Reinforced salt-resistant and oil-resistant foam drainage agent composition as well as preparation method and application thereof

A technology of foam drainage agent and composition, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve the problem of insufficient salt resistance and oil resistance of foam drainage agent, insufficient foam generation ability of foam drainage agent, and discharge liquid treatment Difficulties and other problems, to achieve the effects of saving pharmaceutical costs, enhancing liquid-carrying ability, and good foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

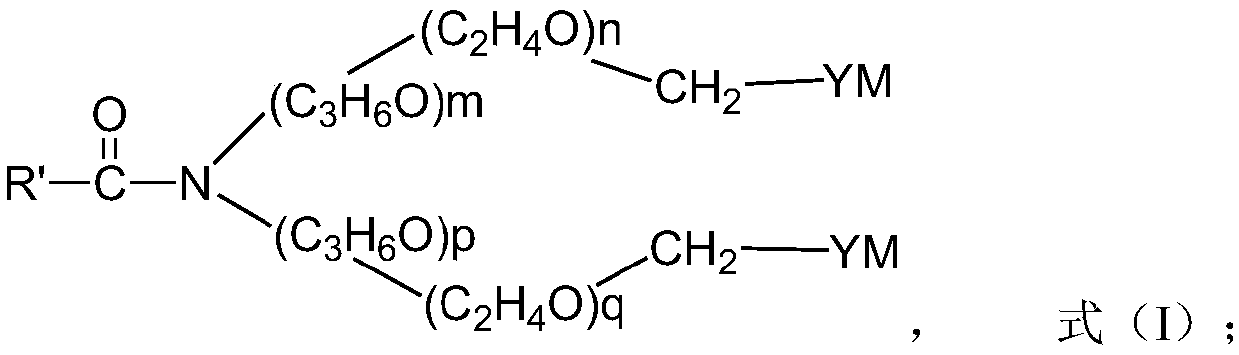

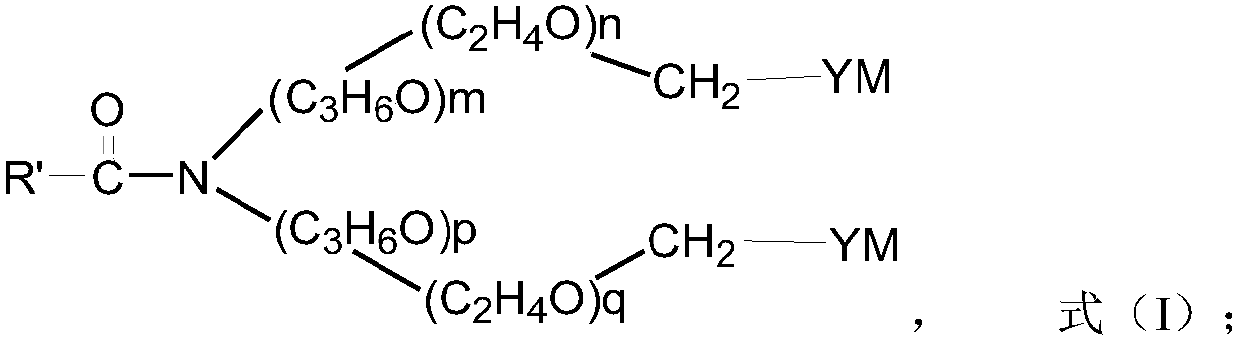

Method used

Image

Examples

Embodiment 1

[0037] Under normal temperature and pressure, the alkylamide polyether anionic surfactant, α-olefin sulfonate, ammonium chloride, and sodium nitrite were mixed at a salinity of 100,000 and 200,000 according to a mass ratio of 1:2:1:1, respectively. , 250,000mg / L simulated aqueous solution was dissolved to prepare a 1.0wt% solution. The resulting foam drainage composition FS-1. The structure of the surfactant component is shown in Table 1.

Embodiment 2

[0039] Under normal temperature and pressure, the alkylamide polyether anionic surfactant, α-olefin sulfonate, ammonium chloride, and sodium nitrite were mixed at a salinity of 100,000 and 200,000 according to a mass ratio of 1:10:5:5, respectively. , 250,000mg / L simulated aqueous solution was dissolved to prepare a 1.0wt% solution. The resulting foam drainage composition FS-2. The structure of the surfactant component is shown in Table 1.

Embodiment 3

[0041] Under normal temperature and pressure, the alkylamide polyether anionic surfactant, α-olefin sulfonate, ammonium chloride, and sodium nitrite were mixed at a salinity of 100,000 and 200,000 according to a mass ratio of 1:1:5:5, respectively. , 250,000mg / L simulated aqueous solution was dissolved to prepare a 1.0wt% solution. The resultant foam drainage agent composition FS-3. The structure of its surfactant component is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com