Monodisperse titanium dioxide nanometer microballoons and preparation method thereof

A technology of titanium dioxide and nano-microspheres, which is applied in the field of nano-materials and photocatalysis, can solve the problems of large specific surface area, achieve the effect of uniform size distribution of microspheres, good crystallization, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Mix hydrofluoric acid, 65% nitric acid and deionized water with a mass concentration of 55% in a volume ratio of 1:3:6 to obtain a pickling solution;

[0028] 2) The size is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with the pickling solution obtained in step 1), then cleaned in ultrasonic waves with deionized water, immersed in 50ml of hydrogen peroxide with a mass concentration of 30%, and taken out after reacting at 80°C for 12 hours A metal titanium plate is obtained to obtain a precursor solution containing tetravalent titanium ions;

[0029] 3) Sodium hydroxide was added to the precursor solution to form a sodium hydroxide solution with a concentration of 5 mol / liter, which was placed in a polytetrafluoroethylene hydrothermal tank, and hydrothermally reacted at 120° C. for 20 hours to obtain a powder. The volume ratio of reaction liquid and hydrothermal tank is 4: 5;

[0030] 4) The powder was washed three times repeatedly with deioni...

Embodiment 2

[0033] 1) with embodiment 1;

[0034] 2) with embodiment 1;

[0035] 3) Sodium hydroxide was added to the precursor solution to form a sodium hydroxide solution with a concentration of 10 mol / liter, which was placed in a polytetrafluoroethylene hydrothermal tank, and subjected to hydrothermal reaction at 120° C. for 40 hours to obtain a powder.

[0036] 4) The powder was repeatedly washed with deionized water for 3 times, then soaked in 0.6 mol / L dilute hydrochloric acid solution for 12 hours, dried, and put into a muffle furnace for heat treatment at 600° C. for 1 hour to obtain monodisperse titanium dioxide nanospheres.

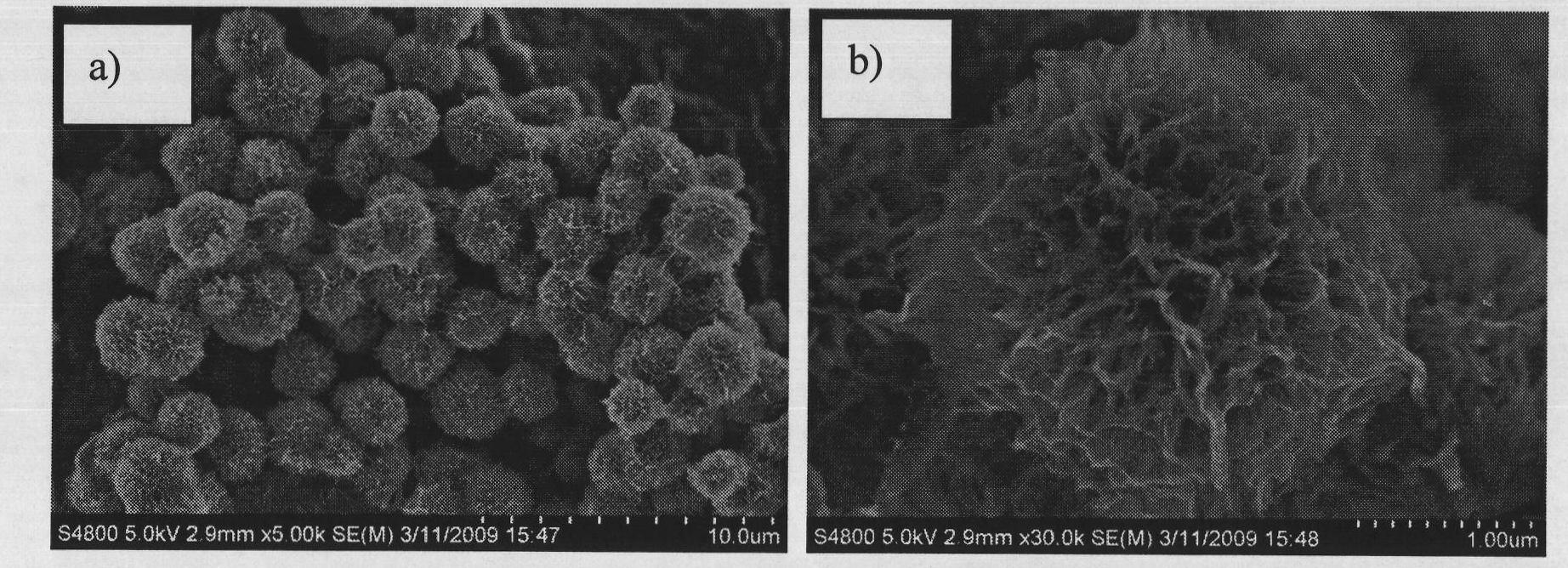

[0037] Depend on image 3 It can be seen that the obtained monodisperse titanium dioxide nano-microspheres have a diameter of 1.5-2.5 microns and are composed of nanowire clusters with a length of 600 nanometers and a diameter of 30 nanometers.

[0038] Figure 4 The high-resolution transmission electron microscopy images of monodisperse titanium dioxide...

Embodiment 3

[0040] 1) with embodiment 1;

[0041] 2) The size is 5×5×0.01(cm 3 ) The surface of the metal titanium plate is pickled with the pickling solution obtained in step 1), then cleaned in ultrasonic waves with deionized water, immersed in 50ml of hydrogen peroxide with a mass concentration of 30%, and reacted at 80°C for 24 hours to take out the metal Titanium plate to obtain a precursor solution containing tetravalent titanium ions;

[0042] 3) Add sodium hydroxide to the precursor solution to form a sodium hydroxide solution with a concentration of 5 mol / liter, put it into a polytetrafluoroethylene hydrothermal tank, and conduct a hydrothermal reaction at 120° C. for 64 hours to obtain a powder.

[0043] 4) with embodiment 2.

[0044] Depend on Image 6 It can be seen that the obtained monodisperse titanium dioxide nano-microspheres have a diameter of 1.5-2.5 microns and are composed of nanowire clusters with a length of 800 nanometers and a diameter of 40 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com