Friction-resistant and anti-pollution super-hydrophobic membrane for membrane distillation process and preparation method thereof

A distillation process, super-hydrophobic technology, applied in water/sewage treatment, general water supply saving, chemical instruments and methods, etc., can solve problems such as loss of separation performance, achieve good stability and anti-friction performance, improve super-hydrophobicity, The effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

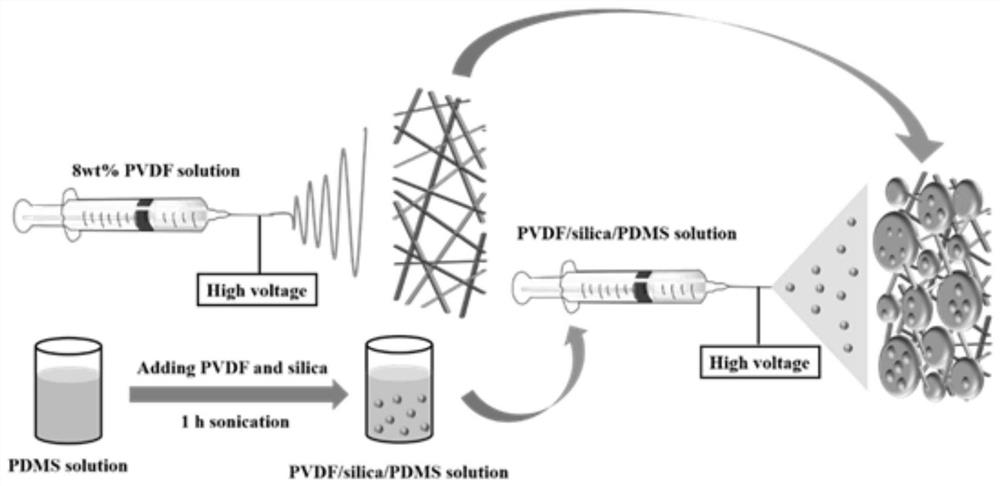

[0028] A high-porosity nanofibrous support layer was prepared by electrospinning 8 wt% PVDF solution. The PVDF nanofibrous membrane is named PVDF.

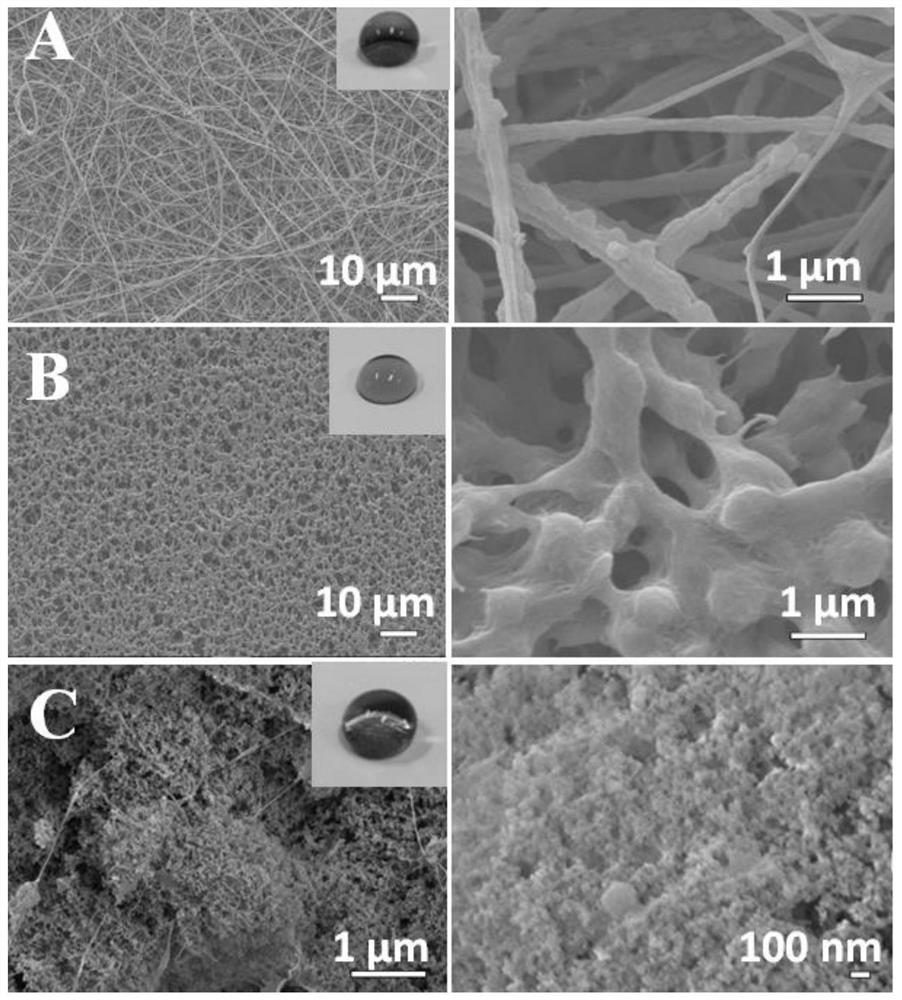

[0029] On the upper part of the nanofiber support layer, a mixed solution prepared by dissolving or dispersing PVDF, PDMS and silicon dioxide in N,N-dimethylformamide (DMF) is used to prepare a superhydrophobic surface layer by electrostatic spraying. The concentrations of PVDF and PDMS in the solution were 2wt% and 3wt%, respectively. Dissolve the PDMS monomer and cross-linking curing agent (10:1) in a mixed solvent of N,N-dimethylformamide (DMF) and tetrahydrofuran (THF) (1:1) to obtain a 3wt% PDMS solution, Then 2 wt% PVDF was added to obtain a homogeneous PVDF / PDMS solution. 3wt% silicon dioxide powder was dispersed in the solution to electrostatically spray the PVDF / PDMS / silicon dioxide composite superhydrophobic layer on the surface of the PVDF nanofiber support layer. The bilayer membrane was named PDMS-3. The preparati...

Embodiment 2

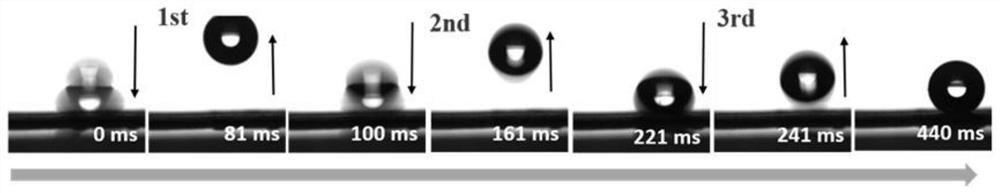

[0031] By testing the hydrophobic performance and anti-friction performance of the superhydrophobic film of the present invention obtained in Example 1, it is concluded that the superhydrophobic film not only exhibits excellent superhydrophobicity, the water contact angle is 170 ± 1 degree, and the superhydrophobic The layer has excellent anti-friction properties and is still superhydrophobic after 40 friction cycles, the results are as follows figure 2 and image 3 shown.

Embodiment 3

[0033] By carrying out anti-scaling and anti-fouling performance tests to the super-hydrophobic membrane of the present invention obtained in Example 1, it can be seen from the membrane distillation test results that compared with PVDF nanofibrous membranes and commercial PVDF membranes, the super-hydrophobic membrane has excellent anti-scaling and anti-fouling properties. Anti-pollution properties. When using 3.5wt% sodium chloride solution as the feed liquid, the temperature of the feed liquid side is 333K, and when the permeation temperature is 293K, 28Lm can be obtained -2 h -1 stable flux.

[0034] The superhydrophobic membrane has excellent anti-fouling and anti-fouling properties, which can make membrane distillation technology treat wastewater containing various inorganic and organic pollutants in practical applications, including: 1) by 35g / L NaCl, 3g / L CaCl 2 ,3g / L Na 2 SO 4 Composed feed liquid: Under the condition of the feed liquid, the feed side and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com