Method for recovering waste secondary battery iron

A secondary battery and recycling method technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of a large amount of impurities, low iron recovery efficiency, poor battery crushing effect, etc., to achieve complete separation and recycling The effect of high efficiency and improved crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

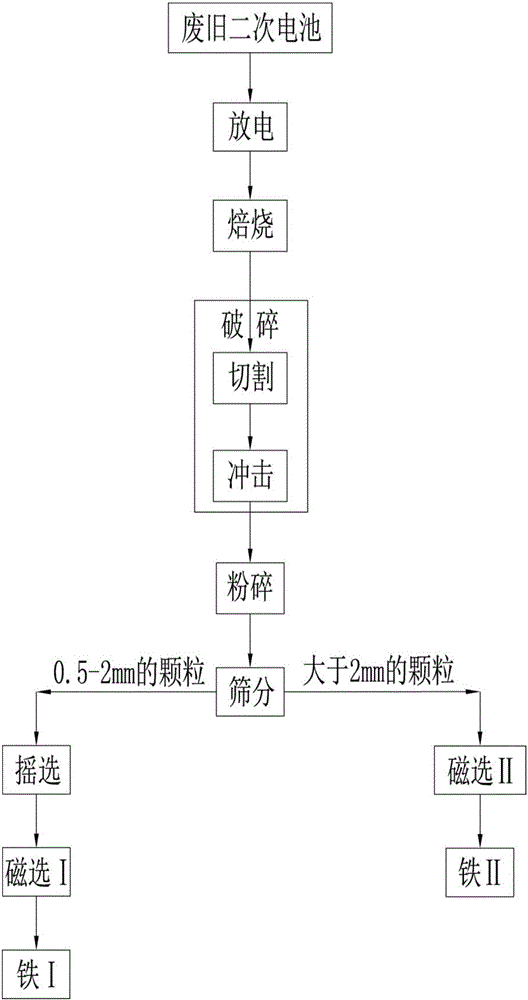

[0029] A kind of recycling method of waste secondary battery iron, such as figure 1 As shown, it specifically includes the following steps:

[0030] a. Put the waste Ni-MH battery into the tank filled with electrolyte, so that the residual power in the waste Ni-MH battery is fully discharged;

[0031] b. Evenly send the discharged waste nickel-hydrogen batteries into the combustion chamber of the rotary kiln for roasting, the roasting temperature is 700°C, and the roasting time is 2.5 hours, and the easily decomposed organic solvents and electrolytes in the waste nickel-hydrogen batteries are heated, decomposed and released;

[0032] c. Preliminarily cut the roasted waste Ni-MH batteries with a vertical crusher, cut the waste Ni-MH batteries, and then use a double-shaft shredder for in-depth impact treatment to completely tear the waste Ni-MH batteries crushed, and then crushed with an energy-saving ball mill to crush and separate the different substances;

[0033] d. Sieve ...

Embodiment 2

[0038] A kind of recycling method of waste secondary battery iron, such as figure 1 As shown, it specifically includes the following steps:

[0039] a. Put the waste lithium battery into the tank filled with electrolyte, so that the residual power in the waste lithium battery is fully discharged;

[0040] b. Evenly send the discharged waste lithium batteries into the combustion chamber of the rotary kiln for roasting, the roasting temperature is 900°C, and the roasting time is 1.5 hours, and the easily decomposed organic solvents and electrolytes in the waste lithium batteries are decomposed and released by heating;

[0041] c. Preliminarily cut the roasted waste lithium battery with a vertical crusher, cut the waste lithium battery, and then use a double-shaft shredder for in-depth impact treatment to completely shred the waste lithium battery, and then , and then crushed with an energy-saving ball mill to crush and separate the different substances;

[0042] d. Sieve the p...

Embodiment 3

[0047] A kind of recycling method of waste secondary battery iron, such as figure 1 As shown, it specifically includes the following steps:

[0048] a. Put the waste lithium battery into the tank filled with electrolyte, so that the residual power in the waste lithium battery is fully discharged;

[0049] b. Evenly send the discharged waste lithium batteries into the combustion chamber of the rotary kiln for roasting, the roasting temperature is 800°C, and the roasting time is 2 hours, and the easily decomposed organic solvents and electrolytes in the waste lithium batteries are decomposed and released by heating;

[0050] c. Preliminarily cut the roasted waste lithium battery with a vertical crusher, cut the waste lithium battery, and then use a double-shaft shredder for in-depth impact treatment to completely shred the waste lithium battery, and then , and then crushed with an energy-saving ball mill to crush and separate the different substances;

[0051] d. Sieve the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com