Siloxane-modified super-hydrophobic geopolymer anticorrosive material and preparation method thereof

A technology of siloxane modification and polymer, applied in cement production, etc., can solve the problems of limited service life of organic waterproof coating, difficulty in achieving long-term hydrophobic effect, poor bonding performance, etc., to achieve super hydrophobicity and high durability Corrosion performance, promotion of rapid development, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

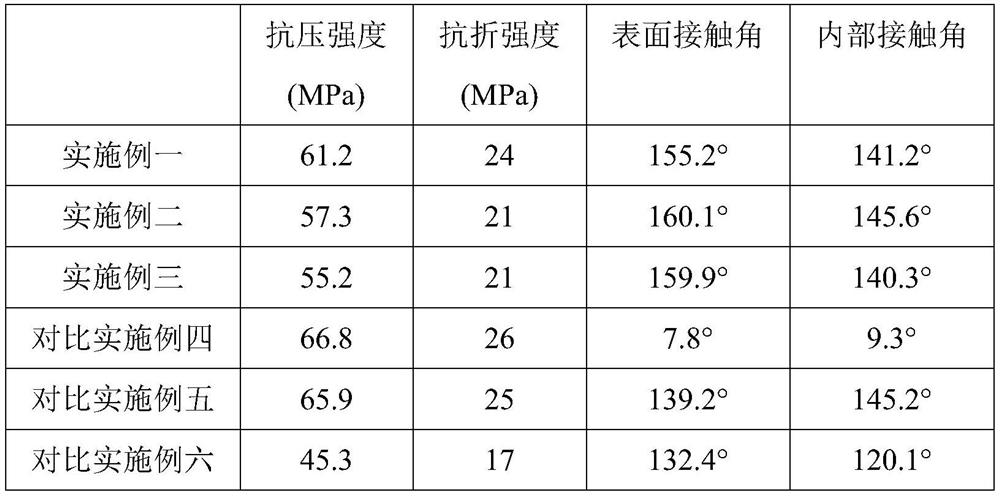

Examples

Embodiment 1

[0028] A siloxane-modified superhydrophobic geopolymer anti-corrosion material, including 45 parts of metakaolin, 20 parts of fly ash, 10 parts of silica fume, 15 parts of sodium hydroxide solid, 50 parts of sodium silicate solution, deionized 18 parts of water, 2 parts of polydimethylsiloxane, 5 parts of methyl hydrogen silicone oil, 0.1 part of silane coupling agent, 5 parts of nano magnesium hydroxide powder, 10 parts of nano silicon dioxide powder, 2 parts of silicon carbide fiber , 2 parts of basalt fiber, 1 part of calcium lignosulfonate, and 1 part of grinding aid.

[0029] SiO in sodium silicate solution 2 with Na 2 The molar mass ratio of O is 3; the viscosity of polydimethylsiloxane is 100 Stokes; the average particle diameter of nano-magnesium hydroxide powder is 35 nanometers; the average particle diameter of nano-silica powder is 15 nanometers; silicon carbide fiber The average diameter is 20 microns, and the average length is 6 mm; the average diameter of basal...

Embodiment 2

[0038] A siloxane-modified superhydrophobic geopolymer anti-corrosion material, including 50 parts of metakaolin, 15 parts of fly ash, 10 parts of silica fume, 18 parts of sodium hydroxide solid, 48 parts of sodium silicate solution, deionized 15 parts of water, 2.5 parts of polydimethylsiloxane, 5 parts of methyl hydrogen silicone oil, 0.15 parts of silane coupling agent, 6 parts of nano magnesium hydroxide powder, 8 parts of nano silicon dioxide powder, 2 parts of silicon carbide fiber , 1 part of carbon fiber, 1 part of calcium lignosulfonate, and 1 part of grinding aid.

[0039] SiO in sodium silicate solution 2 with Na 2 The molar mass ratio of O is 3.5; the viscosity of polydimethylsiloxane is 50 Stokes; the average particle diameter of nano magnesium hydroxide powder is 40 nanometers; the average particle diameter of nano silicon dioxide powder is 20 nanometers; silicon carbide fiber The average diameter is 20 microns, and the average length is 6 mm; the average diame...

Embodiment 3

[0048] SiO in sodium silicate solution 2 with Na 2 The molar mass ratio of O is 3; a siloxane-modified superhydrophobic geopolymer anti-corrosion material, including 55 parts of metakaolin, 15 parts of fly ash, 10 parts of silica fume, 20 parts of sodium hydroxide solid, silicon 50 parts of sodium acid solution, 15 parts of deionized water, 3 parts of polydimethylsiloxane, 5 parts of methyl hydrogen-containing silicone oil, 0.2 parts of silane coupling agent, 6 parts of nano-magnesium hydroxide powder, and nano-silica powder 10 parts, 1 part of silicon carbide fiber, 1 part of basalt fiber, 1 part of carbon fiber, 1.5 parts of calcium lignosulfonate, and 1 part of grinding aid.

[0049] The viscosity of polydimethylsiloxane is 50 Stokes; the average particle size of nano-magnesium hydroxide powder is 40 nm; the average particle size of nano-silica powder is 25 nm; the average diameter of silicon carbide fibers is 20 microns, and the average length The average diameter of bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com