Metallurgy solid-waste-type fireproof and flame-retarding coating and preparing method thereof

A technology for fire-retardant and flame-retardant coatings, pigments and fillers, used in fire-resistant coatings, coatings, etc., can solve the problems of unstable calcium sulfite properties, complex components, and land occupation, so as to enhance market competitiveness and application scope, and improve environmental protection. performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

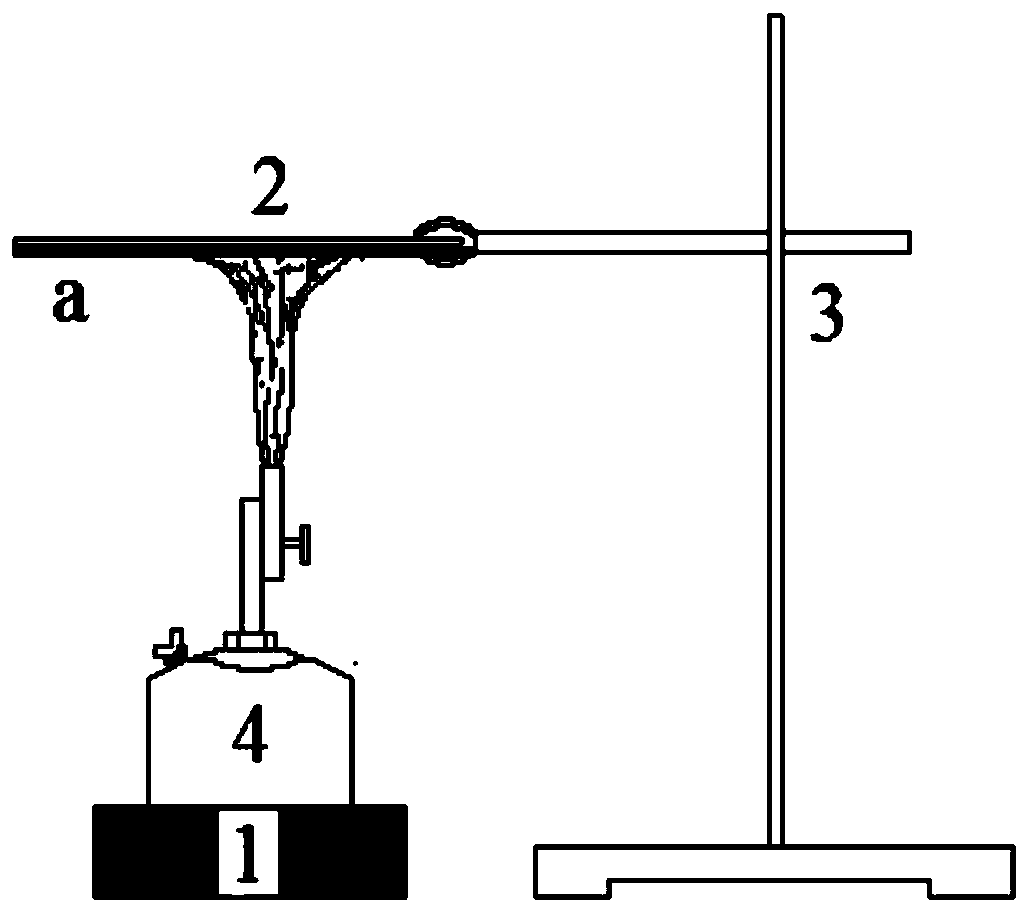

Method used

Image

Examples

Embodiment 1

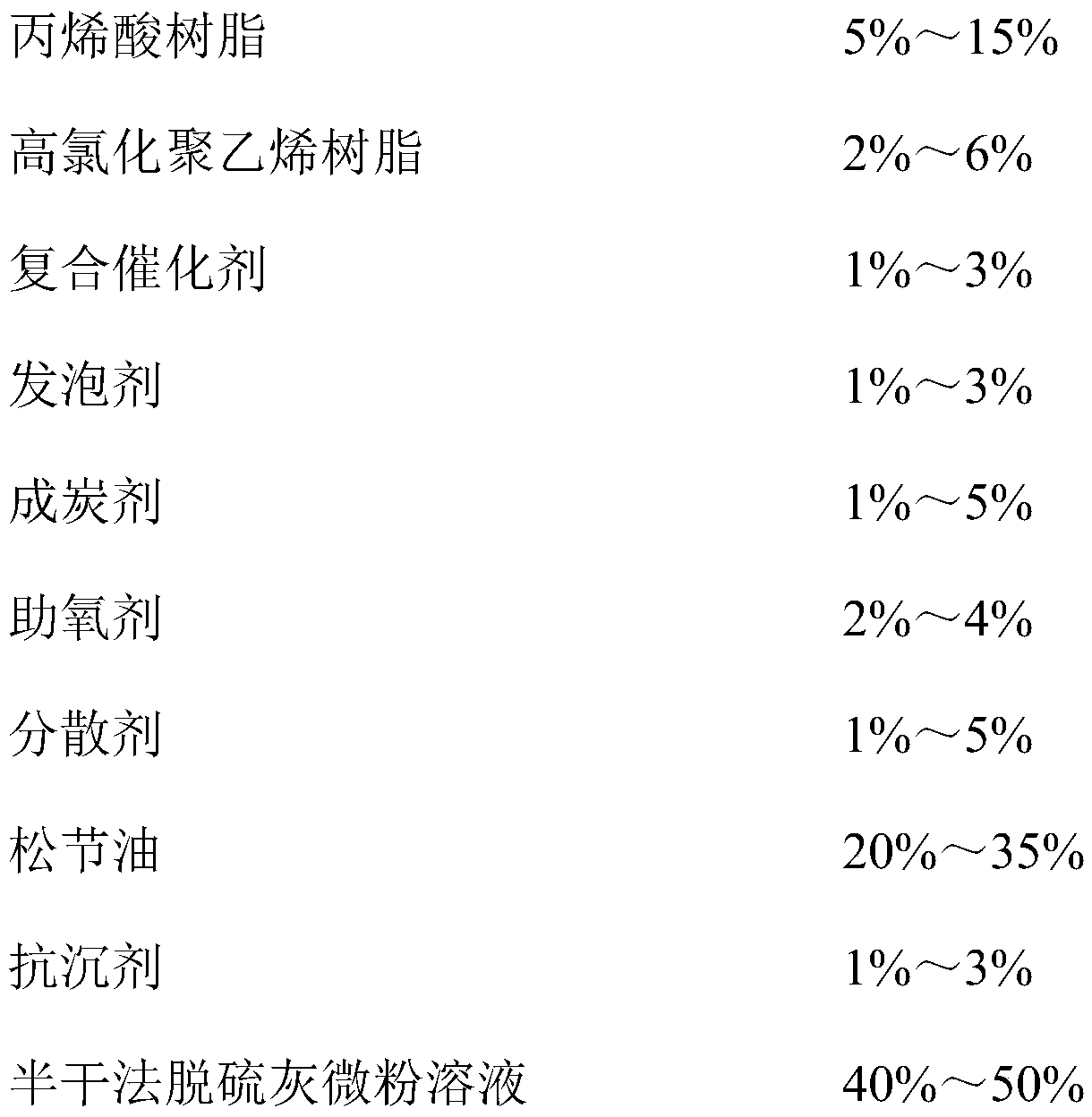

[0026] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0027]

[0028]

[0029] The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:3, boric acid, phosphoric acid guanyl urea and ammonium polyphosphate are industrial pure; Described blowing agent is melamine, and it is industrial pure; Described char-forming agent is pentaerythritol, and it is industrial pure; The oxygen agent is manganese dioxide, which is industrial pure; the dispersant is SRE-4029 dispersant, which is industrial pure; the turpentine is industrial pure; the anti-sedimentation agent is F118, which is an industrial pure pure; the semi-dry desulfurization ash powder solution is a ...

Embodiment 2

[0034] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0035]

[0036] The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:4, boric acid, guanylurea phosphate and ammonium polyphosphate are industrial pure; Described blowing agent is melamine, and it is industrial pure; Described char-forming agent is pentaerythritol, and it is industrial pure; The oxygen agent is manganese dioxide, which is industrially pure; the dispersant is SRE-4029 dispersant, which is industrially pure; the turpentine is industrially pure; the anti-settling agent is F118 anti-settling agent, which is industrially pure The semi-dry desulfurization ash micropowder solution is a ...

Embodiment 3

[0041] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0042]

[0043]

[0044] The acrylic resin is industrially pure; the highly chlorinated polyethylene resin is industrially pure; the composite catalyst is a mixture of boric acid, amidinourea phosphate and ammonium polyphosphate, and the quality of boric acid, amidinourea phosphate and ammonium polyphosphate is Ratio 1:1:1, boric acid, phosphoric acid amidinourea and ammonium polyphosphate are industrial pure; Described blowing agent is melamine, and it is industrial pure; Described carbon forming agent is pentaerythritol, and it is industrial pure; The oxygen agent is manganese dioxide, which is industrially pure; the dispersant is SRE-4029 dispersant, which is industrially pure; the turpentine is industrially pure; the anti-settling agent is F118 anti-settling agent, which is industrially pure The semi-dry desulfurization ash micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com