed materials is <= 3%, the dosed and mixed materials are stand-by, hot slag of a reduction furnace is added into a side blown converter, the dosed and mixed materials are added to the side blown converter, mixed with the hot slag of the reduction furnace for reduction smelting, the tin content of the hot slag of the reduction furnace and the dosed and mixed materials which are added into the side blown converter is more than 3%, and the silicic acid degree of the slag is 1-1.2. In the first stage, the lead and the tin are volatilized in the reduction smelting mode, and lead oxide and tin oxide are obtained through dust collection. In the second stage, vulcanizing agents are added, tin sulfide is volatilized, and tin oxide is obtained after dust collection. In the third stage the slag and the copper settles and are separated to obtain copper matte and waste slag, the slag is quenched through water, and the copper matte is cast into ingots. The process for recovering the copper, the zinc, the tin and the lead by utilizing the side blown converter at the bottom is strong in adaptability, capable of separating out valuable metal such as the copper, the lead, the zinc and the tin through one-step smelting, high in direct recovery rate, and low in valuable metal containing rate of the slag.

Owner:江西自立环保科技有限公司

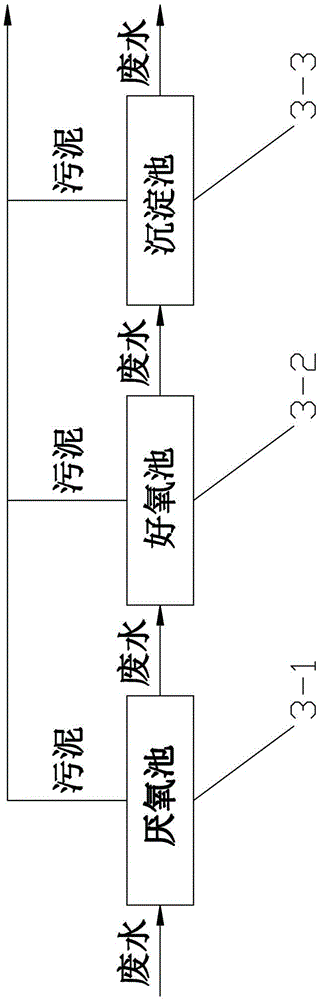

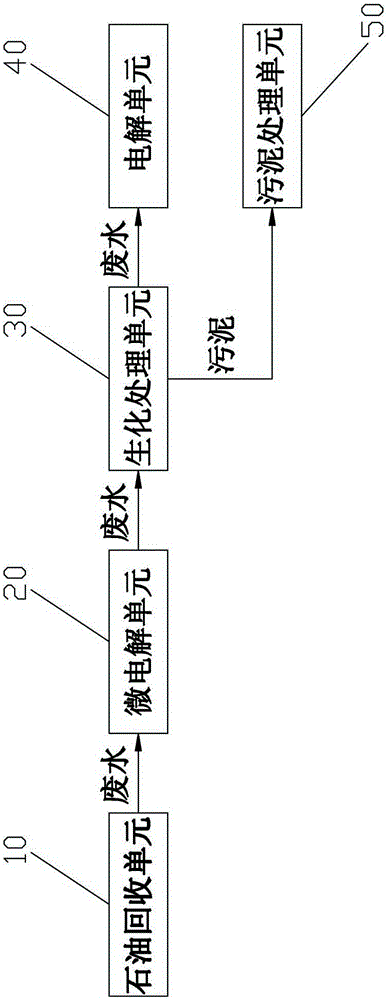

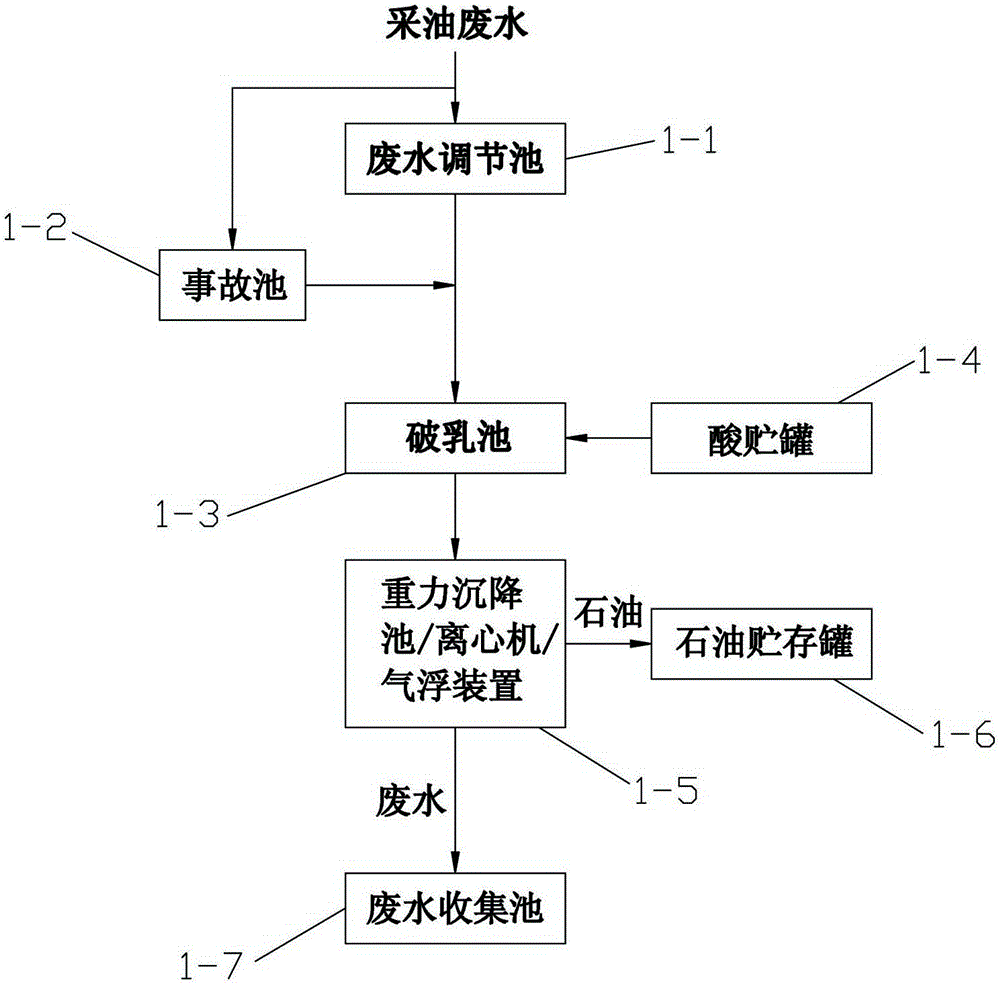

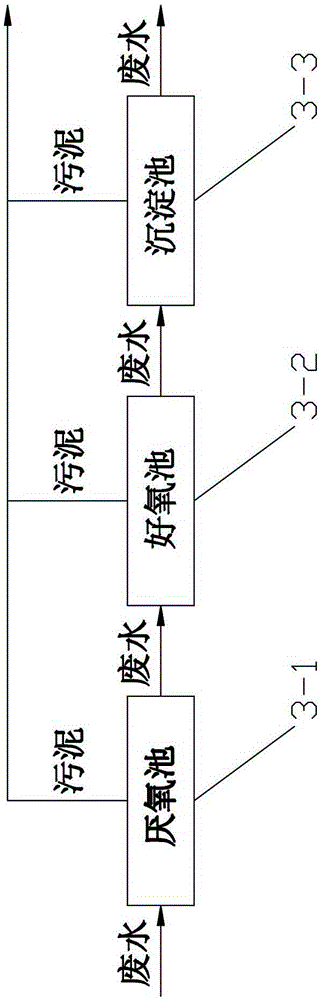

Treatment device and method for oil extraction wastewater

InactiveCN105174657AHigh purityLow costWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningElectrolysisProcess engineering

The invention discloses a treatment device for oil extraction wastewater. The device comprises an oil recovery unit, a microelectrolysis unit, a biochemical treatment unit, an electrolysis unit and a sludge treatment unit; and a treatment method for the oil extraction wastewater comprises the following steps sequentially: carrying out demulsification, carrying out oil recovery, carrying out microelectrolysis, carrying out anaerobic treatment, carrying out aerobic treatment and carrying out electrolytic treatment. According to the device and the method, through recovering petroleum and phenol from the oil extraction wastewater and recovering waxy ingredients, good conditions are created for subsequent wastewater treatment, the influence on biochemical treatment caused during phenolic wastewater treatment is eliminated, and the recycling of resources is realized while oil extraction wastewater pollution is treated, so that the quality of the wastewater can reach emission standards in technical specifications for oil extraction wastewater treatment engineering (HJ2041-2014).

Owner:BOYING XIAMEN SCI & TECH

Method for removing impurity 2,3,4,5-tetrahydropyridine in nylon salt and purified nylon salt

ActiveCN105753718ASolve yellowingContains less impuritiesAmino compound purification/separationOrganic compound preparationNylon materialDicarboxylic acid

The present invention provides a purified nylon salt formed from diamines and dicarboxylic acids, the diamines at least comprise 1,5-Diaminopentane, the content of impurity 2,3,4,5-tetrahydropyridine in the nylon salt is less than 0.1wt%, and the content is calculated on the basis of the weight of the 1,5-Diaminopentane. The present invention further provides a method for removing the impurity 2,3,4,5-tetrahydropyridine in the nylon salt. Compared with conventional nylon salts, the purified nylon salt has the characteristics of less impurities in particular low content of the impurity 2,3,4,5-tetrahydropyridine, and the yellowing problem of nylon obtained by subsequent polymerization can be effectively solved.

Owner:CATHAY R&D CENT CO LTD +1

Straight pulling single crystal furnace and processing method of carbon-carbon composite material for straight pulling single crystal furnace

InactiveCN102731134ASimple processing methodContains less impuritiesBy pulling from meltFiberCarbon composites

The invention discloses a processing method of carbon-carbon composite material for a straight pulling single crystal furnace. The method comprises the steps of processing carbon fiber into a prefabricated body, then heating the prefabricated body in a chemical deposition furnace to 1050-1150 DEG C, and introducing propane gas, wherein the propane gas is decomposed at high temperature to generate carbon and the carbon is deposited in the prefabricated body; placing the compacted prefabricated body in a graphitization furnace; heating to 2300-2800 DEG C, and maintaining the temperature for 2-4 hours and cooling to form the carbon-carbon composite material. The invention further discloses the straight pulling single crystal furnace which comprises a heater processed by the carbon-carbon composite material. Density of the heater is greater than or equal to 1.8g / cm<3>. The processing method of the carbon-carbon composite material provided by the invention replaces a method of repeated impregnation by carrying out compacting treatment to the prefabricated body by using the chemical vapor deposition furnace, so that not only is the process simple, but also more impurities do not be doped in the compacting treatment process, and high temperature purification is not needed, thereby greatly simplifying the processing method.

Owner:BEIJING JINGYI CENTURY ELECTRONICS

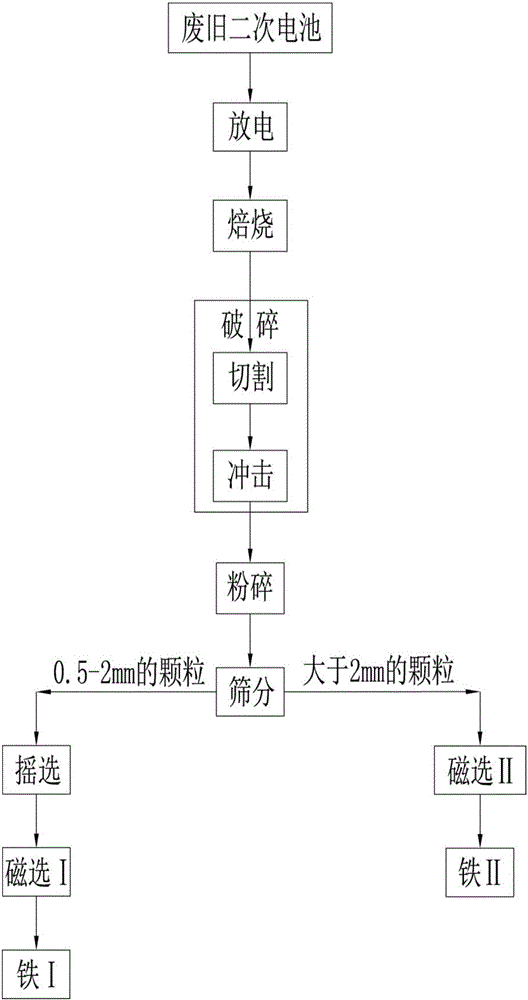

Method for recovering copper and aluminum from waste secondary batteries

InactiveCN106099239AEliminate hazardsTo achieve the effect of safety and environmental protectionWaste accumulators reclaimingBattery recyclingRecovery methodOrganic solvent

The invention relates to a battery recovery method, in particular to a method for recovering copper and aluminum from waste secondary batteries, and aims to eliminate potential safety hazards and avoid leakage pollution in a battery treatment process by providing the method for recovering copper and aluminum from the waste secondary batteries. The method comprises is used for obtaining end products, namely copper and aluminum, in such manners as electric discharging, calcination, crushing, smashing, sieving, shaking separation and magnetic separation, so that the recovery and the utilization of copper and aluminum are realized. Compared with the prior art, the method provided by the invention has the advantages that due to the treatment process of crushing after calcination, that is, easy-to-decompose organic solvents and electrolyte solutions in the waste secondary batteries are decomposed and released through heating and calcination, and then crushing is carried out, so that leakage of organic matters and the electrolyte solutions can be avoided in the follow-up crushing process, treatment safety of follow-up procedures is guaranteed; according to the treatment process provided by the invention, not only is treatment safety realized, but also leakage of harmful substances is prevented, so that the effect of environmental protection is realized.

Owner:GANZHOU HIGHPOWER TECH CO LTD

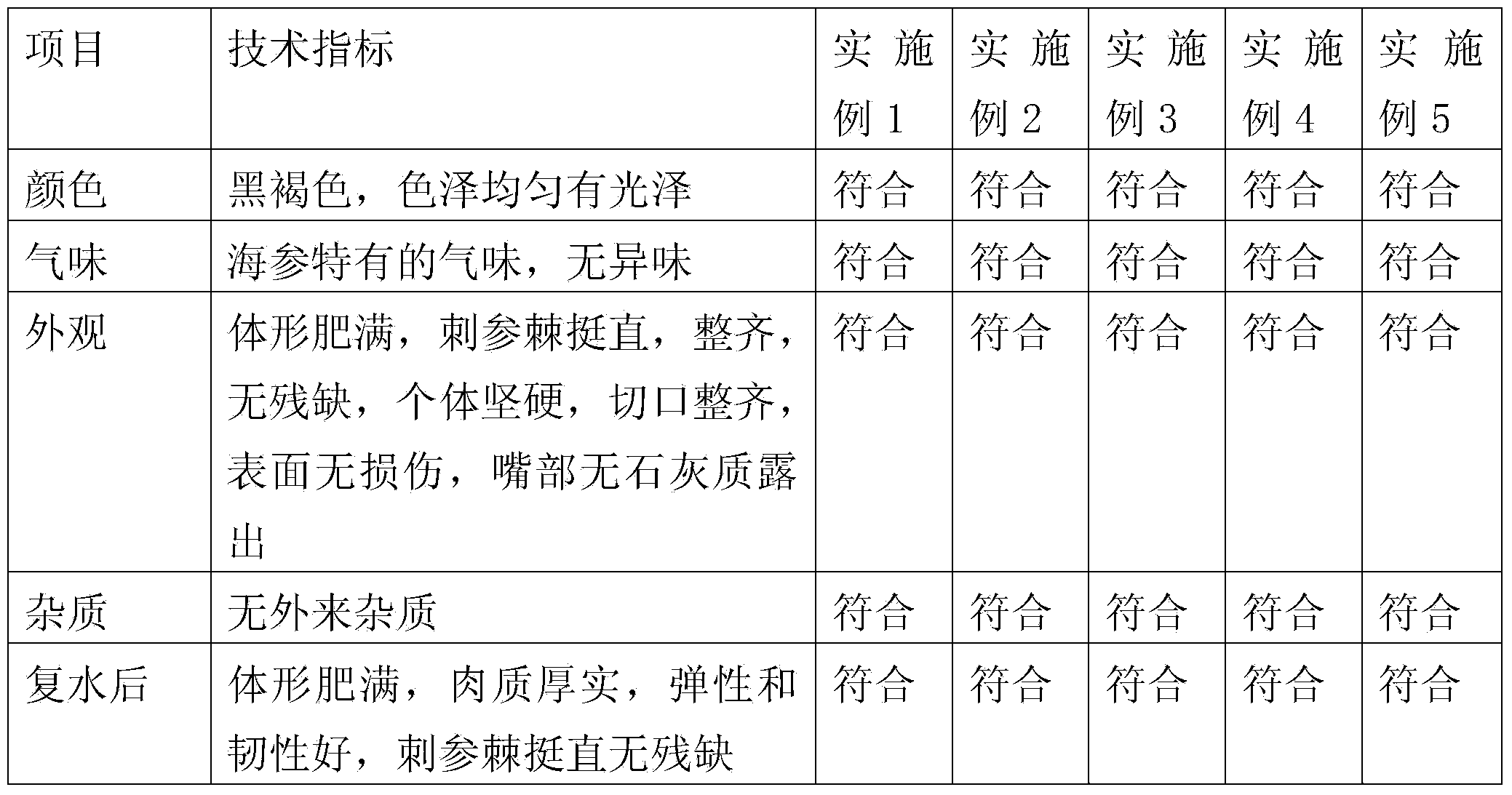

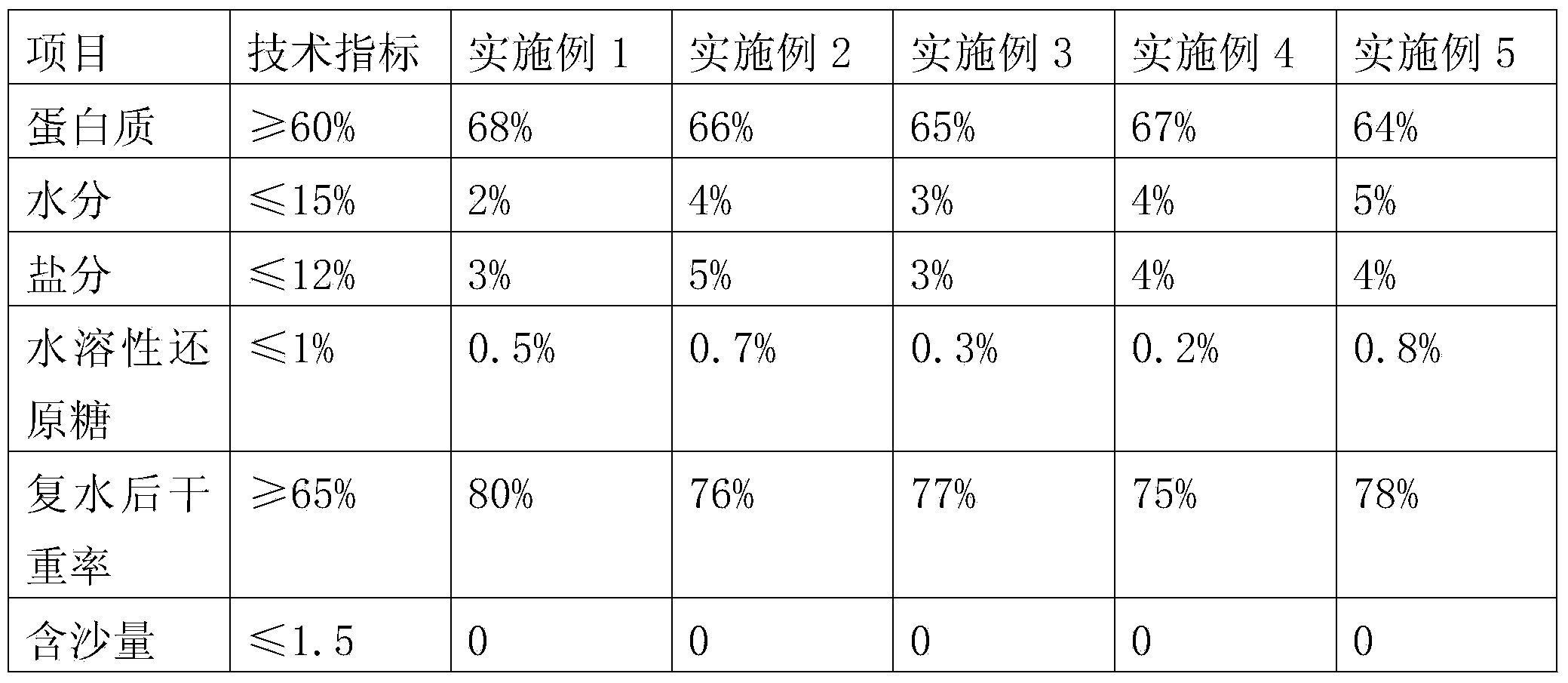

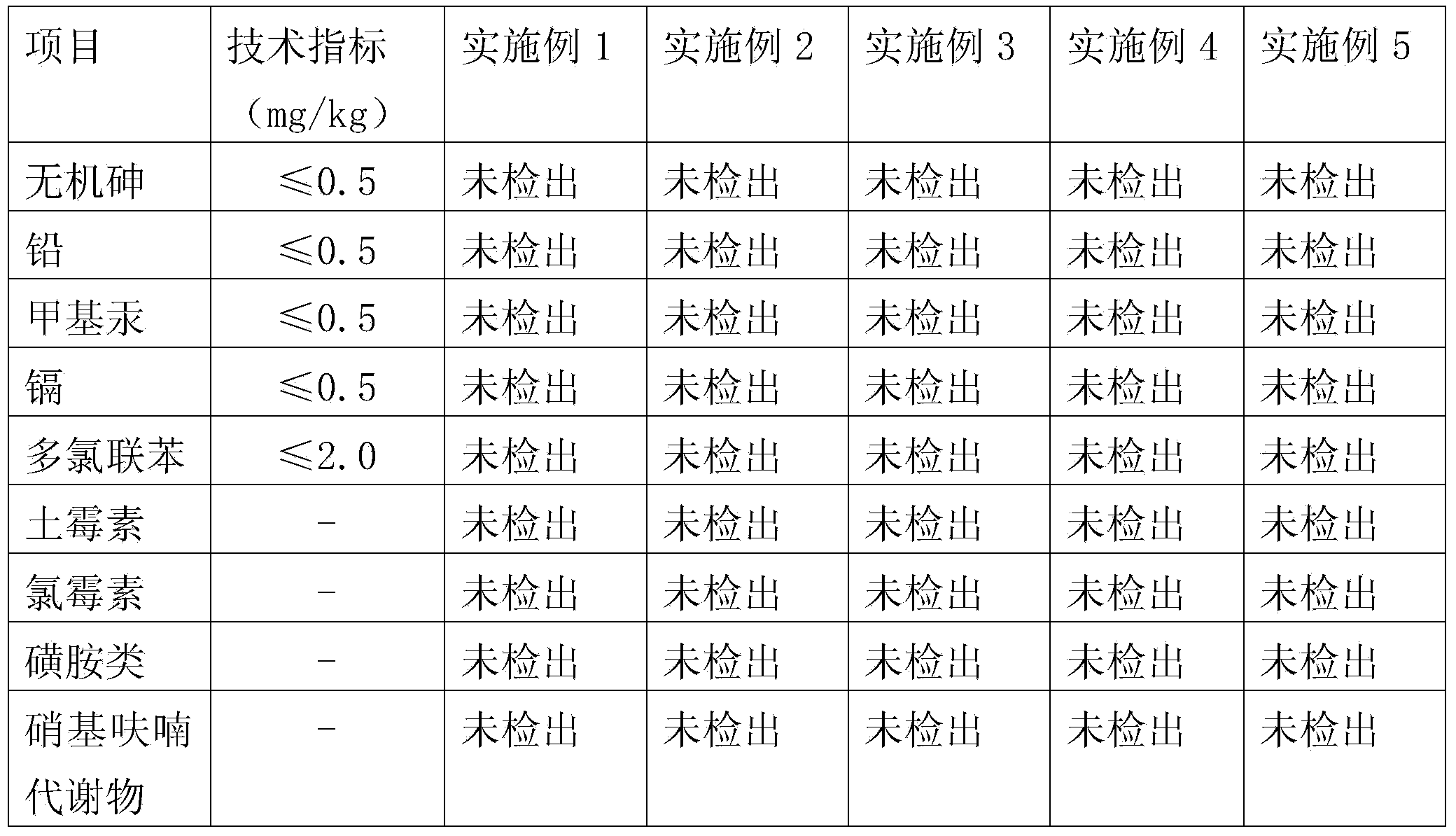

Processing technology for drying trepang through cold air without adding any substance

InactiveCN104256719AShorten the processing cycleContains less impuritiesMeat/fish preservation by heatingMeat/fish preservation by freezing/coolingEngineeringMicrowave

The invention relates to a trepang processing technology, particularly to a processing technology for drying trepang through cold air without adding any substance, and belongs to the technical field of fine finishing of the trepang. The processing technology for drying trepang through cold air is characterized by specifically comprising the following steps: (1) selecting and classifying the light dried trepang; (2) removing internal organs; (3) cleaning and arranging the trepang; (4) stewing the trepang; (5) drying the stewed trepang with cold air; (6) drying the trepang through microwave; (7) vacuum freezing and drying the trepang. The invention aims to provide the simple and convenient processing technology for drying trepang, which has the advantages that the nutritive value of the trepang can be well reserved, the quality guarantee period is long, the trepang contains fewer impurities, and no preservatives are added.

Owner:FUJIAN PROVINCE LIANJIANG COUNTY GUANWU OCEAN DEV

High-efficiency catalysis macroscopic quantity preparation method for graphene oxide or compound thereof reduced and peeled based on microwaves

The invention belongs to the technical field of preparation of graphene and particularly relates to a high-efficiency catalysis macroscopic quantity preparation method for graphene oxide or a compound thereof reduced and peeled based on microwaves. Aiming at solving the problems in a process of reducing the graphene oxide by the microwaves that the reaction time is long (30min or more under a 700W air atmosphere and about 15min under a W air atmosphere) and the peeling effect is not ideal, the method adopts flake graphite powder (with the size of 80-120 meshes) which is cheap and easy to obtain, and trace flake graphite powder is added into a microwave reduction system of the graphene oxide or the compound thereof; a partial ultrahigh-energy environment is realized by utilizing plasmas generated under a microwave environment, and the graphene oxide or the compound thereof is reduced and peeled instantly; and meanwhile, the method has a good quasi-single-layer peeling effect. The method has the advantages that the preparation is simple, raw materials are cheap and easy to obtain, no pollution is caused, and the efficiency is high, so that the method has large-scale industrial production values.

Owner:FUDAN UNIV

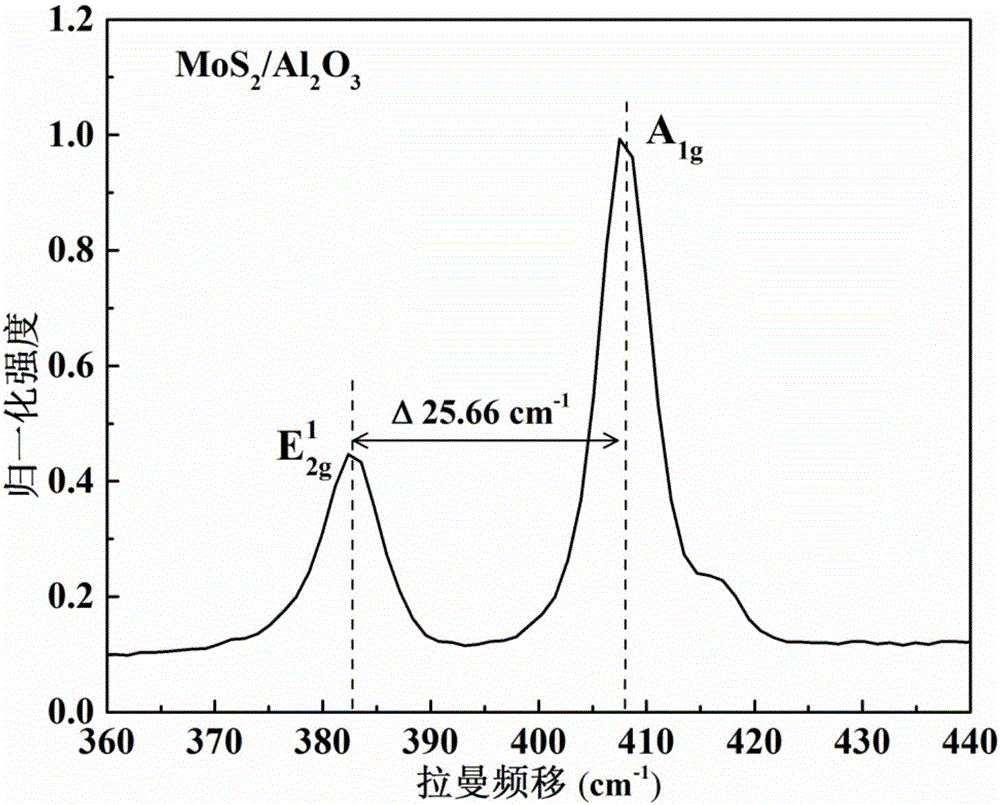

Molybdenum disulfide film and preparation method thereof

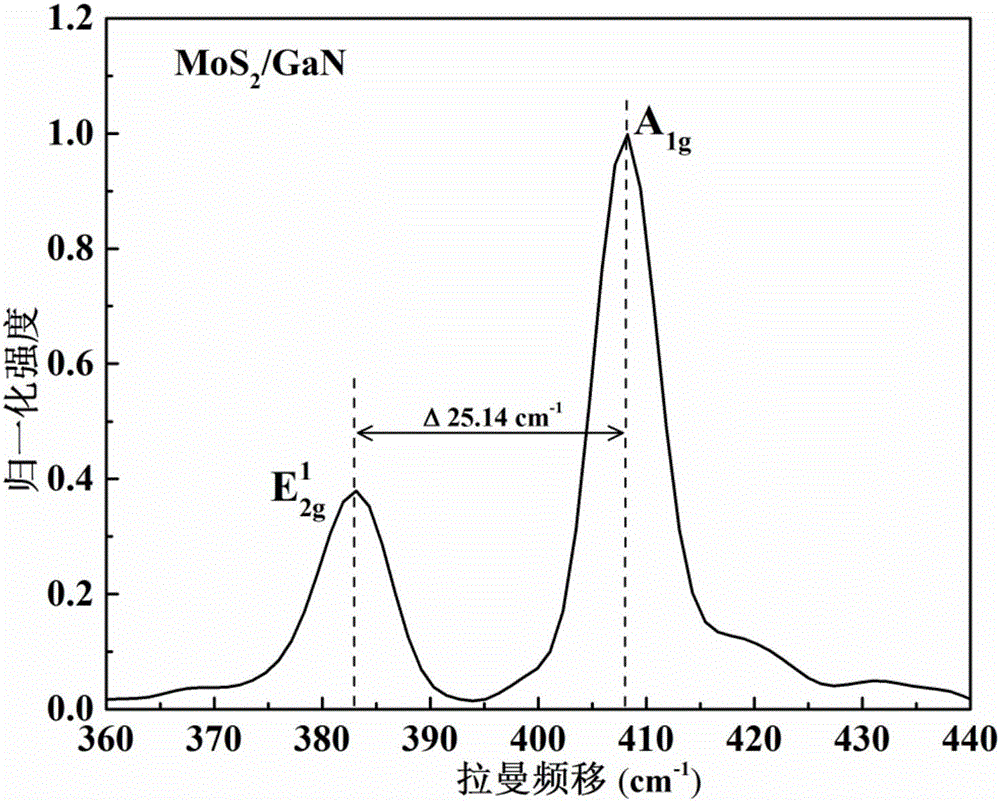

InactiveCN105970296AQuality improvementContains less impuritiesPolycrystalline material growthFrom chemically reactive gasesSulfurChemical vapor deposition

The invention is applicable to the technical field of inorganic nano film materials and provides a preparation method of a molybdenum disulfide film, comprising: using a substrate of sapphire, and growing an MoS2 film on a surface of the substrate by means of CVD (chemical vapor deposition); the process of growing the MoS2 film includes: using sulfur powder and MoO3 as materials and high-purity argon as a carrier gas, depositing the MoS2 film on the substrate. The invention further provides the molybdenum disulfide film prepared by the method. According to the molybdenum disulfide film and the preparation method thereof provided by the invention, the molybdenum sulfide material used is highly bondable with the substrate material sapphire, the quality of the obtained MoS2 film is very high, and the requirements of the electronics field and optical field for the quality of nano film materials can be met.

Owner:SHENZHEN UNIV

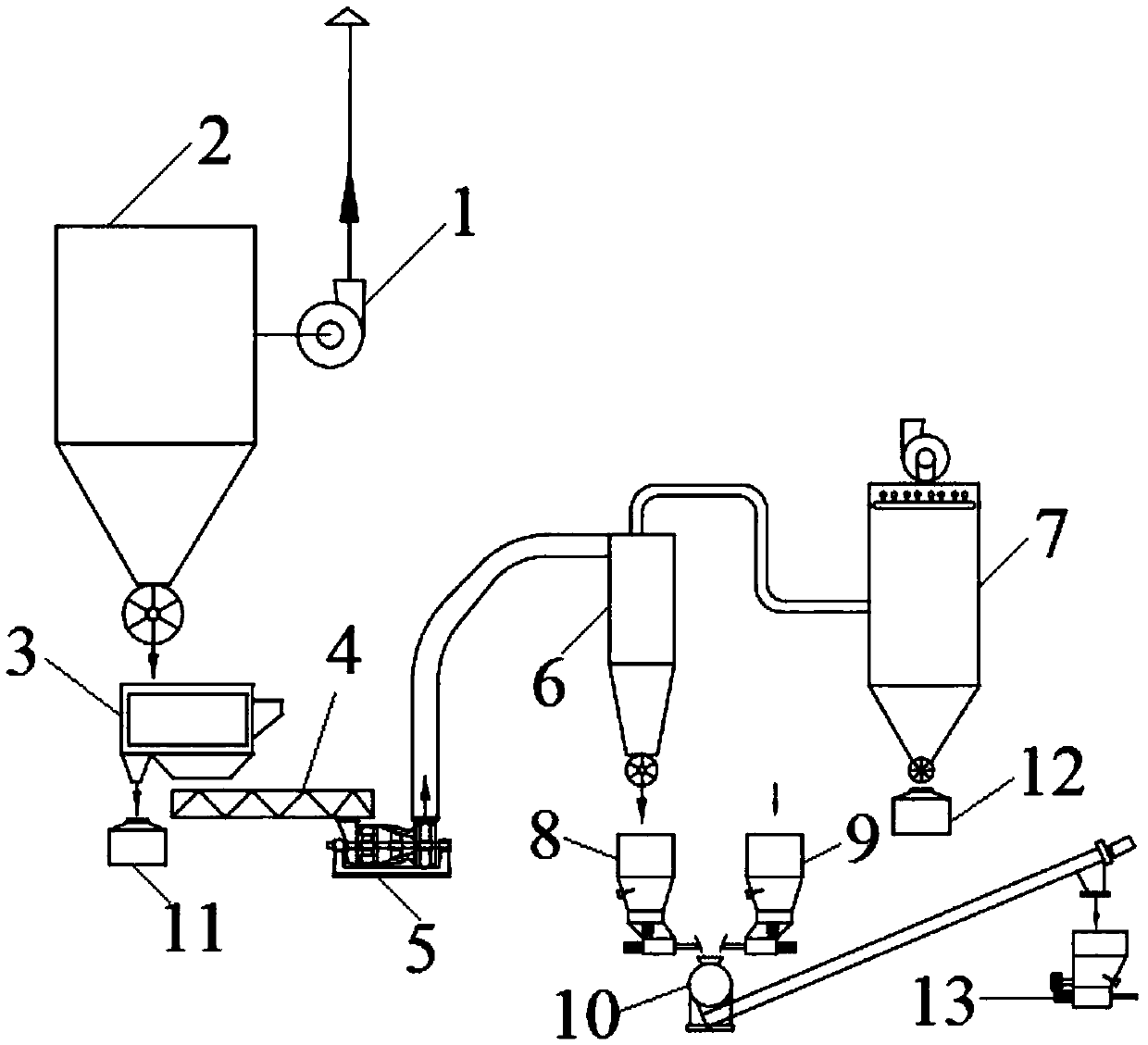

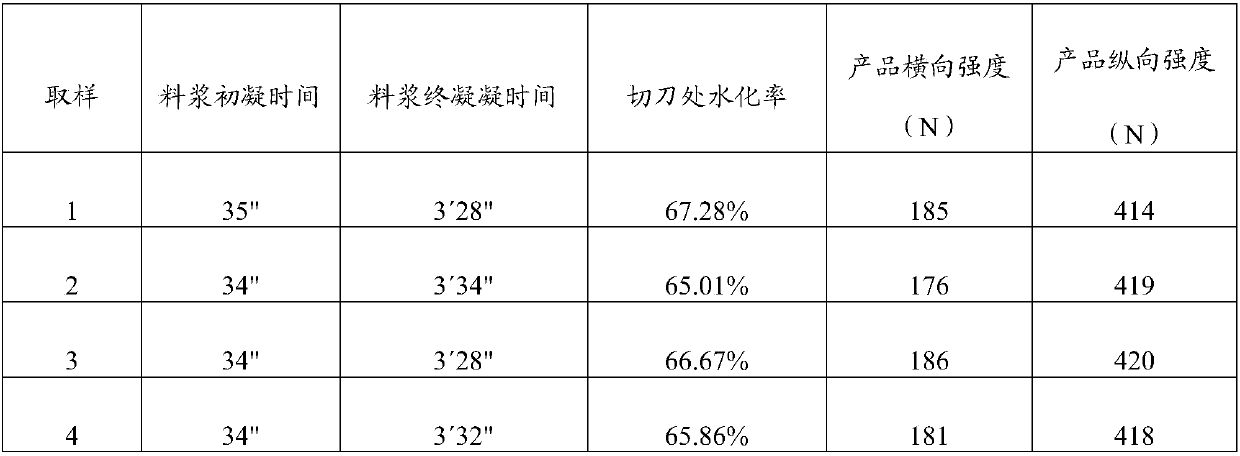

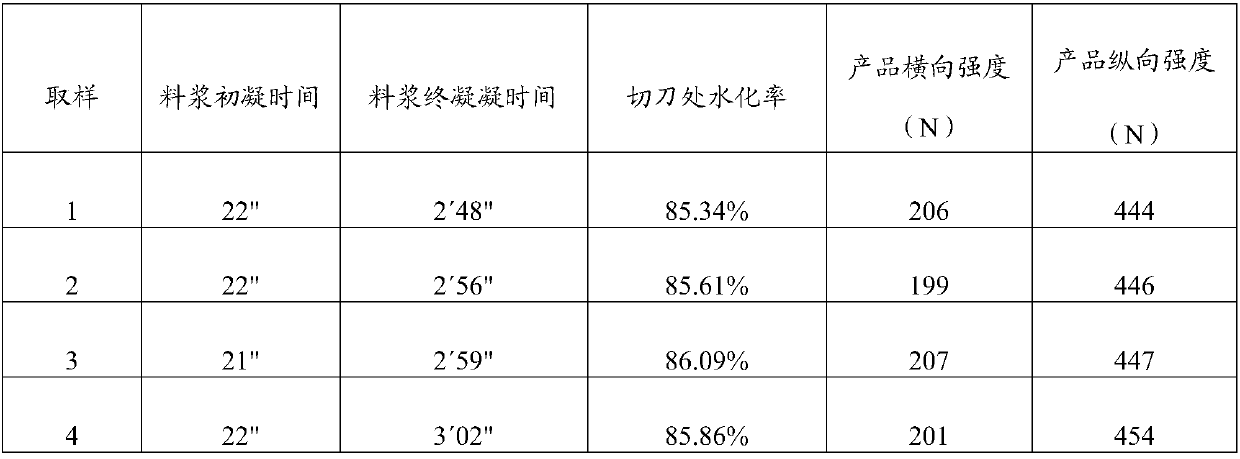

High-efficiency coagulant preparation system and process

The invention provides a high-efficiency coagulant preparation system. The system comprises a dust collecting fan, a first bag-type dust remover, a rotary screen, a first conveyor, a pulverizer, a cyclone separator, a second bag-type dust remover, a second conveyor, a third conveyor and a ball mill. The invention further provides a high-efficiency coagulant preparation process. According to the efficient coagulant preparation system and process, impurities in gypsum board cut materials can be effectively removed, and a coagulant with low fineness and good coagulation promoting effect can be prepared.

Owner:北新建材(嘉兴)有限公司 +1

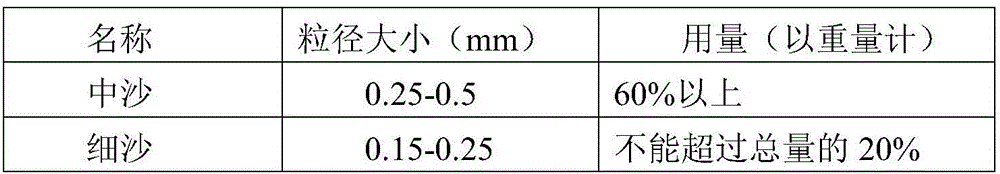

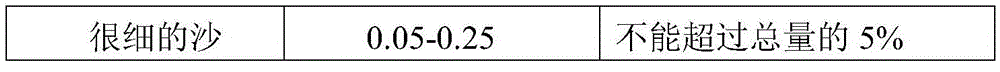

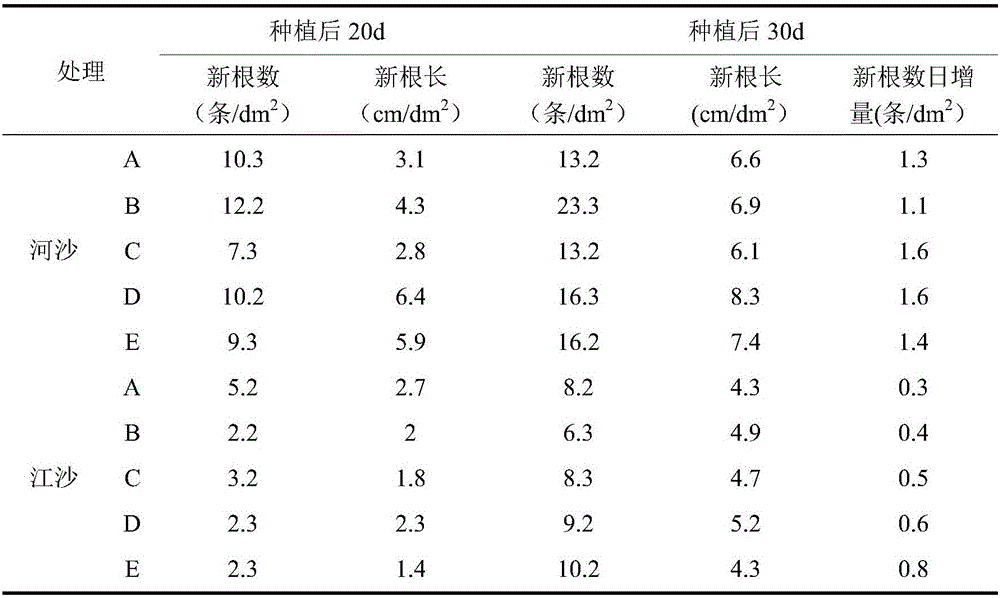

Method for establishing zoysia plant lawn with river sand as matrix

InactiveCN106233955AModerate surface roughnessPromote growthHops/wine cultivationTurf growingDisease damageZoysia

The invention discloses a method for establishing a zoysia plant lawn with river sand as a matrix. The method comprises the following steps that firstly, a soil bed is prepared; secondly, river sand is used for covering; thirdly, creeping stems and erect stems of zoysia plants are collected; fourthly, theziysia stems are planted; fifthly, management after establishing is carried out, wherein 1, watering, 2, topdressing and 3, trimming are carried out. Compared with the prior art, the method has the advantages of the method for establishing a lawn through sand cultivation, and the number of new roots, the length of the new roots and the daily increasing number of the new roots of the planted zoysia plants can be effectively increased with the special river sand in combination with other treatment methods; meanwhile, the method has the advantages that operation is easy and convenient, the growth cycle is short, the survival rate is high, no damage is caused to soil resources, and the incidence rate of pest and disease damage and weeds is low.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Method for measuring content of platinum, palladium, and rhodium in waste automobile exhaust catalyst

ActiveCN106770200AAvoid interferenceEnrichment method is simplePreparing sample for investigationAnalysis by thermal excitationPlatinumRepeatability

The invention discloses a method for measuring the content of platinum, palladium, and rhodium in a waste automobile exhaust catalyst. The method comprises the following steps: (1) preparing reagents; (2) fusing and enriching the metals namely platinum, palladium, and rhodium; (3) drawing a standard work curve; (4) dissolving a sample and measuring the solution; and (5) calculating the content of platinum, palladium, and rhodium. The method can effectively avoid the interference of the matrix in the catalyst, the measurement result is accurate, and the repeatability is good.

Owner:GEM WUHAN URBAN MINE RECYCLING IND PARK DEV +2

Building solid waste recycled concrete admixture

PendingCN112723773AImprove usabilityImproves carbonation resistanceSolid waste managementEnvironmental engineeringRebar

The invention relates to the technical field of building solid waste recycled concrete, in particular to a building solid waste recycled concrete admixture, which comprises the following steps of S1, building solid waste crushing pretreatment, S2, sorting: magnetic sorting and sundry sorting, S3, crushing, S4, flushing and screening: screening the metal reinforcing steel bars, the recycled micro powder, the recycled aggregate and the high-quality recycled sand powder, S5, ultrafine grinding of the recycled fine aggregate or sand powder, and S6, chemical strengthening and physical strengthening of the admixture. The concrete fragments are subjected to building solid waste crushing pretreatment, sorting, crushing, washing and screening, recycled fine aggregate or sand powder superfine grinding and chemical strengthening and physical strengthening of the admixture, the high-quality recycled aggregate with good grading and low impurity content can be obtained through the production mode, and by adjusting a screen, products with different particle sizes and different gradations can be obtained so as to meet various requirements.

Owner:郑加专

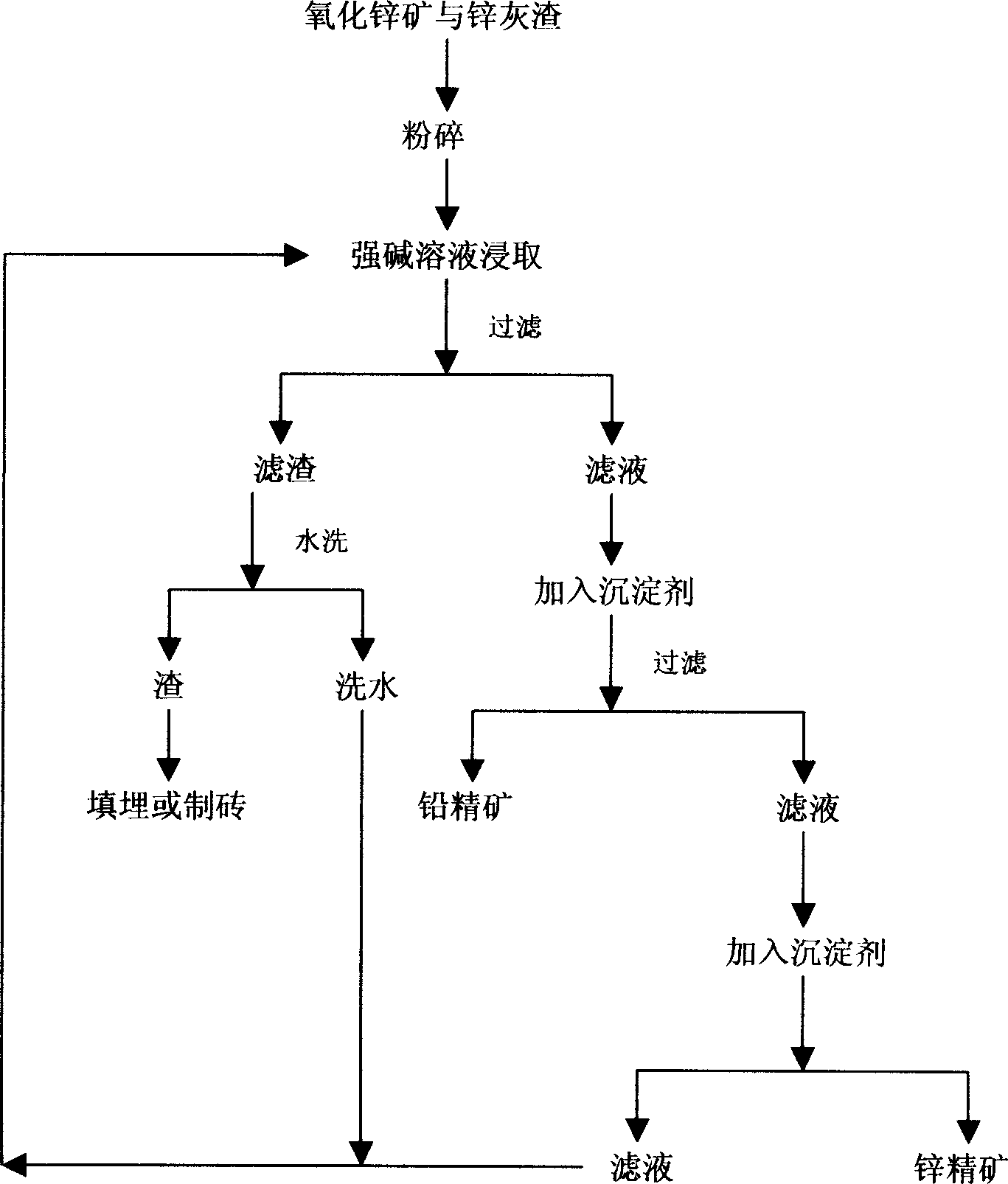

Mehtod for producing zinc concentrate and lead concentrate using zinc oxide ore and zinc slag

InactiveCN1858275AGood environmental and social benefitsSimple processProcess efficiency improvementSlagLow graded

The process of producing zinc concentrate and lead concentrate with zinc oxide and zinc slag includes the following steps: grinding material to granularity of 0.1-1mm, leaching in strong alkaline solution, stirring at 10-100deg.c for 60-100 min to leach out zinc and lead from the material; filtering, water washing filter residue, and producing slag brick or land filling of filter residue; adding precipitant in 0.5-3 times the lead content, stirring for 60 min, and filtering to obtain lead concentrate; adding precipitant in the amount of 0.5-5 times zinc content, stirring at 10-100 for 1-5 hr and filtering to obtain zinc concentrate; and returning filtrate and washing water for reuse. The present invention has simple technological process, low production cost and no environmental pollution, and can utilize zinc and lead resource, especially low grade resource, effectively.

Owner:TONGJI UNIV

Process for producing anode copper by adoption of four connected furnaces

InactiveCN105002371AAchieve separationInto continuous stabilityRotary drum furnacesCrucible furnacesSlagSlow cooling

The invention provides a process for producing anode copper by adoption of four connected furnaces. The process is particularly characterized in that a smelting furnace, a slagging furnace, a copper preparation furnace and an anode furnace are connected in series from front to back and are connected through chutes. The process mainly comprises the steps that copper concentrate and flux enter the smelting furnace to react with oxygen-enriched air to generate smelting slag and copper matte, and the smelting slag continuously overflows and is put into a slow cooling slag bag through the corresponding chute; the copper matte is siphoned to continuously flow into the slagging furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, white matte and high-temperature smoke; the converting slag continuously overflows and is put into the slow cooling slag bag through the corresponding chute; the white matte is siphoned to continuously flow into the copper preparation furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, crude copper and high-temperature smoke; copper preparation slag is discharged regularly and is quenched and broken to return to the slagging furnace; crude copper is siphoned and continuously or discontinuously flows into the anode furnace through the corresponding chute, the anode furnace operates alternately, and anode copper is obtained through oxidation and reduction. The process achieves continuous operation of the crude copper production process.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

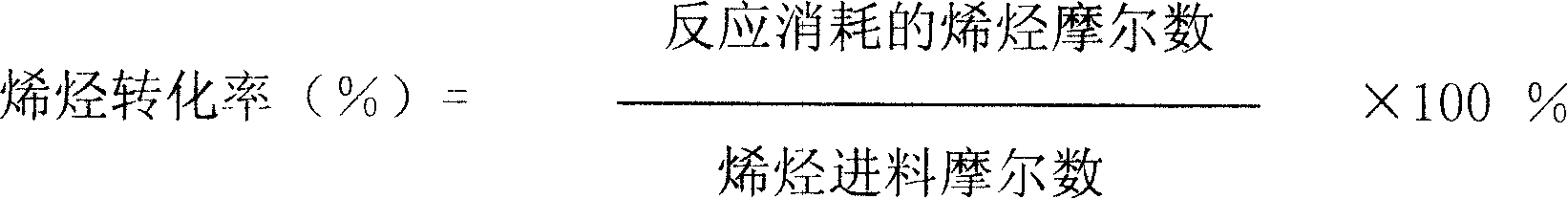

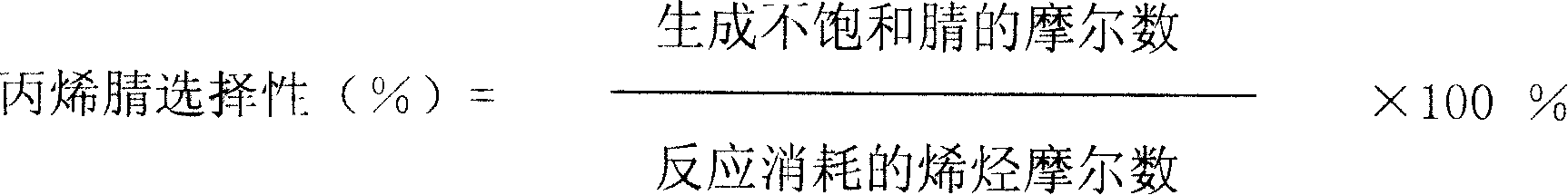

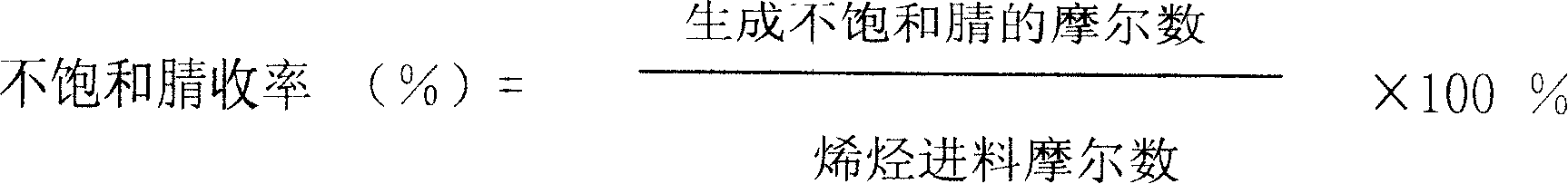

Catalyst for olefin ammoxidation producing unsaturated nitriles

ActiveCN101168129AIncrease reaction pressureExtended service lifeCatalyst carriersCarboxylic acid nitrile preparationReaction temperatureCerium

The invention is a catalyst used in the producing of unsaturated nitriles by the ammonoxidation of olefin, in particular to a catalyst adaptable for the producing of acrylonitrile and methacrylonitrile by the ammonoxidation of propylene and butylenes. A general formula of the active component of the catalyst is a complex of catalytic oxidation of BiaFebNicMgdLaeC1gAlhAiBjCkMo12Ox, wherein the A isone element or a compound of more than two elements of lithium, potassium, rubidium and caesium, the B is one element or a compound of more than two elements of cerium, gadolinium and samarium, and the C is one element or a compound of more than two elements of zinc, manganese, cobalt, calcium, copper, wolfram and phosphorus. The catalyst is capable of producing unsaturated nitriles of which theyield rate reaches to 84% or higher under the condition of high catalyst load, high reaction pressure, low reaction temperature, low ratio of air and olefin and low ratio of ammonia and olefin, and with the adoption of the catalyst, the catalyst is capable of long-term operation under the condition of low reaction temperature, and the catalyst has long service life. Further, reaction products havea small amount of impurity substances, and the catalyst is environment friendly.

Owner:PETROCHINA CO LTD +1

Method for preparing molybdenum disulfide thin film by taking GaN as substrate

InactiveCN106098533AQuality improvementContains less impuritiesSemiconductor/solid-state device manufacturingSemiconductor devicesSulfurOptoelectronics

The invention is applicable to the technical field of inorganic nano-film materials, and provides a method for preparing a molybdenum disulfide thin film using GaN as a substrate, using GaN as a substrate, and using CVD to generate MoS on the surface of the substrate 2 thin films; the generation of MoS 2 The process of thin film is: with sulfur powder and MoO 3 as the raw material, high-purity argon as the carrier gas, depositing MoS on the substrate 2 film. The present invention also provides a molybdenum disulfide thin film, which is prepared by the above-mentioned preparation method. In the molybdenum disulfide thin film and preparation method thereof provided by the present invention, the bonding force between the molybdenum sulfide material and the substrate material GaN is extremely strong, and the prepared MoS 2 The quality of the thin film is extremely high, which can meet the quality requirements for nano thin film materials in the fields of electricity and optics.

Owner:SHENZHEN UNIV

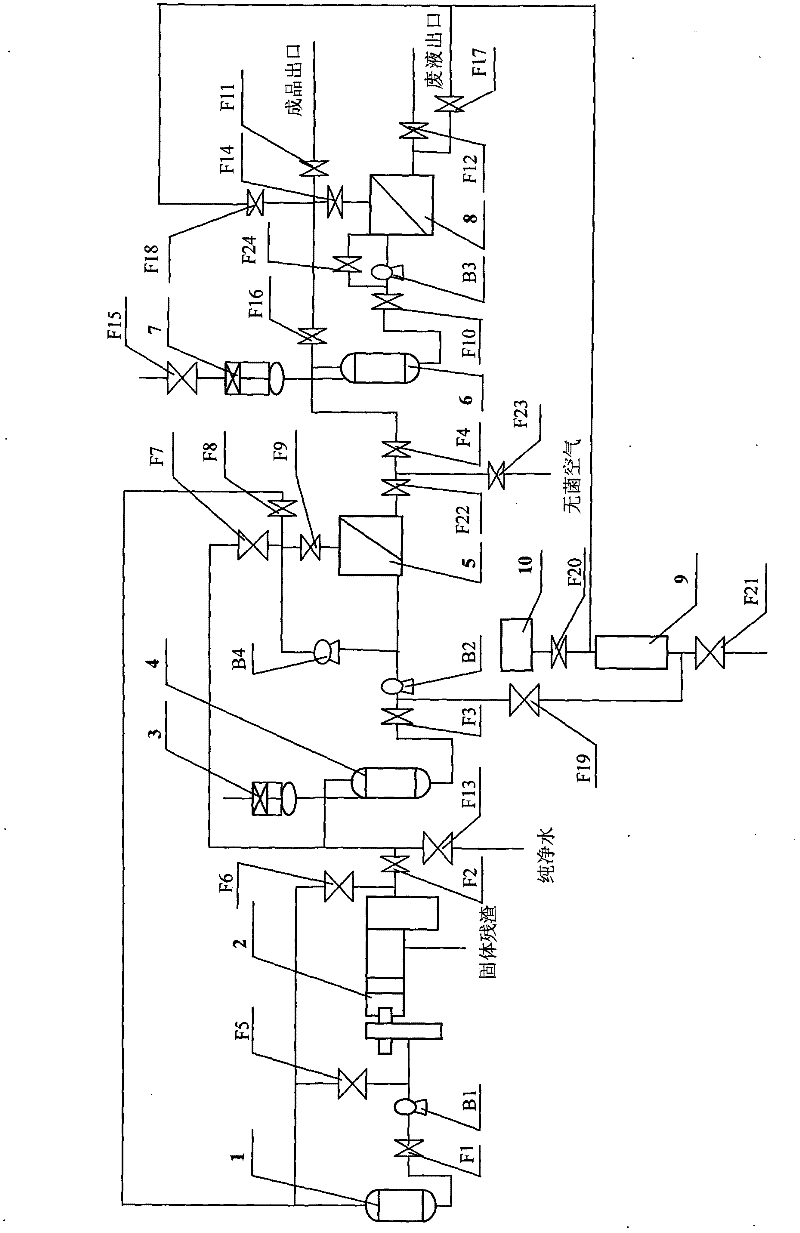

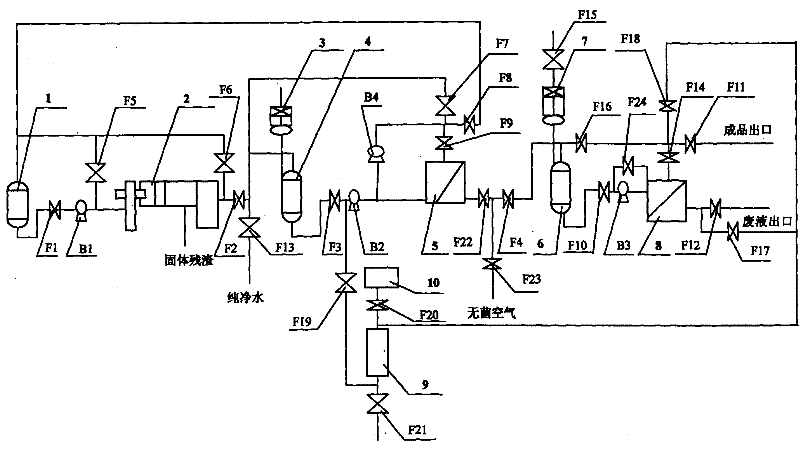

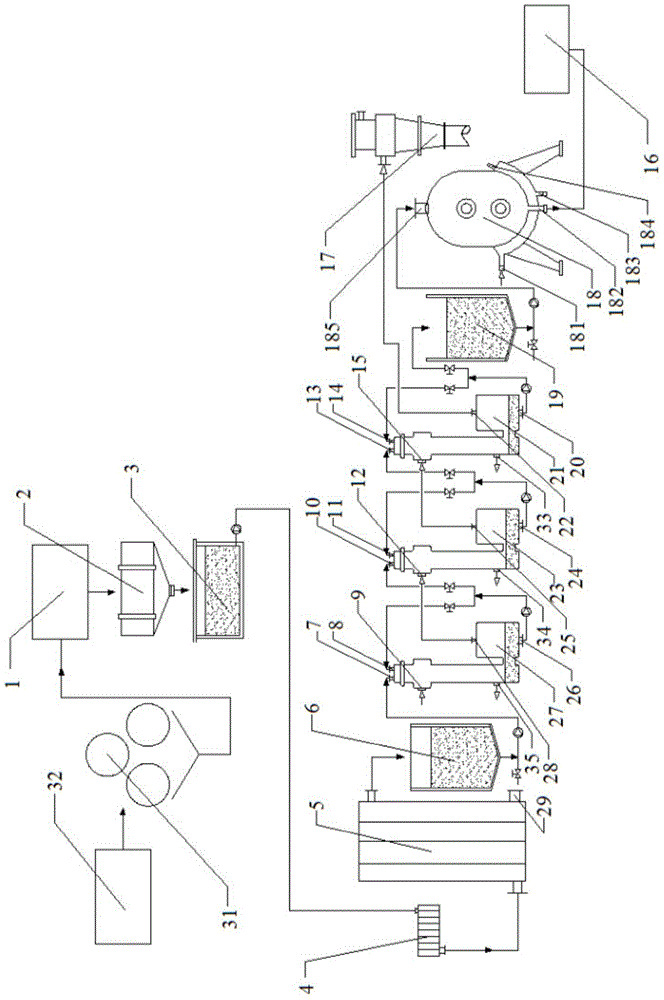

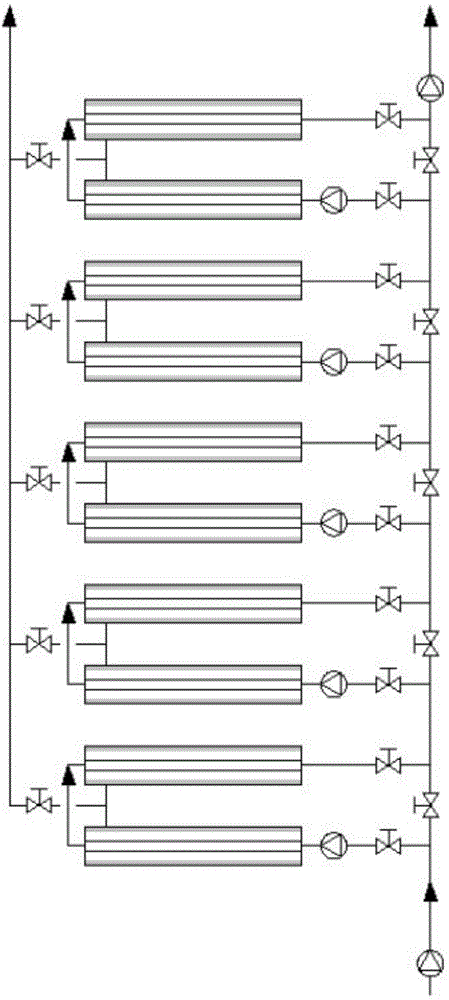

Multifunctional post-extraction production line for enzyme preparation fermentation liquid

InactiveCN102399687AReduce labor intensityLow moisture content in solidsBiological substance pretreatmentsApparatus sterilizationProduction lineWastewater

The invention discloses a multifunctional post-extraction production line for an enzyme preparation fermentation liquid, and the provided post-extraction production line for an enzyme preparation fermentation liquid has multiple functions of improving enzyme preparation purity, regulating enzyme liquid activity, reducing wastewater discharge, realizing sterile ultrafiltration and condensation, solving a finished product residual liquid, etc. The multifunctional post-extraction production line for an enzyme preparation fermentation liquid in the invention is characterized by making fully use of the advantages of plate and frame filter pressing, tubular membrane microfiltration, and rollup membrane ultrafiltration in solid-liquid separation and liquid-liquid separation respectively. By means of structural design of each operation unit detail and perfect combination, the post-extraction production line of the invention achieves substantial effects in degerming, deslagging, active ingredient purification, sterile condensation, finished product residual liquid recovery, labor intensity reducing, as well as energy saving and emission reduction, etc.

Owner:淮北市三和诺生物工程有限责任公司

Method for recovering waste secondary battery iron

InactiveCN106099238AAchieve removalImprove crushing efficiencyWaste accumulators reclaimingProcess efficiency improvementRecovery methodEngineering

The invention relates to a method for recovering a battery, and more particularly relates to a method for recovering waste secondary battery iron. The technical problem to be solved by the invention is to provide a method for recovering the waste secondary battery ion, with high recovery efficiency, and few impurities. The final product iron is obtained by discharging, roasting, crushing, smashing, sieving, shaking separation, magnetic separation and other methods, thereby recovering and utilizing iron. Compared with the prior art, the secondary crushing is carried out, so that the crushing efficiency of the waste secondary battery is greatly improved, the crushed particles are more uniform, and the substances are separated more thoroughly by the following smashing, and thus the impurities of the product iron are few; meanwhile, the substances are separated more thoroughly by secondary crushing and following smashing, so that the magnetic separation can be directly carried out, and the recovery efficiency is high; the impurities are few, so that the iron can also be used for reprocessing, without a follow-up clean-up process, thus greatly simplifying the processing flow.

Owner:GANZHOU HIGHPOWER TECH CO LTD

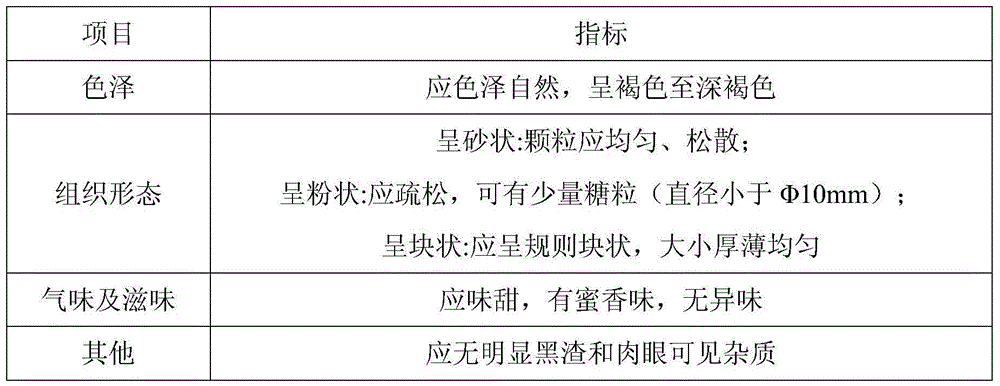

Originally ecological black sugar processing device

ActiveCN104805224ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

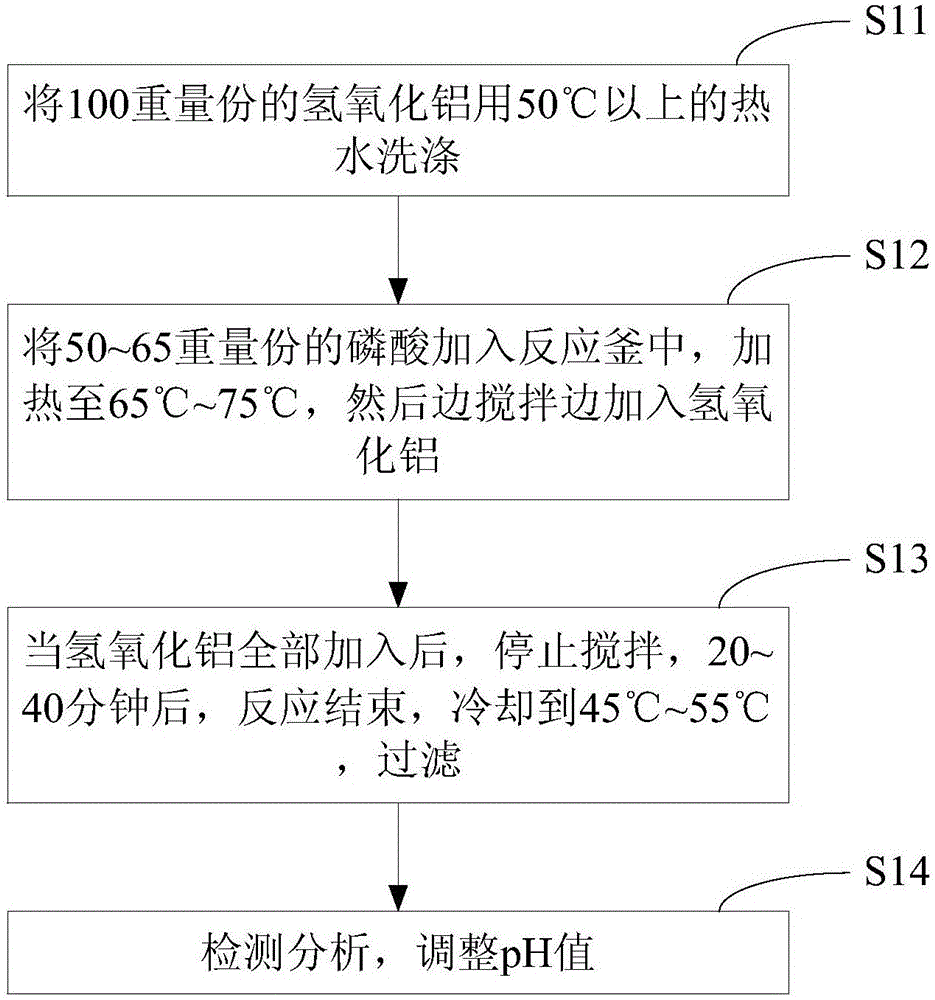

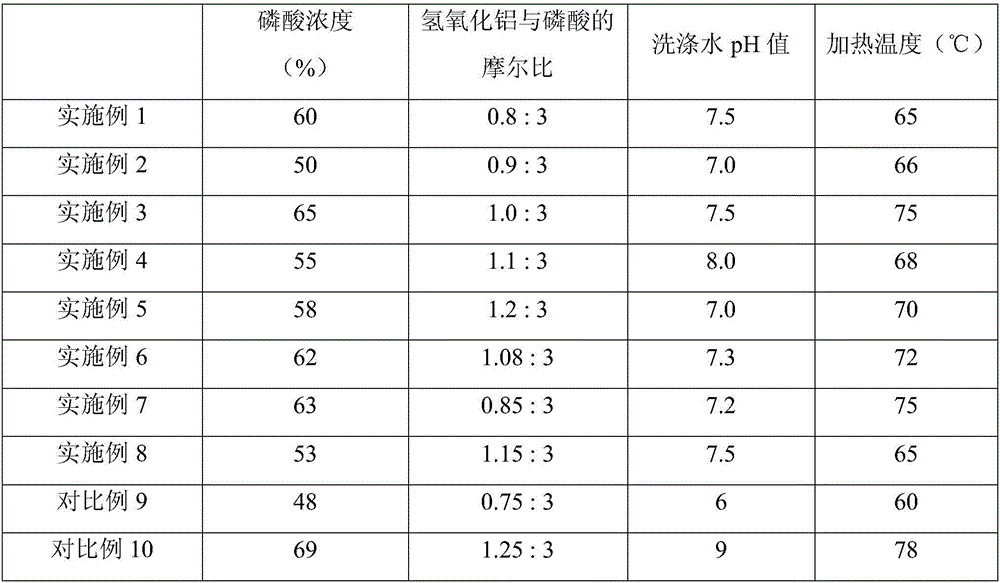

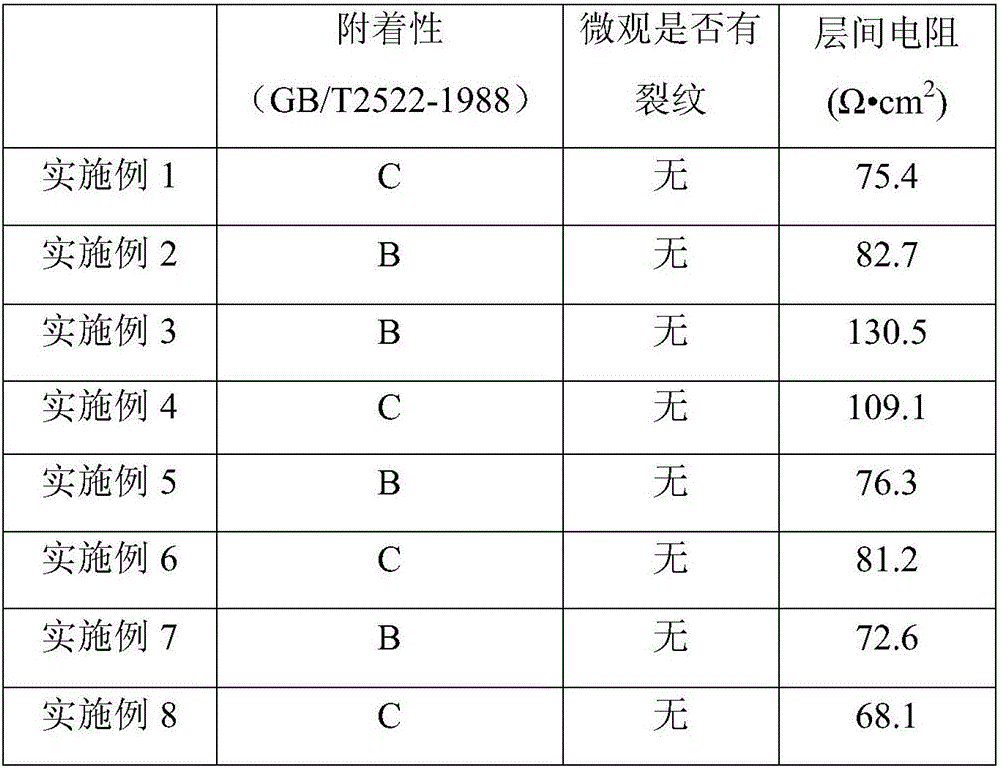

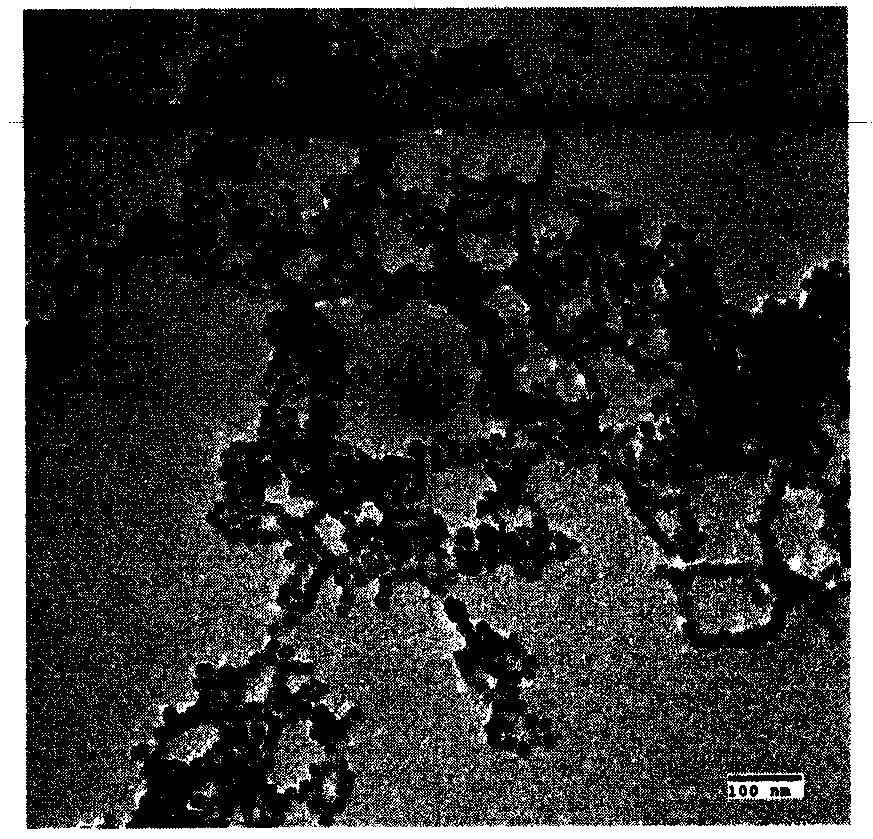

Preparation method of aluminium dihydrogen phosphate paint for silicon steel

InactiveCN106497164AContains less impuritiesImprove stabilityCoatingsPhosphorus compoundsAluminium hydroxidePhosphate

The invention relates to a preparation method of aluminium dihydrogen phosphate paint for silicon steel. The preparation method of aluminium dihydrogen phosphate paint for silicon steel comprises the following steps: washing 100 parts by weight of aluminium hydroxide by the use of hot water of 50 DEG C and above; adding 50-65 parts by weight of phosphoric acid into a reaction vessel, heating to 65-75 DEG C, and stirring while adding aluminium hydroxide; stopping stirring after adding all aluminium hydroxide, finishing the reaction after 20-40 min, cooling to 45-55 DEG C, and filtering; and defecting and analyzing, and regulating pH value. The produced aluminium dihydrogen phosphate contains few impurities and is easy to be compatible with other components in the paint for silicon steel. Stability of an insulating coating solution is raised. In addition, free phosphoric acid in the prepared aluminium dihydrogen phosphate is reduced such that cracks on the surface of the coating are reduced. Thus, it helps enhance insulating property and adhesion of the coating.

Owner:湖北武洲新材料科技有限公司

Double-furnace blister copper continuous converting process

InactiveCN104532015ALow running costHigh recovery rateRotary drum furnacesCrucible furnacesChemical reactionSlag

The invention relates to the production process technology of double-furnace blister copper continuous converting. According to the technical scheme, a double-furnace blister copper continuous converting process is uniquely characterized in that two furnace kilns which are arranged front and back continuously complete the process of forming blister copper through copper matte by means of converting, and the two furnace kilns are named as a slag formation furnace and a copper formation furnace. The process flow includes the steps that the copper matte produced by a smelting furnace continuously flows into the slag formation furnace, and in the slag formation furnace, the copper matte chemically reacts with solvent added into the slag formation furnace and oxygen-enriched air blown into the slag formation furnace, so that converting slag, white copper matte and high-temperature gas are generated; the converting slag is continuously discharged out of a slag discharge opening in an overflow mode, and placed in a slow cooling slag ladle through a chute, the white copper matte sinks to the furnace bottom, is discharged through siphoning and continuously flows into the copper formation furnace through the chute, and the high-temperature gas enters a waste heat boiler; in the copper formation furnace, the white copper matte chemically reacts with the solvent and the oxygen-enriched air which is blown in, so that the blister copper, a trace of converting slag and the high-temperature smoke are generated; the blister copper is continuously or intermittently discharged through siphoning by means of the chute, the converting slag is regularly discharged out of the slag discharge opening in the overflow mode, and the high-temperature gas enters the waste heat boiler.

Owner:CHIFENG YUNTONG NONFERROUS METALS +1

Process for producing granular rare earth chloride crystals by using rare earth chloride solution

InactiveCN103172102AContains less impuritiesUniform particlesRare earth metal compoundsHydrogen chlorideImpurity

The invention relates to a process for producing granular rare earth chloride crystals by using a rare earth chloride solution, which belongs to the field of rare earth hydrometallurgy. According to the invention, a hydrochloric acid is added into the rare earth chloride solution, and after the pH value of the obtained mixture is 1-3, the obtained mixture is evaporated, so that the mass concentration of the obtained mixture is increased to 700-750g / L; water vapor and escaped hydrogen chloride gas are condensed and then recycled; the solution subjected to evaporation enters a cooling system through self-flowing, so that the solution is cooled to room temperature and crystallized; then the crystallized solution is fed into a centrifugal machine to carry out solid-liquid separation; and mother liquor is recycled, and solids are granular rare earth chloride crystals. According to the invention, a hydrochloric acid is added into the rare earth chloride solution to adjust the pH value, so that the impurity content of products is low; through concentration control, granules are uniform and stable in quality; the process method is simple in operation, short in production cycle and serialized; the rare earth content of produced granular rare earth chloride crystals can reach 62-67%; and escaped hydrogen chloride steam and water vapor, after recovered by a condensing system, is reused, therefore, an effect of industrialized production is easily achieved.

Owner:BAOTOU HUAMEI RE PRODS

Preparation method of small particle size ferroferric oxide magnetic nano particles

InactiveCN108285176AUniform particle size distributionContains less impuritiesMaterial nanotechnologyFerroso-ferric oxidesMagnetite NanoparticlesIron(II,III) oxide

The invention relates to a preparation method of small particle size ferroferric oxide magnetic nanoparticles, wherein the small particle size nano particles have a particle diameter of 10-20 nm, andare prepared by a high temperature pyrolysis method for decomposing iron oleate. As an important nanomaterial, the obtained ferroferric oxide magnetic nanoparticles have broad application prospects inthe fields of magnetic recording materials, wave absorbing materials, pigments, catalysts, and biomedicine and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Total-thermal-state copper matte continuous converting method

The invention relates to a total-heat-state copper matte continuous converting method, and belongs to the technical field of metallurgical processes. According to the method, a novel smelting and converting metallurgical furnace configuration mode is adopted, configuration and operation are optimized, and a smelting furnace and a converting furnace are connected, so that the continuous smelting-converting process of continuously treating copper concentrate, continuously blowing air, continuously feeding hot copper matte into the furnace, continuously slagging, continuously discharging slag andcontinuously or discontinuously discharging blister copper is realized. According to the method, a clean, safe and environment-friendly process is achieved, the cost is reduced, potential safety hazards are reduced, and industrial production is facilitated.

Owner:黑龙江紫金铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com