Preparation method of small particle size ferroferric oxide magnetic nano particles

A technology of magnetic nanoparticles and ferric oxide, applied in iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of easy agglomeration of magnetic particles, wide particle size distribution, and difficulty in preparing magnetic nanoparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

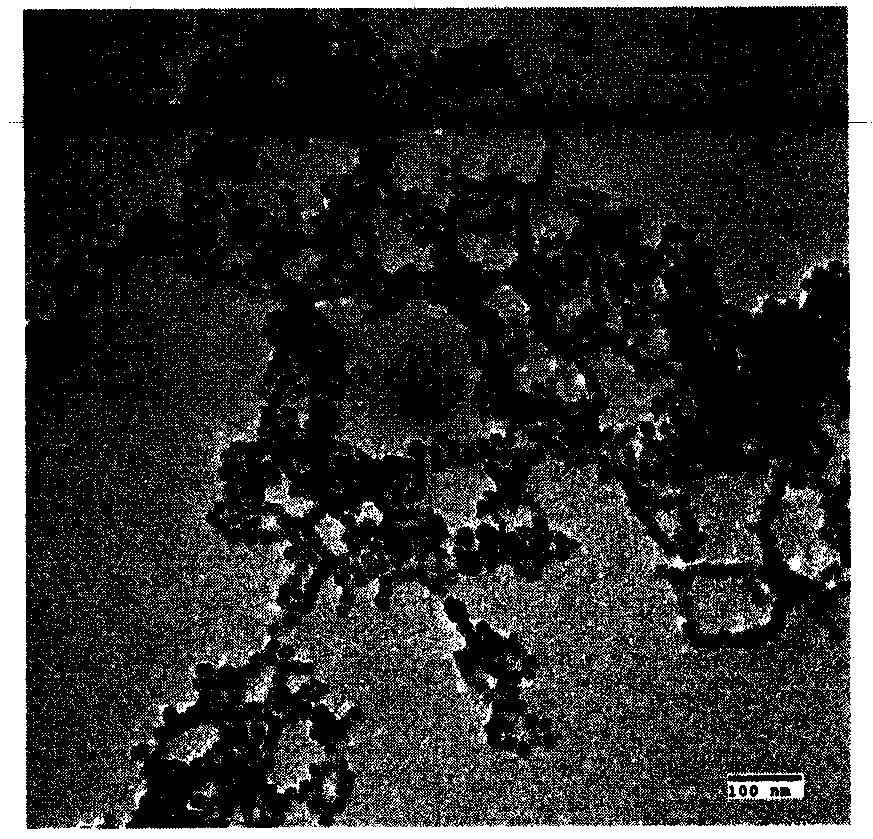

Image

Examples

Embodiment 1

[0021] (1) Put 60mL of ethanol, 10mL of distilled water, and 20mL of n-hexane in a three-neck flask, stir for 10min, then add 1g of ferric chloride and 3.65g of sodium oleate, then stir in an oil bath at 75°C for 4h, cool to room temperature, and separate the liquids Wash and dry in vacuum at 60°C for 12 hours in a watch glass.

[0022] (2) 4g of iron oleate, 25mL of 1-octadecene, and 0.65g of oleic acid are ultrasonically dissolved and poured into a 100mL three-neck flask, distilled under nitrogen protection, first heated to about 100°C, and then heated at 5°C / min to 330°C, keep the temperature for 30min, cool to room temperature, separate and wash with ethanol, and disperse in 30mL cyclohexane.

Embodiment 2

[0024] (1) Put 60mL of ethanol, 10mL of distilled water, and 20mL of n-hexane in a three-neck flask, stir for 10min, then add 1g of ferric chloride and 3.65g of sodium oleate, then stir in an oil bath at 75°C for 4h, cool to room temperature, and separate the liquids Wash and dry in vacuum at 60°C for 12 hours in a watch glass.

[0025] (2) 4g of iron oleate, 20mL of 1-octadecene, and 0.65g of oleic acid are ultrasonically dissolved and poured into a 100mL three-neck flask, distilled under nitrogen protection, first heated to about 100°C, and then heated at 5°C / min to 330°C, keep the temperature for 1h, cool to room temperature, separate and wash with ethanol, and disperse in 30mL cyclohexane.

Embodiment 3

[0027] (1) Put 60mL of ethanol, 10mL of distilled water, and 20mL of n-hexane in a three-neck flask, stir for 10min, then add 1g of ferric chloride and 3.65g of sodium oleate, then stir in an oil bath at 75°C for 4h, cool to room temperature, and separate the liquids Wash and dry in vacuum at 60°C for 12 hours in a watch glass.

[0028] (2) 4g of ferric oleate, 15mL of 1-octadecene, and 0.65g of oleic acid were ultrasonically dissolved and poured into a 100mL three-neck flask, distilled under nitrogen protection, first heated to about 100°C, and then heated at 5°C / min to 330°C, keep the temperature for 2h, cool to room temperature, separate and wash with ethanol, and disperse in 30mL cyclohexane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com