Laminated complete full-automatic breeding cage for broilers

A layered, fully automatic technology, applied in the poultry industry, poultry cages or houses, applications, etc., can solve the problems of high technical professional requirements, high epidemic outbreak rate, economic losses of farmers, etc., to save drug costs , reduce morbidity and avoid injury effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

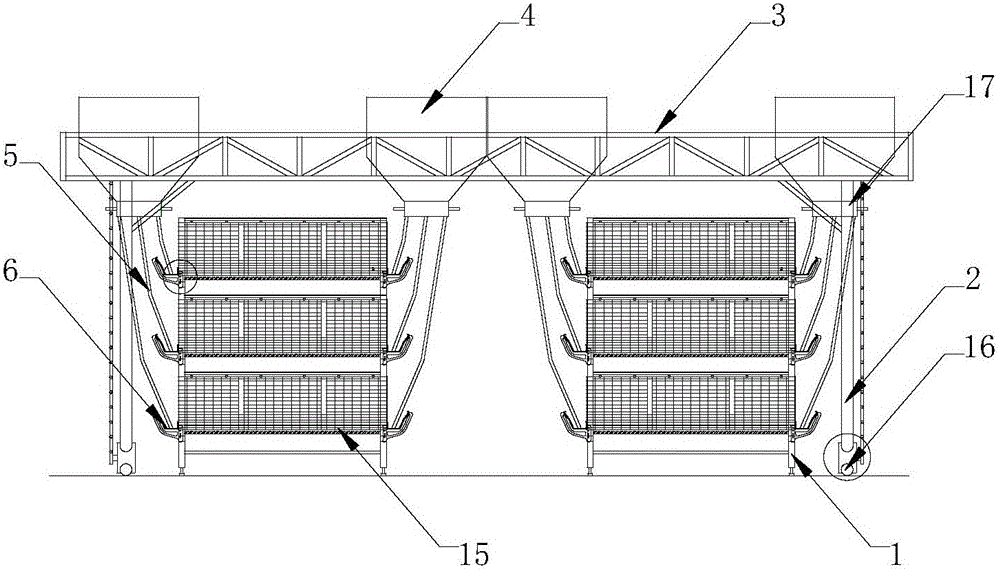

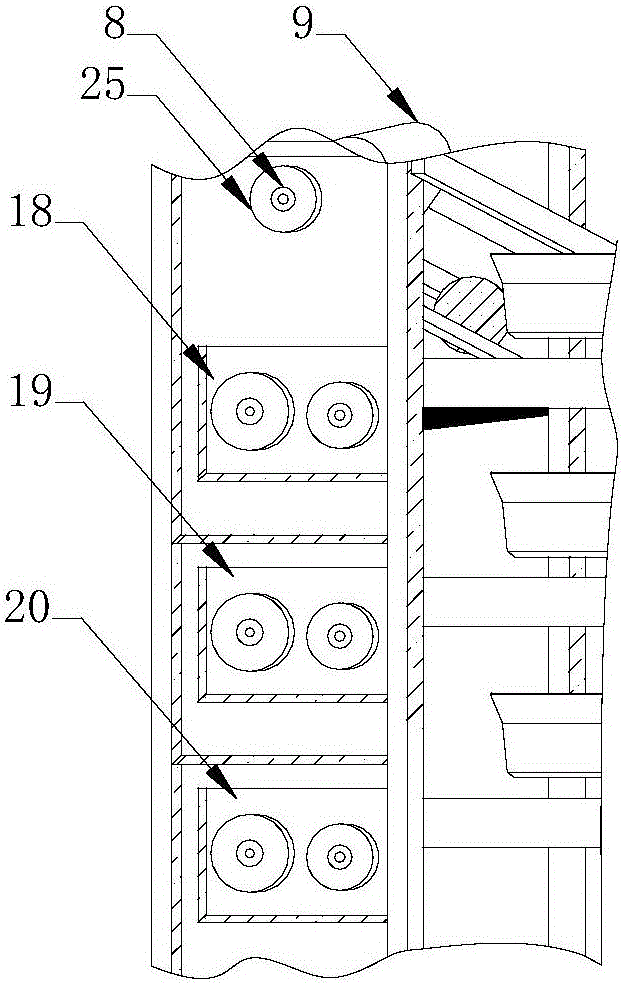

[0022] Attached below Figure 1-7 The present invention is described in detail below.

[0023] as attached Figure 1-7 As shown, the present invention includes a machine head end, a machine tail end, a broiler cage 1 and a broiler cage 15, and the machine head and the machine tail are respectively arranged at two ends of the broiler cage 1, and the broiler cage 15 is set On the broiler cage frame 1; the broiler cages 15 are arranged in upper, middle and lower layers, and each layer of the broiler cages 15 is equipped with two broiler nipple overall adjustment automatic drinking devices, and there is a broiler chicken respectively on both sides. Special trough 6; The head end is provided with upper shaft area 18, middle shaft area 19, lower shaft area 20 and drive reducer 9; Shaft rail 14; the upper shaft area 18, the middle shaft area 19, and the lower shaft area 20 are all provided with a driving shaft 27, a driven shaft 28, a driving shaft gear 22 and a driven shaft gear 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com