Fine-particle iron tailing unfired water permeable brick and preparation method thereof

A technology of iron tailings and permeable bricks, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of less research, environmental hazards, and large discharge of iron tailings, and achieve good water retention and water permeability , The preparation process is short, and the effect of environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing fine-grained iron tailings permeable bricks, comprising the following raw materials in terms of mass percentage: 80 parts of fine-grained iron tailings, 20 parts of commercial tailings curing agent, 10 parts of water-based epoxy resin emulsion, and 10 parts of slag , 5 parts of sodium silicate.

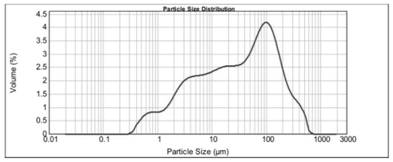

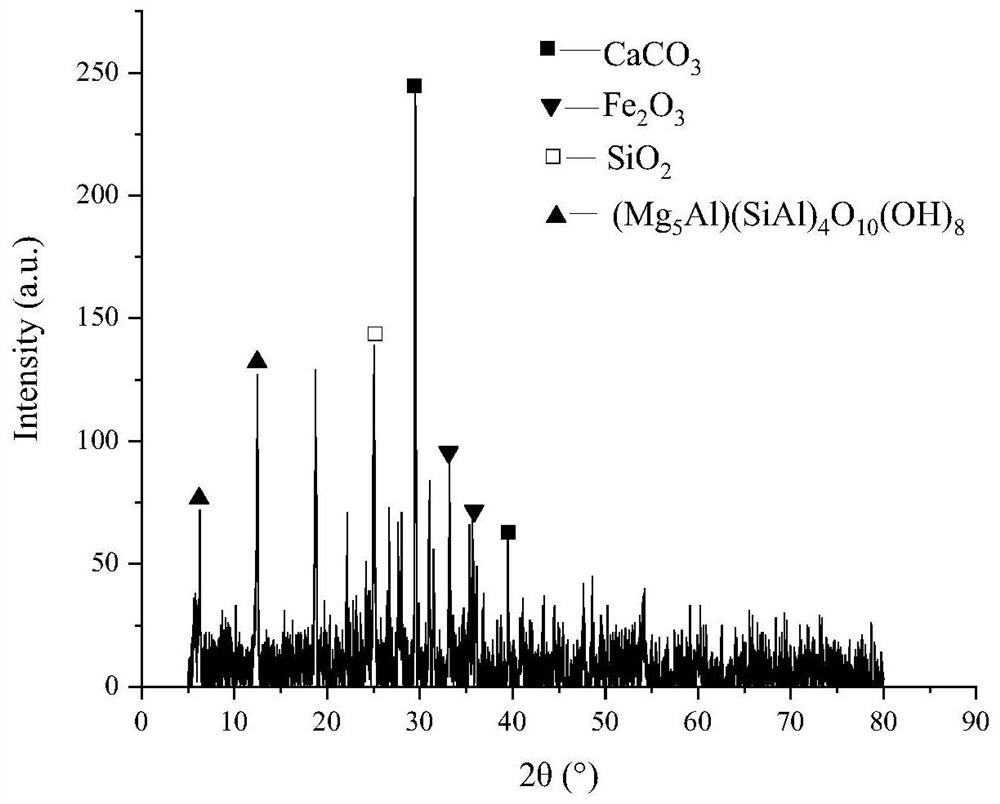

[0031] In the present invention, the chemical composition of the fine-grained iron tailings is represented by SiO 2 、Al 2 o 3 , Fe 2 o 3 , MgO, and the total content of the two oxides reached more than 83% of the total. The specific chemical composition is shown in Table 1. The main mineral composition in iron tailings is calcite (CaCO 3 ), hematite (Fe 2 o 3 ), quartz (SiO 2 ), clinolite ((Mg 5 Al)(SiAl) 4 (OH) 8 )Wait. The average particle size of fine-grained iron tailings is 75 microns, and the particle size range is 20-140 microns.

[0032] Table 1 Iron tailings chemical composition (wt%)

[0033]

[0034] Put the fine-grained iron t...

Embodiment 2

[0038] A method for preparing fine-grained iron tailings permeable bricks. In terms of mass percentage, raw materials are prepared: 85 parts of fine-grained iron tailings, 15 parts of commercial tailings curing agent, 5 parts of vinyl acetate-ethylene copolymer emulsion, and 10 parts of fly ash parts, steel slag 5 parts.

[0039] Put the fine-grained iron tailings into a drying oven at 105°C for drying. After drying, the iron tailings are ball milled to produce powder materials. Mix the iron tailings powder materials with 15% commercial tailings curing agent to make a diameter of 6.0mm The ceramsite samples were obtained from the iron tailings ceramsite after curing in a 90°C hydrothermal curing box for 3 days.

[0040] The ceramsite is broken into 3mm-5mm particle size iron tailings ceramsite body sample, and the composite cementitious material is prepared by using vinyl acetate-ethylene copolymer emulsion, fly ash and steel slag, and the iron tailings pottery is prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com