Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce drug costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

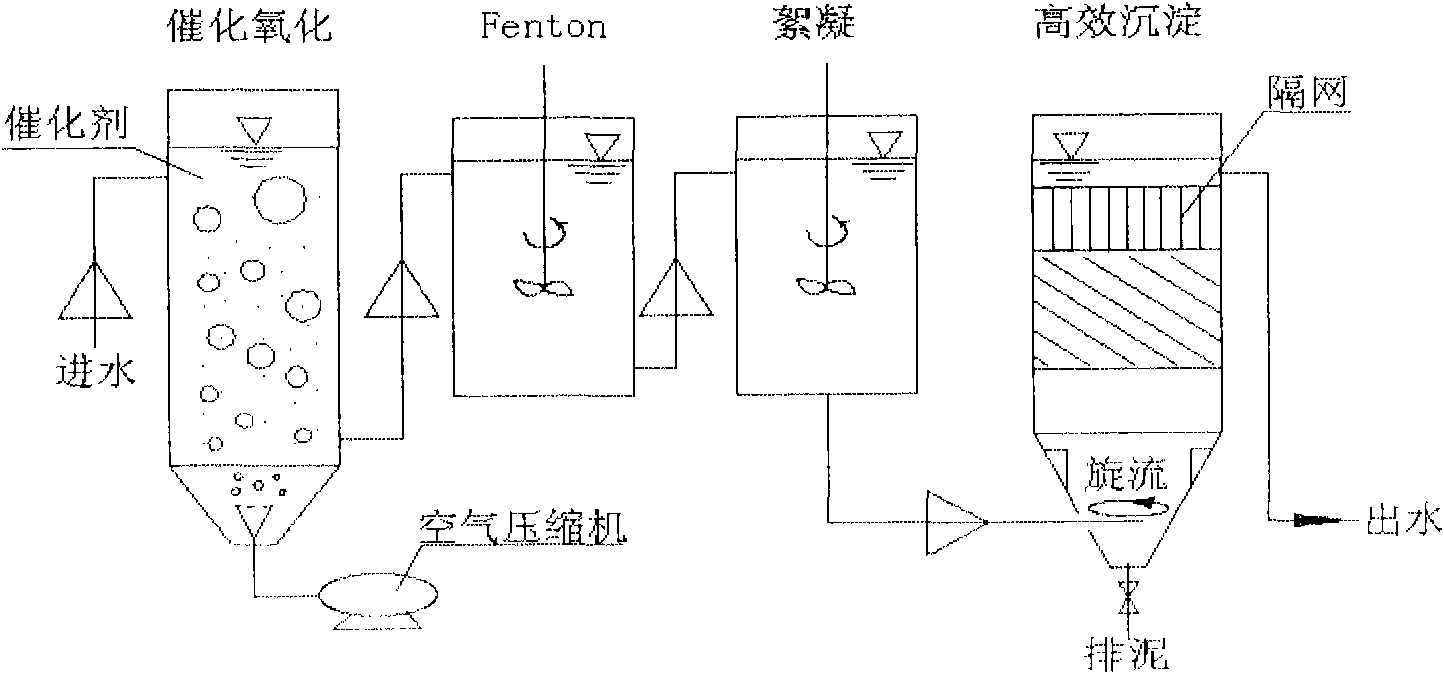

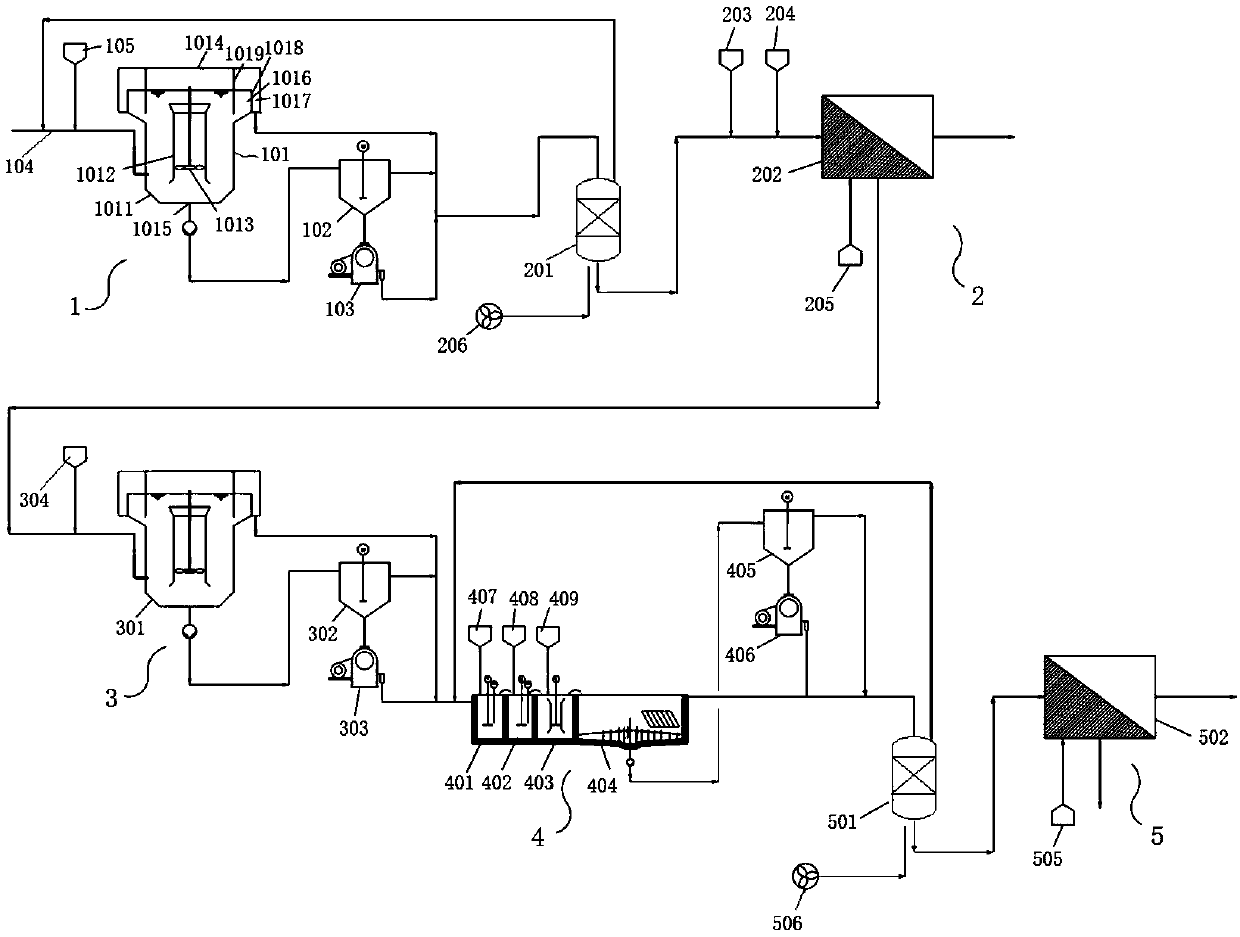

Process for catalytic oxidation-compound flocculation integrated treatment of comprehensive waste water

InactiveCN102126803AReduce drug costsReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationChemistryTreatment effect

The invention provides a catalytic oxidation-compound flocculation integrated treatment process which aims to solve the problem that organic comprehensive waste water is difficult to treat because the organic comprehensive waste water contains organic substances difficult to biologically degrade. The treatment process integrates catalytic oxidation, Fenton oxidation, compound flocculation, high-efficiency precipitation and other technical advantages; a high-efficiency catalyst is used to improve the treatment efficiency or biodegradability; and a compound flocculant is used as the core to simplify the treatment process and ensure the stable treatment effect, thereby achieving the catalytic oxidation-compound flocculation integration. The invention has the characteristics of concise technical line, high treatment efficiency and simple operation process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Combined use method of iron ore anion reverse flotation desulfurizing and silicon reducing agent

The invention discloses a combined use method of an iron ore anion reverse flotation desulfurizing and silicon reducing agent, which comprises the following steps: obtaining iron ore rough concentrates through magnetic selection or magnetogravity combined selection of iron ores achieving base unit dissociation through fine grinding, and adopting anion reverse flotation for the desulfurization andsilicon reduction of the obtained rough concentrates, wherein the agent comprises the components in the following types and dosages (computed according to the flotation feeding dry basis): 80-100g / t of ethyl xanthate, 950-1150g / t of NaOH, 450-600g / t of starch, 320-420g / t of CaO and 600-750g / t of anion reverse flotation collector. The method can remove sulfur as a detrimental impurity in the iron ore concentrates while extracting iron and reducing silicon of the iron ores without considering the influence of numerous foams generated by an oil foamer on an iron separation process, lowers the medicament cost, simplifies the process flow, is easy to implement in production, can be widely used for the iron increase, desulfurization and silicon reduction of magnetite separation plants and hematite separation plants, and can also be used for the desulfurizing and silicon reducing flotation of limonite, martite and semi-martite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Clay-free drilling fluid filter cake removing system

The invention relates to a clay-free drilling fluid filter cake removing system. In the system, cleaning-gelout working solution is prepared by uniformly mixing xylene, petroleum ether, nonylphenol polyoxyethylene ether with the HLB value of 5, nonylphenol polyoxyethylene ether with the HLB value of 13 and 8-10 alcohol polyoxyethylene ether in a weight ratio of 56:25:7:7:5 and mixing clean water,ammonium persulfate, potassium chloride, sodium carbonate, a stratum cleaning agent in a weight ratio of 86:3:2:5:4; corroding-gelout working solution is prepared by mixing the clean water, hydrochloric acid, phosphoric acid, hydrofluoric acid, a corrosion inhibitor SA1-3 and ammonium citrate in a weight ratio of 69.5:15:7.7:5.5:1.8:0.5; and post cleaning working solution is prepared by mixing the clean water, the potassium chloride and the tratum cleaning agent in a weight ratio of 94:2:4. The system has the advantages of obvious improvement on gelout effect, good cleaning effect, high dissolution rate, good anti-swelling effect, strong discharge aiding capability and low corrosion rate.

Owner:PETROCHINA CO LTD

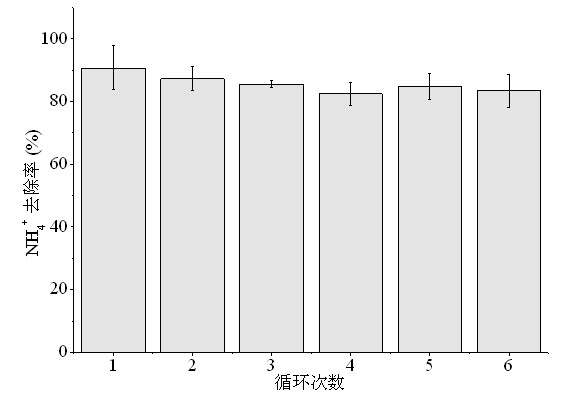

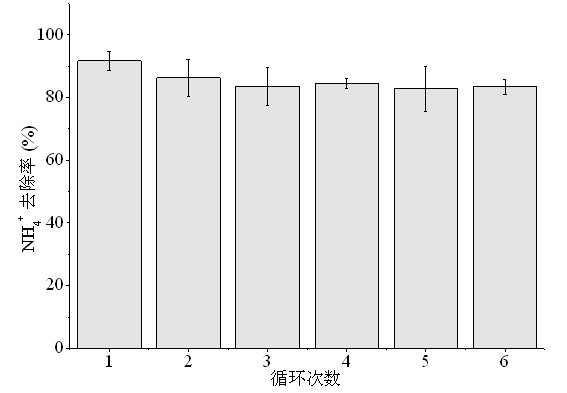

Method for recycling ammonia and nitrogen in waste watery by aid of chemicrystallization

ActiveCN102674523AReduce drug costsIncrease release rateWater/sewage treatmentEnvironmental chemistryMagnesium ammonium phosphate crystals

The invention discloses a method for recycling ammonia and nitrogen in waste water by the aid of chemicrystallization, and belongs to the field of waste water treatment. The method includes (1) adding sodium hydroxide powder into magnesium ammonium phosphate solid, performing pyrolysis to obtain a pyrolysis product; (2) feeding the pyrolysis product obtained in the step (1) into the waste water to obtain magnesium ammonium phosphate crystal sediment; (3) recycling the magnesium ammonium phosphate crystal obtained in the step (2), drying the magnesium ammonium phosphate crystal, feeding sodium hydroxide powder into the magnesium ammonium phosphate crystal, carrying out heating pyrolysis, and feeding a pyrolysis product into the waste water to obtain the ammonia by means of circulating sedimentation; and (4) feeding the pyrolysis product obtained in the step (3) into acidic liquor to carry out acid pyrolysis once after the step (1), the step (2) and the step (3) are carried out twice and five times, and feeding an acid pyrolysis product into the waste water to obtain ammonia by means of circulating sedimentation. By the aid of the method, the problem of over high medicament cost of a magnesium ammonium phosphate method is solved, and the difficult problem that ammonia and nitrogen removal rate is reduced along with increase of ammonia circulating sedimentation frequency of magnesium ammonium phosphate is also solved.

Owner:NANJING UNIV

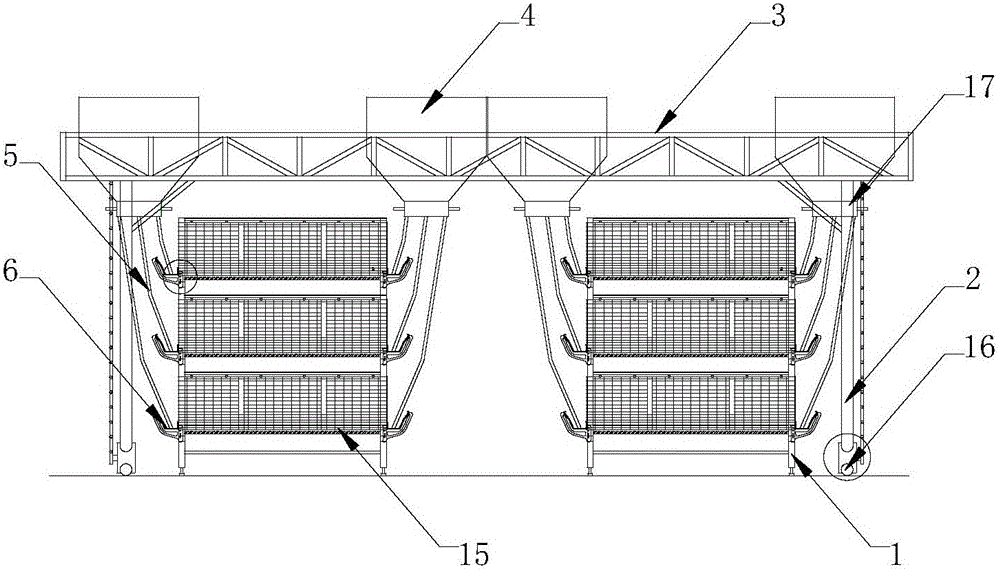

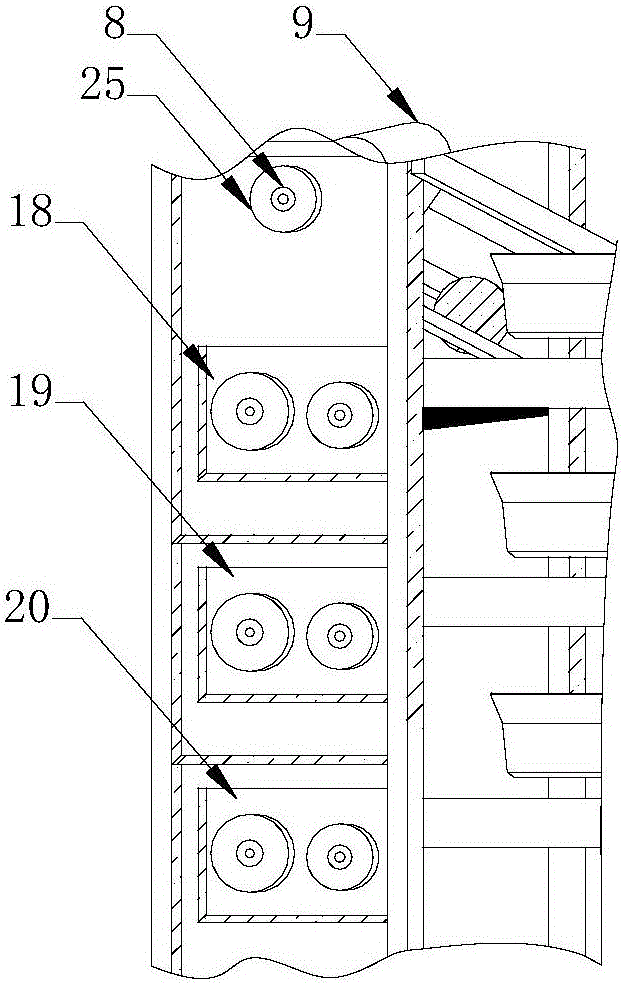

Laminated complete full-automatic breeding cage for broilers

The invention discloses a laminated complete full-automatic breeding cage for broilers. The laminated complete full-automatic breeding cage for broilers comprises a machine head end, a machine tail end, a broiler cage rack and a broiler cage, wherein the machine head end and the machine tail end are respectively arranged on two ends of the broiler cage rack; the broiler cage is arranged on the broiler cage rack; the broiler cage rack is divided into three layers; two broiler nipple integral adjusting automatic watering devices are disposed in each layer broiler cage; a broiler specific food groove is respectively formed on two sides of each broiler cage; the machine head end is provided with an upper layer shaft area, a middle layer shaft are and a lower layer shaft area; a driving shaft gear, a driven shaft gear and a driving decelerator are disposed in each shaft area; the driving shaft gear is connected with a driving shaft; the driven shaft gear is connected with a driven shaft; and the machine tail end is provided with a watering tightening shaft, a tensioning shaft and a shaft stopping rail. Land resource can be effectively utilized and chicken morbidity can be reduced; broiler large-scale, intensive and automatic culture can be achieved; and poultry houses can be automatically managed.

Owner:山东益圆农牧机械科技有限公司

Ribavirin liposome preparation

InactiveCN1346633AEnhance immune functionEffective treatmentOrganic active ingredientsAntiviralsPhosphateCholesterol

A liposome preparation of ribavirin used as an antivirus medicine is disclosed. Said liposome preparation is the artificial cells, which can carry the ribavirin into the cells infected by virus, resulting in high effect and low toxin. It is prepared through dissolving ribavirin in the buffering solution of phosphate, adding the mixture of phosphatide, cholesterin and VE, heating to 58-62 deg.C, and maintaining the temp for 30 min to obtain uniform emulsion.

Owner:SHENYANG PHARMA UNIVERSITY

Wide-size-fraction flotation system and process

ActiveCN109731697AReduce drug costsImprove flotation effectVortex flow apparatusFlotationSystem structureHigh energy

The invention belongs to the technical field of coal washing and deashing, relates to a wide-size-fraction flotation system and process and solves problems of complexity, high cost, high energy consumption and environmental hazards in application of an existing wide-size-fraction flotation process. The wide-size-fraction flotation process includes steps: step one, feeding to-be-floated coal slimeinto an agitator, adding water into the agitator, well stirring and mixing, and feeding into a classification cyclone through a first feeding pump to realize preliminary classification; step two, after classification of coal slime is completed in the classification cyclone, feeding overflow in the classification cyclone into a flotation column through a second feeding pump to realize flotation, discharging flotation tailings through an underflow port of the flotation column, collecting flotation concentrate through an overflow port of the flotation column, and feeding into a bubble generator through a fourth feeding pump; step three, feeding underflow in the classification cyclone into a hydraulic flotation machine through a third feeding pump to realize flotation recovery. The process issimple, energy saving and environmental friendliness are realized, and the flotation system is simple in structure and low in cost.

Owner:CHINA UNIV OF MINING & TECH

Oilfield reinjection water scale inhibitor and preparation method thereof

InactiveCN103991974AReduce drug costsInfinitely dilutedScale removal and water softeningPolyaspartic acidBis epoxide

The invention provides an oilfield reinjection water scale inhibitor and a preparation method thereof. The scale inhibitor consists of styrene sulfonic acid (SSS), polyepoxysuccinic acid (PESA), polyaspartic acid (PASP) and 2-phosphonic butane-1,2,4-tricarboxylic acid (PBTC), wherein the mass ratio of the SSS, PESA, PASP and PBTC is (30-50):(15-25):(20-30):(5-10). The invention provides the preparation method for the oilfield reinjection water scale inhibitor. The four materials are sequentially added into a stirring container at a certain mass ratio, stirred and dissolved to obtain the scale inhibitor. The scale inhibitor is a super concentrated liquid agent, and can be infinitely diluted for use. The four materials are compounded at a certain mass ratio, so that the scale inhibiting effect of the scale inhibitor is obviously superior to that of a single material; the consumption of the scale inhibitor is lower than that of any domestic existing oilfield reinjection water scale inhibitor, so that the agent cost of oilfield development can be saved. The oilfield reinjection water scale inhibitor disclosed by the invention has a stable hydrolysis effect under the condition of high hardness, high alkalinity and high temperature, an excellent scale inhibiting dispersion effect on calcium carbonate and calcium phosphate and good effects of dispersing iron oxide and stabilizing zinc salts, so that the scale inhibitor can be widely applied in the field of oilfield reinjection water and conventional water treatment and the like.

Owner:WEIHAI XIANGYU TECH

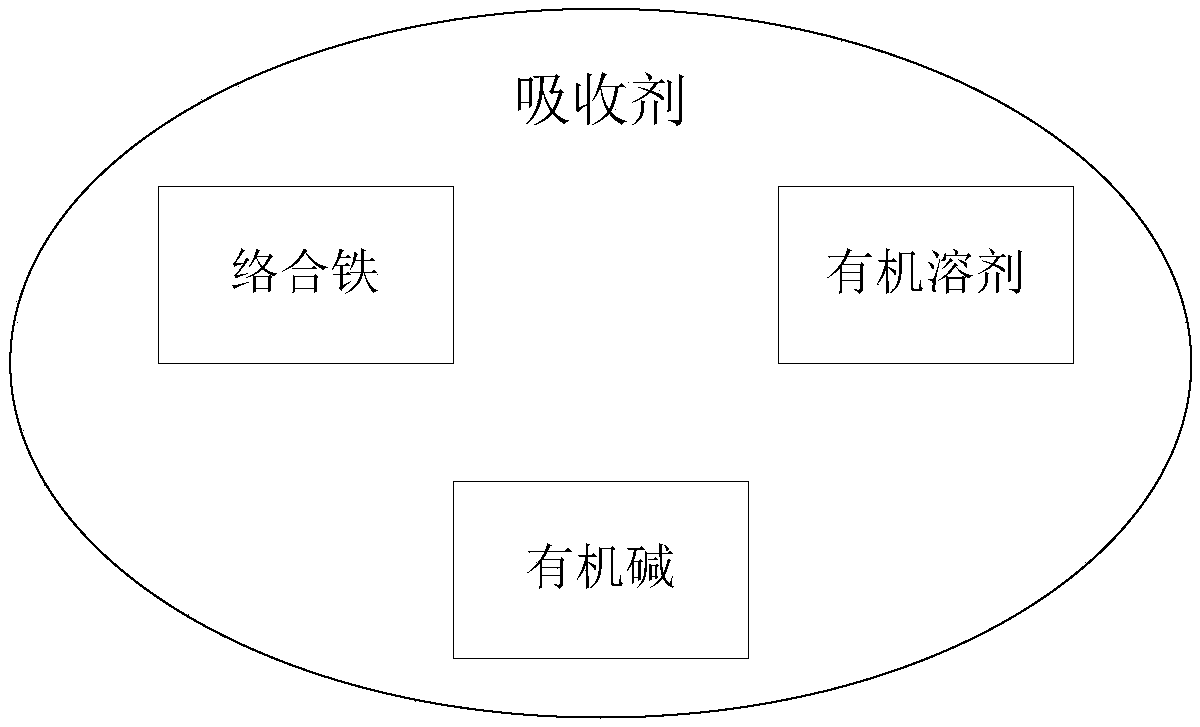

Desulfurizing and decarbonizing absorbent

InactiveCN109432990AAvoid degradationLow costProductsGas treatmentEthylenediaminePoly(ethylene glycol) dimethyl ether

The invention discloses a desulfurizing and decarbonizing absorbent which comprises complex iron, an organic solvent and organic alkali, wherein the mass content of the iron is 0.3-10 g / L, and the mass content of the organic alkali is 0-100 g / L; the complex ion comprises 1-butyl-3-methylimidazole EDTA-Fe, EDTA-Fe and EDTA ferric sodium salt, the organic solvent comprises dimethyl sulfoxide, polyethylene glycol dimethyl ether, or a mixture of dimethyl sulfoxide and polyethylene glycol dimethyl ether; the organic alkali can be dissolved into the organic solvent and specifically comprises 1-butyl-3-methylimidazole. According to the absorbent, the degradation of a complexing agent is avoided by adopting nonaqueous solution of the complex ion, and the cost of liquid phase catalytic oxidation islowered. Additionally, absorption liquid can be used for physically absorbing carbon dioxide while oxidation absorption of hydrogen sulfide, so that the cost of equipment for absorption is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for flotation separation of lead sulfide and zinc sulfide minerals

The invention relates to a method for flotation separation of lead sulfide and zinc sulfide minerals and belongs to the technical field of mineral flotation separation. The method comprises the stepsthat the pH value of ore pulp is regulated to be 8.5-10.5, zinc sulfate, sodium carbonate and ferricyanide are adopted as an inhibitor of blende, ethyl thio carbamate, xanthate and aerofloat are adopted as a collecting agent of galena, 2<#> oil is adopted as a foaming agent, and a qualified lead concentrate product is separated from the minerals; and then, copper sulfate is adopted as an activating agent of the blende, the xanthate is adopted as a collecting agent, a qualified zinc concentrate product is obtained through flotation, and thus a lead mineral and a zinc mineral are effectively separated. According to the method for flotation separation of the lead sulfide and zinc sulfide minerals, the galena and the blende can be separated through a flotation method, a reagent system is simple, the procedure is reasonable in structure, and the grade and the recovery rate of the lead and zinc minerals can be effectively increased; and a combined reagent containing the ferricyanide is adopted to inhibit the zinc mineral, the advantages of good selectivity, high inhibitive capacity, less dosage and the like are achieved, the ferricyanide is stable and has little influence on the environment, the zinc content in lead concentrates is effectively decreased under the premise of saving the reagent cost and under the precise of the low-alkali environment, and the lead mineral and the zincmineral are efficiently separated.

Owner:KUNMING UNIV OF SCI & TECH

Plant growth regulator containing nanometer titanium dioxide and preparation method thereof

ActiveCN101785481AReduce drug costsReduce human inputBiocidePlant growth regulatorsTitanium dioxideTitanium

The invention discloses a plant growth regulator containing nanometer titanium dioxide and a preparation method thereof, relating to a plant growth regulator and a preparation method thereof. The invention solves the problems of low use density, low absorption and utilization ratio and poor adhesive force of nanometer titanium in the existing plant growth regulator containing nanometer titanium dioxide. The growth regulator is prepared from the nanometer titanium dioxide, adhesive, water, dispersing agent, penetrating agent and additive. The preparation method is as follows: sequentially adding the adhesive, the penetrating agent, the dispersing agent, the nanometer titanium dioxide and the additive in water; continuously stirring for 1-2 minutes to obtain the plant growth regulator containing the nanometer titanium dioxide. The plant growth regulator of the invention can accelerate plant growth and is used for crop increment.

Owner:海南利环农业科技有限公司

Insecticidal composition for preventing and controlling plant hopper

InactiveCN101077071ASignificant synergyLow application costBiocideAnimal repellantsSulfonatePolyvinyl alcohol

The present invention discloses one kind of pesticide composition for preventing and killing plant hopper. The pesticide composition consists of pymetrozine 0.5-25 wt%, buprofezin 0.5-25 wt%, assistant 5-25 wt%, and stuffing 25- 94 wt%. The stuffing may be bentonite, fine particle calcium carbonate, kaolin, silica white or water; and the assistant may be starch, PVA, lignin sulfonate, etc. The pesticide composition of the present invention has the advantages of fast acting, lasting action, less influence on environment and low cost.

Owner:YANCHENG SHUANGNING AGRI CHEM

Quick water fracturing fluid and preparation method thereof

The invention relates to fracturing fluid and a preparation method thereof, in particular to multifunctional green and clean quick water fracturing fluid. The quick water fracturing fluid comprises adissolution agent and an anti-drag thickening agent prepared from polyacrylamide emulsion; the quick water fracturing fluid is prepared from, by mass, 99.00-99.95% of the dissolution agent and 0.05-1.0% of the anti-drag thickening agent, wherein the anti-drag thickening agent is prepared from 10-40% of polyoxyethylene, 40-85% of organic solvents, 0-10% of a non-ionic surface active agent and 0-10%of a dispersing agent, wherein the fracturing fluid prepared from the polyacrylamide emulsion is low in damage and easily discharged reversely; quick water prepared from the polyacrylamide emulsion is low in cost, compared with traditional fracturing, the medicament cost is saved, the labor cost is saved by 50%, and the anti-drag thickening agent can enable a shale layer to generate a more complex and larger cracking layer; the quantity of additives in anti-drag water is small, recycling is facilitated, and environmental protection is achieved; the anti-drag thickening agent is rapid in dispersion, no emulsion breaking is needed, and use is quite convenient.

Owner:大庆中联信实石油科技开发有限公司

Lead-antimony-zinc sulfide ore bulk flotation collecting agent and preparation and application thereof

InactiveCN106423581AThe amount of blowing agent is reducedReduce drug costsFlotationSingle useKerosene

The invention relates to a lead-antimony-zinc sulfide ore bulk flotation collecting agent and preparation and application thereof. The gearbox left box body shell is prepared by mixing tert-dodecyl mercaptan and emulsified kerosene. The mass ratio of the tert-dodecyl mercaptan to the emulsified kerosene is 1:(0.9-1.2). The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the better collecting effect on sulfide, and can be applied to lead-antimony-zinc sulfide ore bulk flotation. The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the good foaming property, can adopt a small amount or no foaming agent, and can decrease the consumption of an activating agent copper sulfate; compared with traditional MA or single use of emulsified kerosene and tert-dodecyl mercaptan, the grade and recycling rate of sulfide can be increased, and types and consumption of medicament are reduced.

Owner:CENT SOUTH UNIV +1

Zeolite strengthened anaerobic ammoxidation sewage processing technique

InactiveCN101054233APromote growthReduce startup timeTreatment with anaerobic digestion processesStart timeBiological filter

A zeolite intensifing anaerobic ammonoxidation sewage treatment technology relates to anaerobic ammonoxidation sewage treatment and zeolite intensifying biological denitrification sewage treatment technology, which is applicable to municipal wastewater, domestic sewage treatment, rubbish percolate, waste water with low carbon-nitrogen ratio treatment. The invention combines the zeolite intensifying biological denitrification sewage treatment technology with the anaerobic ammonoxidation technology, adopting an anaerobic zeolite biological filter using powder or granular zeolite as filtering material or an anaerobic biological filter (3) arranged directly in a reactor, accelerating growth of anaerobic ammonoxidation microorganism zeolite by zeolite, shortening hydraulic power residence time and starting time of the technology, and realizing zeolite regeneration in anaerobic condition. The invention is applicable to treatment of municipal wastewater, domestic sewage, rubbish percolate, organism with low carbon-nitrogen ratio, ammonia nitrogen, total nitrogen up-to-standard, has advantages of saving investment, low operating cost, a little occupation of land, flexible running, and improves treatability of surplus sludge, has good economic, environment and social benefit.

Owner:TONGJI UNIV

Reverse osmosis concentrated water treatment system with high permanent hardness

PendingCN109592815AReduce drug costsReduce complexityWater/sewage treatment by centrifugal separationSemi-permeable membranesSaline waterSalt water

The invention belongs to the technical field of sewage treatment, and particularly relates to a reverse osmosis concentrated water treatment system with high permanent hardness. The treatment system comprises a primary crystallizer unit, a primary reverse osmosis filter unit, a secondary crystallizer unit, a lime softening unit and a secondary reverse osmosis filter unit. The treatment system caneliminate permanent hardness and temporary hardness in strong brine, and the hardness in strong brine can be reduced to 50mg / L or lower.

Owner:GREENTECH ENVIRONMENTAL CO LTD

Traditional Chinese medicine compound composition for delaying progress of chronic kidney diseases and clinical application of traditional Chinese medicine compound composition

InactiveCN106890275AEasy to takeTargetedUrinary disorderPlant ingredientsClinical researchSide effect

The invention discloses a traditional Chinese medicine compound composition for delaying progress of chronic kidney diseases and clinical application of the traditional Chinese medicine compound composition. The traditional Chinese medicine compound composition which is a pure traditional Chinese medicine preparation comprises a plurality of traditional Chinese medicines including radix astragali, radix angelicae sinensis, rhizoma chuanxiong, radix achyranthis bidentatae, radix et rhizoma rhei preparata, serissa japonica, radix glycyrrhizae, hedyotis diffusa, herba centellae and caulis bambusae in taenia. The traditional Chinese medicine compound composition and the clinical application have the advantages that as shown by completed pharmacodynamical research and clinical research, the kidney fibrotic lesion degrees of experimental animals can be obviously improved by the preparation, the creatinine levels can be lowered, and kidney functions can be protected; the kidney pathological lesion degrees related to the chronic kidney diseases can be improved, and mechanisms related to curative effects are verified from the angle of molecular biology; as shown by clinical research, proteinuria and hematuria conditions related to the chronic kidney diseases can be reduced by the traditional Chinese medicine preparation, and deterioration of creatinine clearance rates (computed by the aid of Cockcraft-Gault formulas) of patients suffering from the chronic kidney diseases can be obviously controlled; the total treatment effective rate can reach 98% at least, expenditure required for treating the diseases can be reduced for the patients, the stable curative effects can be realized, and the traditional Chinese medicine compound composition is free of obvious toxic and side effects.

Owner:THE FIRST AFFILIATED HOSPITAL OF SOOCHOW UNIV

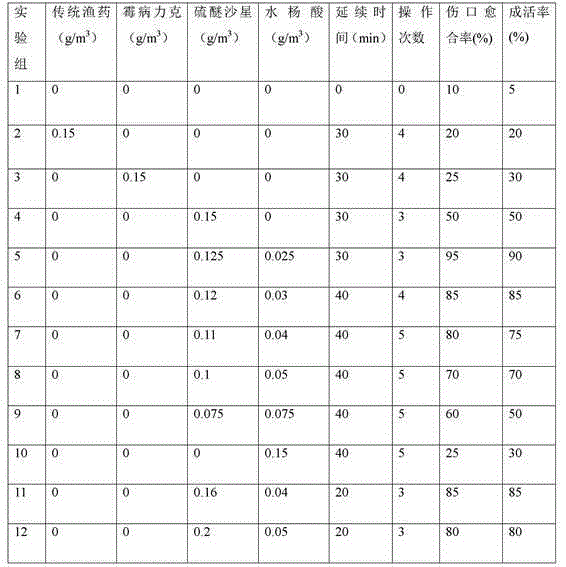

Composition for preventing and treating trout saprolegniasis

InactiveCN105213406ALow costGood effectSalicyclic acid active ingredientsAntimycoticsMalachite greenTrout

The invention discloses a composition for preventing and treating trout saprolegniasis. The composition comprises the following ingredients in parts by mass: 1 to 5 parts of diallyl-2,3-thioether and 0.2 to 1 part of salicylic acid. A preparing method comprises the following steps of: proportionally mixing the diallyl-2,3-thioether and the salicylic acid; stirring the mixture to be made into raw medicine; putting 0.15 to 0.25g of raw medicine in per cubic meter of area; adding water for diluting the solution to 1000 times to form medicine liquid; spreading the prepared medicine liquid into a fishpond; meanwhile, breaking the water supply, and turning on aeration equipment; injecting fresh water after 15 to 45min; adding the medicine once every other day; and performing continuous operation for 3 to 5 times. The diallyl-2,3-thioether and the salicylic acid are scientifically matched, so that the permeability of the composition is high; the sterilization effect is exponentially increased; the residue content of the diallyl-2,3-thioether and the salicylic acid in the environment and trout bodies is low; the medicine cost is low; and the composition can be used for replacing malachite green. Compared with traditional Chinese herbal medicine and Meibinglike in an aspect of the curative effect on the saprolegniasis, the composition has the advantages that the cure rate and the survival rate are high; and the national aquatic product fish medicine new standard is met.

Owner:ZUNYI QINGXIHE FUYUAN ECOLOGICAL FISHERY DEV CO LTD

Compound bionic insecticide

The present invention relates to a bionic low-toxic composite pesticide. It is formed from two active components of chlorfluazuron and monosultap (or bisultap) and adjuvant, filler or solvent. By pure dosage for every mu said composite pesticide contains 0.1-5 g of chlorfluazuron and 5-75g of monosultap (or bisultap). Said composite pesticide can obviously raise the effect for controlling rice leaf roller, also can be used for controlling rice borers, and can be substituted for high-toxic pesticide.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Infusion preparation for dialysis patient

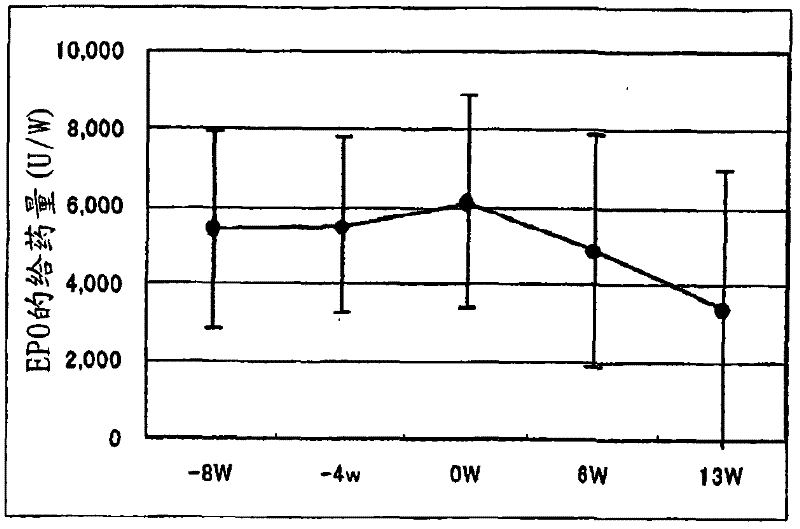

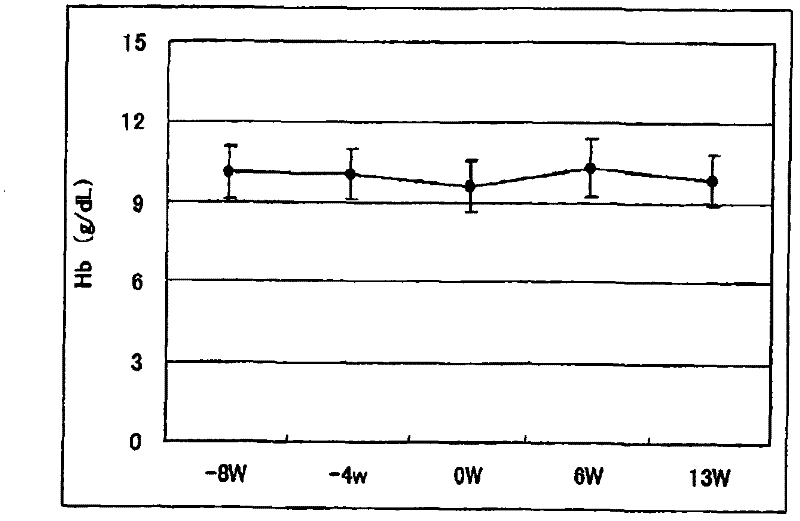

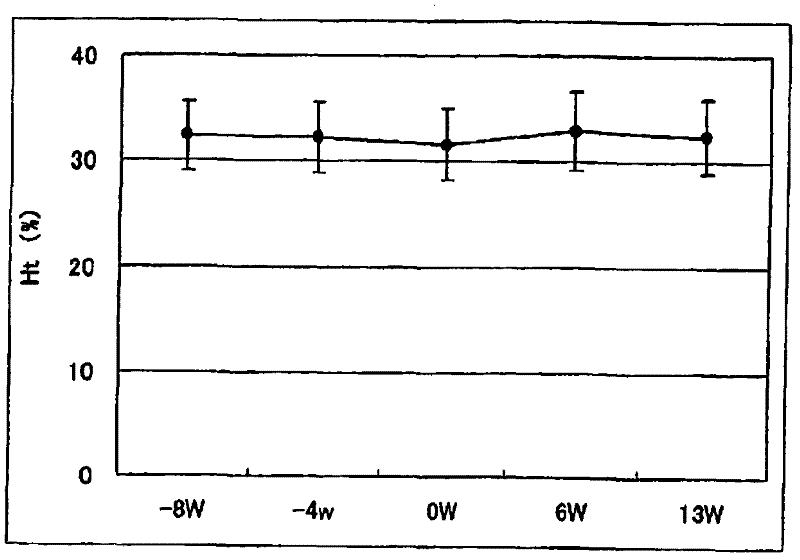

InactiveCN102600138AReduce dosageReduce drug costsOrganic active ingredientsPeptide/protein ingredientsArginineTryptophan

An infusion preparation which is to be used in dialyzing a dialysis patient for ameliorating the anemic state by improving nutritional conditions, thus reducing the dosing amount of erythropoietin, controlling the serum phosphorus level to thereby regulate the serum phosphorus level within a definite range and inhibiting the protein catabolism and which contains at least essential amino acids, characterized in that the amino acids are composed of at least L-isoleucine, L-leucine, L-lysine, L-methionine, L-phenylalanine, L-threonine, L-tryptophan, L-valine, L-alanine, L-arginine, L-aspartic acid, L-glutamic acid, L-histidine, L-proline, L-serine, L-tyrosine, glycine and L-cysteine and the ratio of essential amino acids : non-essential amino acids is 2.5 or higher.

Owner:AJINOMOTO CO INC

Method and device for achieving ultra-low emission of sulfur dioxides and nitrogen oxides from flue gas by two-stage ozone oxidation synergistic absorption

InactiveCN108671716ASimple transformationReduce drug costsGas treatmentDispersed particle separationFlue gasLow emission

The invention discloses a method and device for achieving ultra-low emission of sulfur dioxide and nitrogen oxide from flue gas by two-stage ozone oxidation synergistic absorption and belongs to the technical field of flue gas pollution control. The method comprises the following steps: enabling to-be-treated flue gas to sequentially pass through a first-stage oxidizer, a first-stage absorption tower, a second-stage oxidizer and a second-stage absorption tower to realize the efficient removal of the nitrogen oxide and obtain purified flue gas; performing defogging treatment on the purified flue gas at the top of the second-stage absorption tower and then emptying; recycling the absorption mother liquor of the second-stage absorption tower till an absorption effect is lost, conveying to a sub-salt oxidation reactor through a pump and then conveying to a subsequent by-product processing process by utilizing air oxidation. The method and the device disclosed by the invention have the benefits that the absorption efficiency of the nitrogen oxide is regulated and controlled through regulating and controlling the addition ratio of O3 subjected to first-stage oxidation and second-stage oxidation, so that the excessive addition of the O3 can be effectively avoided, and the energy consumption is reduced; through the method disclosed by the invention, the nitrogen oxide is reduced into N2, so that the efficient absorption and removal of the nitrogen oxide can be realized, and the secondary pollution is avoided.

Owner:BEIHANG UNIV

Agent for treating refractory organic wastewater and preparation method of agent

InactiveCN106745606AReduce drug costsImprove processing effectWater contaminantsWaste water treatment from food industrySodium silicatePolyacrylamide

The invention discloses an agent for treating refractory organic wastewater. The agent is composed of the following raw materials in parts by weight: 60-120 parts of strong base, 15-28 parts of sodium silicate, 5-12 parts of lithopone, 3-6 parts of cellulose, 4-7 parts of mushroom residues, 7-15 parts of polyacrylamide, 2-8 parts of calcium oxide, 10-18 parts of kaolin and 4-10 parts of lotus root juice. The invention further discloses a preparation method of the agent. According to the agent disclosed by the invention, the cost of the agent is reduced, the treatment effect is improved, and the agent is simple in preparation process, convenient in source of raw materials, high in wastewater treatment efficiency, excellent in water purification effect, high in flocculating velocity, less in produced sludge and convenient to use, is particularly suitable for treatment of mixed discharged organic wastewater in industries such as printing and dyeing, foods and the like, and has excellent social benefits and economic benefits.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Method and device for low-temperature drying of residual activated sludge from sewage treatment

ActiveCN110255846AReduce drug costsFast dehydrationSludge treatment by de-watering/drying/thickeningChemical agentsResource utilization

The invention discloses a method and device for low-temperature drying of residual activated sludge from sewage treatment. The device comprises sludge freezing equipment, a sludge maintenance chamber, a sludge unfreezing and primary dehydrating device, sludge dehydrating equipment and a sludge airing device; and the residual activated sludge, which is obtained after primary dehydrating treatment is conducted, of a sewage treatment plant is treated by the sludge freezing equipment, the sludge maintenance chamber, the sludge unfreezing and primary dehydrating device, the sludge dehydrating equipment and the sludge airing device sequentially to obtain sludge subjected to low-temperature drying. According to the method and device for low-temperature drying of the residual activated sludge from sewage treatment, through cooperation of the sludge unfreezing and primary dehydrating device, the sludge dehydrating equipment and the sludge airing device, the sludge is continuously dehydrated and aired, a sludge drying cycle is shortened, and a drying effect is obvious. All drying processes are conducted under conditions of normal temperature and temperature lower than the normal temperature, and volatile gas which is generated due to secondary fermentation of microorganisms in the sludge is reduced, so that pollution is reduced. According to the method and device for low-temperature drying of the residual activated sludge from sewage treatment, the sludge is directly frozen, no other chemical agents need to be added, the drying cost is reduced, and meanwhile, the biology characteristics of the sludge remain unchanged, so that a foundation is laid for resource utilization of the sludge.

Owner:杨红兵

Oil-containing sewage treatment apparatus and oil-containing sewage treatment method

ActiveCN109553241AReduce drug costsReduced sludge productionWaste water treatment from quariesFatty/oily/floating substances removal devicesSewage treatmentSewage

The invention discloses an oil-containing sewage treatment apparatus and an oil-containing sewage treatment method. The oil-containing sewage treatment apparatus comprises a water inlet, a water outlet, an oil stain removal part and a suspended matter removal part, wherein the oil stain removal part comprises an oil stain aggregation unit and an oil stain inclination plate precipitation unit, a first baffle is arranged between the oil stain aggregation unit and the oil stain inclination plate precipitation unit, the suspended matter removal part comprises an electric flocculation unit, a suspended matter inclination plate sedimentation unit and a sludge sedimentation concentration unit, a second baffle is arranged between the electric flocculation unit and the suspended matter inclinationplate sedimentation unit, the sludge sedimentation concentration unit is arranged on the lower portion of the suspended matter inclination plate sedimentation unit, and a third baffle is arranged between the oil stain inclination plate precipitation unit and the electric flocculation unit. With the apparatus and the method of the present invention, the removal rate of oil and suspended matter in sewage can achieve more than 95% without the adding of agents.

Owner:CHINA PETROLEUM & CHEM CORP +1

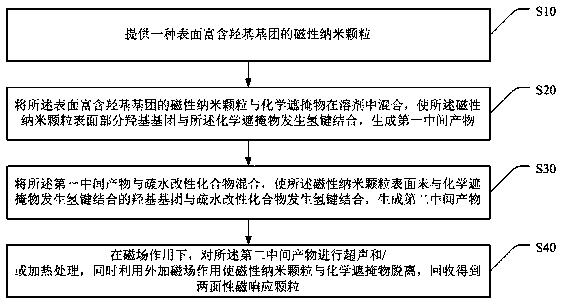

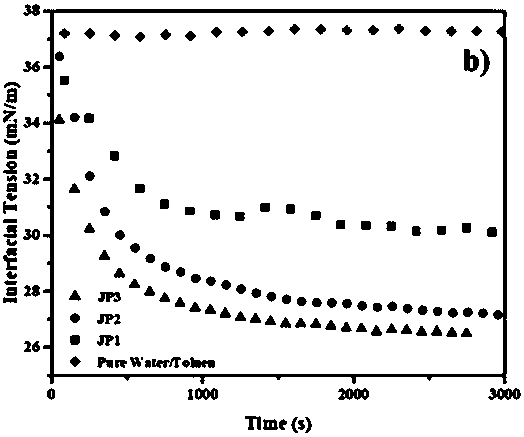

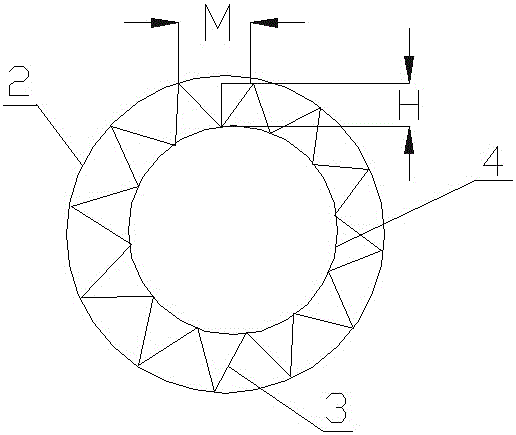

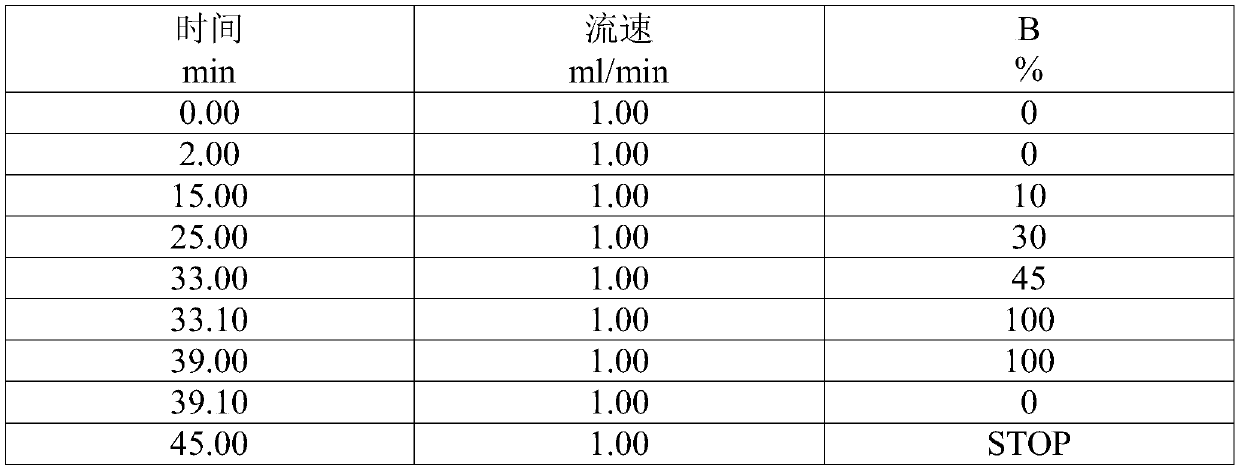

Double-side magnetically responsive particles, and preparation method and applications thereof

ActiveCN110105978AStrong interface activityReduce drug costsDewatering/demulsification with chemical meansNon-miscible liquid separationWater in oilChemistry

The invention discloses double-side magnetically responsive particles, and a preparation method and applications thereof. The preparation method comprises following steps: a chemical covering compoundextremely high in surface area and rich in surface hydroxyl groups is adopted for mixing with magnetic nanometer particles containing surface hydroxyl groups for formation of hydrogen bond interaction, so that the reaction performance of a part of hydroxyl function groups on the surfaces of the magnetic nanometer particles is shielded; and then, the left hydroxyl groups without hydrogen bond interaction are subjected to hydrophobic modification so as to achieve the different hydrophilic and hydrophobic characteristics on the two sides of the magnetic nanometer particles. The obtained double-side magnetically responsive particles possess extremely high interface activity, are capable of moving to the oil water interfaces in oil-in-water or water-in-oil systems, so that microemulsion surface magnetization is realized, and in addition, microemulsion movement mode can be changed using an applied magnetic field, and rapid aggregation and polymerization are realized; and the double-side magnetically responsive particles can be recycled.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Method for efficiently trapping and controlling Armadillidium vulgare Latreille in field of panax notoginseng

InactiveCN105918019AReduce the amount of applicationEfficient trappingAnimal trapsPlant protectionPANAX NOTOGINSENG ROOTChlorpyrifos

The invention discloses a method for efficiently trapping and controlling Armadillidium vulgare Latreille in the field of panax notoginseng. According to the method, in the early planting stage of panax notoginseng: panax notoginseng seeds are sown or panax notoginseng seedlings are transplanted, 5% chlorpyrifos granules are applied twice in the first ten days of May in the standard that 2 kg of chlorpyrifos granules are applied to every 667 m<2> of the field; in the later planting period of panax notoginseng, an Armadillidium vulgare Latreille trap is adopted for physically controlling Armadillidium vulgare Latreille after the first ten days of August. Through combination of chemical control and physical control, the application quantity of pesticides is reduced by 2-4 kg all the year round, the trapping effect in 3-7 days reaches 61.96%-64.20%, increase of the Armadillidium vulgare Latreille in the field of panax notoginsen is effectively controlled, the Armadillidium vulgare Latreille is effectively trapped, pesticide residues are reduced, the farm land environment is protected, safety of panax notoginseng products is guaranteed, and the yield and the quality of panax notoginseng are improved.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

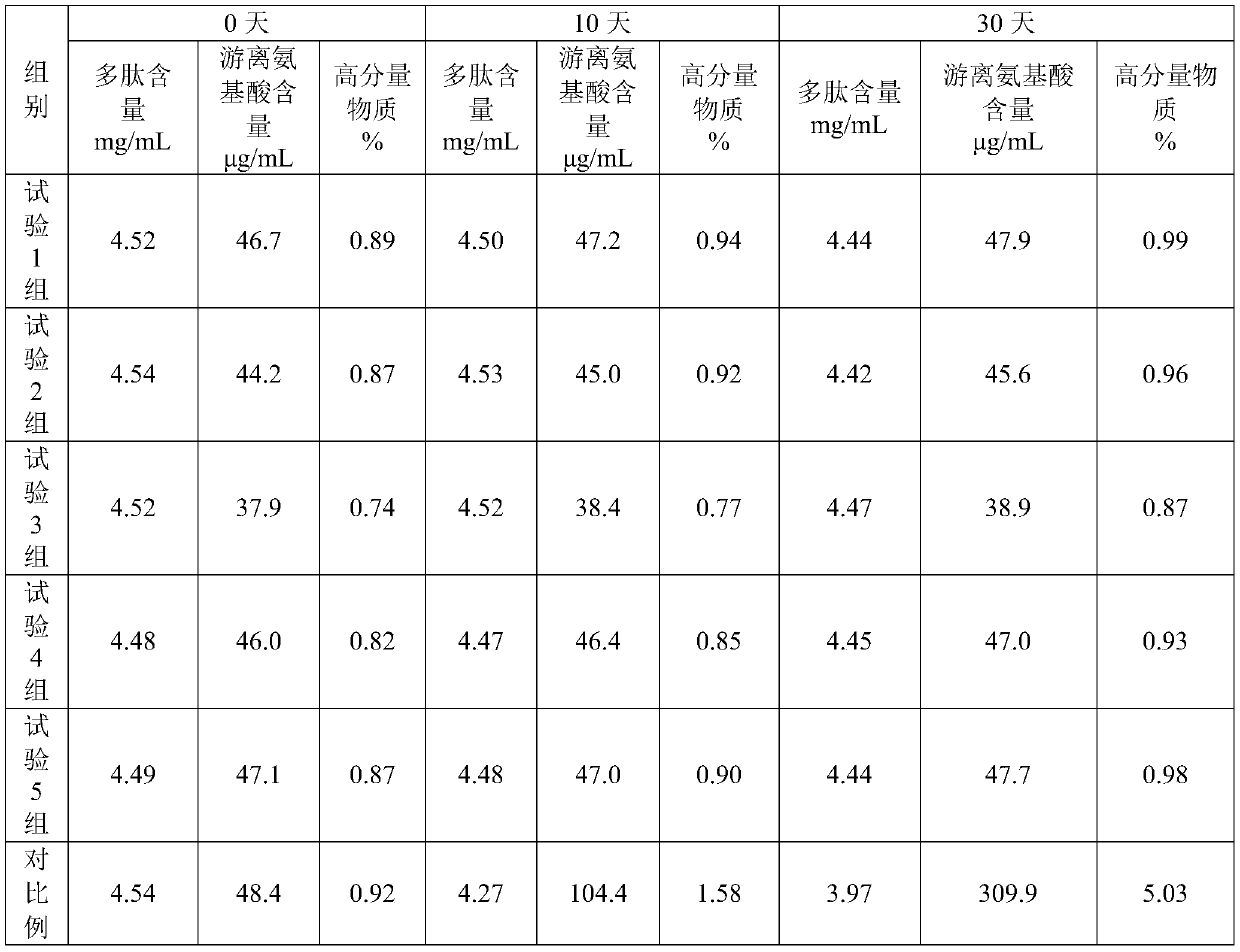

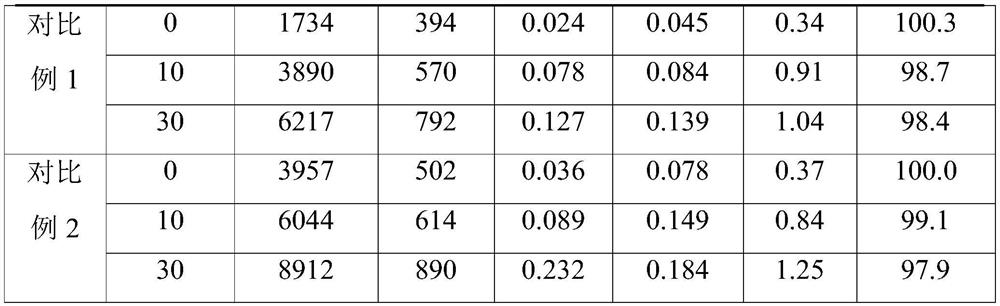

Preparation method of cervus and cucumis polypeptide injection preparation

InactiveCN110339336ASimple processSuitable for industrial productionHydrolysed protein ingredientsAntipyreticCervusChemistry

The invention belongs to the technical field of biological medicine, and more specifically relates to a preparation method of a cervus and cucumis polypeptide injection preparation. The injection is prepared from a polypeptide extracted from deer bone, a polypeptide extracted from melon seeds, and sodium alginate; the research shows that the injection preparation has simple process, is suitable for industrial production, removes activated carbon process method, and meets the requirements of consistency evaluation; the sodium alginate is used as an auxiliary material for the preparation to ensure the stability of the preparation product, and further, a product with better quality can be obtained. The injection preparation of the invention meets the requirements of the conventional preparation of the injection preparation, such as endotoxin, difference in the amount of the preparation, and the like, and has higher potential safety; the dosage of the preparation auxiliary materials is small, the product cost is lower, and the medication cost of the patient is lowered. Through the stability test for the preparation of the invention, the polypeptide content, the free amino acid content,and the high molecular substance content are hardly increased or increased, and the safety is better.

Owner:哈尔滨誉衡制药有限公司

Method for obtaining keratin from feather

InactiveCN111004313AShort reaction timeReduce drug costsDepsipeptidesPeptide preparation methodsComposite materialWaste material

The invention discloses a method for obtaining keratin from feather. Feather materials are used as raw materials, a reaction tank containing inner and outer tanks and the appropriate ratio of reagentsare utilized to sequentially soften and dissolve the feathers, through the quick completion of processes of reaction, dissolution, centrifugation, and filtration, keratin solution can be produced ina high-efficiency and mass production mode, feather waste can be reused and the problem of low added value will be improved.

Owner:KWONG LUNG ENTERPRISE

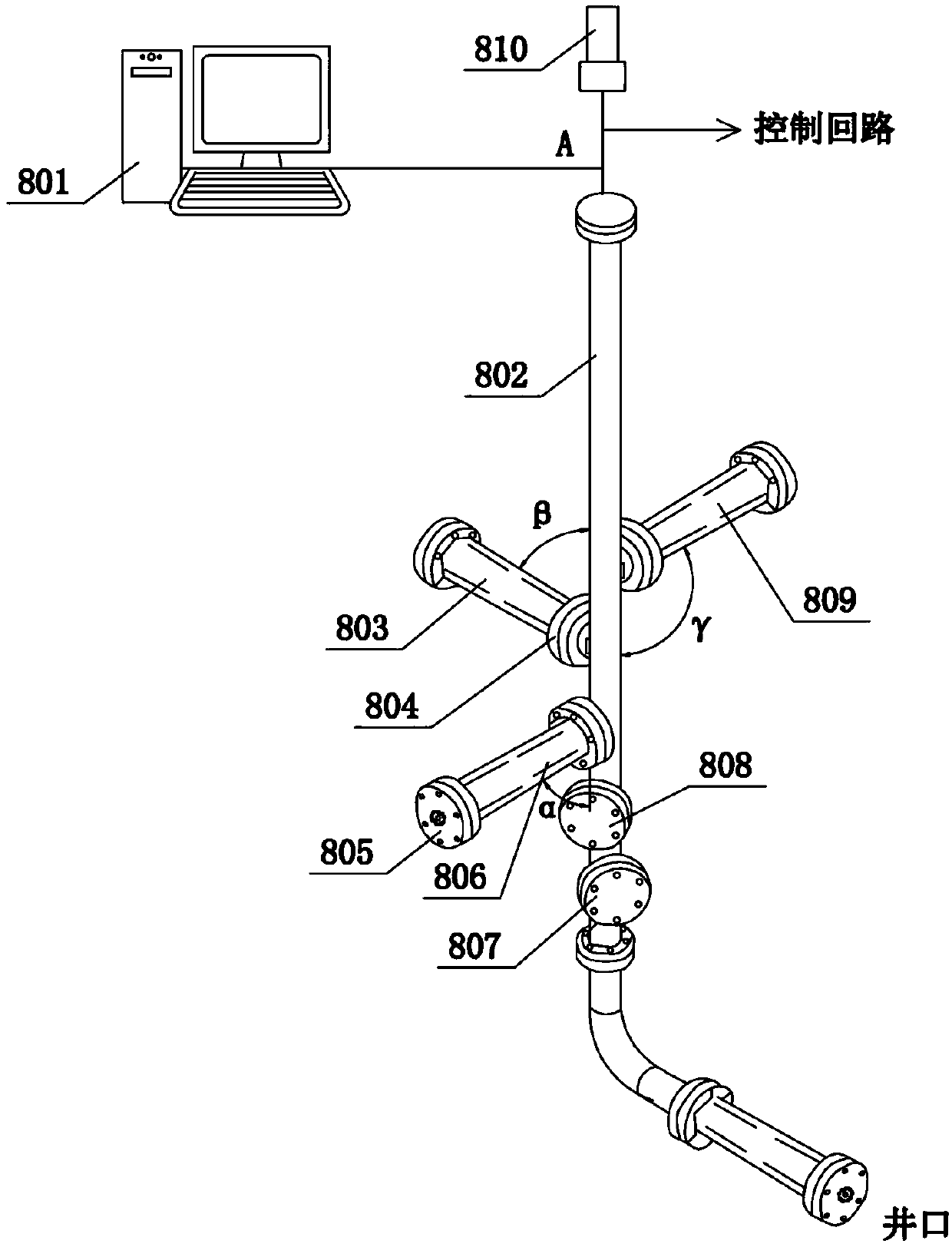

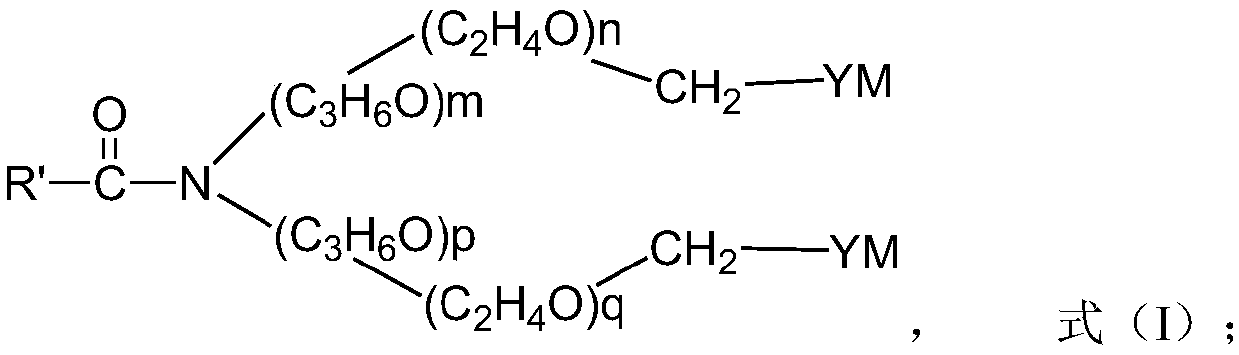

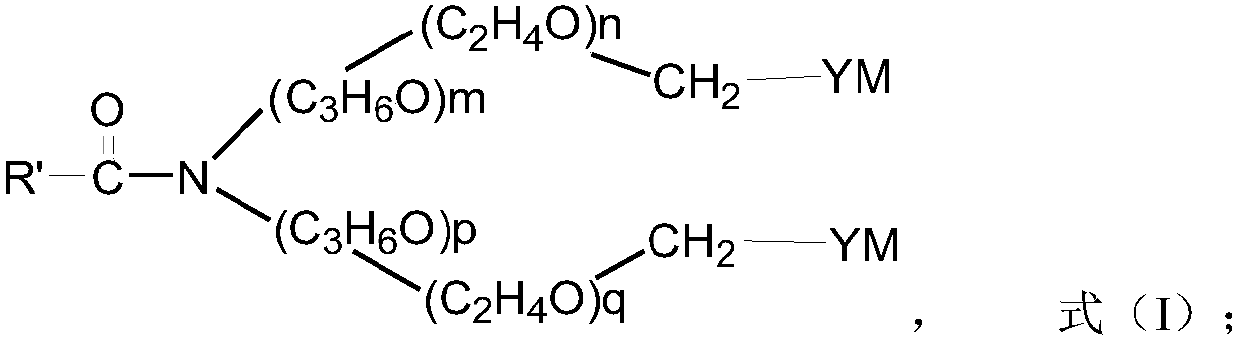

Reinforced salt-resistant and oil-resistant foam drainage agent composition as well as preparation method and application thereof

The invention relates to a reinforced salt-resistant and oil-resistant foam drainage agent composition as well as a preparation method and application thereof. The problems that in the low-pressure condensate oil gas well development process, an existing foam drainage agent is insufficient in formed foam gas amount, insufficient in oil resistance and poor in foam drainage performance, and consequently liquid accumulation at the bottom of a well, gas well production reduction and even blowout stop are caused are mainly solved. The foam drainage agent composition comprises the following components in parts by mass: 1 part of an alkyl amide polyether anionic surfactant with a molecular general formula shown in a formula (I); 0.1 to 50 parts of alpha-olefin sulfonate; 0.1 to 100 parts of a strengthening auxiliary agent A; and 0.1 to 100 parts of a strengthening auxiliary agent B. The problems are well solved, and the composition can be applied to the low-pressure condensate oil gas well drainage gas recovery industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com