Steel-slag-based biomass activated carbon for degrading formaldehyde and preparation method of activated carbon

A technology of activated carbon and biomass, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unfavorable ecological environment sustainable development, secondary pollution of indoor environment, short service life of activated carbon, etc., to promote sustainable development. Development, short service life, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

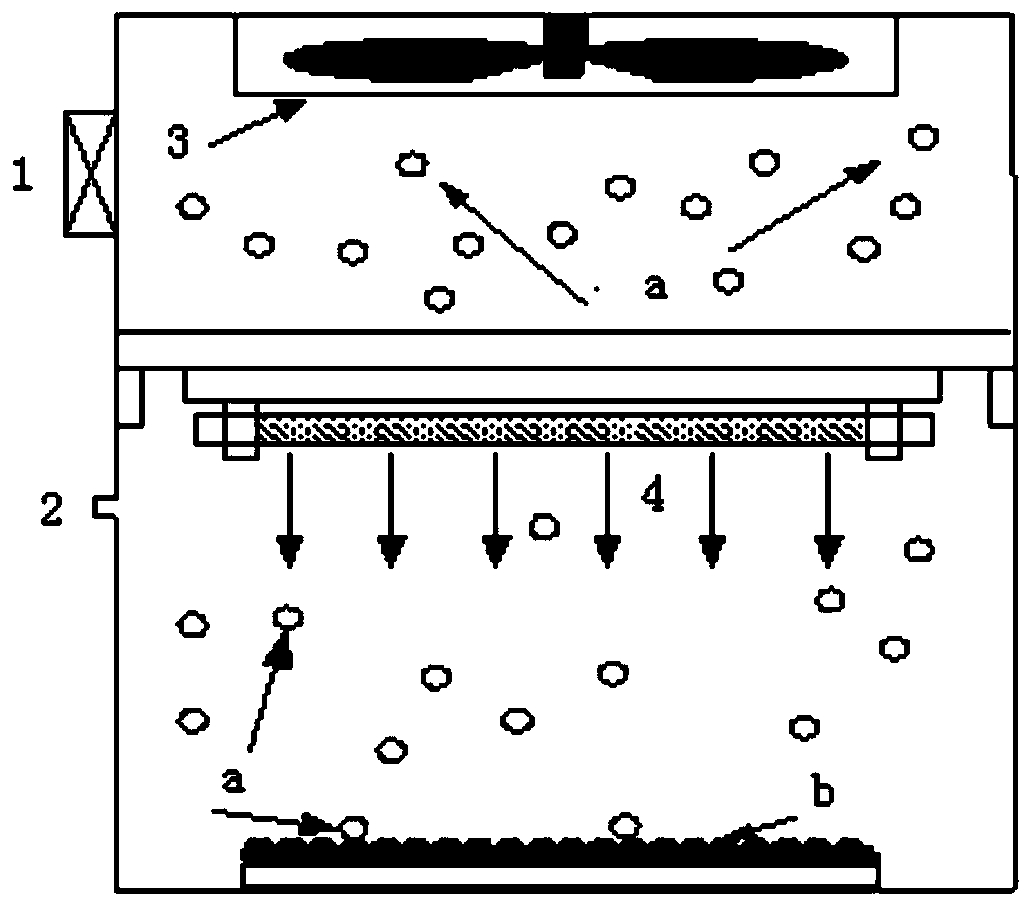

Method used

Image

Examples

Embodiment 1

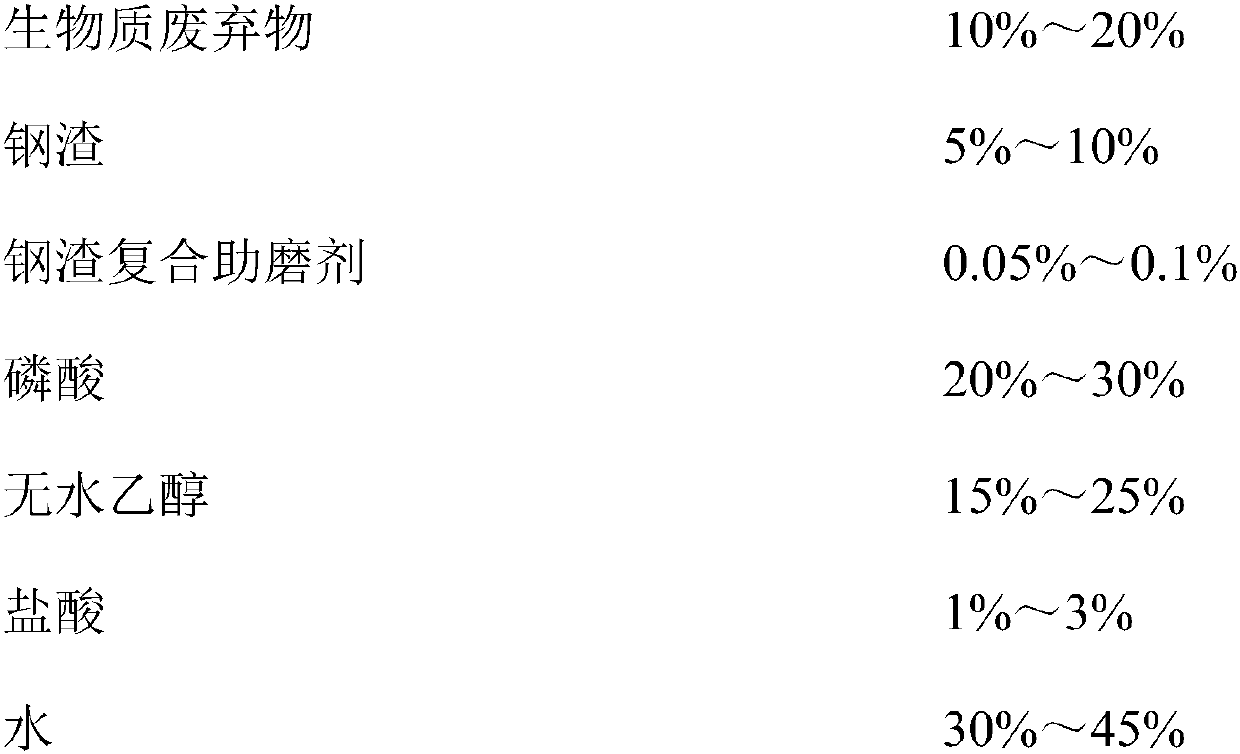

[0027] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0028]

[0029] The biomass waste is fruit shell; the steel slag is electric furnace slag; the steel slag composite grinding aid is a mixture of ethylene glycol, triethanolamine and absolute ethanol, and the quality of ethylene glycol, triethanolamine and absolute ethanol The ratio is 1:1:1, wherein ethylene glycol, triethanolamine and absolute ethanol are analytically pure; the phosphoric acid is analytically pure; the absolute ethanol is analytically pure; the hydrochloric acid is analytically pure; the water for deionized water.

[0030] Firstly, after cleaning and drying the biomass waste, use a frequency conversion planetary ball mill to grind at a speed of 500r / min for 45min to obtain biomass waste micropowder; after mixing steel slag and steel slag compound grinding aid, use a frequency conversion planetary ball mill Grind for 9...

Embodiment 2

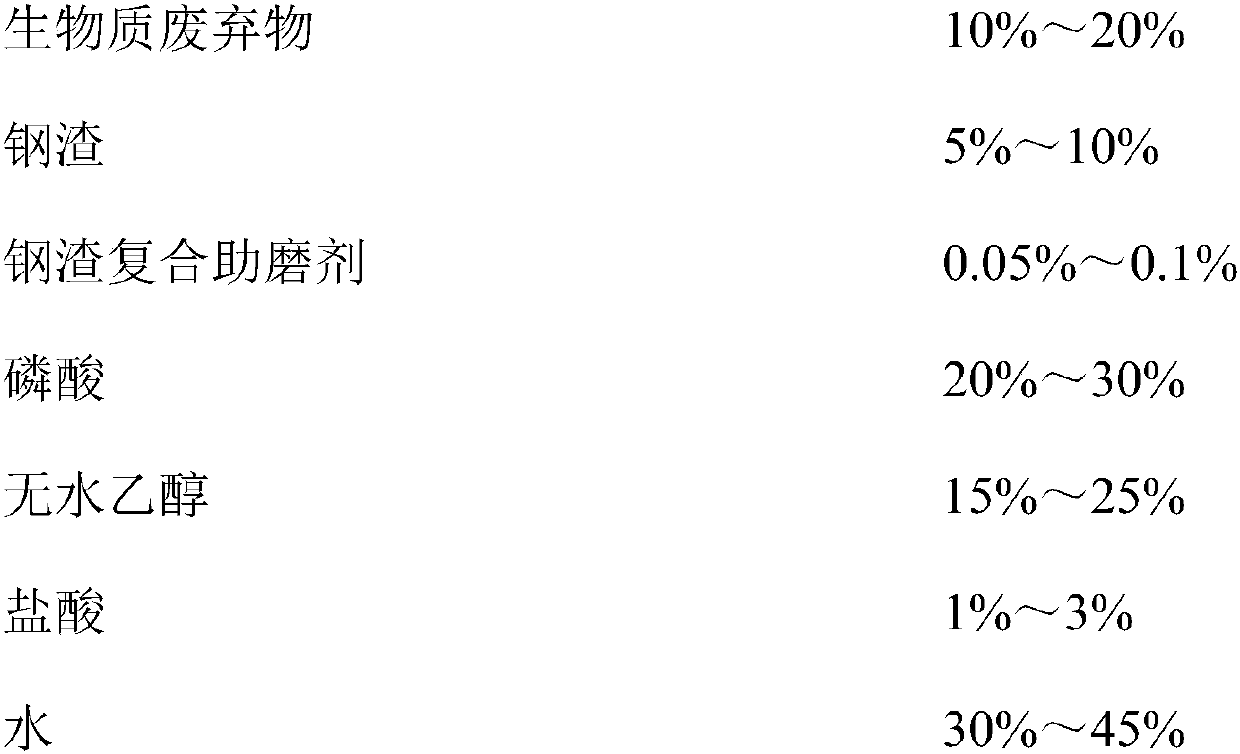

[0034] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0035]

[0036] The biomass waste is straw; the steel slag is hot stuffy slag; the steel slag composite grinding aid is a mixture of ethylene glycol, triethanolamine and absolute ethanol, and the mass of ethylene glycol, triethanolamine and absolute ethanol The ratio is 1:1:1, wherein ethylene glycol, triethanolamine and absolute ethanol are analytically pure; the phosphoric acid is analytically pure; the absolute ethanol is analytically pure; the hydrochloric acid is analytically pure; the water for deionized water.

[0037]First, after cleaning and drying the biomass waste, use a frequency conversion planetary ball mill to grind 90min at a speed of 600r / min to obtain biomass waste micropowder; after mixing steel slag and steel slag compound grinding aid, use a frequency conversion planetary ball mill Grinding for 105min at a rotation...

Embodiment 3

[0041] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0042]

[0043] The biomass waste is fruit stone; the steel slag is wind crushed slag; the steel slag composite grinding aid is a mixture of ethylene glycol, triethanolamine and absolute ethanol, and the mixture of ethylene glycol, triethanolamine and absolute ethanol The mass ratio is 1:1:1, wherein ethylene glycol, triethanolamine and absolute ethanol are analytically pure; the phosphoric acid is analytically pure; the absolute ethanol is analytically pure; the hydrochloric acid is analytically pure; the Water is deionized water.

[0044] First, after cleaning and drying the biomass waste, use a frequency conversion planetary ball mill to grind at a speed of 400r / min for 75min to obtain biomass waste fine powder; after mixing steel slag and steel slag compound grinding aid, use a frequency conversion planetary ball mill Grind for 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com