Alkali-activated fluidized bed fly ash geopolymer and preparation method thereof

A geopolymer and fluidized bed technology, applied in cement production, etc., can solve the problems of low activity of fly ash in fluidized bed, difficulty in effective utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

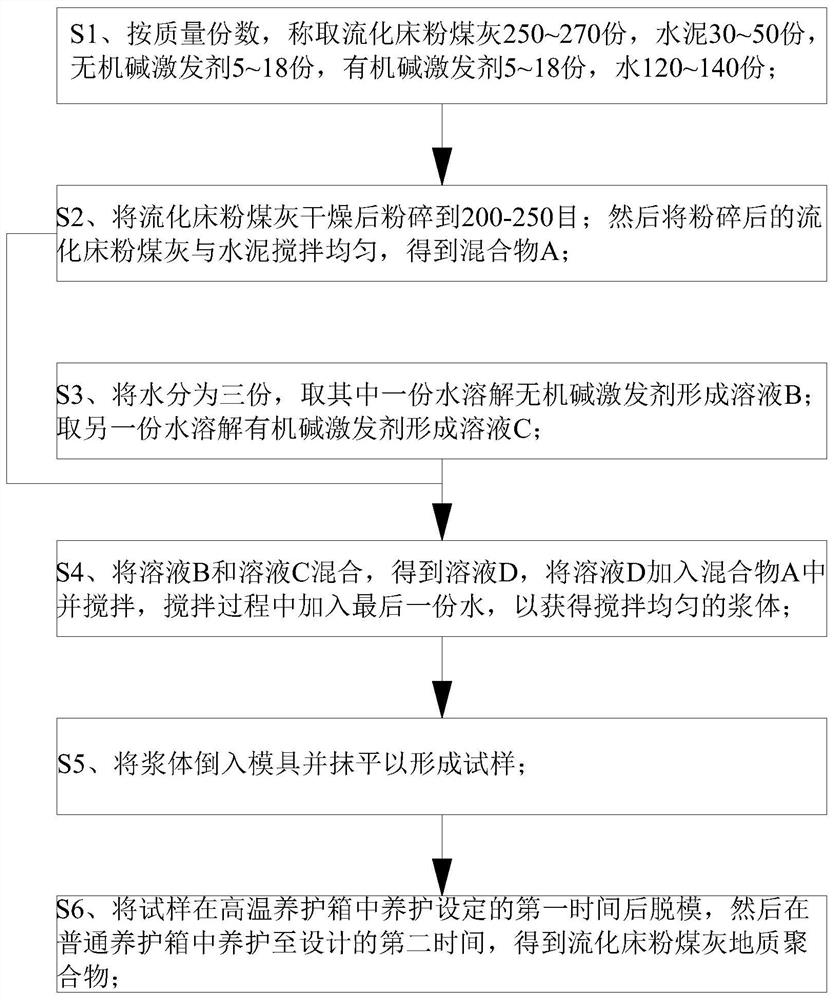

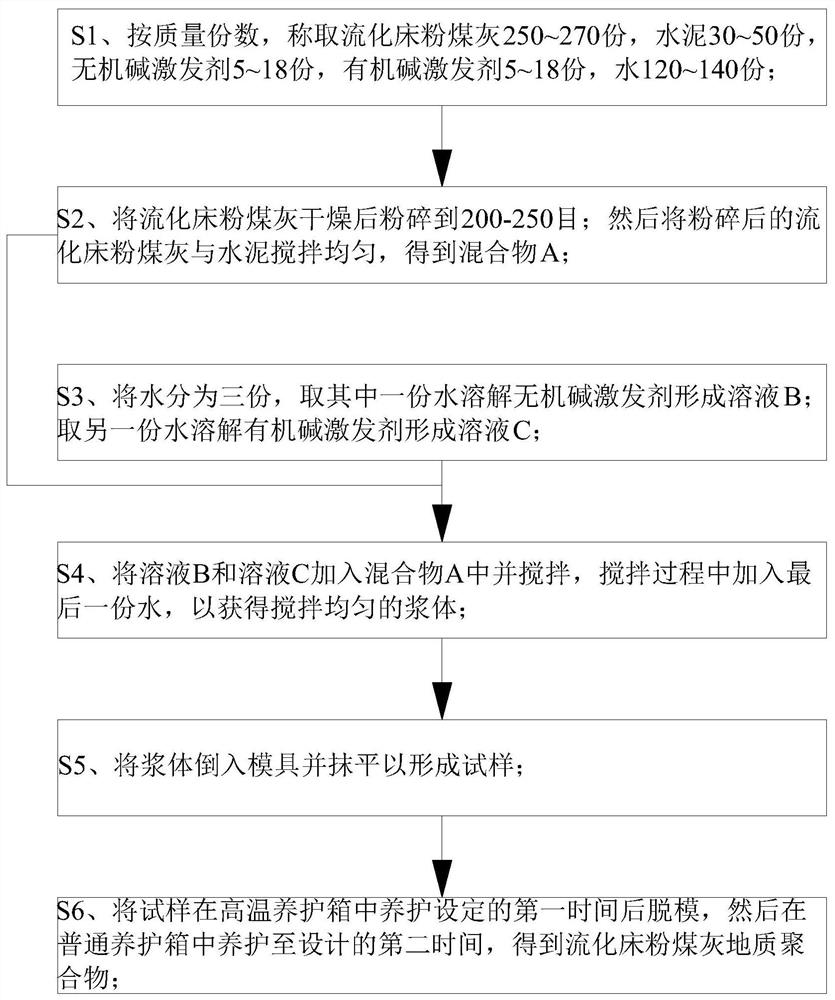

[0054] In this embodiment, the preparation steps of the alkali-activated fluidized bed fly ash geopolymer are as follows:

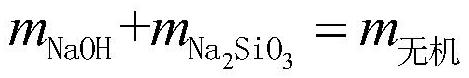

[0055] S1. In parts by mass, weigh 250 parts of fluidized bed fly ash, 50 parts of cement, 15 parts of inorganic base activator, 15 parts of organic base activator, and 126 parts of water. The inorganic alkali activator adopts sodium silicate Na with a modulus of 1.8. 2 O nSiO 2 , The organic base activator uses sodium acetate NaAc.

[0056] S2. Dried and pulverized the fluidized bed fly ash to 200-250 mesh; then uniformly stirred the pulverized fluidized bed fly ash and cement to obtain a mixture A.

[0057] S3. Divide the water into three parts, take one part of water to dissolve the inorganic base activator to form solution B; take the other part of water to dissolve the organic base activator to form solution C.

[0058] S4. Mix solution B and solution C to obtain solution D, add solution D to mixture A, stir in a slurry mixer at 1000-1200r / min, ad...

Embodiment 2

[0064] The preparation steps of the alkali-activated fluidized-bed fly ash geopolymer in this example are the same as those in Example 1. Compared with Example 1, only the components of the alkali-activated fluidized-bed fly ash geopolymer in this example are changed.

[0065] The components of the alkali-activated fluidized-bed fly ash geopolymer in this embodiment are counted in parts by mass, including: 250 parts of fluidized-bed fly ash, 50 parts of cement, 18 parts of inorganic alkali activator, organic alkali-activated 12 parts of medicine, 132 parts of water. Among them, sodium water glass with a modulus of 1.8 is used as the inorganic base activator, and NaAc is used as the organic base activator.

Embodiment 3

[0067] The preparation steps of the alkali-activated fluidized-bed fly ash geopolymer in this example are the same as those in Example 1. Compared with Example 1, only the components of the alkali-activated fluidized-bed fly ash geopolymer in this example are changed.

[0068] The components of the alkali-activated fluidized-bed fly ash geopolymer in this embodiment are counted in parts by mass, including: 250 parts of fluidized-bed fly ash, 50 parts of cement, 12 parts of inorganic alkali activator, organic alkali excited 18 parts of medicine, 132 parts of water. Among them, sodium water glass with a modulus of 1.8 is used as the inorganic base activator, and NaAc is used as the organic base activator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com