Laterite nickel ore slag-red mud composite rubber filler with flame retardant and reinforcement performance

A technology of composite rubber and laterite nickel, which is applied in the field of recycling of solid waste resources, can solve the problems of single performance, poor compatibility, high price of filler carbon black and silica, and achieve the effect of reducing costs and promoting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

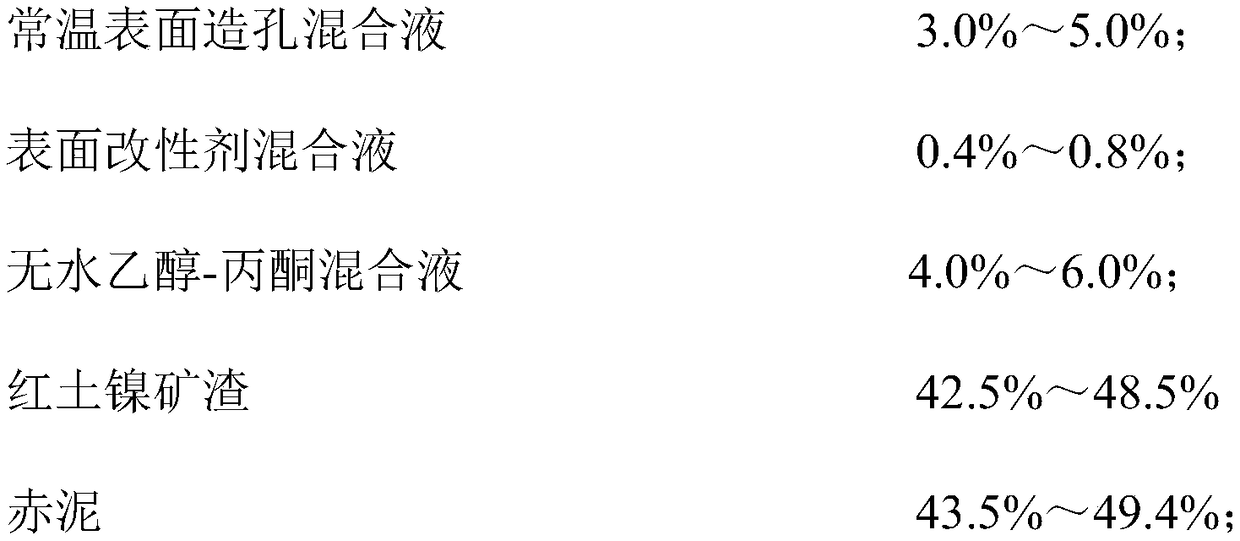

[0020] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0021]

[0022] The mass ratio of dihydrate oxalic acid to phosphoric acid in the normal temperature surface pore-forming mixed solution is 1:1, dihydrate oxalic acid is analytically pure, and phosphoric acid is analytically pure; in the surface modifier mixed solution, silane coupling agent KH560 and silane The mass ratio of coupling agent KH550 is 1:3, and silane coupling agent KH560 is industrial pure, and silane coupling agent KH550 is industrial pure; : 1, dehydrated alcohol is analytically pure, acetone is analytically pure; the particle diameter of described laterite nickel slag is 3.6 μ m~98.2 μ m, and chemical composition (mass fraction) is SiO 2 (28.31%), FeO (0.66%), Al 2 o 3 (25.64%), CaO (27.94%), MgO (9.81%), Cr 2 o 3 (0.75%), MnO (2.02%) and others (4.87%). The chemical composition (mass fraction) of the red mud is S...

Embodiment 2

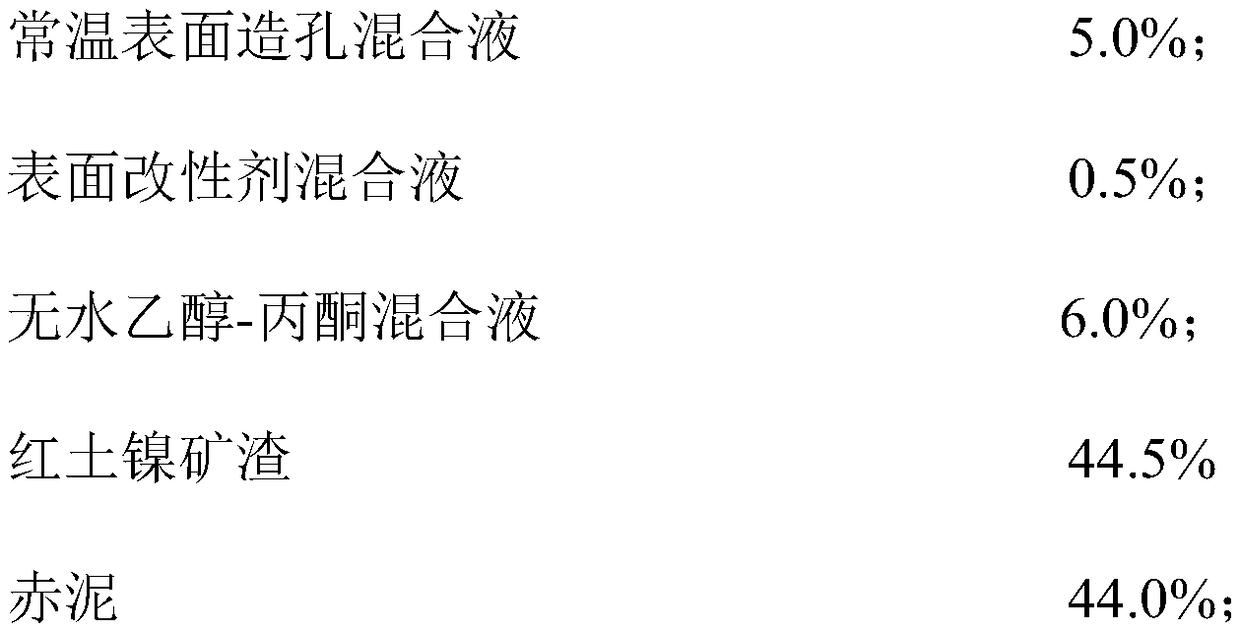

[0025] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0026]

[0027]The mass ratio of dihydrate oxalic acid to phosphoric acid in the normal temperature surface pore-forming mixed solution is 3:1, dihydrate oxalic acid is analytically pure, and phosphoric acid is analytically pure; in the surface modifier mixed solution, silane coupling agent KH560 and silane The mass ratio of coupling agent KH550 is 2:1, and silane coupling agent KH560 is industrial pure, and silane coupling agent KH550 is industrial pure; : 2, absolute ethanol is analytically pure, acetone is analytically pure; the particle diameter of described laterite nickel slag is 3.2 μm~96.9 μm, and chemical composition (mass fraction) is SiO 2 (28.15%), FeO (0.79%), Al 2 o 3 (26.52%), CaO (27.51%), MgO (10.29%), Cr 2 o 3 (0.77%), MnO (1.86%) and others (4.11%). The chemical composition (mass fraction) of the red mud is SiO ...

Embodiment 3

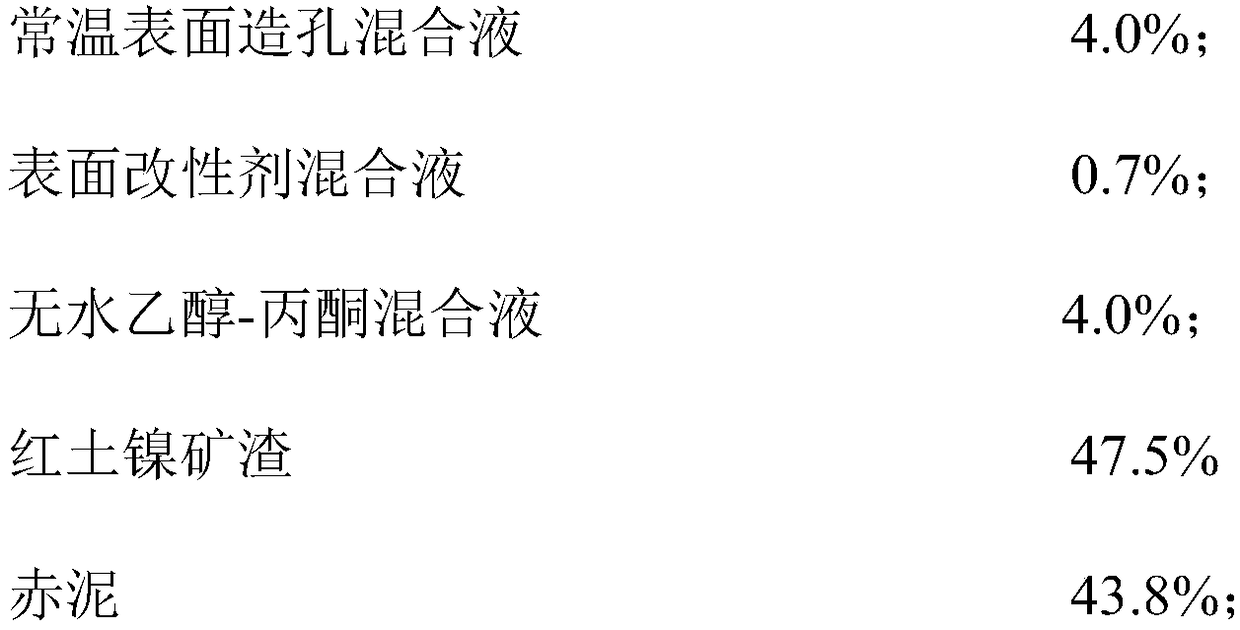

[0030] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0031]

[0032] The mass ratio of oxalic acid dihydrate to phosphoric acid in the normal temperature surface pore-forming mixed solution is 1:2, oxalic acid dihydrate is analytically pure, and phosphoric acid is analytically pure; in the mixed solution of surface modifier, silane coupling agent KH560 and silane The mass ratio of coupling agent KH550 is 1:1, and silane coupling agent KH560 is technically pure, and silane coupling agent KH550 is technically pure; : 1, dehydrated alcohol is analytically pure, acetone is analytically pure; the particle diameter of described laterite nickel slag is 4.4 μ m~101.8 μ m, and chemical composition (mass fraction) is SiO 2 (28.55%), FeO (0.59%), Al 2 o 3 (26.57%), CaO (27.67%), MgO (10.33%), Cr 2 o 3 (0.59%), MnO (1.56%) and others (4.14%). The chemical composition (mass fraction) of the red m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com