Composite alkali-activated solid waste type high performance inorganic adhesive, and preparation method thereof

An inorganic glue, high-performance technology, applied in cement production and other directions, can solve the problems of poor thermal stability of epoxy organic glue, the upper limit of temperature resistance is less than 80 ℃, insufficient shear force of inorganic glue, etc., to enhance market competition force and application range, improving mechanical properties, and the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

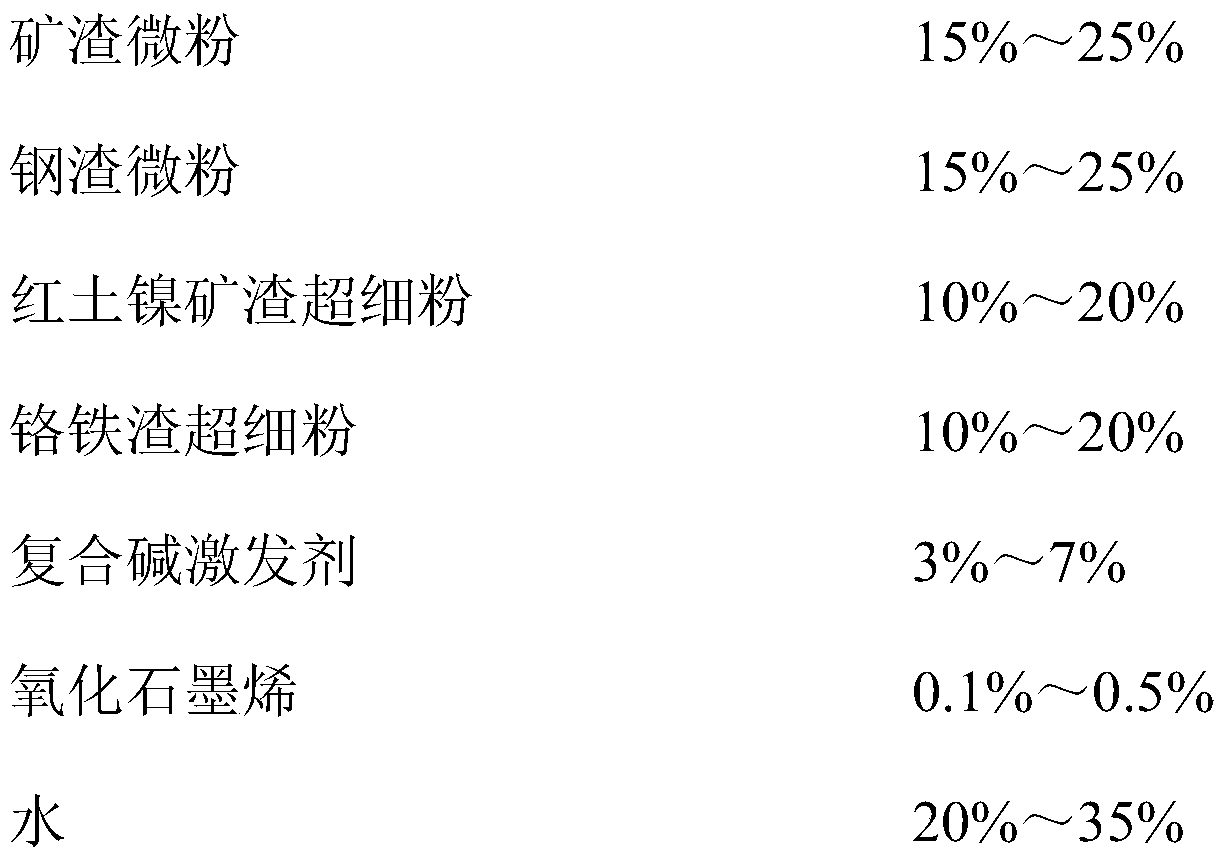

[0027] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0028]

[0029] The slag powder is granulated blast furnace slag powder with a particle size of 25 μm to 45 μm; the steel slag powder is converter hot slag powder with a particle size of 25 μm to 45 μm; the laterite nickel slag ultrafine powder has a particle size of 0.5 μm~2.5 μm; The particle size of the superfine powder of the ferrochrome slag is 0.5 μm~2.5 μm; The composite alkali activator is the mixture of sodium hydroxide and water glass, and the mass ratio of sodium hydroxide and water glass is 3: 1. Sodium hydroxide is industrially pure, water glass is industrially pure, and its modulus is 1.6; graphene oxide is a mixture of Staudemaier method graphene oxide and Brodie method graphene oxide; water is deionized water.

[0030] (1) Using a constant temperature magnetic stirrer to mix the slag fine powder and the steel slag fine p...

Embodiment 2

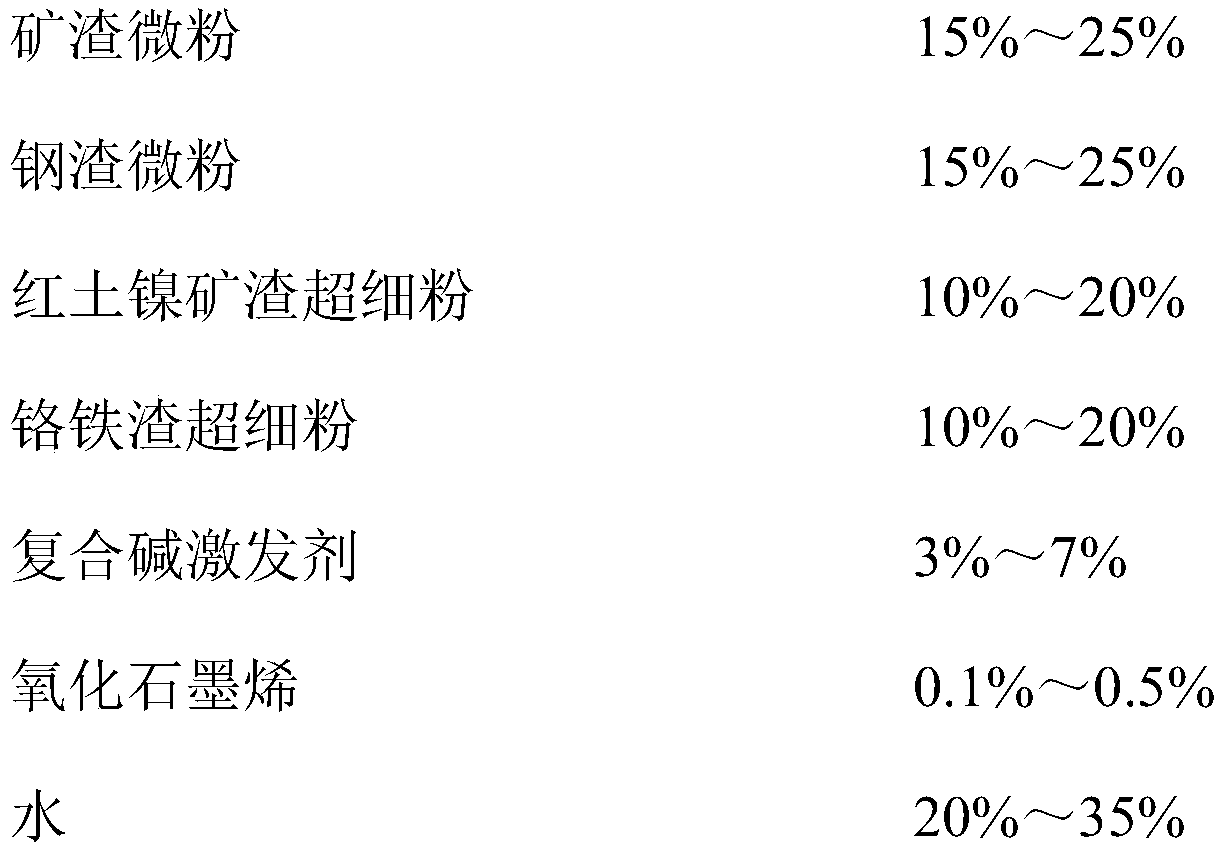

[0035] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0036]

[0037] The slag powder is granulated blast furnace slag powder with a particle size of 25 μm to 45 μm; the steel slag powder is electric furnace drum slag powder with a particle size of 25 μm to 45 μm; the laterite nickel slag ultrafine powder has a particle size of 0.5 μm ~2.5μm; the particle size of the ferrochrome slag ultrafine powder is 0.5μm~2.5μm; the composite alkali activator is a mixture of sodium hydroxide and water glass, and the mass ratio of sodium hydroxide and water glass is 1:1 , sodium hydroxide is industrially pure, water glass is industrially pure, and its modulus is 1.0; graphene oxide is Hummers method graphene oxide; water is deionized water.

[0038] (1) Using a constant temperature magnetic stirrer to mix slag fine powder and steel slag fine powder at normal temperature, the stirring speed is 400r / min, ...

Embodiment 3

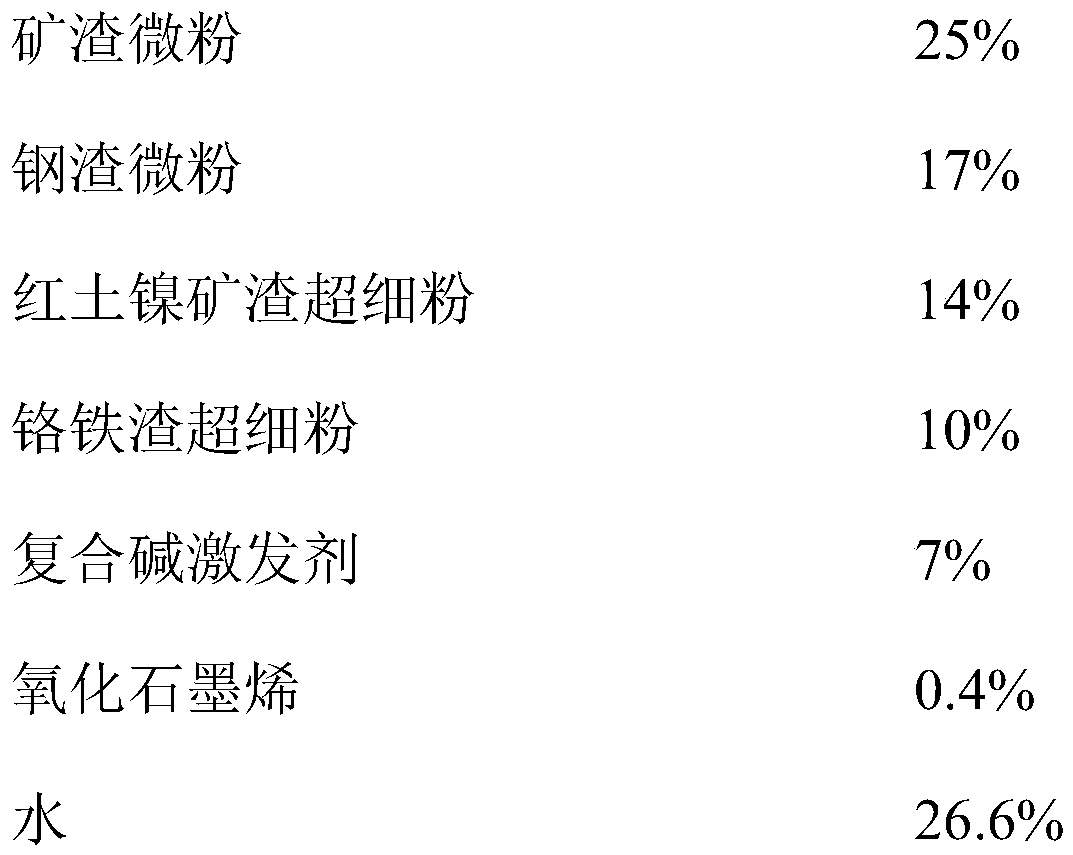

[0043] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0044]

[0045] The slag powder is granulated blast furnace slag powder with a particle size of 25 μm to 45 μm; the steel slag powder is a mixture of hot stuffy slag powder and wind-quenched slag powder with a particle size of 25 μm to 45 μm; the laterite nickel slag is super The particle size of the fine powder is 0.5 μm to 2.5 μm; the particle size of the ferrochrome slag superfine powder is 0.5 μm to 2.5 μm; the composite alkali activator is a mixture of sodium hydroxide and water glass, and sodium hydroxide and water glass The mass ratio of sodium hydroxide is 1:3, sodium hydroxide is industrial pure, water glass is industrial pure, and its modulus is 0.8; Graphene oxide is a mixture of Brodie method graphene oxide and Hummers method graphene oxide; water is deionized water .

[0046] (1) Using a constant temperature magnetic stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com