High scattering super-hydrophobic quantum dot film and preparation method thereof

A scattering and super-hydrophobic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of being susceptible to moisture and oxygen, failure of quantum dots, unstable properties of quantum dot materials, etc., to improve the spatial distribution of color temperature. The effect of uniformity, conversion efficiency improvement, and quantum dot material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

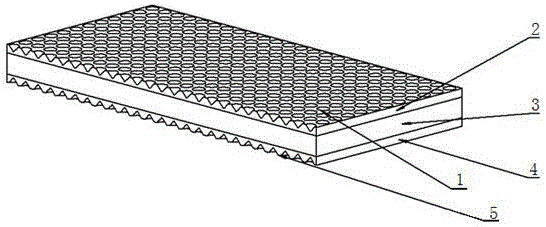

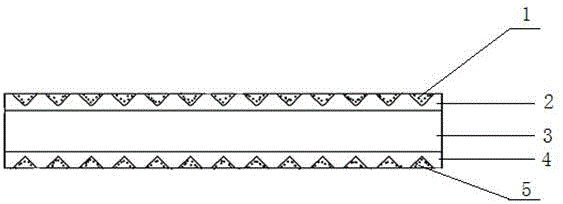

[0047] Preparation of Highly Scattering Superhydrophobic Quantum Dot Film

[0048] (1) Preparation of quantum dot layer: Use a balance to measure 24mg of cadmium selenide quantum dot powder and 0.9g of Dow Corning OE6650 B-type silica gel liquid and dissolve them in 6ml of acetone solution to form a mixture. Stir the mixture in a magnetic stirrer at a constant temperature of 80°C. Until the acetone solution in the mixture is completely volatilized; after adding 0.3g of mixed curing agent to the obtained quantum dot-silica gel solution, the Dow Corning OE6650 A type silica gel liquid is mixed with 36wt% of the curing agent component. Mix evenly with a centrifugal mixer and defoam, pour into a mold with a film thickness of 2mm, bake and cure in an oven at 160°C for 2 hours, and release the mold after curing to obtain a quantum dot layer 2 with a thickness of 2mm;

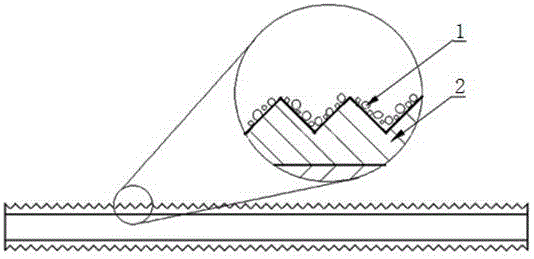

[0049] (2) Preparation of conical hole layer: use photolithography technology to process uniformly distributed cone m...

Embodiment 2

[0054] Same as Example 1, the difference is that the particles of the super-hydrophobic particle layer adopt a particle diameter of 25nm and 125nm silicon dioxide particles;

[0055] And in step (3): the smooth surface of the cone layer obtained in step (2) is pasted on a round smooth sapphire sheet with a diameter of 50 mm without surface structure as a self-assembled substrate; combined with phase separation technology, the orthosilicon ethyl orthosilicate (TEOS), absolute ethanol (ETH), glycerol, deionized water, and 13mol / L concentrated ammonia water at a volume of 1:10:1:5:2 Proportional mixing, stirring quickly on a magnetic stirrer to make it evenly mixed, after the reaction was carried out for 30 minutes, it was left to stand at room temperature for 24 hours to obtain an opalescent and translucent alkali sol; the mass ratio of adding TEOS to the alkali sol was 16 % polyacrylic acid; the alkali sol added with polyacrylic acid was uniformly plated on the clean above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com