Method for preparing molybdenum disulfide thin film by taking GaN as substrate

A molybdenum disulfide and thin-film technology, which is used in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of uncontrollable electrical properties of devices and inability to meet electronic components, so as to facilitate industrial production and meet quality requirements. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Clean the GaN substrate, the cleaning process is as follows:

[0032] 1. Ultrasonic cleaning with acetone and deionized water;

[0033] 2. Ethanol ultrasonic cleaning, deionized water cleaning;

[0034]3. Sulfuric acid: nitric acid = 1:1, cook at 80°C for several minutes, rinse with deionized water;

[0035] 4. Hydrochloric acid: hydrogen peroxide: water = 3:1:1, shake gently for a few minutes, rinse with deionized water;

[0036] 5. Hydrofluoric acid: water = 1:20, shake gently for a few minutes, rinse with deionized water;

[0037] 6. Rinse several times in a beaker of deionized water and rinse with running water.

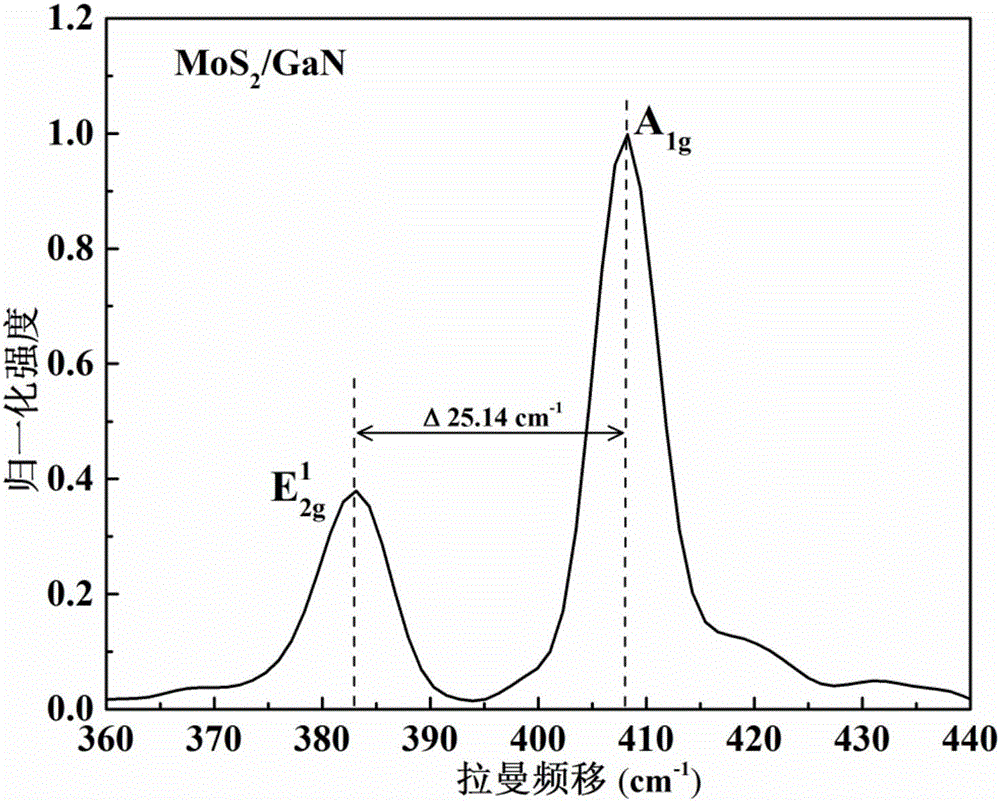

[0038] 2. Using sulfur powder and MoO 3 (99.9%, analytically pure) is the source of sulfur and molybdenum, high-purity argon is used as the carrier gas, and MoS is deposited on GaN by CVD 2 film. The growth temperature is 700° C., the mass of the sulfur source is 0.8 g, the mass of the molybdenum source is 0.04 g, and the pressure is normal pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com