Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Compliant with energy saving and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified porous steel slag for rubber filler and preparation method thereof

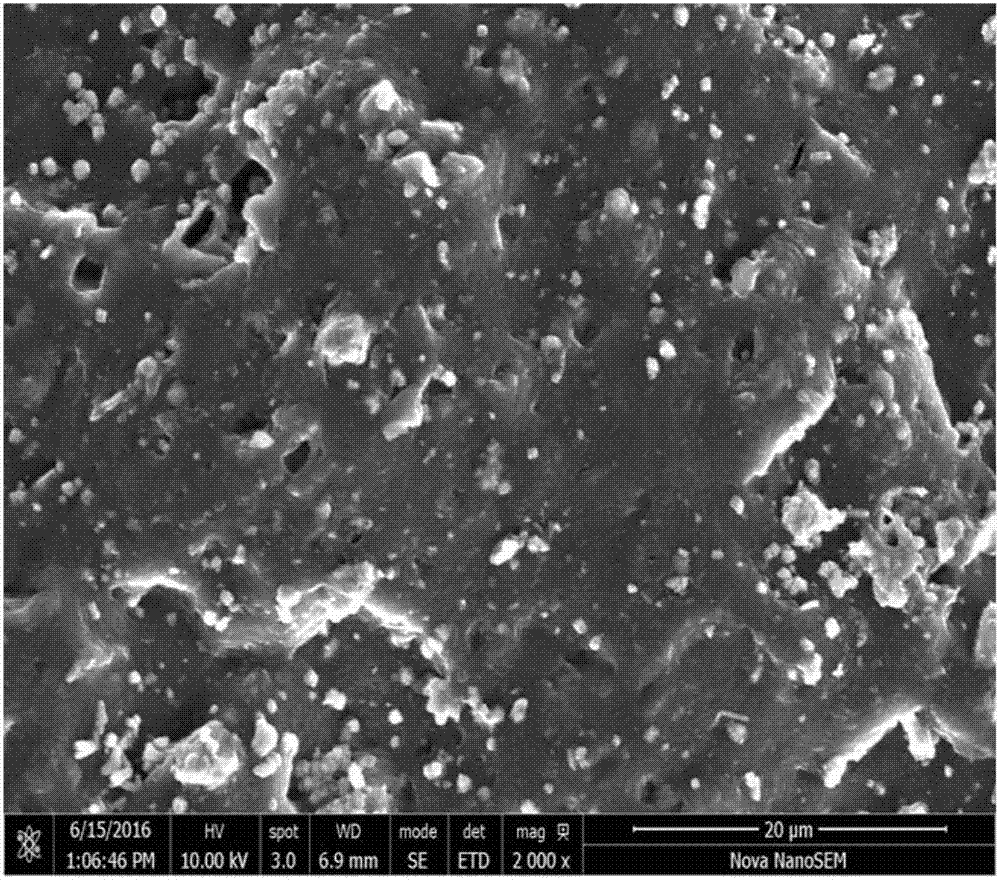

The invention discloses a modified porous steel slag for rubber filler and a preparation method thereof, and belongs to the field of recycling utilization of resource. The modified porous steel slag comprises phosphoric acid solution, silane coupling agent, stearic acid and steel slag; the mass percent of the phosphoric acid solution is 70-90%, the grain diameter of the steel slag is 2.2 miu m-115.0 miu m. The modified porous steel slag is prepared by firstly mixing the phosphoric acid solution with the steel slag, and stirring it for 4h-6h under the constant temperature, and acquiring the porous steel slag; then mixing the porous steel slag with the silane coupling agent and stearic acid; and mixing the components by a constant temperature magnetic mixer and acquiring the modified porous steel slag. The modified porous steel slag solves the problems that price of the main fillers carbon black and white carbon black of the existing rubber industry is very high, the steel slag is directly added in the rubber and extremely easy to cause reuniting, and the compatibility between the inorganic interface of the steel slag and the rubber organic interface is bad, and the circular use of the industrial waste is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

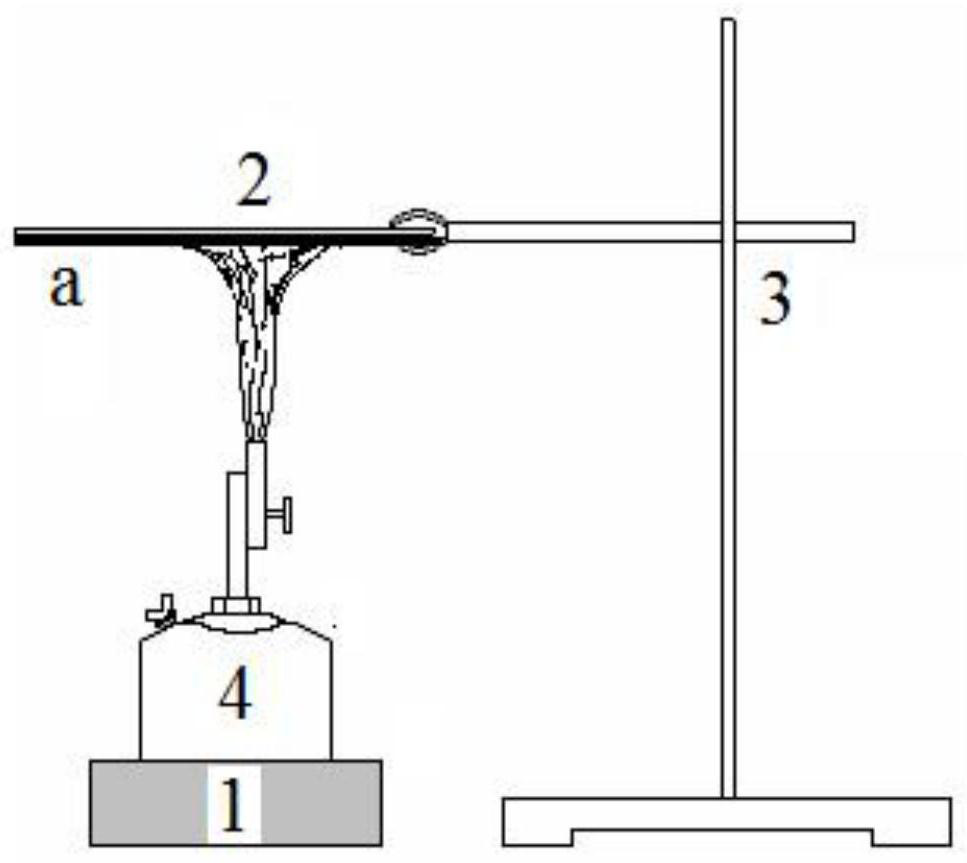

Supersonic dewatering method for mud

InactiveCN1821130AImprove dehydration treatment effectLow priceSludge treatment by de-watering/drying/thickeningSludgeSewage

The present invention relates to supersonic mud dewatering method and belongs to the field of solid waste treating technology. The supersonic mud dewatering method includes: the first treatment of dewatered mud from sewage treating yard in a stirrer and a press to form cake, treating in a supersonic treating unit, further dewatering in a dewatering unit to obtain dewatered mud as resource, and draining the separated water back to sewage treating yard. The treated mud has water content lowered from 80-85 % to 60-70 % and is suitable for use as resource. Compared with available technology, the present invention has low power consumption, low cost and excellent application foreground.

Owner:TSINGHUA UNIV

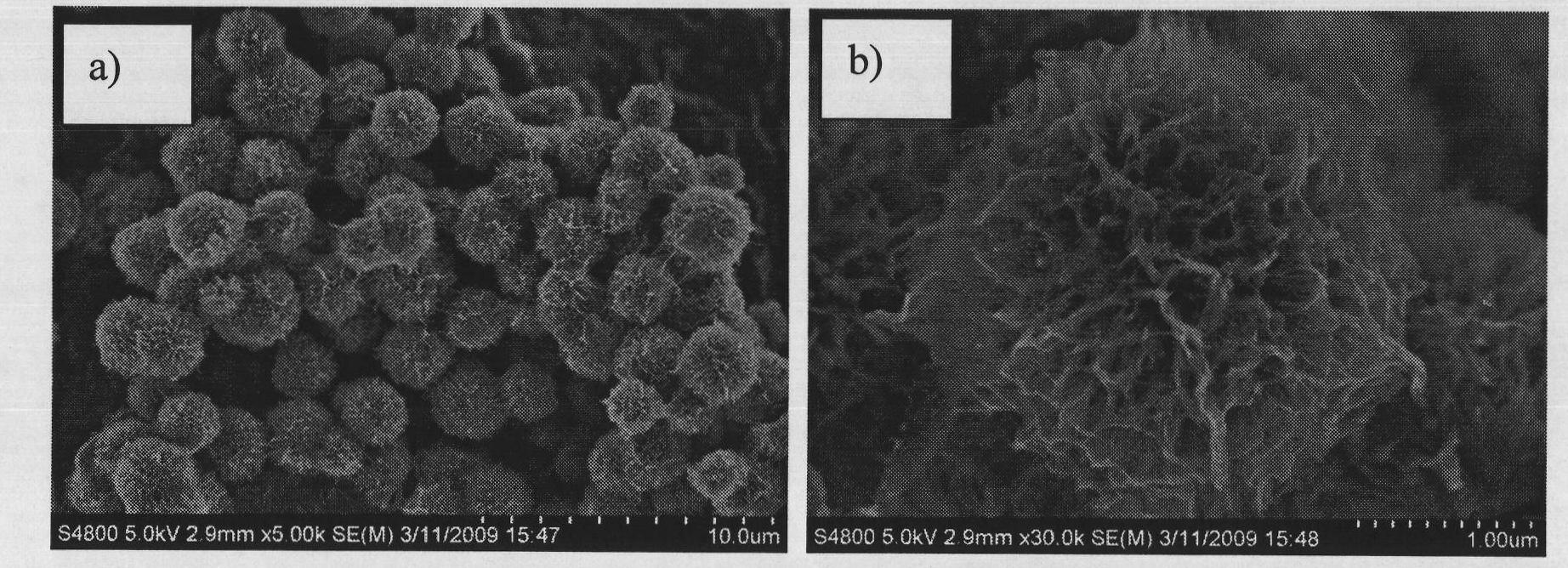

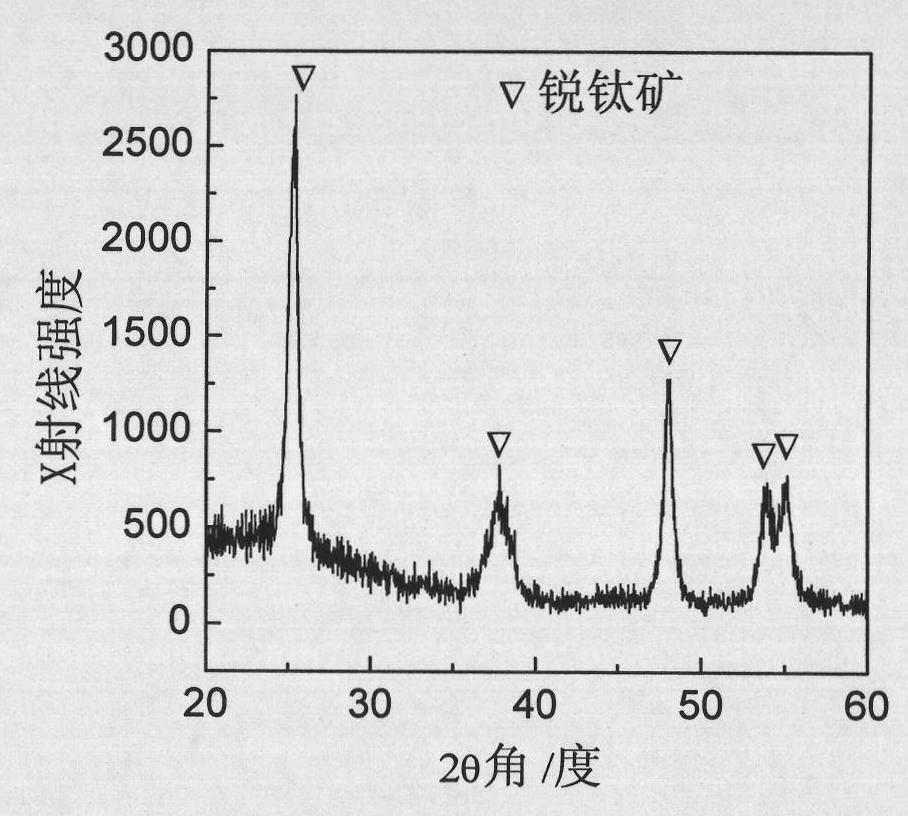

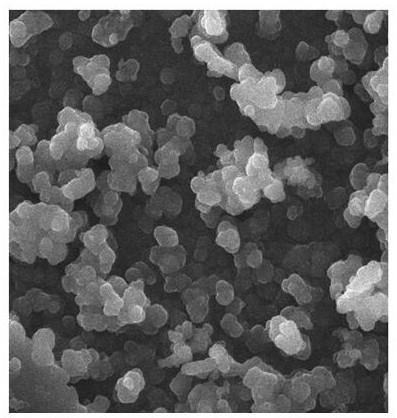

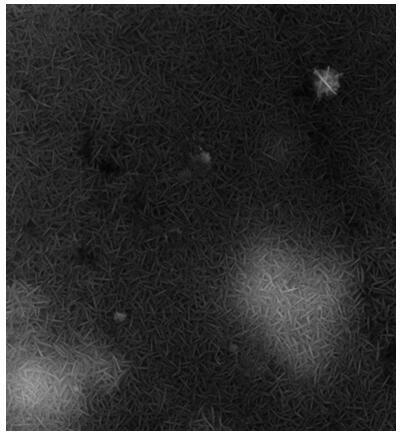

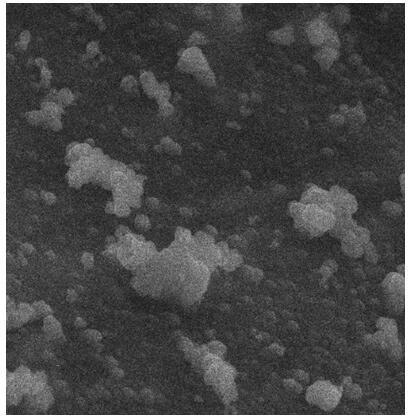

Monodisperse titanium dioxide nanometer microballoons and preparation method thereof

InactiveCN101830502AUniform size distributionReduce the difficulty of separation and recoveryTitanium dioxideDispersityNanowire

The invention discloses monodisperse titanium dioxide nanometer microballoons and a preparation method thereof. The diameters of the nanometer microballoons are 1.5-2.5 micrometers, and the microballoons have uniform size, good dispersity and high specific surface area. The single microballoon is formed by clustering nanometer wires with a length of 0.5-1.0 micrometer and a diameter of 20-30 nanometers. A reaction system consists of a residual solution left after a metal titanium plate reacts with hydrogen peroxide and a sodium hydroxide solution and is subjected to a hydro-thermal reaction for 20-64 hours at 120 DEG C to prepare the microballons; and after adopting subsequent proton exchange and heat treatment at 450-700 DEG C, the nanometer microballoons are crystallized into anatase. In the presence of the same condition, the efficiency of the nanometer microballoons subjected to heat treatment at 600 DEG C for assisting photocatalysis to degrade rhodamine B dye in water is obviously superior to that of commercial titanium dioxide nanometer powder Degussa P25.

Owner:ZHEJIANG UNIV

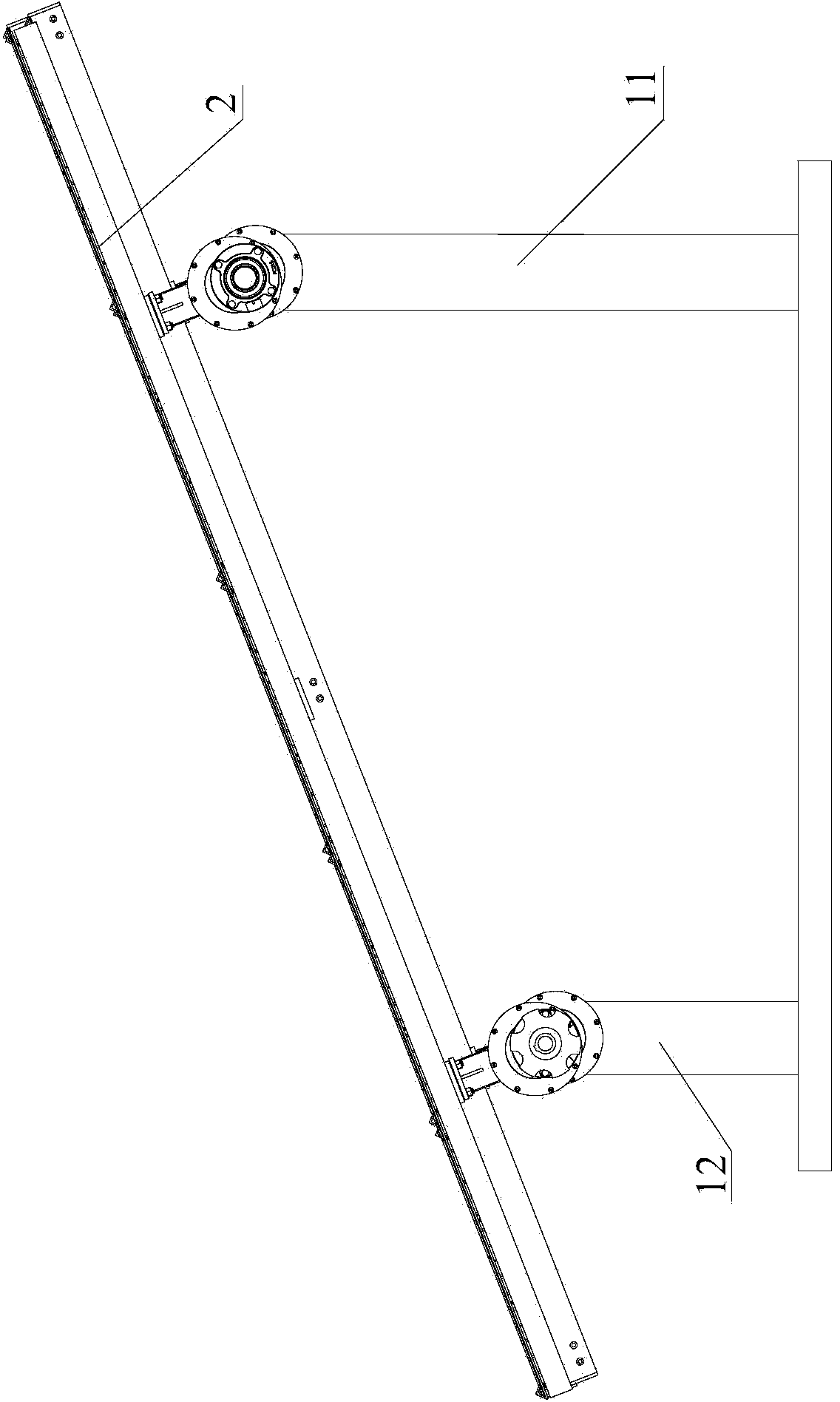

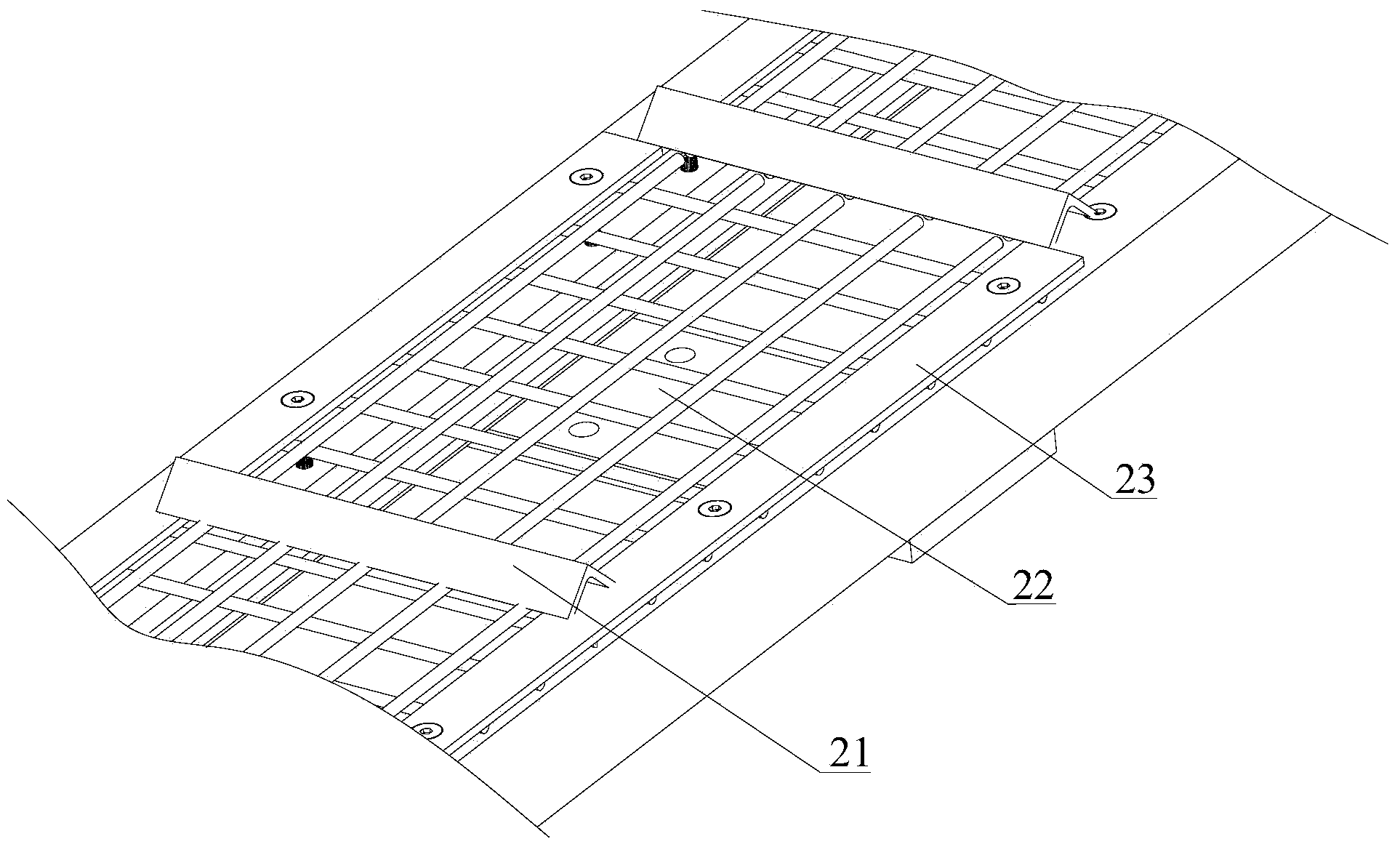

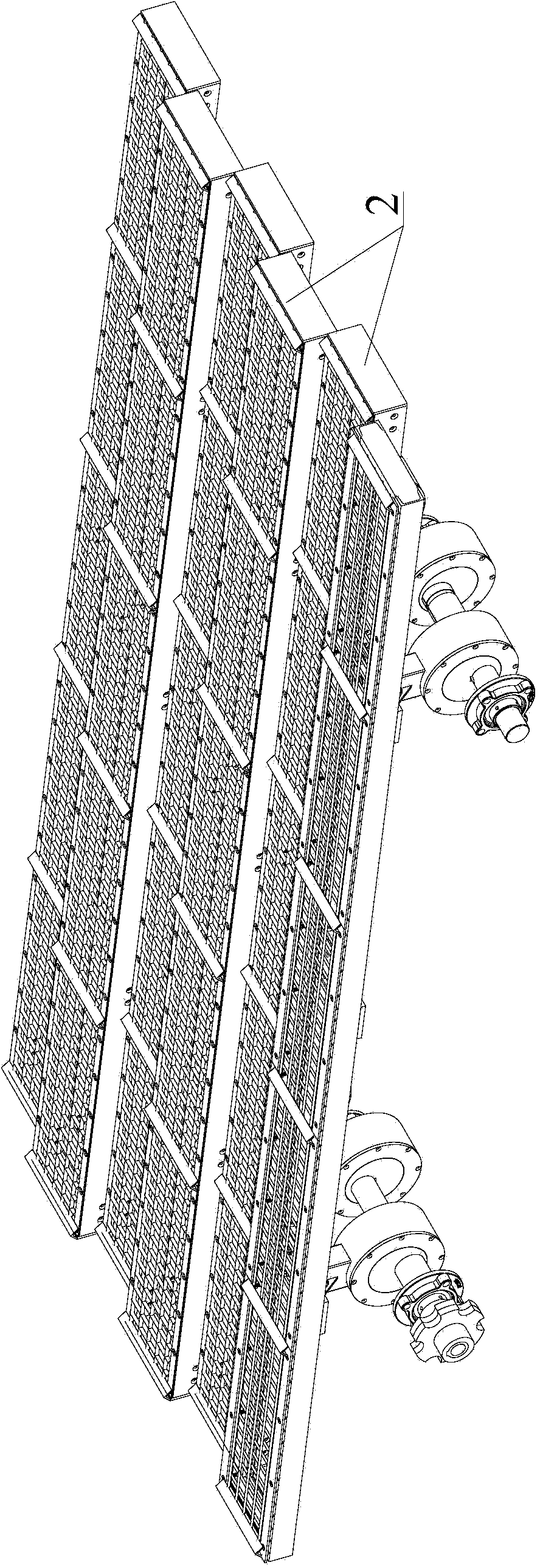

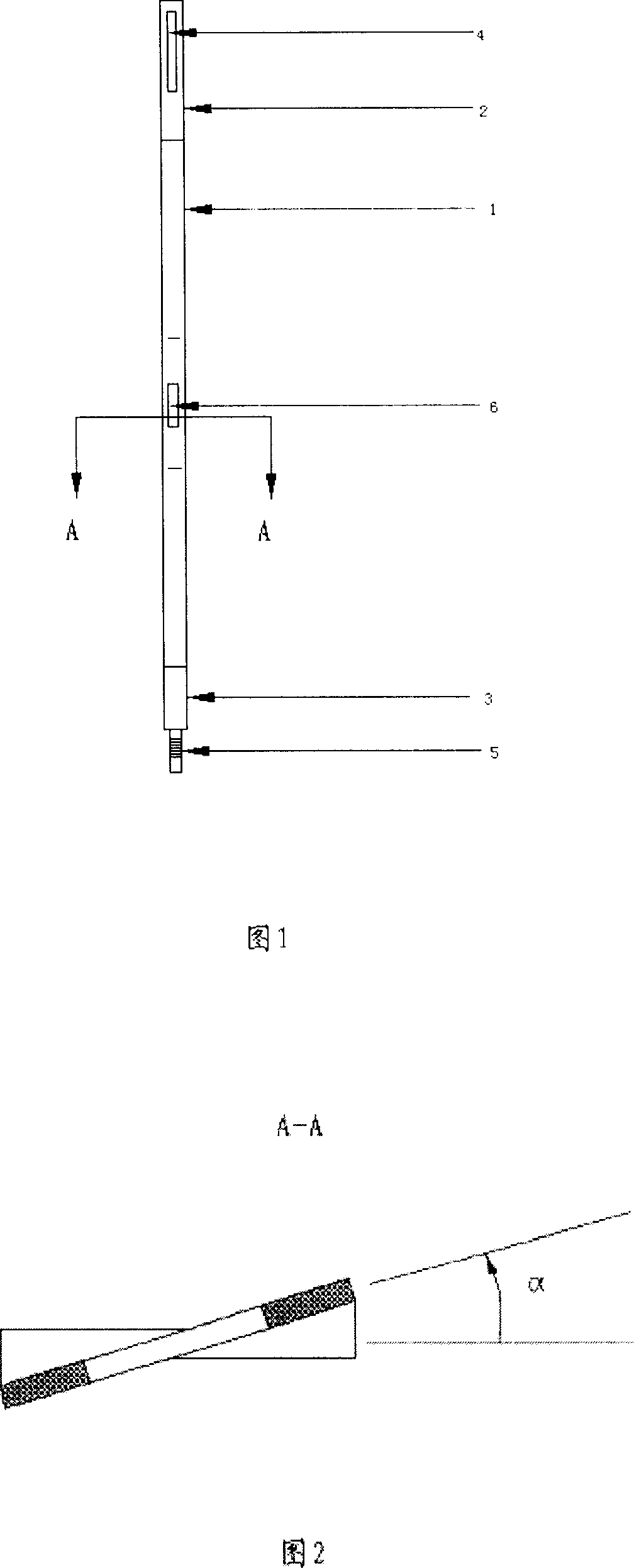

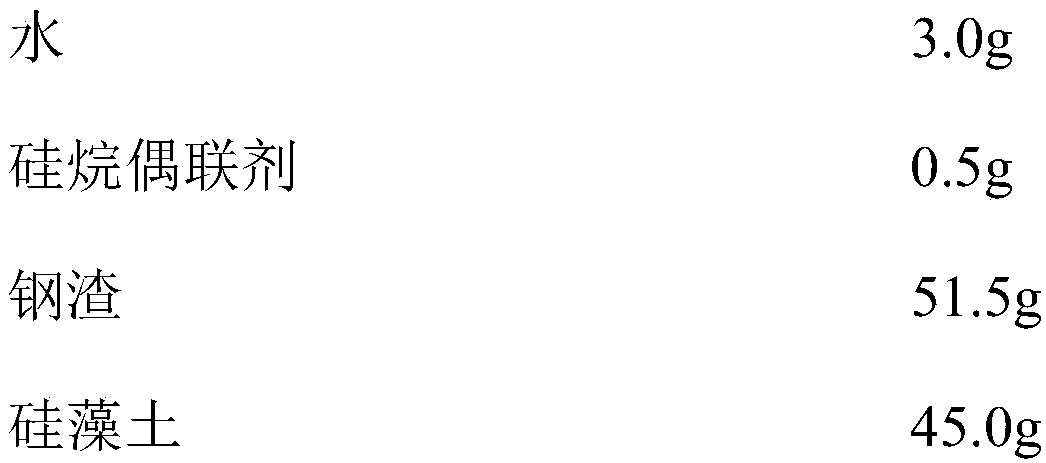

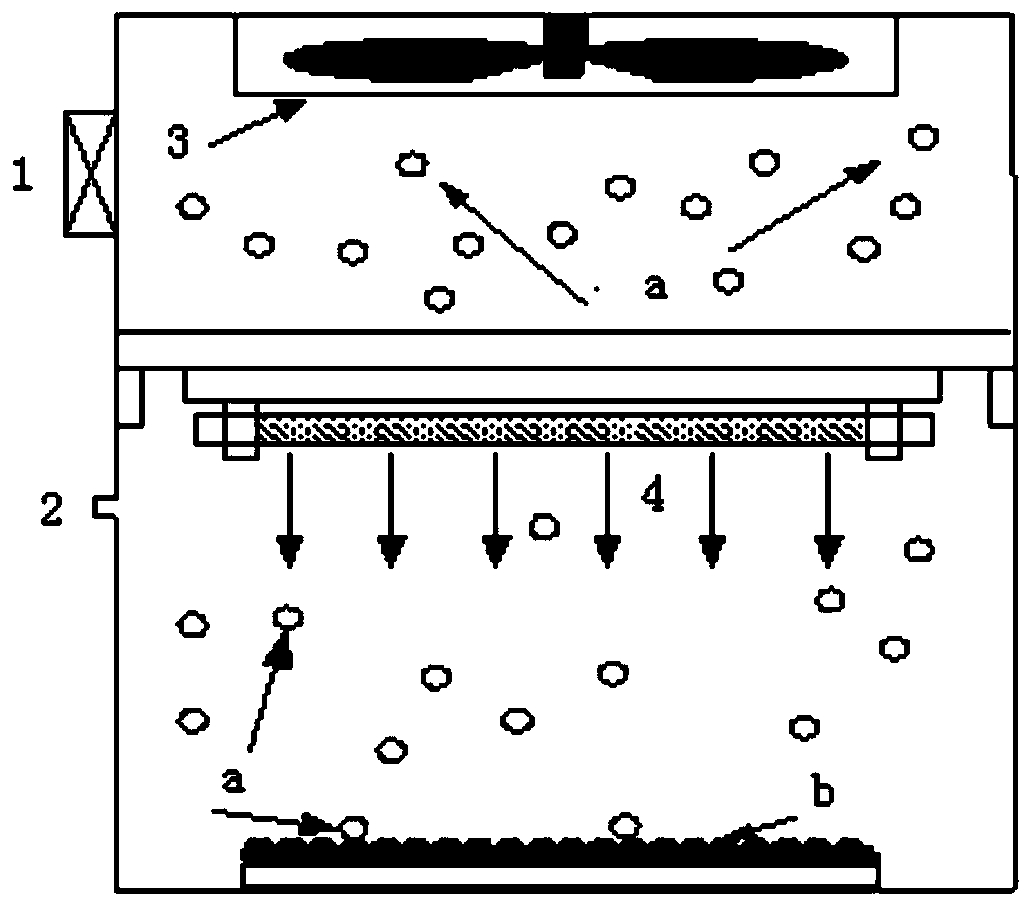

Screening machine and screening device of screening machine

ActiveCN103962302ASmall footprintEffective screening classificationSievingGas current separationEngineeringEnergy consumption

The invention discloses a screening device used for screening and separating mixed materials. The screening device comprises a screening body, a driving mechanism which drives the screening body to move, and supports which support the screening body. The screening body comprises a screening mesh plate, a plurality of strip-shaped protrusions are arranged on the working surface of the screening mesh plate, and the protrusions divide the screening mesh plate into a plurality of screening regions in the length direction. The supports comprise the first support and the second support lower than the first support, wherein the first support and the second support are distributed in the length direction and connected to the ends of the screening body. The screening device is simple in structure, three types of materials can be screened and separated at the same time, the screening process can be effectively shortened, occupied work space is reduced, screening efficiency and screening quality are improved, and energy consumption is remarkably reduced. On this basis, the invention further provides a screening machine with the screening device.

Owner:北京金亮点市政园林工程有限公司 +1

Integral heald wire for jacquard loom and its making process

The integral heald wire for jacquard loom as yarn guide has members in two ends for connection with other parts and one mail eye in the middle part. One of the connecting member has small hole and the other has thread. Warp is threaded via the mail eye to form one opening with the elevated heald wire, so that the weft introduced into the opening perpendicularly to the warp can be interwoven with the warp. The section with mail eye of the heald wire is turned by one 0-55 deg angle to the other sections. The making process of the integral heald wire includes the steps of rolling, punching, polishing and injection molding. The integral heald wire has no rust, no contamination to the fabric, long service life and other advantages.

Owner:DANYANG CITY XINLONG TEXTILE +1

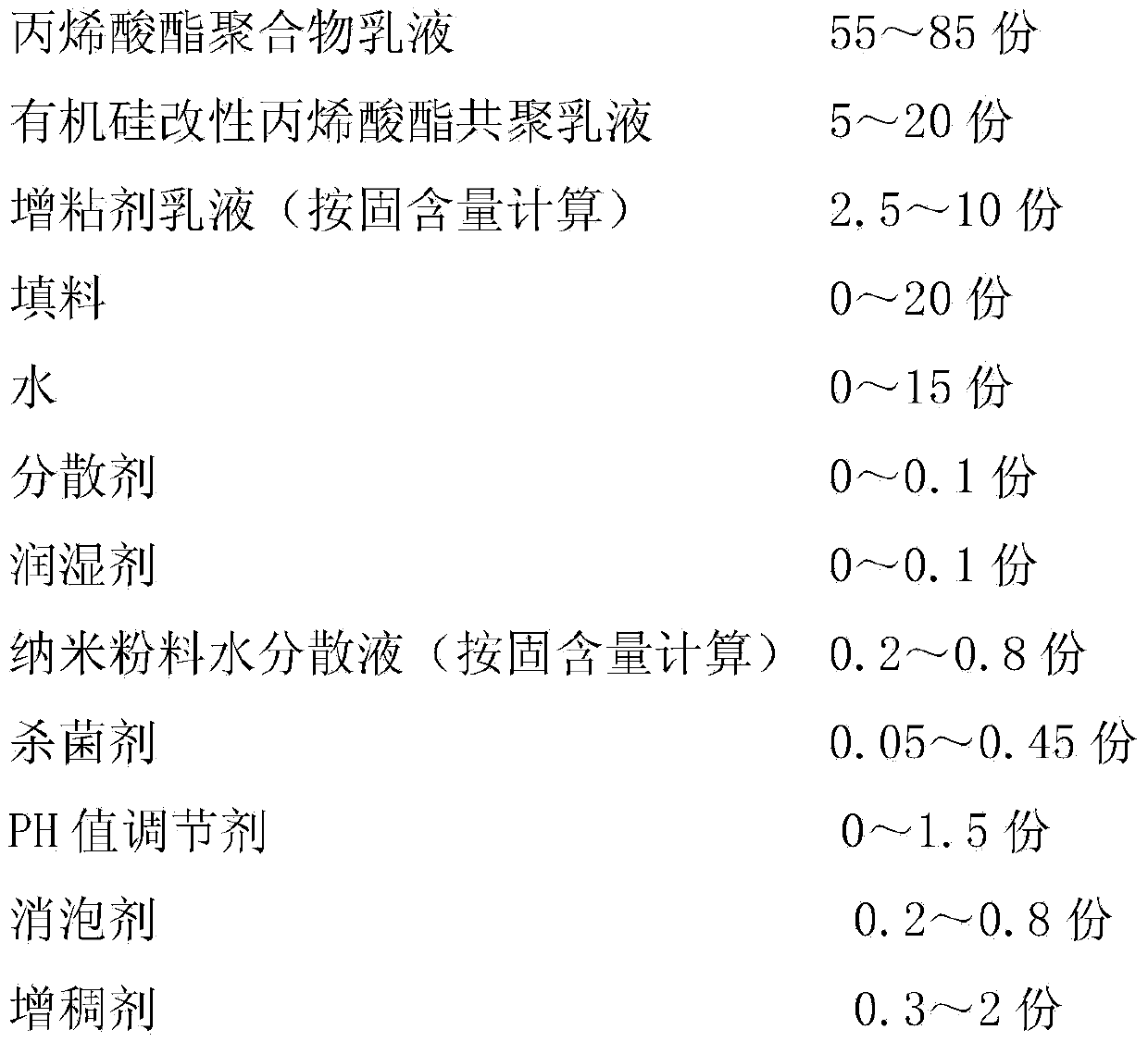

Steel slag-diatomite composite rubber filling material with reinforcing and flame-retarding synergistic performance

The invention discloses a steel slag-diatomite composite rubber filling material with reinforcing and flame-retarding synergistic performance, belonging to the field of cyclic utilization of solid waste resources. The filling material comprises water, a silane coupling agent, steel slag, and diatomite. The preparation method for the filling material comprises the following concrete steps: mixing the water and the silane coupling agent, and carrying out dispersing so as to obtain a silane coupling agent solution; then mixing the steel slag and the diatomite, and carrying out stirring so as to obtain a steel slag-diatomite mixture; mixing the steel slag-diatomite mixture and the silane coupling agent solution, and carrying out stirring so as to obtain the steel slag-diatomite composite rubber filling material. The steel slag-diatomite composite rubber filling material provided by the invention solves the problems of high price and single function of main filling materials of carbon blackand white carbon black in the rubber industry, improves mechanical properties and flame retardancy of rubber, realizes cyclic utilization of industrial wastes, promotes efficiency of metallurgical enterprises, reduces the cost of the rubber product industry, and meets the requirements of current industrial development for energy conservation, environmental protection and cyclic economy.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

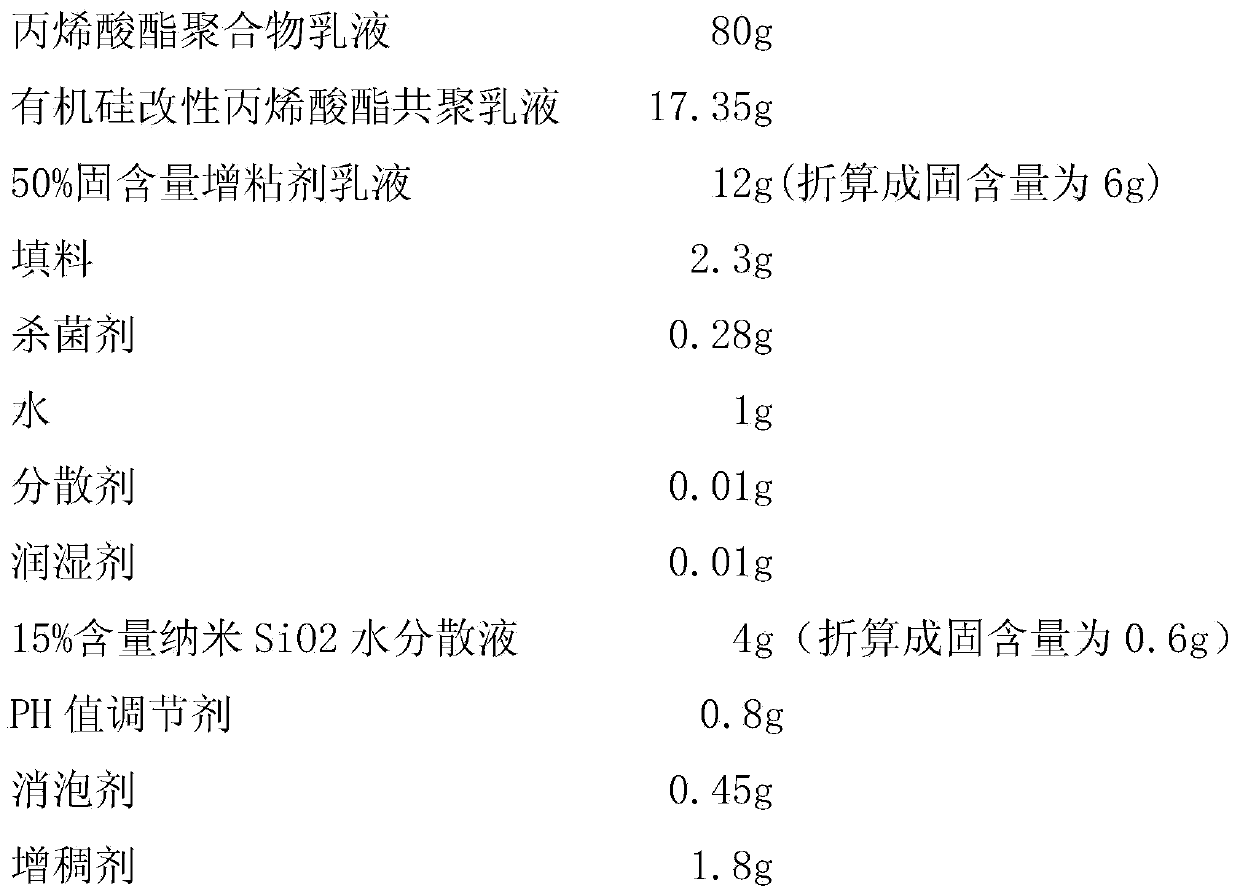

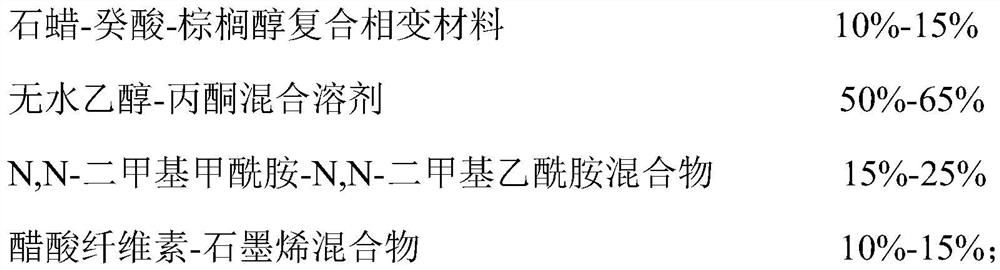

Nano-modified water-based weather-resistant sound isolation adhesive and preparation method thereof

InactiveCN103436204AImprove effective utilizationReduce usageEster polymer adhesivesWater basedAdhesive

The invention discloses a nano-modified water-based weather-resistant sound isolation adhesive. The nano-modified water-based weather-resistant sound isolation adhesive consists of an acrylate polymer emulsion, an organic silicone modified acrylate copolymer emulsion, a tackifier emulsion, a filler, water, a dispersing agent, a wetting agent, nano-powder aqueous dispersion, a sterilizing agent, a PH value regulating agent, a de-foaming agent and a thickening agent. A preparation method of the nano-modified water-based weather-resistant sound isolation adhesive comprises the steps of emulsion polymerization, emulsion blending, filler slurry preparation, mixture nano-modification and finished product synthesis. The nano-modified water-based weather-resistant sound isolation adhesive has the advantages of wide temperature range, wide frequency, high damping platform, high peeling strength, energy conservation, environment friendliness and light weight; the cost is saved, the construction difficulty is lowered, and the effective space utilization rate is greatly improved. Due to modification of a nano material, the nano-modified water-based weather-resistant sound isolation adhesive is wide in temperature range, good in moisture protection, resistant to heat, light, salt spray and the like, good in ageing resistance, wide in using environment range, high in sound isolation efficiency and high in using value. The sound isolation adhesive is aqueous, has environment-friendly and pollution-free effects, and belongs to novel energy-saving and environment-friendly high molecular materials.

Owner:南京创宁空间新材料科技有限公司

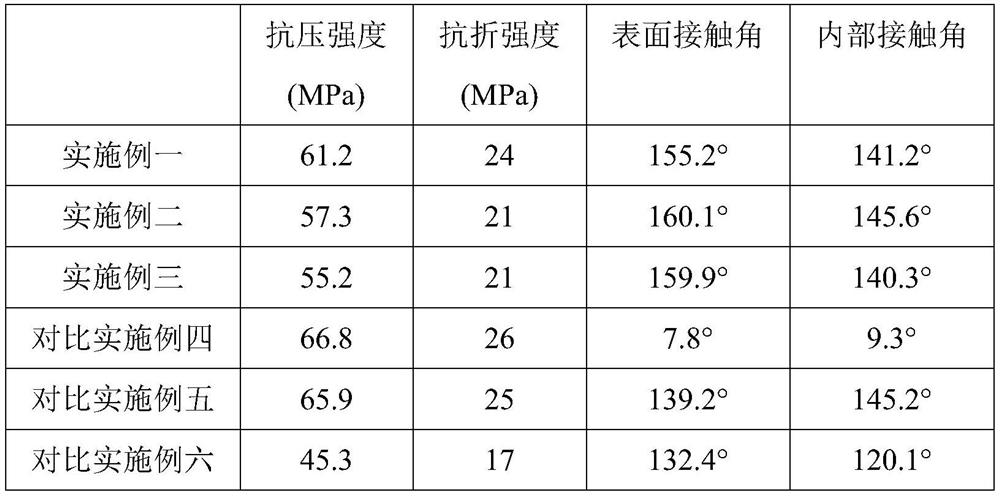

Siloxane-modified super-hydrophobic geopolymer anticorrosive material and preparation method thereof

ActiveCN112079593AImprove superhydrophobicityAccelerated corrosionCement productionFiberMicron scale

The invention discloses a siloxane-modified super-hydrophobic geopolymer anticorrosive material which comprises the following raw materials, by weight: 70-90 parts of a silicon-aluminum mineral raw material, 75-100 parts of an alkali activator, 2-3 parts of polydimethylsiloxane, 4-5 parts of methyl hydrogen-containing silicone oil, 0.1-0.2 part of a silane coupling agent, 4-6 parts of nano magnesium hydroxide powder, 7-10 parts of nano silicon dioxide powder, 3-5 parts of short fibers, 1-2 parts of calcium lignosulphonate and 1-1.5 parts of a grinding aid. The invention also discloses a preparation method of the siloxane modified super-hydrophobic geopolymer anticorrosive material. According to the invention, a method of combining siloxane with matrix and surface super-hydrophobic modification is utilized, and matrix surface chemical structure modification and nanoscale and micron-scale roughness modification are combined, so that the super-hydrophobic and high-corrosion-resistance properties of the compact high-strength geopolymer material are improved; the raw materials, the nano material and the short fibers are added, so that the material is high in strength, compact in structure and high in durability, and the resistance of the material to ion erosion, substance dissolution, freeze-thaw damage and the like is achieved through super-hydrophobic modification.

Owner:ZHEJIANG UNIV

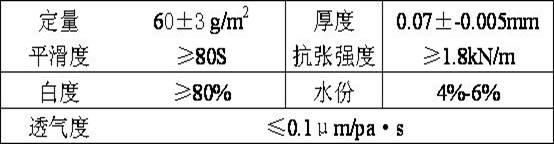

Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

InactiveCN102587206ALow priceNothing producedCoatings with pigmentsSpecial paperPolyvinyl alcoholAdhesive

The invention provides an aluminum-free anti-counterfeiting lining paper for cigarettes and a production method thereof. The lining paper is composed of an anti-counterfeiting paper layer, a coating layer and an aqueous printing oil layer. The technical indexes are as follows: the fixed quantify is 60+ / -3 g / m<2>; the thickness is 0.07+ / -0.005 mm; the flatness is more than or equal to 80 S; the tensile strength is more than or equal to 1.8 kN / m; the whiteness is more than or equal to 80%; the water content is 4-6%; and the air permeability is less than or equal to 0.01 micron / Pa.s. The production method comprises the following steps of: firstly preparing a coating; and then, coating the prepared coating on front and back sides of anti-counterfeiting paper on a coating machine, so as to prepare a product. According to the production method, the anti-counterfeiting paper is used as basic paper and an anti-counterfeiting function is organically combined with the lining paper for the cigarettes, thereby achieving the anti-counterfeiting effect and greatly reducing the cost. The formula of the coating used in the preparation method is unique and a main paint part is papermaking porcelain clay which is widely applied to the papermaking industry and is low in price and an adhesive is polyvinyl alcohol and has no extraneous odor or toxicity; in the production process, no organic solvent is used and no pollutant is generated, thereby protecting environment. Non-ferrous metal such as aluminum foils, aluminum powder and copper powder, is not used, so that the product cost is low, the energy consumption is low, and ideals of energy saving and environmental protection and low-carbon lifestyle are realized.

Owner:杜荣安 +2

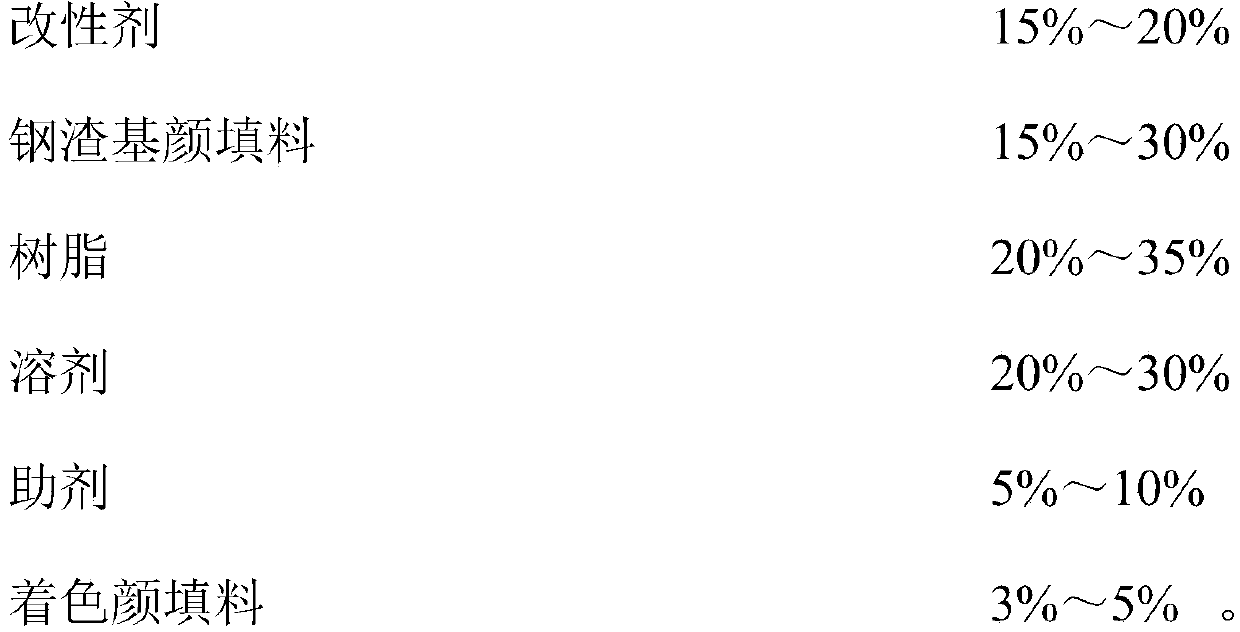

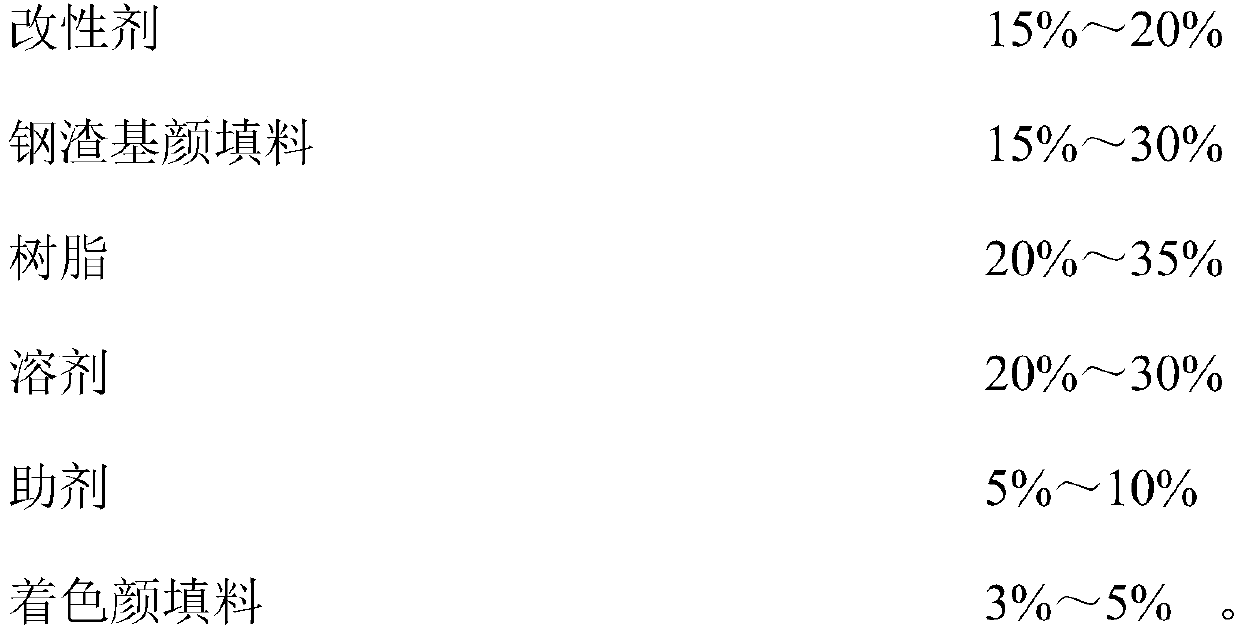

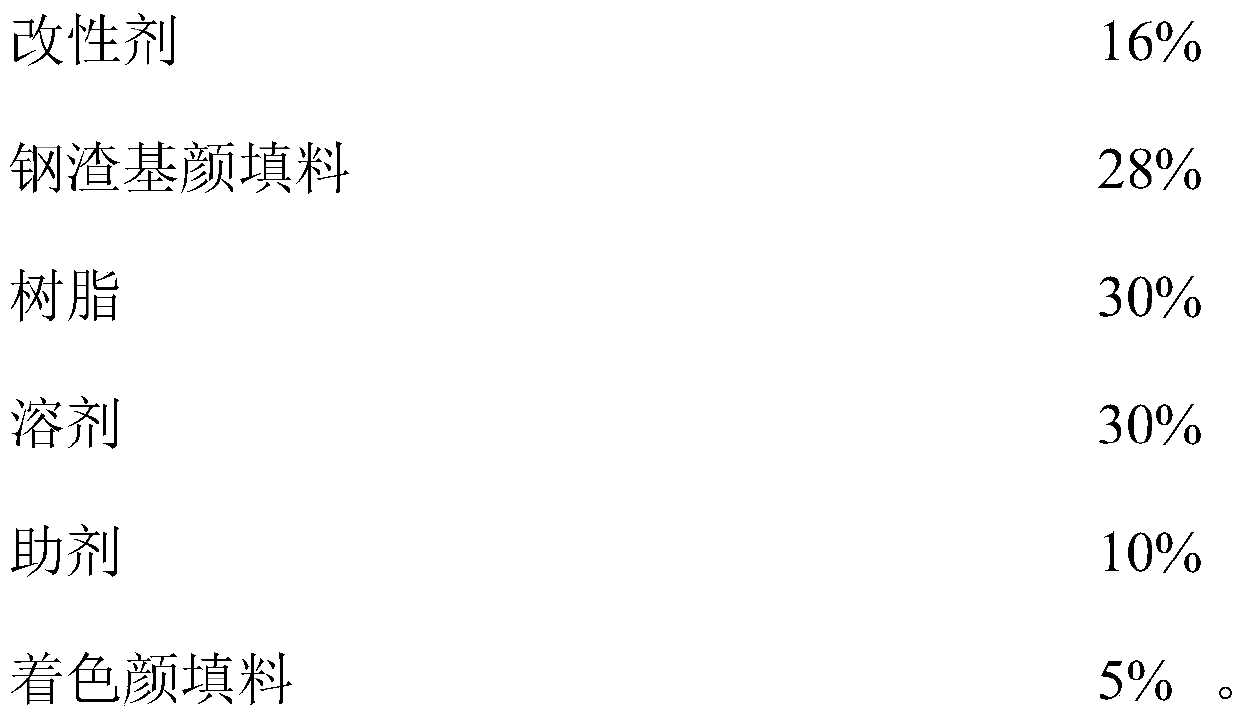

Metal antirust paint with modified steel slag-based pigment and filler replacing iron oxide red, and preparation method

InactiveCN110845887AExpensive to fixExpand large scaleAnti-corrosive paintsEpoxy resin coatingsSlagPigment

The invention discloses a metal antirust coating with modified steel slag-based pigment and filler replacing iron oxide red and a preparation method thereof. The metal antirust coating has the advantages of easily available raw materials, low price, excellent performance, simple process, convenience in operation and environmental friendliness. The metal antirust paint is composed of the followingcomponents in percentage by mass: 15-20% of a modifier, 15-30% of a steel slag-based pigment filler, 20-35% of a resin, 20-30% of a solvent, 25-10% of an auxiliary agent, and 3-5% of a coloring pigment filler. The metal antirust coating is prepared by four steps of preparation of a modified steel slag-based pigment and filler precursor, preparation of the modified steel slag-based pigment and filler, preparation of a metal antirust coating precursor and preparation of the product metal antirust coating.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Method for synthesizing 4A molecular sieve by double crystallization

InactiveCN109292792AEliminate the effects ofReduce the degree of reunionMolecular-sieve silicatesAluminosilicate zeolite type-AMolecular sieveAl powder

The invention discloses a method for synthesizing a 4A molecular sieve by double crystallization. The method comprises the following steps: pre-treating a raw material, sufficiently mixing the raw material with a NaOH solution, and performing stirring at constant speed; performing filtering and separating under a vacuum state to obtain supernate; mixing and stirring Al powder and the NaOH solutionuntil the Al powder is completely dissolved to obtain a mixed solution; mixing the mixed solution with the supernate, performing standing at constant temperature, and performing filtering to obtain aclear solution; and aging the clear solution under a room temperature condition, performing microwave assisted hydrothermal double crystallization to obtain the 4A molecular sieve. According to the method, the yield and synthesizing efficiency can be greatly improved, cost can be reduced, and industrial synthesizing application of the 4A molecular sieve can be benefited.

Owner:KUNMING UNIV OF SCI & TECH

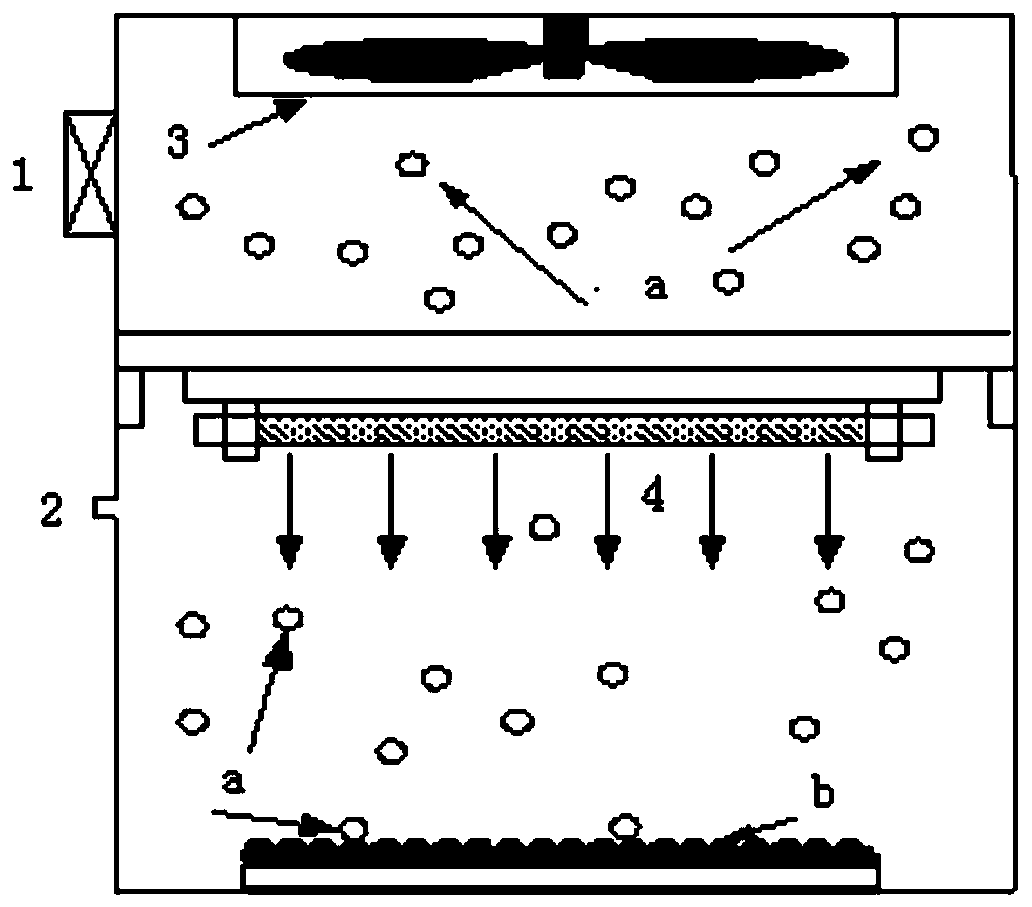

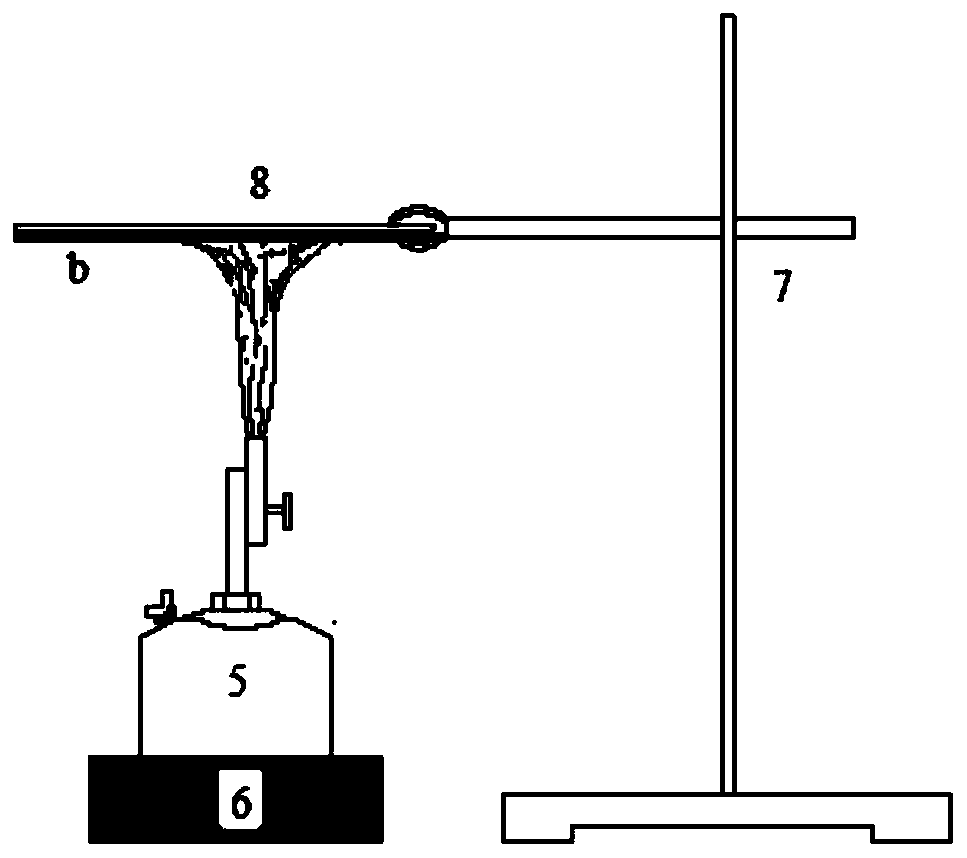

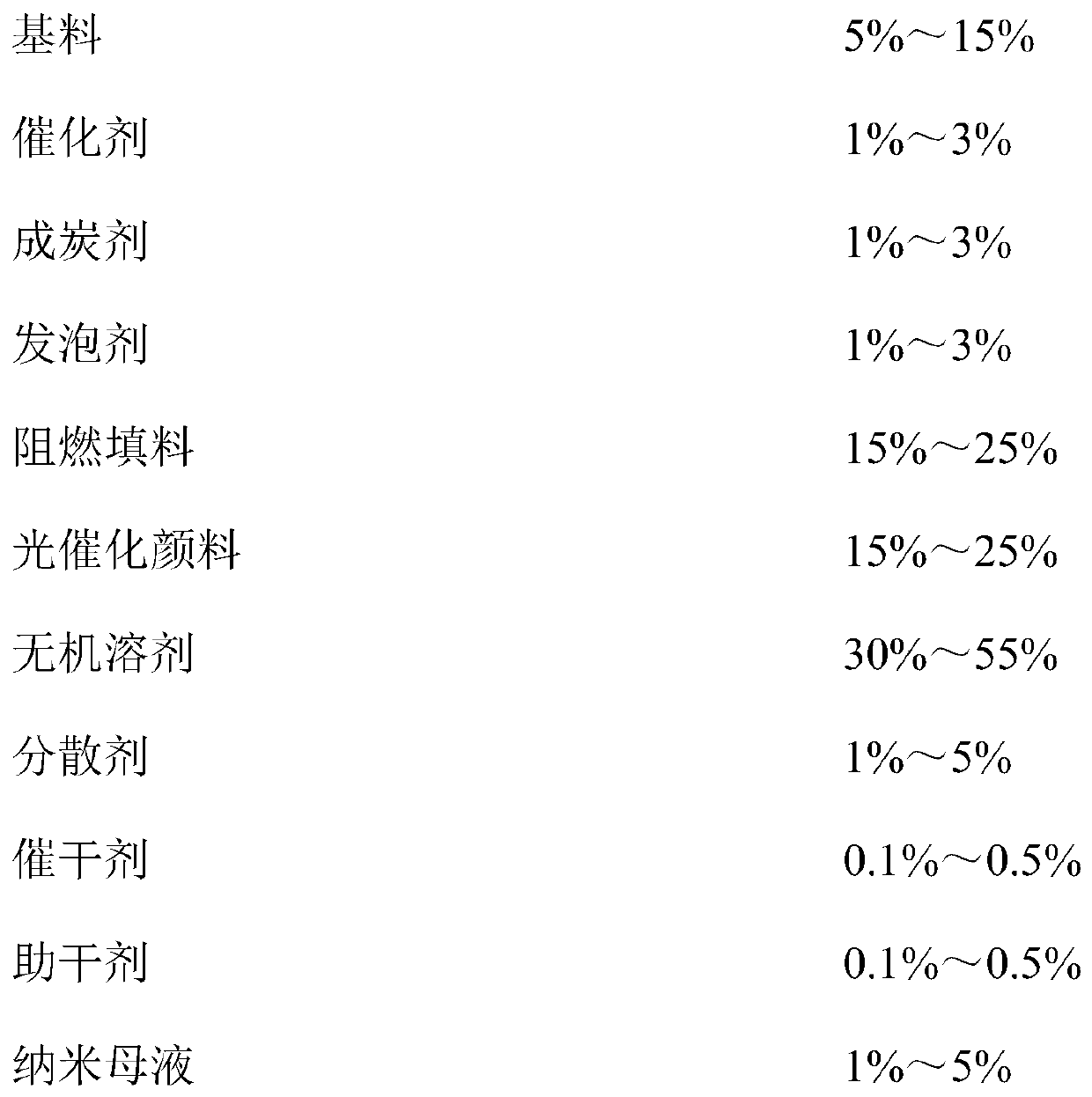

Ecological photo-catalytic fireproof coating for air purification and preparation method of ecological photo-catalytic fireproof coating

ActiveCN109943112ASolve the shortcomings of single functionOpen up avenuesFireproof paintsRare-earth elementPhoto catalytic

The invention discloses an ecological photo-catalytic fireproof coating for air purification and a preparation method of the ecological photo-catalytic fireproof coating, belonging to the field of functional coatings. The ecological photo-catalytic fireproof coating contains a base material, a catalyst, a carbon forming agent, a flame-retardant filler, a photo-catalytic pigment, an inorganic solvent, a dispersant, a drying agent, a drying aid and a nano-mother solution. According to the ecological photo-catalytic fireproof coating, the problems of high cost and complex process caused when TiO2is modified by virtue of metal elements and rare earth elements in the prior art are solved, the disadvantage of single function of a coating filler is avoided, the fireproof coating is endowed withbrand new functions, the way of novel functional coatings is exploited, the production cost of the photo-catalytic fireproof coating is lowered by 30%, and the market competitiveness of the fireproofcoating is increased. TiO2 is modified with steel slag as the photo-catalytic pigment, red mud micro-powder is taken as the flame-retardant filler, and the ecological photo-catalytic fireproof coatingis prepared, so that the new way for the utilization of metallurgic solid waste is exploited, and the high added value application of the metallurgic solid waste is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

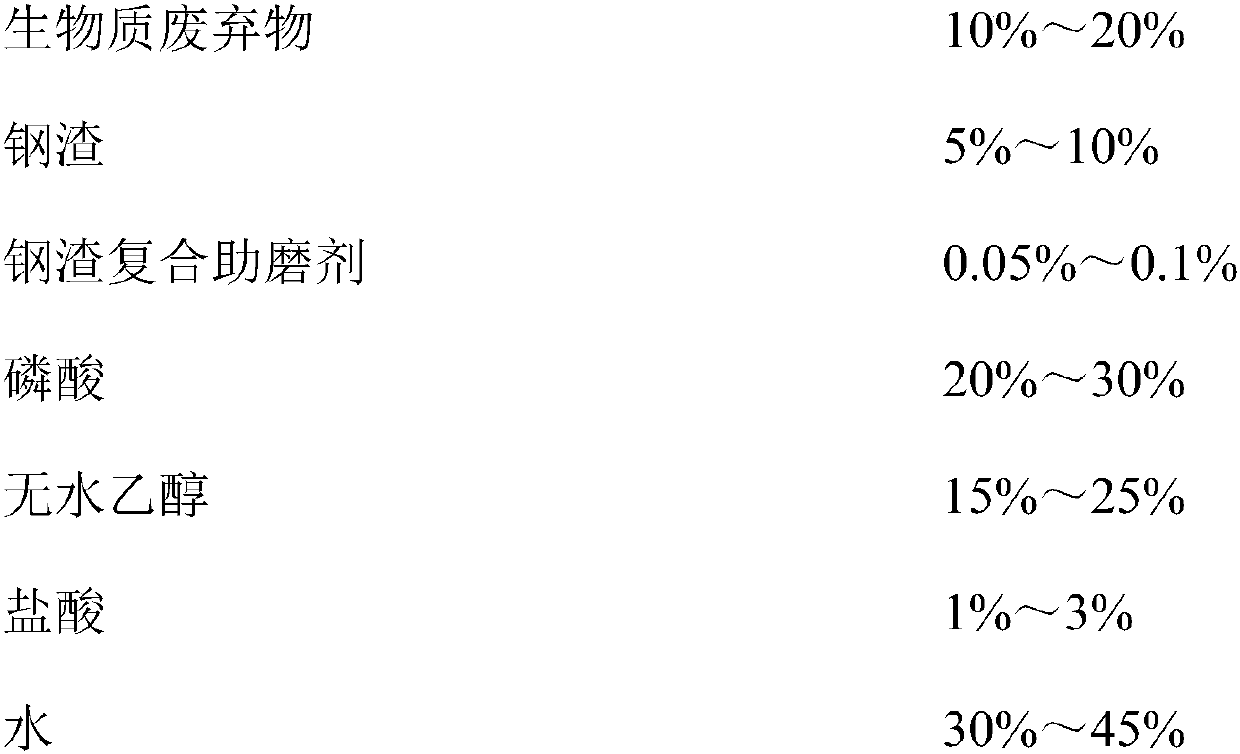

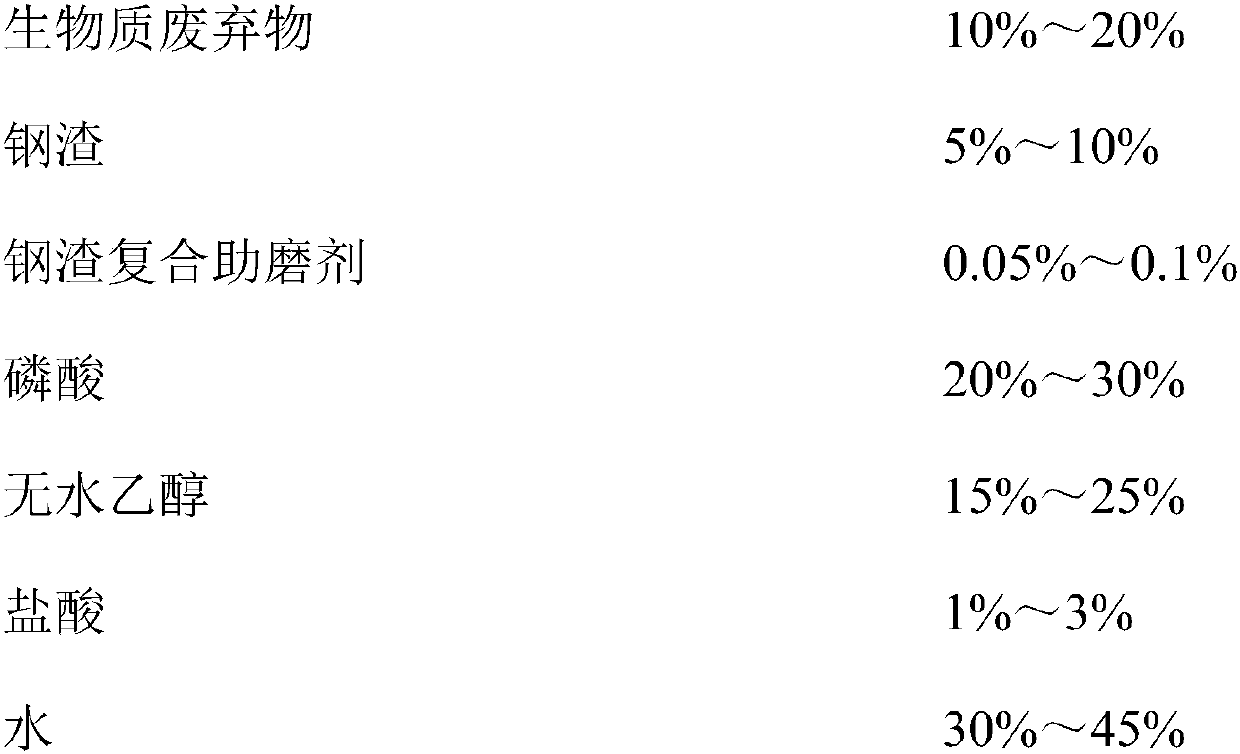

Steel-slag-based biomass activated carbon for degrading formaldehyde and preparation method of activated carbon

InactiveCN109734090AReduce manufacturing costPromote sustainable developmentCarbon compoundsSlagPhosphoric acid

The invention discloses steel-slag-based biomass activated carbon for degrading formaldehyde and a preparation method of the activated carbon, and belongs to the field of solid waste utilization. Thesteel-slag-based biomass activated carbon comprises biomass waste, steel slag, steel slag compound grinding aids, phosphoric acid, absolute ethyl alcohol, hydrochloric acid and water. The biomass waste includes one or more of fruit shells, fruit kernels and straws, and the steel slag includes one or more of heat stuffy slag, electric furnace slag and wind chopped slag. The steel slag and the biomass waste are compounded to prepare the steel-slag-based biomass activated carbon, the biomass waste is modified by metallic oxide in the steel slag, high value-added application of the steel slag andthe biomass waste is widened, and a new idea of 'danger control by waste' is achieved. Compared with a current technique of physically mixing steel slag and activated carbon to modify the activated carbon, a grind-aiding technique and a chemical combination technique are combined, and the performance and stability of the steel-slag-based biomass activated carbon are greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

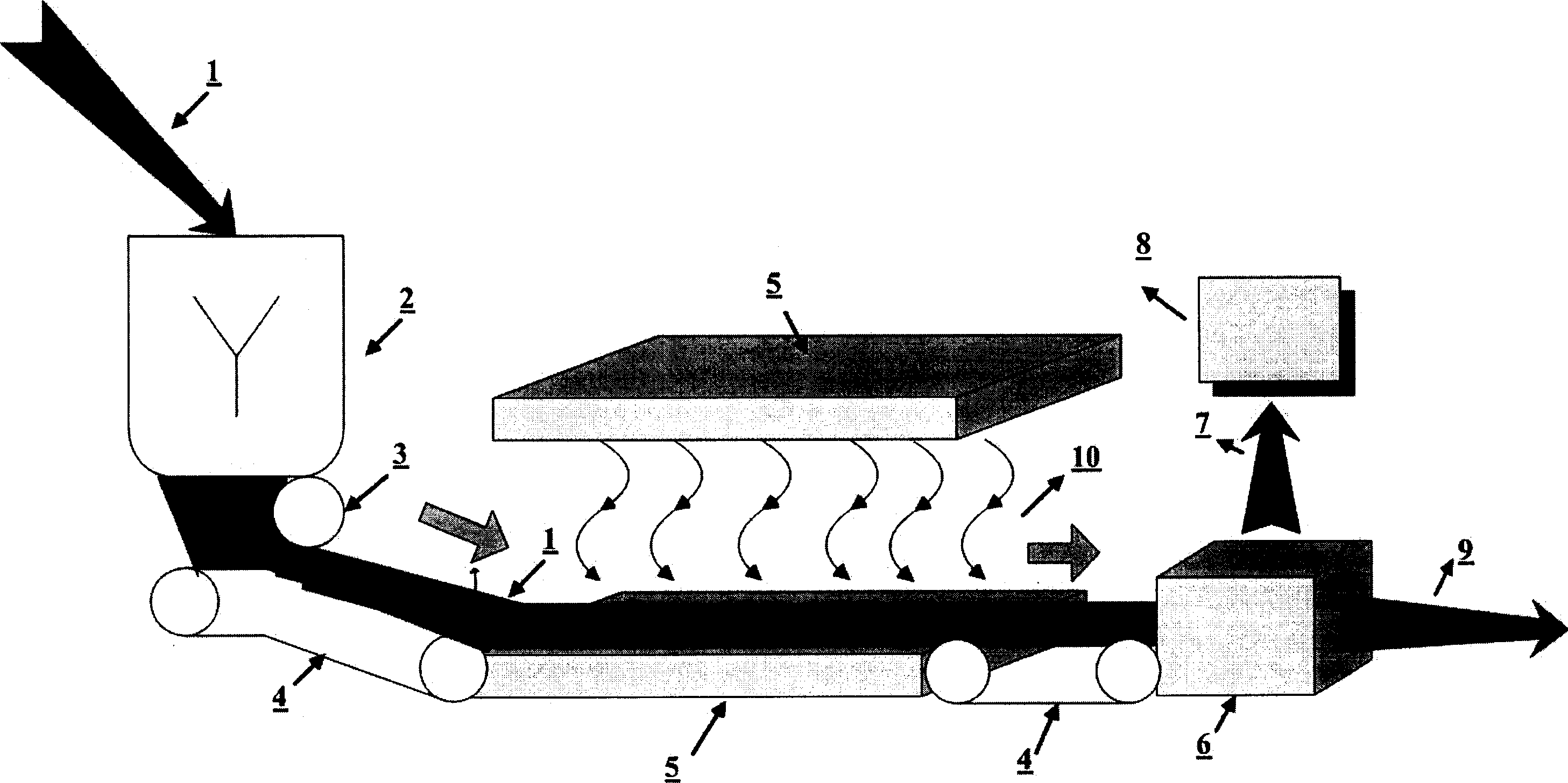

Biomass granular fuel applied to tobacco curing and application of biomass granular fuel

InactiveCN108294353ACompliant with energy saving and environmental protectionComply with energy saving requirementsTobacco preparationFinal product manufactureCooking & bakingAdditive ingredient

The invention discloses a biomass granular fuel applied to tobacco curing and an application of the biomass granular fuel, and belongs to the field of renewable energy. The biomass granular fuel provided by the invention, which is made from saw dust, tobacco stems and coal, conforms to requirements of energy conservation and environmental protection as well as green-going agricultural development;firstly, problems on land occupation of accumulation and atmospheric pollution caused by combustion of tobacco stems and saw dust in a tobacco planting area can be solved; secondly, since making costof the tobacco stems and the saw dust is much lower than development cost of coal resources, the cost of tobacco curing is greatly reduced in overall; and thirdly, the tobacco stems are derived fromtobacco, and biomass ingredients in the tobacco stems, after volatilization, blend into tobacco leaves in a curing process, so that the tobacco leaves, which are prepared by curing the tobacco stems,are much better than tobacco leaves, which are prepared through coal baking, in quality. The biomass granular fuel is low in cost and good in tobacco curing effect; the biomass granular fuel, when burned, has the characteristics of gas and solid fuel combustion; the biomass granular fuel is low in construction cost and relatively low in harmful ingredients in discharged waste, so that environmental pollution is reduced to a great extent; and the biomass granular fuel has huge economic and social benefits.

Owner:SOUTH CHINA AGRI UNIV +1

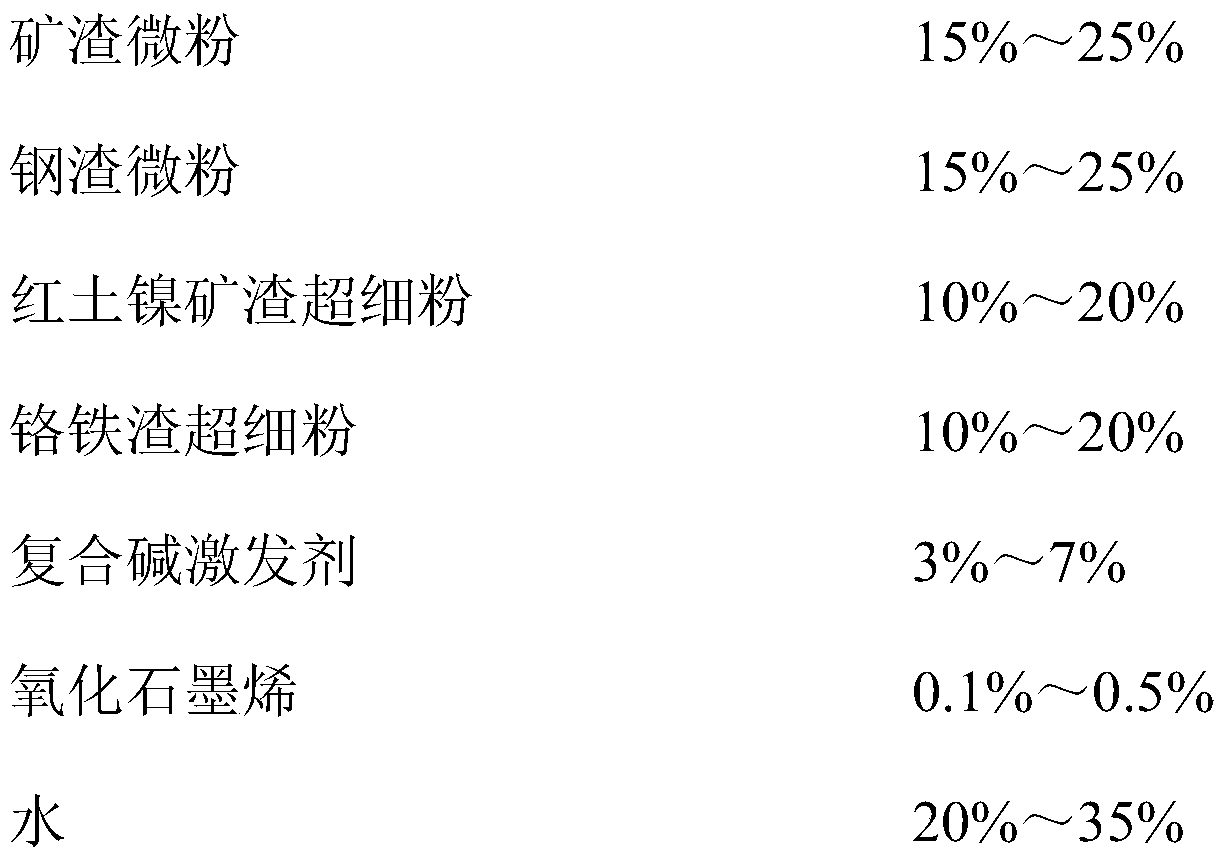

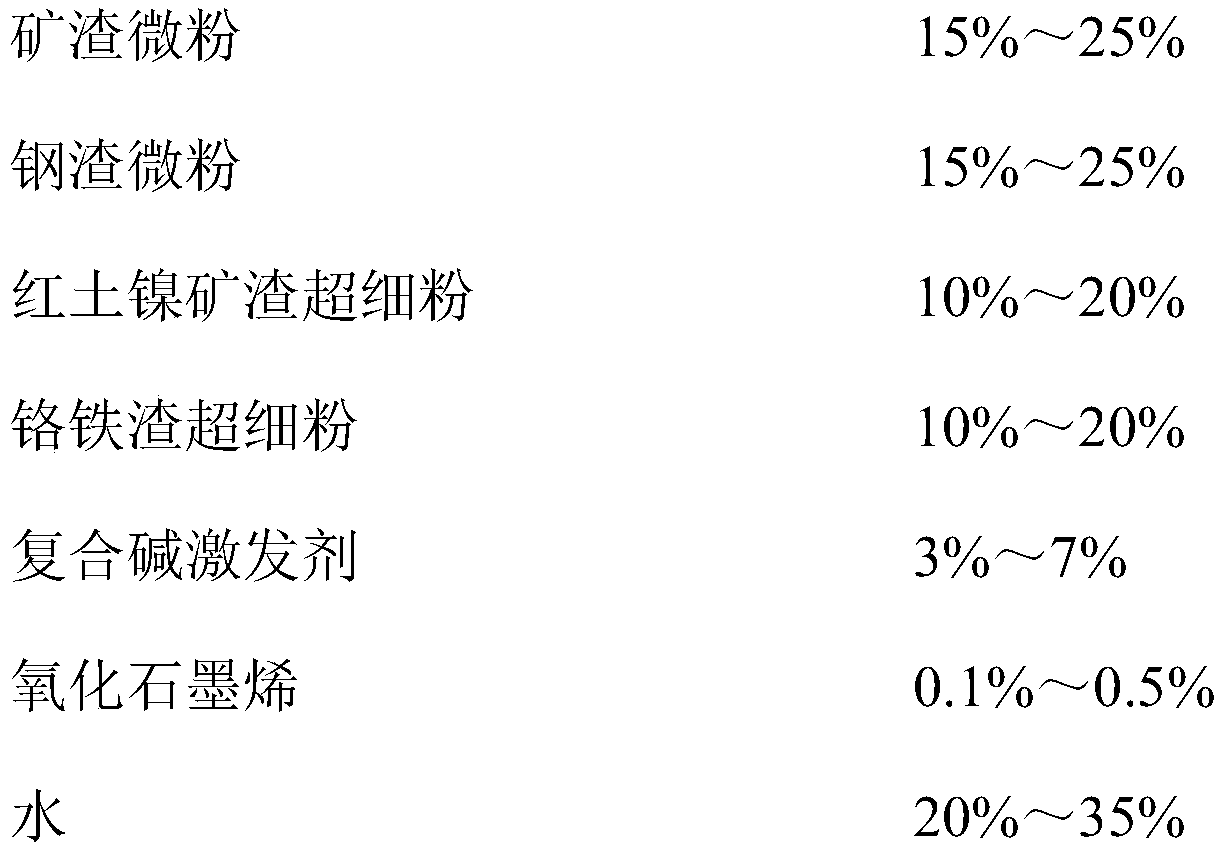

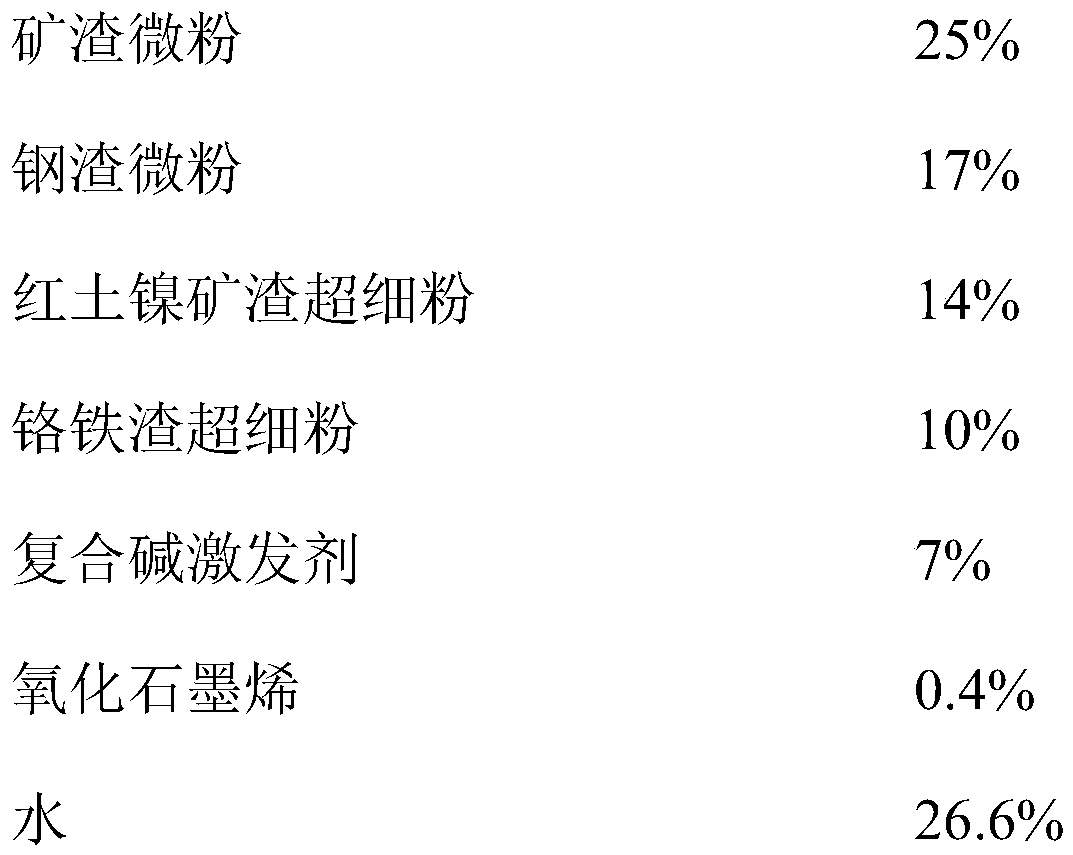

Composite alkali-activated solid waste type high performance inorganic adhesive, and preparation method thereof

ActiveCN110330242APromote hydrationImprove mechanical propertiesCement productionResource utilizationAdhesive

The invention discloses a composite alkali-activated solid waste type high performance inorganic adhesive, and a preparation method thereof, and belongs to the field of solid waste resource utilization. The composite alkali-activated solid waste type high performance inorganic adhesive comprises mineral slag micropowder, steel slag micropowder, laterite nickel ore slag ultrafine powder, ferrochromium slag ultrafine powder, a composite alkali exiciting agent, oxidized graphene, and water; the mineral slag micropowder is granulated blast furnace slag micropowder; the steel slag micropowder is one or a plurality of components selected from hot disintegrating slag micropowder, air granulation slag micropowder, molten iron desulphurization slag micropowder, casting slag micropowder, converter layer pouring slag micropowder, converter roller slag micropowder, electric furnace layer pouring slag micropowder, and electric furnace roller slag micropowder. The preparation method is capable of reducing production cost of conventional inorganic adhesive, improving the high temperature resistance and shearing force of inorganic adhesive, realizing combination of high temperature resistance andhigh shearing force on inorganic adhesive, improving inorganic adhesive market competition greatly, enlarging application range, and providing large scale high added value application ideas for utilization of mineral slag, steel slag, laterite nickel slag, and ferrochromium slag.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

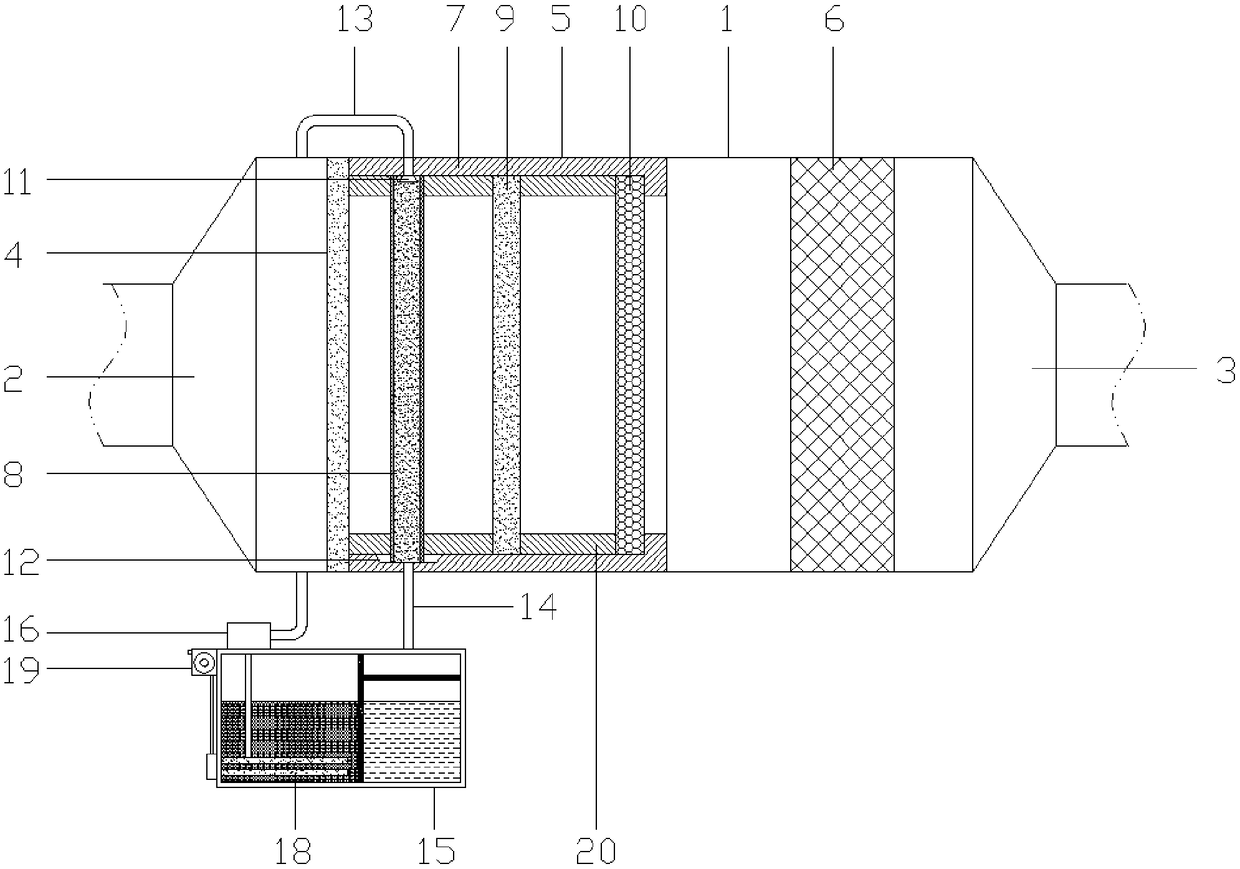

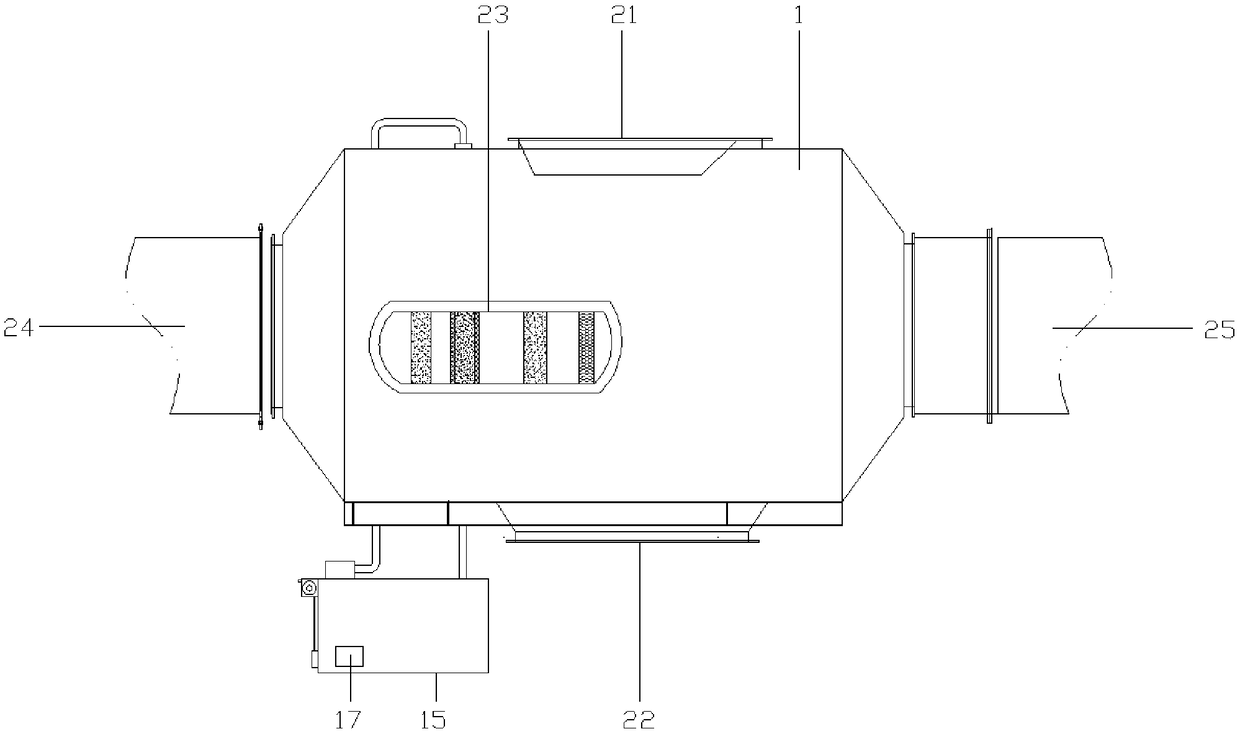

Low-temperature plasma waste gas purification equipment

InactiveCN108619817AExtended service lifeImprove air purification efficiencyCombination devicesGas treatmentActivated carbonWater storage tank

The invention discloses low-temperature plasma waste gas purification equipment. The low-temperature plasma waste gas purification equipment comprises a low-temperature plasma reaction chamber; the low-temperature plasma reaction chamber is provided with both a gas inlet and a gas outlet; a filtering net, a filtering device and a plasma generation device are arranged in the low-temperature plasmareaction chamber sequentially; the filtering device comprises a bracket as well as a filtering layer, a demisting layer and an activated carbon adsorbing layer which are arranged in the bracket sequentially; a spraying pipe is arranged at the top of the low-temperature plasma reaction chamber; a water return pipe is arranged at the bottom of the low-temperature plasma reaction chamber; one end ofthe water return pipe is connected with a water storage tank and the other end of the water return pipe is connected with an activated carbon water tank; and one end of the spraying pipe is connectedwith a spraying head and the other end of the spraying pipe is connected with the activated carbon water tank through a water pump. The low-temperature plasma waste gas purification equipment can prolong the service life and improve the gas purification effect, has a good purification effect on the waste gas, solves the problems of incomplete purification and insufficient purification degree, andenables the discharged gas to be more environment-friendly.

Owner:FOSHAN JIANJINJIAN ELECTRONICS TECH CO LTD

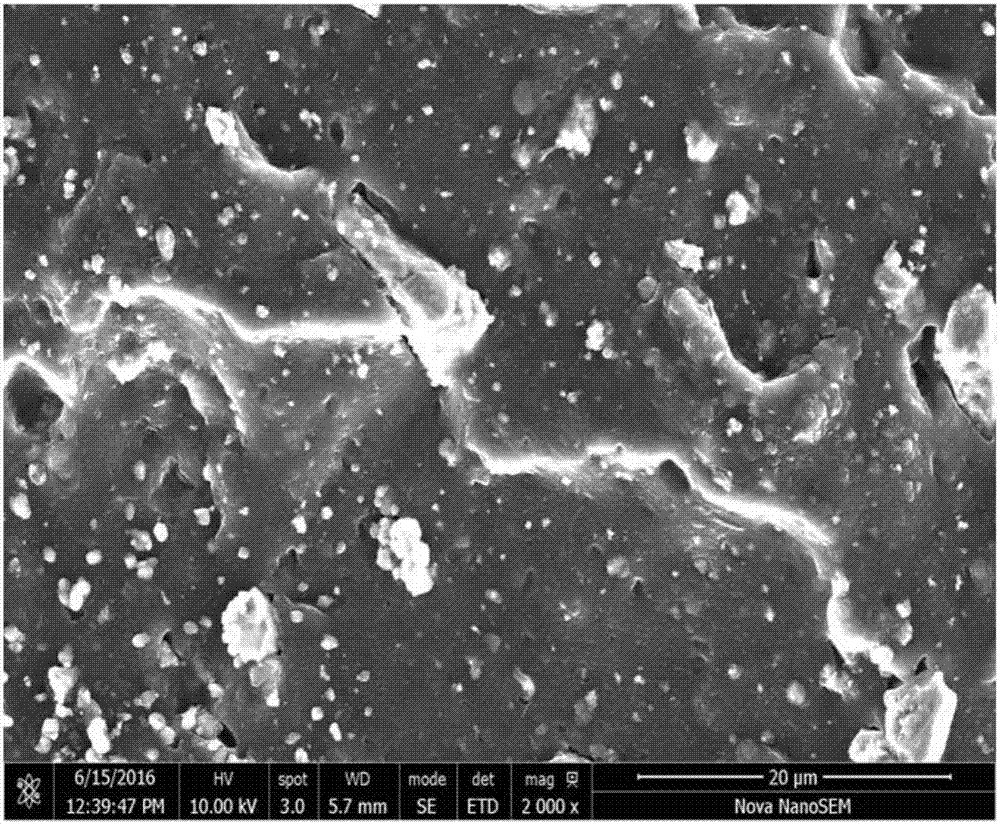

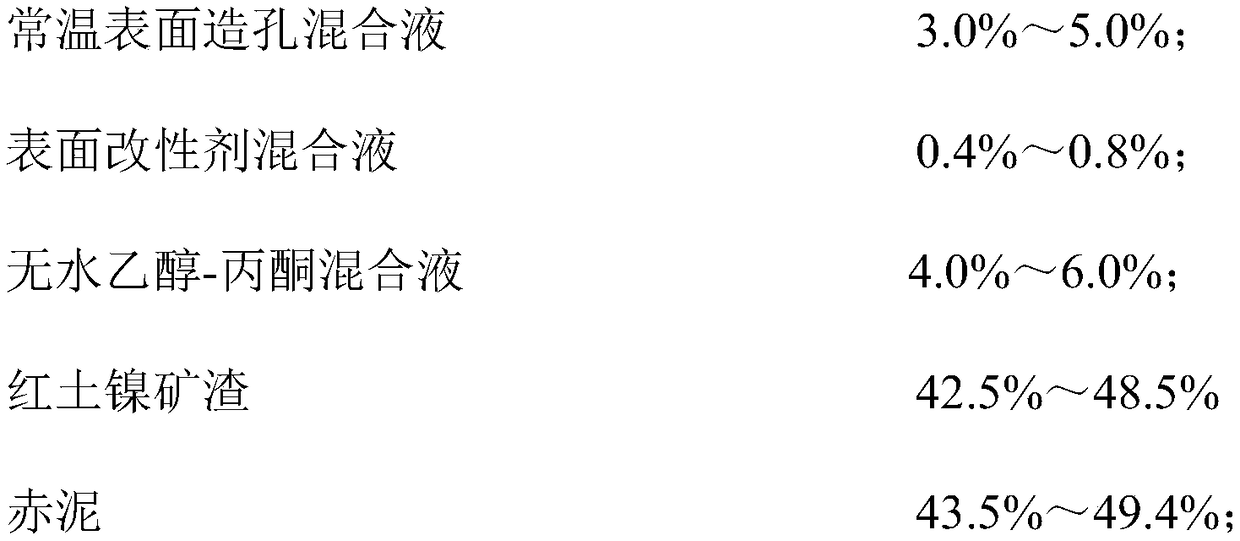

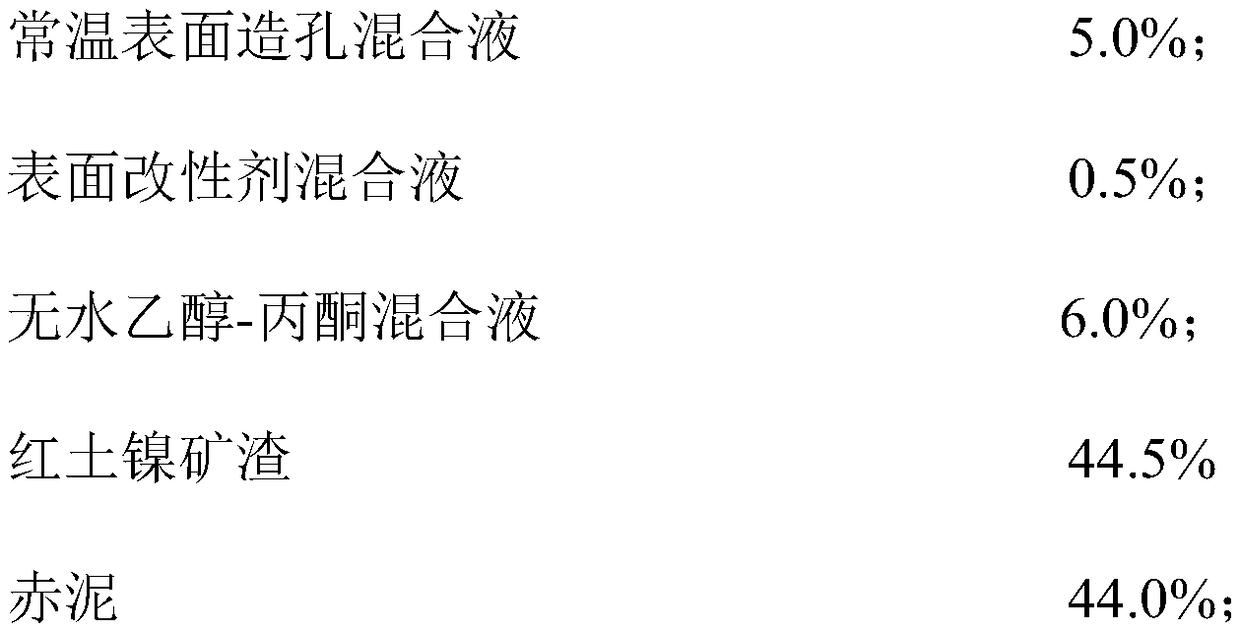

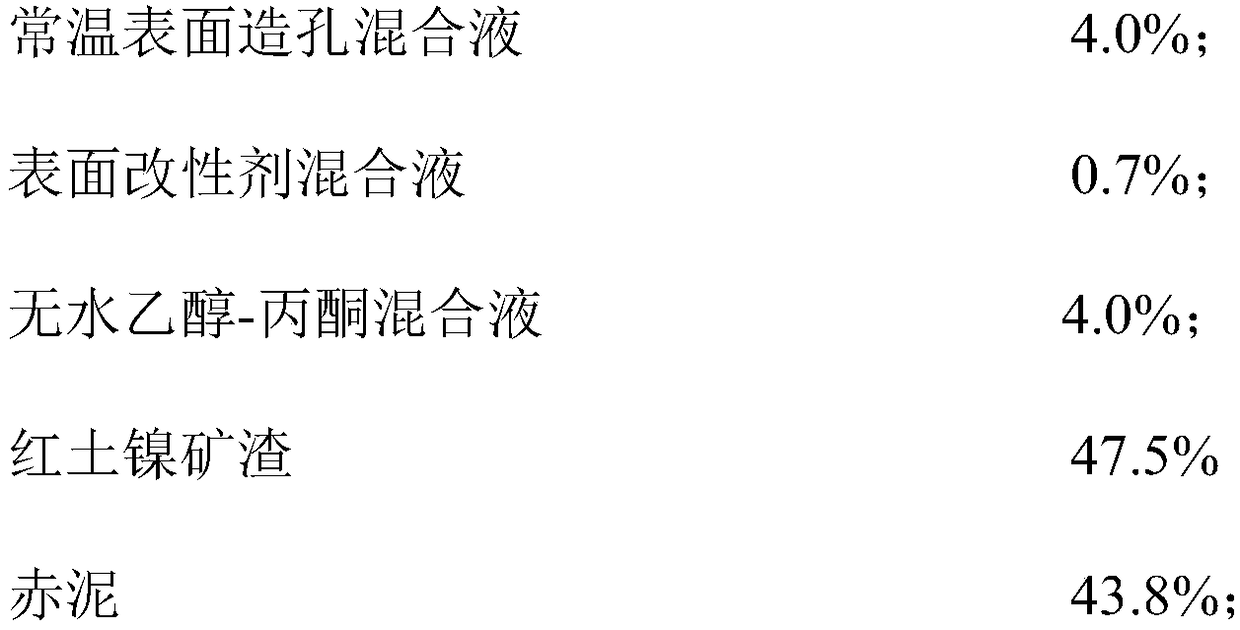

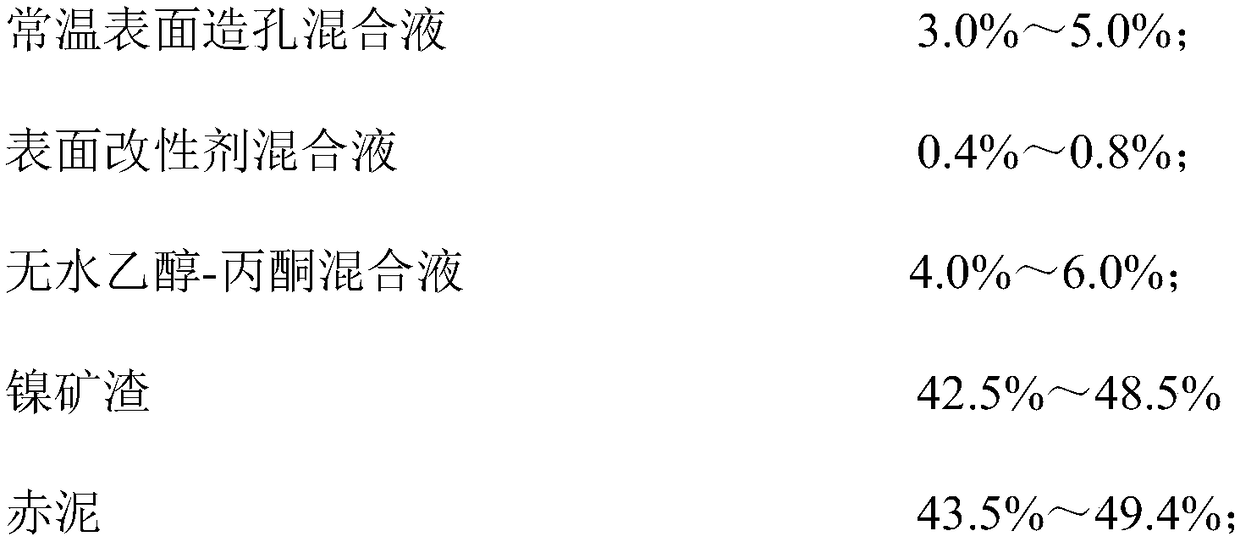

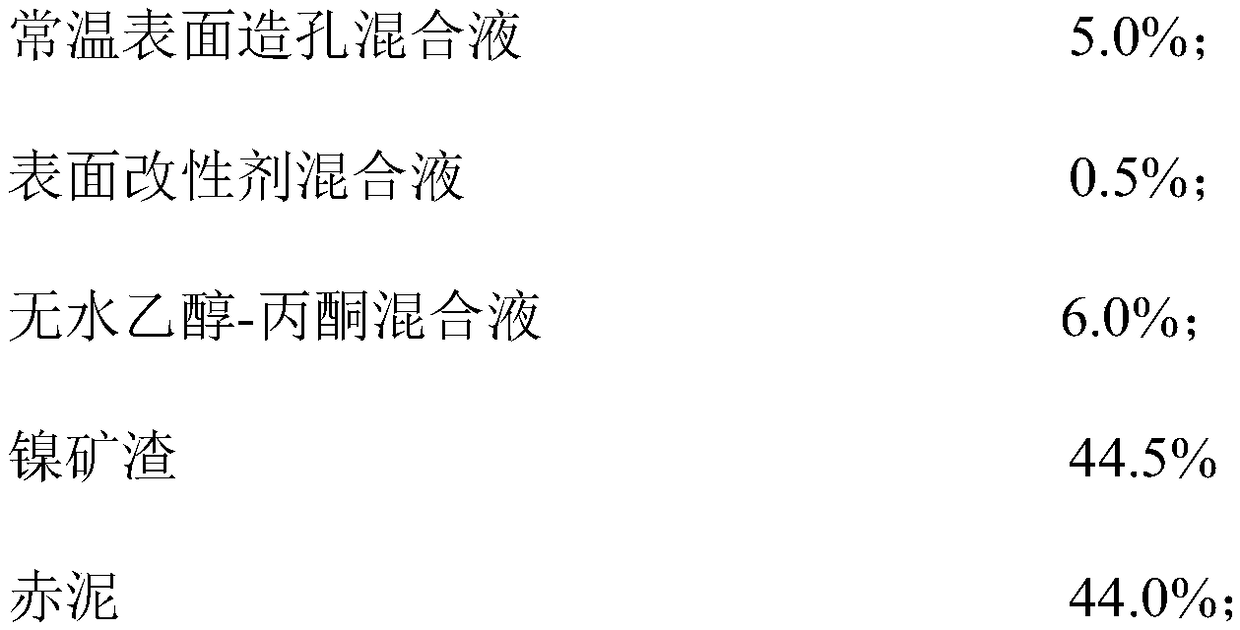

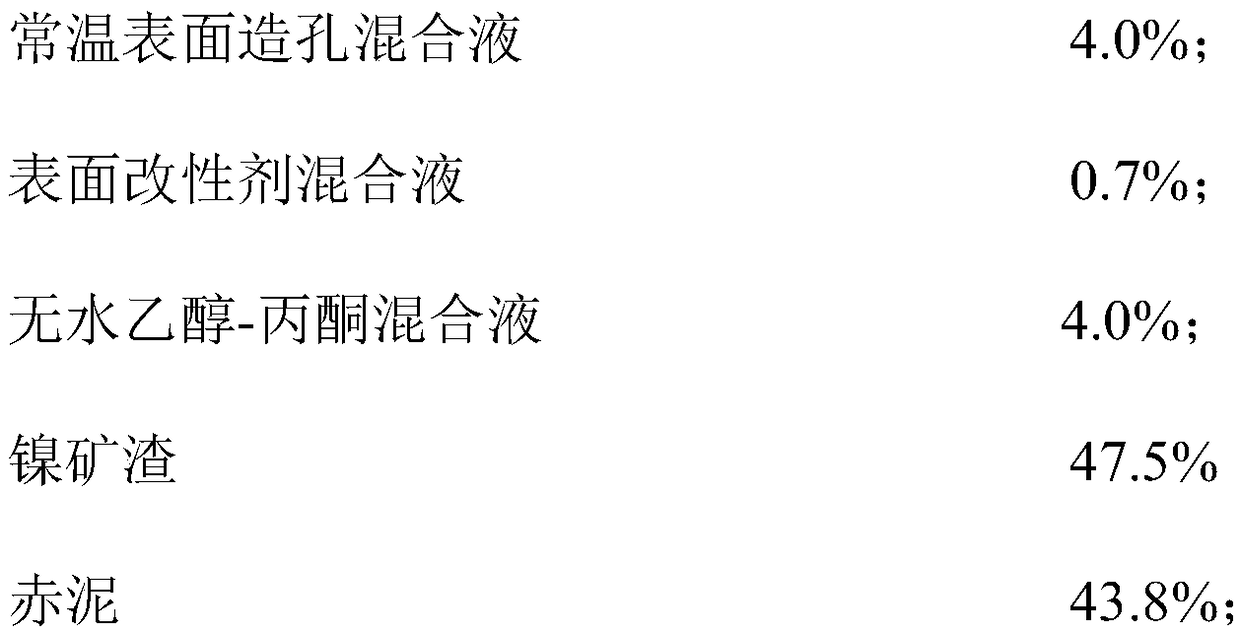

Laterite nickel ore slag-red mud composite rubber filler with flame retardant and reinforcement performance

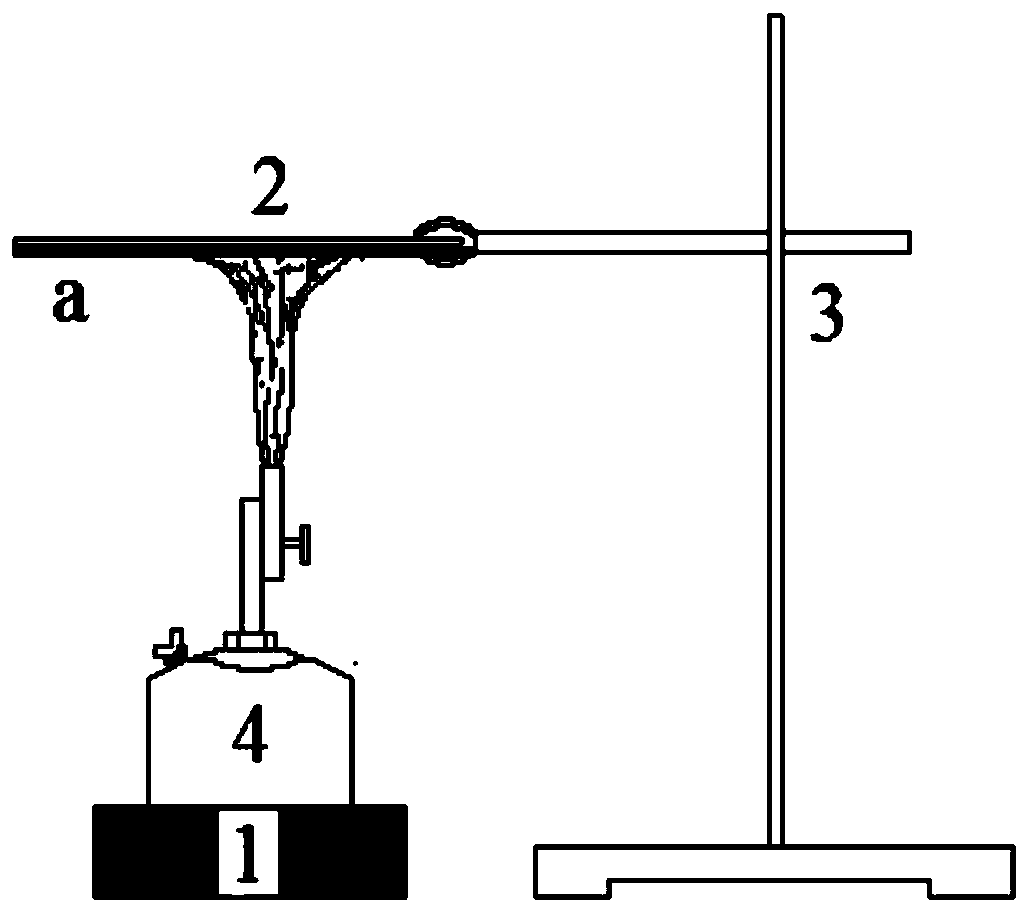

The invention discloses laterite nickel ore slag-red mud composite rubber filler with flame retardant and reinforcement performance and belongs to the field of resource recycling. The laterite nickelore slag-red mud composite rubber filler comprises a normal-temperature surface pore-forming mixed solution, a surface modifier mixed solution, an absolute ethyl alcohol-acetone mixed solution, laterite nickel ore slag and red mud. The normal-temperature surface pore-forming mixed solution consists of oxalic acid dihydrate and phosphoric acid; the surface modifier mixed solution consists of a silane coupling agent KH560 and a silane coupling agent KH550; the particle size of the laterite nickel ore slag is 2.8-102.0 mu m. The problems that in existing rubber industry, main filler including carbon black and white carbon black is higher in price and single in function and only has reinforcing performance, laterite nickel ore slag-red mud aggregates very easily after being directly added to rubber and the compatibility of inorganic interfaces of laterite nickel ore slag-red mud and organic interfaces of rubber is poorer are solved, and high-added-value recycling of industrial waste is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

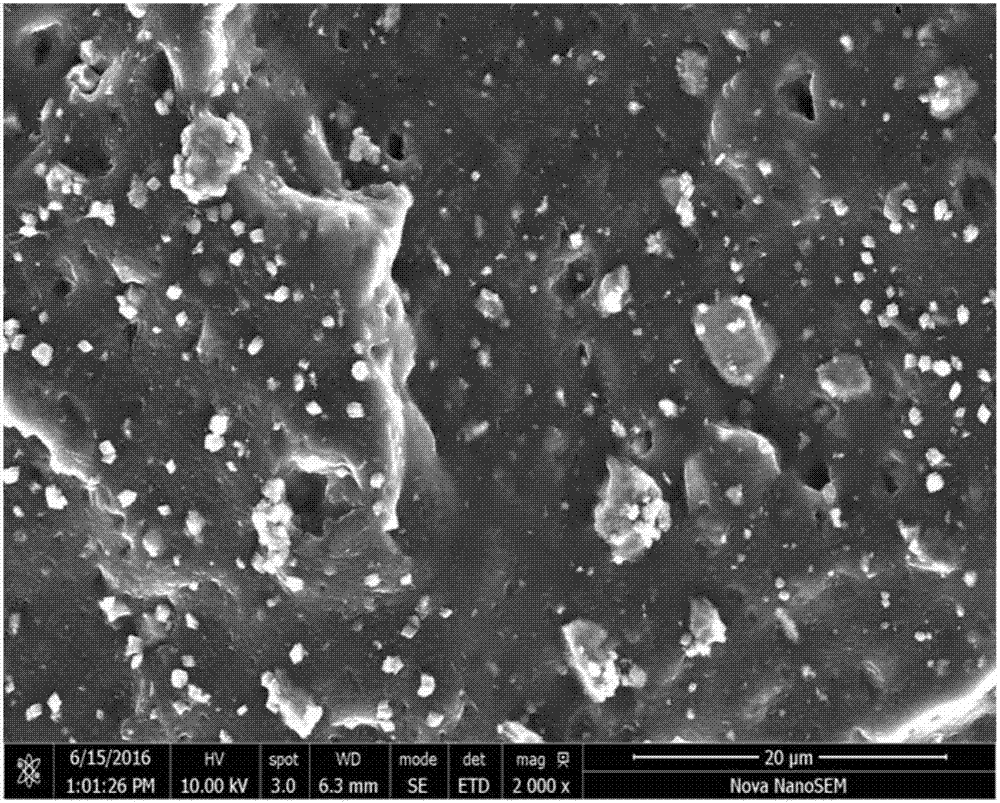

Desulfurized ash-kieselguhr compound rubber filling with synergic reinforcement-flame retardance performance

The invention discloses desulfurized ash-kieselguhr compound rubber filling with synergic reinforcement-flame retardance performance and a preparation method of the filling and belongs to the field ofsolid waste resource recycling. The filling comprises water, stearic acid, desulfurized ash and kieselguhr. The preparation method of the filling comprises the steps of mixing and dispersing water and a silane coupling agent to form a silane coupling agent solution, mixing and stirring the desulfurized ash and the kieselguhr to form a desulfurized ash-kieselguhr mixture, and mixing and stirring the desulfurized ash-kieselguhr mixture and the silane coupling agent solution to form the desulfurized ash-kieselguhr compound rubber filling. The filling solves the problems of higher price and a single function of major filling, namely carbon black and white carbon black, in the rubber industry, improves mechanical properties and flame resistance of rubber, achieves industrial waste recycling, promotes benefit increase of a metallurgical enterprise and cost reduction of the rubber product industry, and meets the current industrial development requirements of energy conservation, environmental protection and circular economy.

Owner:桂林鸿程矿山设备制造有限责任公司

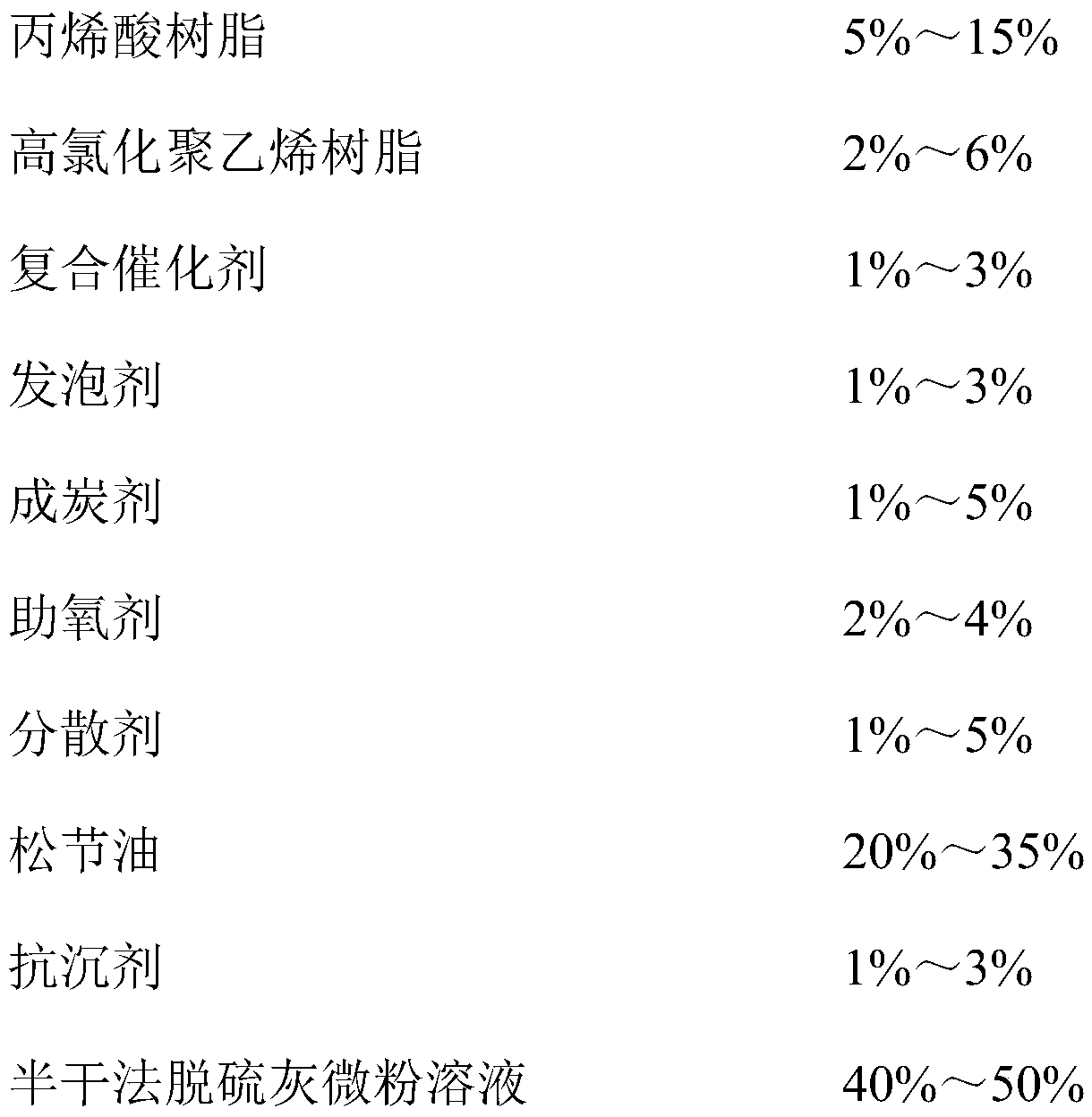

Metallurgy solid-waste-type fireproof and flame-retarding coating and preparing method thereof

The invention discloses a metallurgy solid-waste-type fireproof and flame-retarding coating and a preparing method thereof, and belongs to the field of metallurgy solid-waste resource utilization. Thecoating is prepared from acrylic resin, high chlorinated polyethylene resin, a compound catalyst, a foaming agent, a charring agent, a pro-oxygenic agent, a dispersing agent, turpentine, an anti-precipitation agent and a semi-dry-process desulfurized fly ash micro powder solution; the compound catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate; the semi-dry-process desulfurized fly ash micro powder solution is a mixture of semi-dry-process desulfurized fly ash micro powder and water. By means of the metallurgy solid-waste-type fireproof and flame-retarding coating, about 25% of production cost of an existing fireproof and flame-retarding coating is lowered, the flame-retarding performance of the fireproof and flame-retarding coating is improved, integration of metallurgy solid-waste resource utilization and flame-retarding performance in the field of coatings is achieved, the market competitiveness of the fireproof and flame-retarding coating is greatly enhanced, and the application range of the fireproof and flame-retarding coating is greatly enlarged; high-added-value application of the semi-dry-process desulfurized fly ash is achieved, a new idea of synergism with waste is expanded, and the relevant policy for energy saving, environmental friendly and circular economy is accorded with.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Ferrochromium slag-red mud composite rubber filler with flame retardant and reinforcement performance

The invention discloses ferrochromium slag-red mud composite rubber filler with flame retardant and reinforcement performance and belongs to the field of resource recycling. The ferrochromium slag-redmud composite rubber filler comprises a normal-temperature surface pore-forming mixed solution, a surface modifier mixed solution, an absolute ethyl alcohol-acetone mixed solution, ferrochromium slagand red mud. The normal-temperature surface pore-forming mixed solution consists of oxalic acid dihydrate and phosphoric acid; the surface modifier mixed solution consists of a silane coupling agentKH570 and a silane coupling agent KH550; the particle size of the ferrochromium slag is 4.2-113.8 mu m. The problems that in existing rubber industry, main filler including carbon black and white carbon black is higher in price and single in function and only has reinforcing performance, ferrochromium slag-red mud aggregates very easily after being directly added to rubber and the compatibility ofinorganic interfaces of ferrochromium slag-red mud and organic interfaces of rubber is poorer are solved, and high-added-value recycling of industrial waste is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

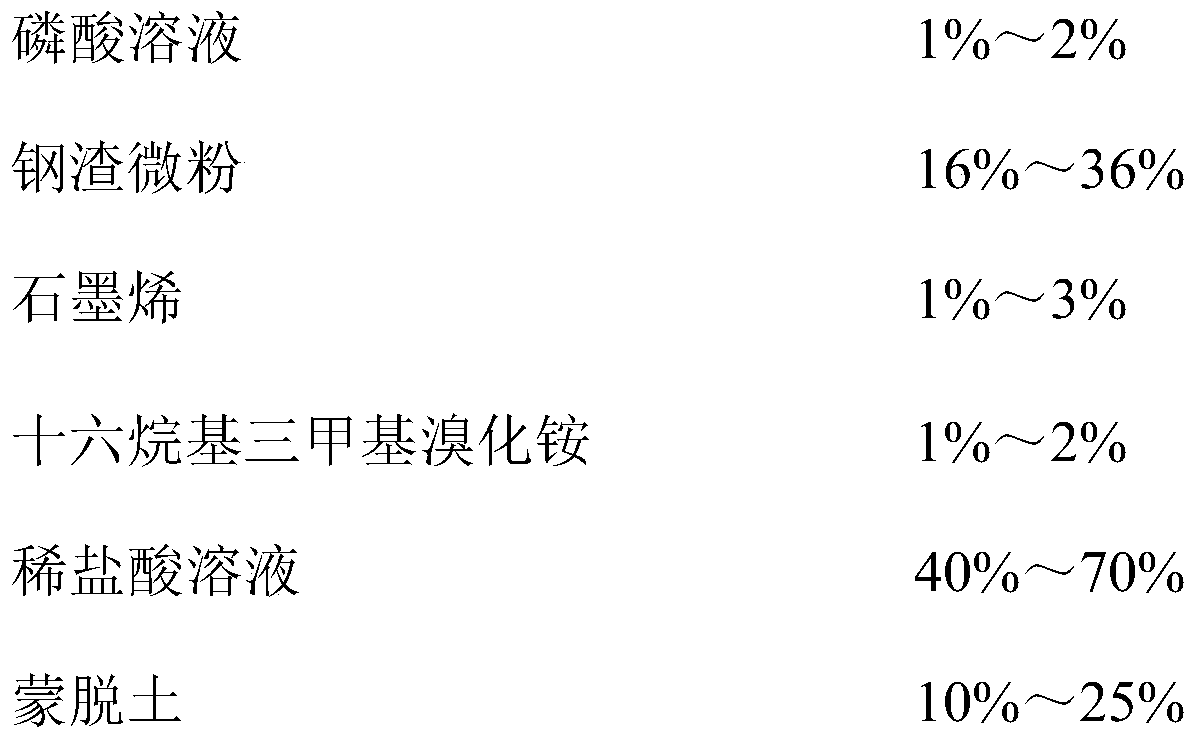

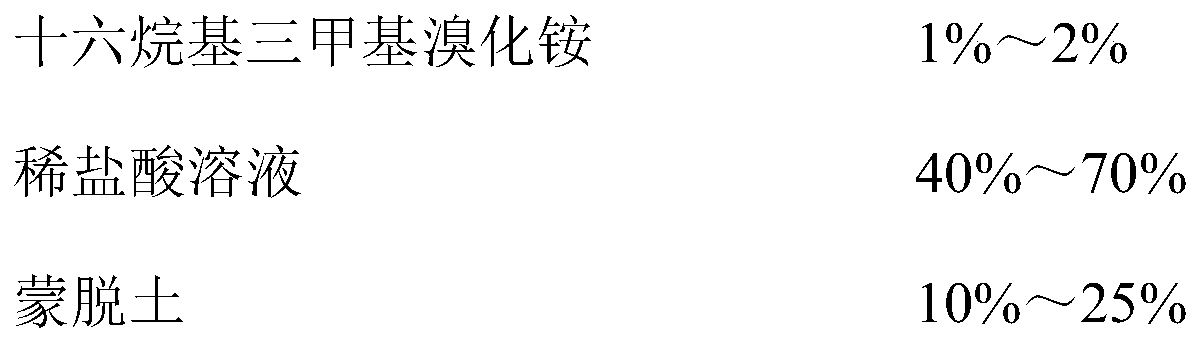

Composite physical pigments and fillers with anti-rust and flame-retardant properties and preparation method thereof

ActiveCN110283484AReduce manufacturing costImprove rust resistanceFireproof paintsAnti-corrosive paintsSlagMontmorillonite

The invention discloses composite physical pigments and fillers with anti-rust and flame-retardant properties and a preparation method thereof, and belongs to the field of utilization of solid waste resources. The pigments and fillers comprise a phosphoric acid solution, steel slag micro powder, graphene, cetyltrimethylammonium bromide, a dilute hydrochloric acid solution and montmorillonite, wherein the steel slag powder is one or more of hot braised slag micro powder, air quench slag micro powder, molten iron desulfurization slag micro powder, casting residual slag micro powder, converter hot splashing slag micro powder, converter drum slag micro powder, electric furnace hot splashing slag micro powder and electric furnace drum slag micro powder. According to the composite physical pigments and fillers with anti-rust and flame-retardant properties and the preparation method thereof, not only is the production cost of existing physical pigments and fillers reduced by 30%-50%, but the anti-rust property, flame-retardant property and adhesive force of the physical pigments and fillers are also improved; the integration of anti-rust property, flame-retardant property and high adhesive force on the physical pigments and fillers is realized; the market competitiveness and application range of the physical pigments and fillers are significantly enhanced; the high value-added application of steel slag and the montmorillonite is expanded; a new thought of using waste to enhancing the effect is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

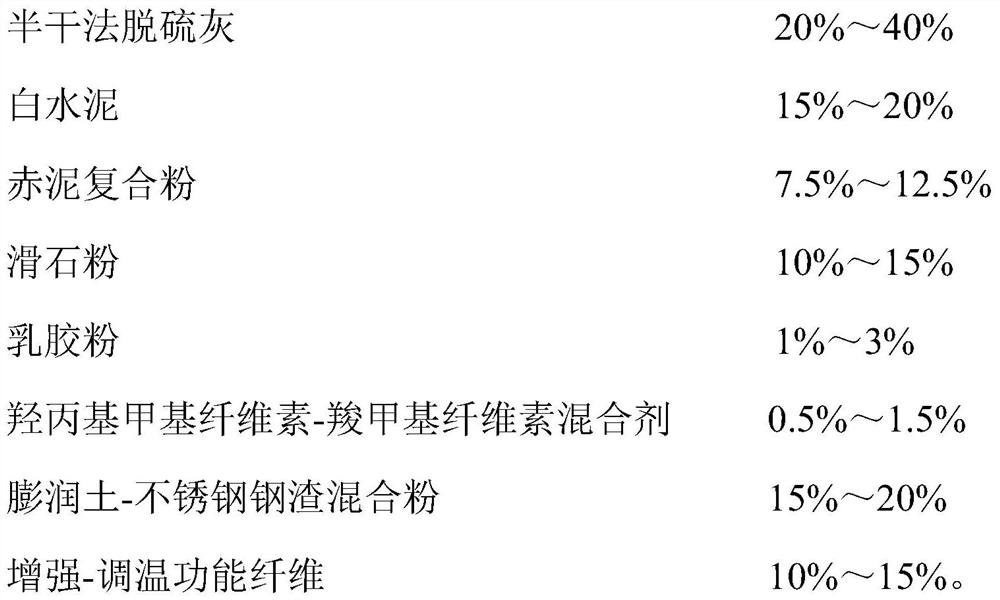

Semi-dry desulfurization ash-based enhanced-temperature-adjusted-flame-retardant interior wall putty powder and preparation method thereof

The invention provides semi-dry desulfurization ash-based enhanced-temperature-adjusted-flame-retardant interior wall putty powder and a preparation method thereof, and belongs to the field of utilization of metallurgical refractory solid waste resources. The interior wall putty powder comprises semi-dry desulfurized fly ash, white cement, red mud composite powder, talcum powder, latex powder, a hydroxypropyl methyl cellulose-carboxymethyl cellulose mixture, bentonite-stainless steel slag mixed powder and reinforcing-temperature adjusting functional fibers. The white cement is white portland cement, and the grade of the white cement is P.W 32.5. The lowest film forming temperature of the latex powder is 0-5 DEG C. The viscosity of the hydroxypropyl methyl cellulose-carboxymethyl cellulosemixing agent ranges from 100000 cps to 200000 cps, and the viscosity of the hydroxypropyl methyl cellulose-carboxymethyl cellulose mixing agent ranges from 100000 cps to 200000 cps. The length-diameter ratio of the fiber with the enhancing-temperature adjusting function is 50-150. According to the invention, the integration of enhancement, temperature adjustment and flame retardance of the interior wall putty powder is realized, the high-performance and high-added-value resource utilization of the refractory semi-dry desulfurized ash, red mud and stainless steel slag is realized, the enterprise efficiency is promoted, and the current industrial development requirements of energy conservation, environmental protection and circular economy are met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

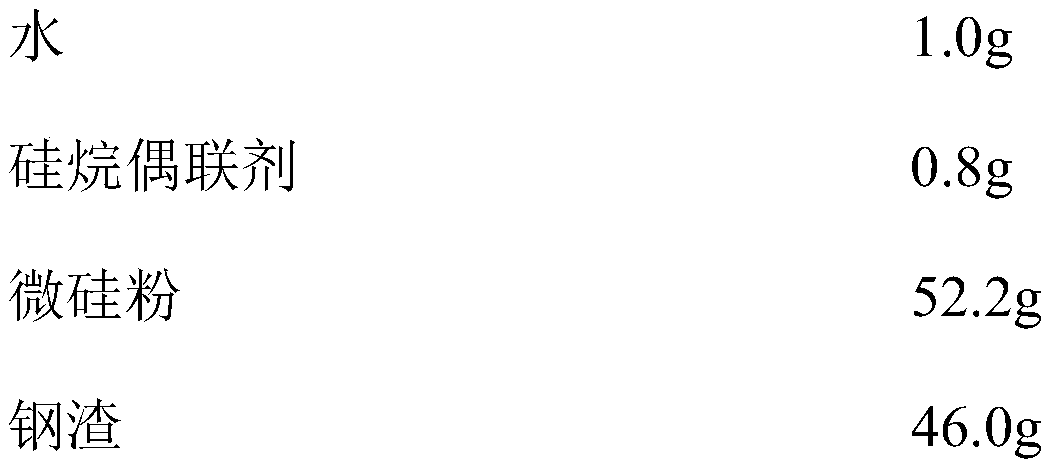

Steel slag-micro-silicon powder composite rubber filler with reinforcing-flame retarding cooperative performance

The invention discloses steel slag-micro-silicon powder composite rubber filler with reinforcing-flame retarding cooperative performance and a preparation method thereof and belongs to the field of cyclic utilization of solid waste resources. The filler is prepared from water, a silane coupling agent, steel slag and micro-silicon powder. The preparation method of the filler comprises the followingsteps: firstly, mixing and dispersing the water and the silane coupling agent to obtain a silane coupling agent solution; then mixing the steel slag and the micro-silicon powder and stirring to obtain a steel slag-micro-silicon powder mixture; finally, mixing and stirring the steel slag-micro-silicon powder mixture and the silane coupling agent solution to obtain the steel slag-micro-silicon powder composite rubber filler. According to the steel slag-micro-silicon powder composite rubber filler with the reinforcing-flame retarding cooperative performance, the problems that main filler carbonblack and white carbon black in a rubber industry have a relatively high price and a single function are solved, and the mechanical property and flame-retarding property of rubber are improved; the cyclic utilization of industrial wastes is realized, the benefit increasing of a metallurgical enterprise is promoted and the cost of a rubber product industry is reduced; current energy-saving and environment-friendly and cyclic economy industrial development requirements are met.

Owner:桂林鸿程矿山设备制造有限责任公司

Construction method for preventing hollowing and cracking of wall plastering

PendingCN112942709AAvoid secondary processingNo adhesionCovering/liningsArchitectural engineeringAdhesive glue

The invention discloses a construction method for preventing hollowing and cracking of wall plastering. The construction method comprises the following steps: (a) wall surface treatment is conducted, specifically, firstly, the surface of a to-be-constructed wall is cleaned to remove falling dust and residual soil blocks and dirt on the wall, and a plastering structural surface is watered and uniformly wetted; and (b) primary gluing is conducted on the wall surface, specifically, building glue is evenly mixed and then smeared on the to-be-constructed wall surface through a brush. The construction method has the beneficial effects that firstly, the building glue is smeared on the surface layer of the treated wall surface, it is guaranteed that the dust attachment phenomenon cannot occur in the using process of the wall surface, and the plastering quality is improved; a steel wire mesh is hung on the surface of the wall surface, so that the wall surface is smooth, mortar is attached to the wall surface, the hollowing phenomenon cannot occur in the later period, the anti-cracking effect is good, and the wall surface quality is improved; and spray-type moisturizing treatment is adopted, so that water is uniformly sprayed to the wall surface, the wall surface maintenance effect is improved, and wall surface cracking can be effectively avoided.

Owner:福建筑兆建设有限公司

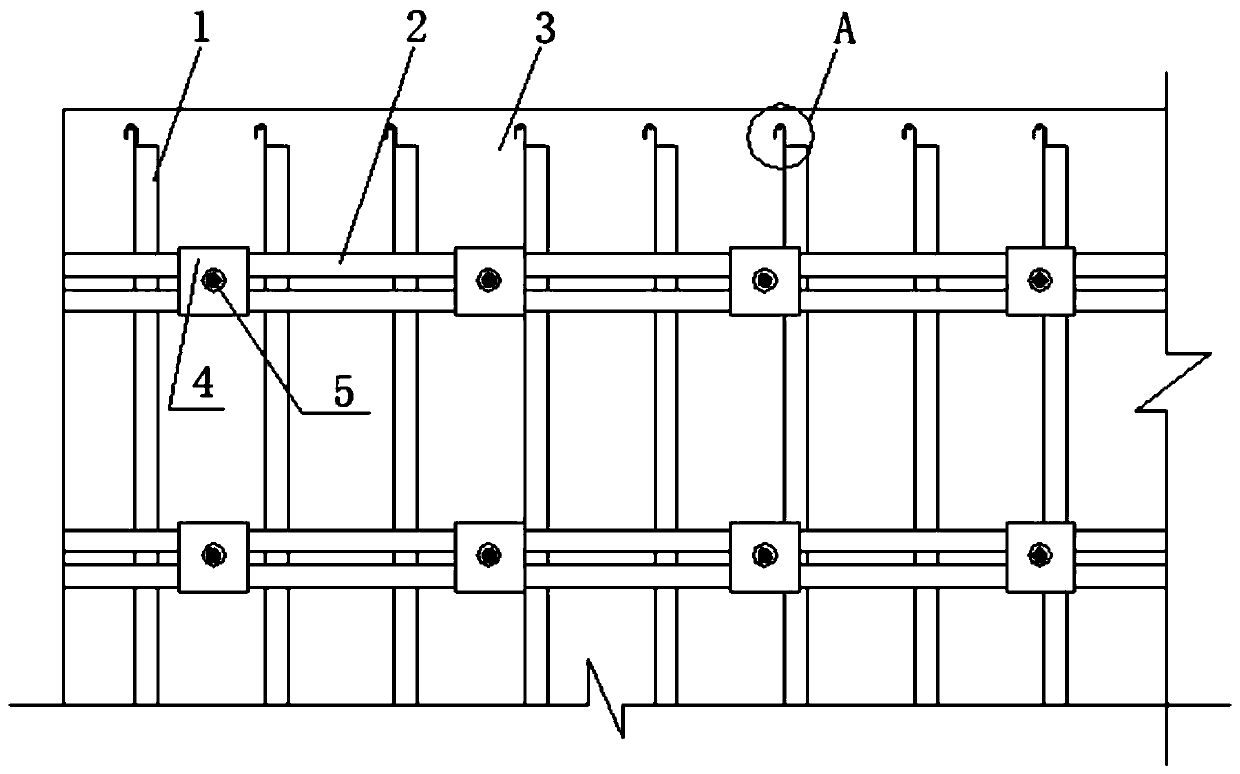

Green fixing device for vertical template square steel of welded elbow and construction method of green fixing device

PendingCN111119477AHigh speedLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksKeelRebar

The invention discloses a green fixing device for vertical template square steel of a welded elbow and a construction method of the green fixing device, and belongs to the technical field of construction. The green fixing device for the vertical template square steel of the welded elbow comprises a square steel keel. The front side of the square steel keel is in overlap joint with four secondary keels, and the back of the square steel keel is in overlap joint with the front of a template. According to the green fixing device for the vertical template square steel of the welded elbow, the square steel keel, a steel bar elbow, the secondary keels and fasteners are arranged, when the staff needs to fix the square steel keel to the template, then the fasteners are fixed to the template throughsplit bolts, and the fasteners and the split bolts are arranged, so that the green fixing device is low in cost and high in speed and can be recycled, the through-end head of the square steel keel iswelded to the steel bar elbow, installation and disassembly are convenient, construction is convenient, and labor cost input is low; and the scrap rate of the square steel keel is low, the number oftimes of turnover is high, the residual value is high, the material is saved, the use of square wood strips is reduced, the forest is protected, and the sustainable development of resources is achieved.

Owner:广西建工第五建筑工程集团有限公司

Multi-layer living paper

InactiveCN102578945AReduce usageReduce manufacturing costPaper/cardboard layered productsDomestic applicationsSurface layerPulp and paper industry

The invention discloses a multi-layer living paper. The multi-layer living paper comprises at least one piece of outer surface layer thin paper and at least one piece of core layer thin paper, wherein the at least one core layer thin paper is made of one or mixture of a virgin unbleached pulp and a recycled unbleached pulp not subjected to deinking and bleaching.

Owner:GOLD HONG YE PAPER

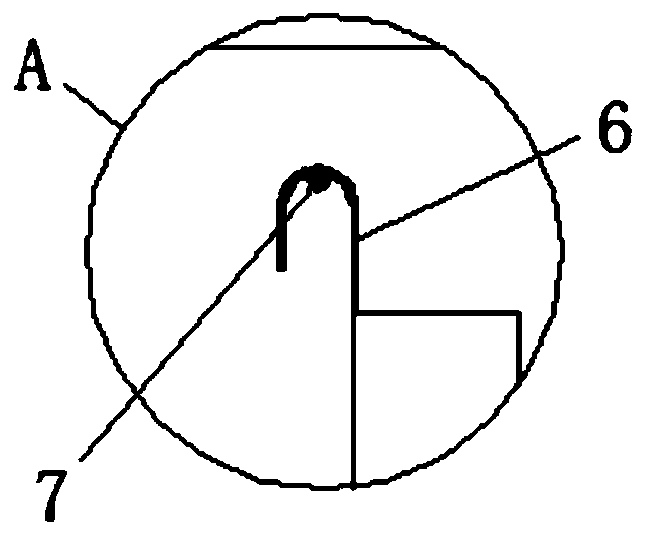

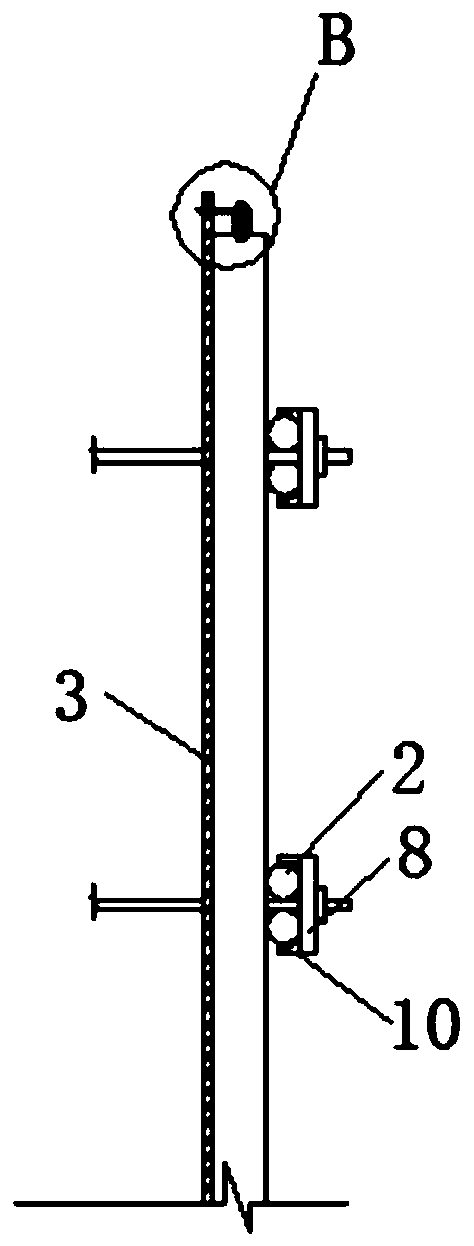

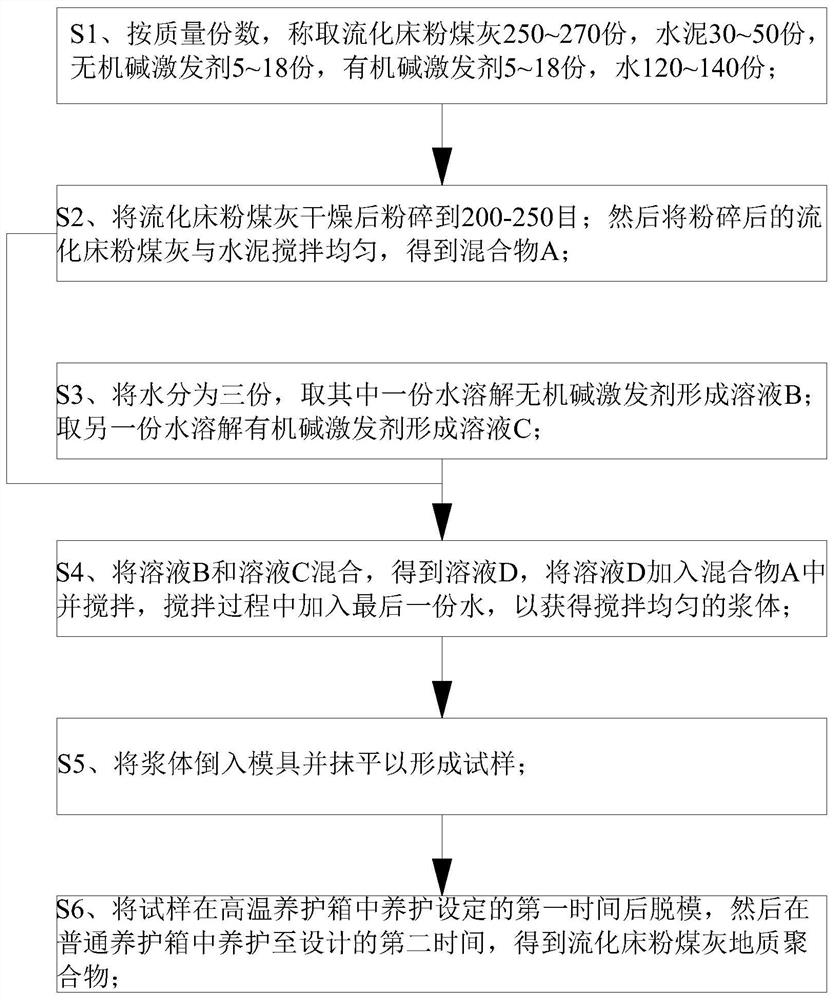

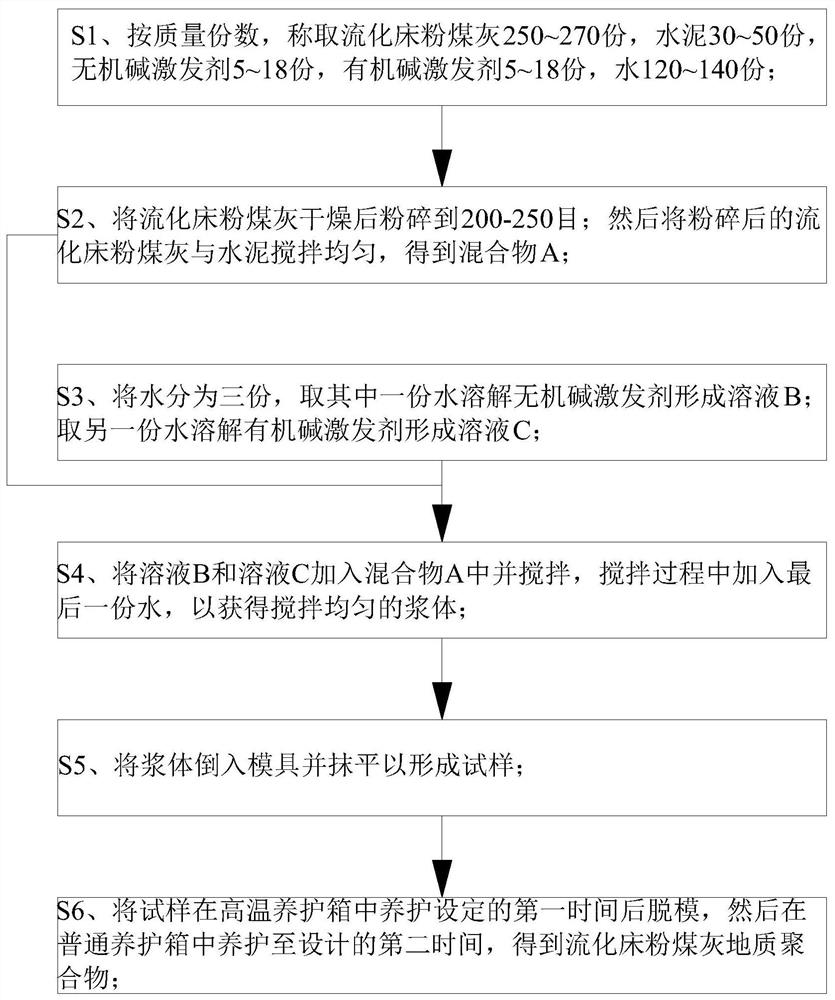

Alkali-activated fluidized bed fly ash geopolymer and preparation method thereof

PendingCN113321435ASolve problems that are difficult to useRealize high dosage utilizationCement productionFluidized bedOrganic base

An alkali-activated fluidized bed fly ash geopolymer comprises, by mass, 250-270 parts of fluidized bed fly ash, 30-50 parts of cement, 5-18 parts of an inorganic alkali activator, 5-18 parts of an organic alkali activator and 120-140 parts of water. The fluidized bed fly ash is subjected to composite alkali excitation through the organic alkali activator and the inorganic alkali activator, so that the problem of high utilization difficulty of the fluidized bed fly ash due to complex components and low activity of the fluidized bed fly ash is effectively solved, high-dosage utilization of the fluidized bed fly ash is realized, and the mechanical properties of the prepared fluidized bed fly ash geopolymer are ensured.

Owner:中能化江苏地质矿产设计研究院有限公司

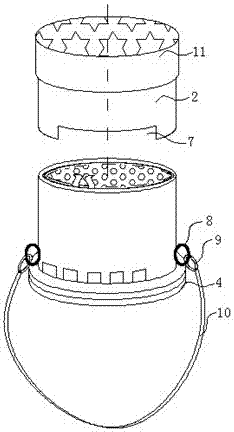

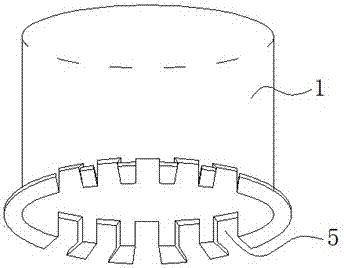

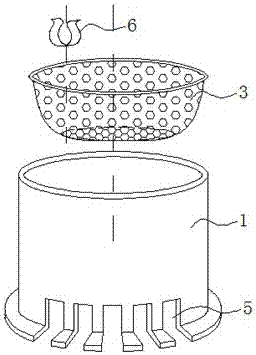

Environment-friendly moxa-moxibustion device and preparation method thereof

InactiveCN106974824ACompliant with energy saving and environmental protectionIn line with the theme of energy saving and environmental protectionDevices for heating/cooling reflex pointsEngineeringSmoke

The invention relates to an environment-friendly moxa-moxibustion device which comprises a round barrel, a cover and a blocking net. A heat insulating base ring is arranged on the bottom edge of the round barrel, one or more vent holes are formed in the side face close to the base ring, the vent holes are symmetrically formed around the round barrel, the blocking net is horizontally arranged in the round barrel, and a clamp for fixing a moxa cone is arranged at the position, 1-2 cm away from the bottom face of the round barrel, of the blocking net. The cover covers the round barrel, and slots are formed in the positions, corresponding to the vent holes, of the bottom of the cover. After the device is adopted, a waste ring-pull can is made into the moxa-moxibustion device, and energy saving and environmental friendliness are achieved. Temperature is conveniently adjusted by adjusting the number of the vent holes, a moxa-moxibustion box and the body are not spaced, the heat and medicine effect of a moxa stick can directly reach the acupoint, the effect is good, and on the premise of guaranteeing moxa-moxibustion temperature, the moxa stick is saved. Less moxa smoke is generated.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

Method for extracting diamond powder from water-based diamond liquid

The invention provides a method for extracting diamond powder from water-based diamond waste liquid. The method comprises the following steps: A) filtering water-based diamond polishing liquid to remove disintegrated dental plate slag in the polishing liquid; B) adding concentrated hydrochloric acid, carrying out stirring, then performing standing for liquid separation, and carrying out suction filtration to obtain a diamond powder enriched solution, wherein the mass fraction of the concentrated hydrochloric acid is 20-25%; C) cleaning the diamond powder enrichment liquid with deionized water,then adding a sodium hydroxide solution, and carrying out an alkalization reaction; and D) cleaning the diamond powder enrichment liquid having undergone the alkalization reaction with deionized water, and then carrying out drying to obtain the diamond powder. According to the method disclosed by the invention, waste liquid can be recycled and centralizedly treated, so resources are saved, production cost is reduced, and the waste of auxiliary materials can be greatly reduced. Experimental results prove that the diamond powder recovery rate of the method is 81-85%.

Owner:LENS TECH CHANGSHA

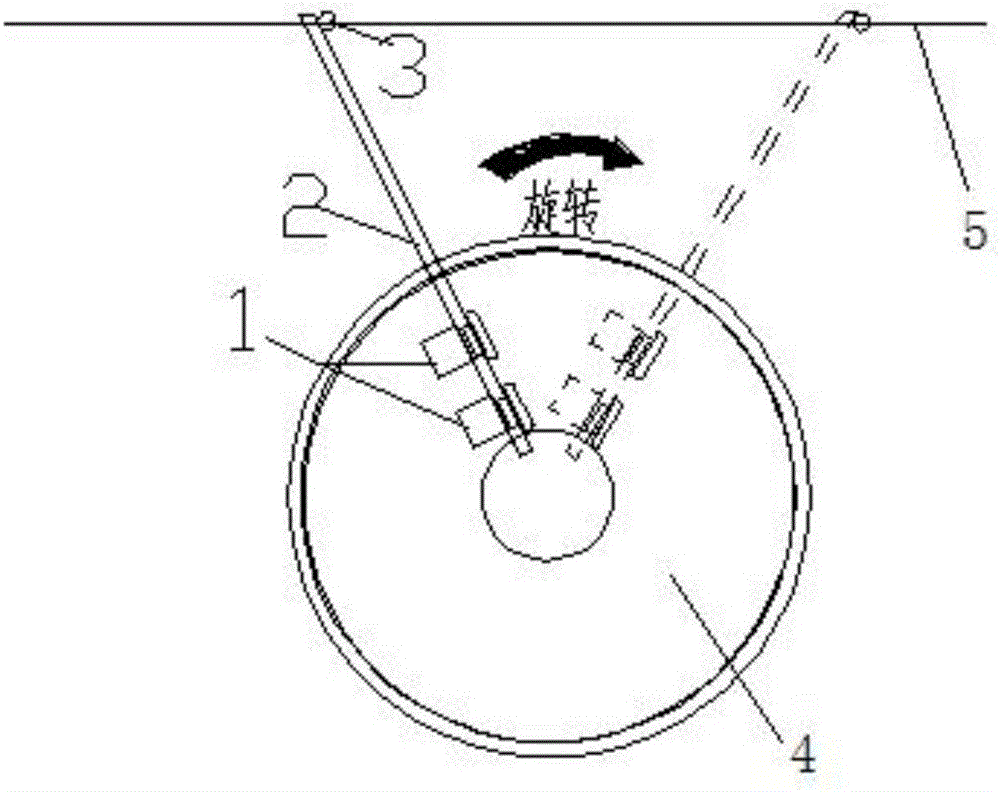

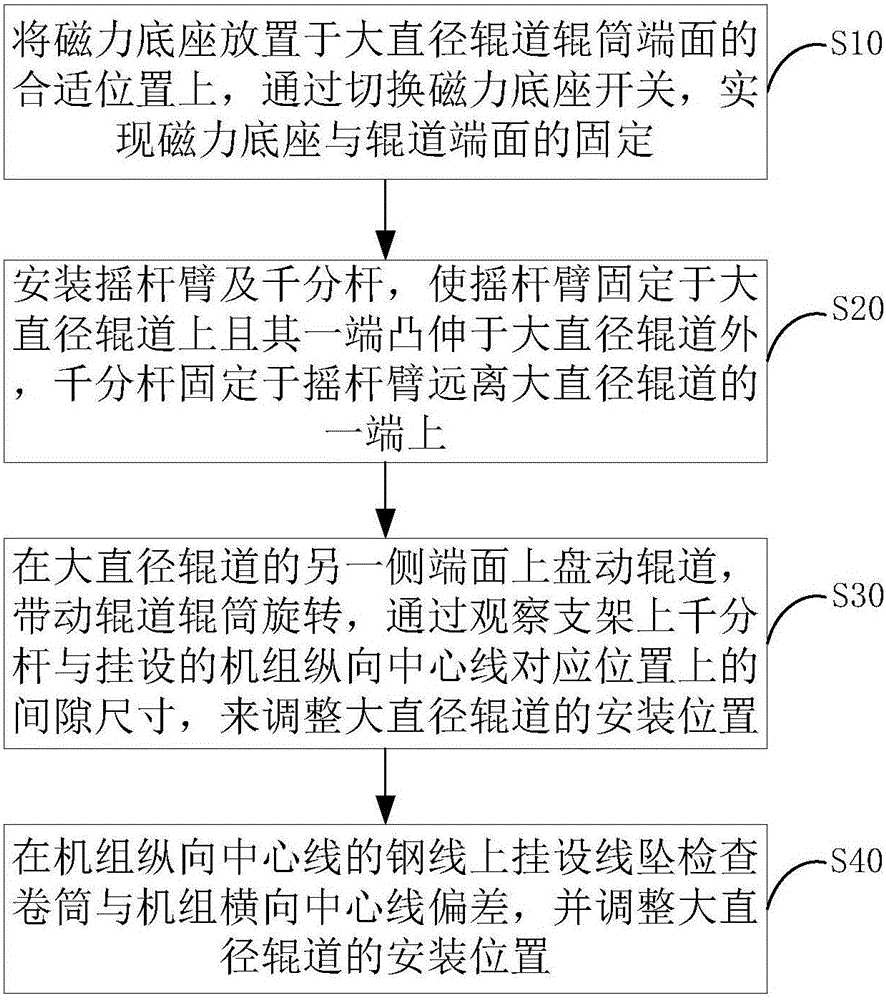

Alignment device and method for large-diameter roller bed

ActiveCN105057367ATo overcome the lack of versatilityImprove general performanceMetal rolling arrangementsMicrometerRocker arm

The invention discloses an alignment device and method for a large-diameter roller bed. The alignment device comprises a magnetic base, a rocker arm and a micrometer rod, wherein the magnetic base is attracted to the end face of the large-diameter roller bed, the rocker arm is installed on the magnetic base, one end of the rocker arm stretches out of the end face of the roller bed, and the micrometer rod is installed at the end, far away from the magnetic base, of the rocker arm. The magnetic base is in a switching magnetism type. Magnetism of the magnetic base is switched through a switch of the magnetic base. The micrometer rod is installed on the rocker arm through a pipe clamp. By means of the alignment device for the large-diameter roller bed, the problems that when a large-diameter roller bed is aligned in a conventional mode, a fixing supporting frame is poor in universality, a large number of materials are wasted, operation is complex, consumed time is long.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com