Green fixing device for vertical template square steel of welded elbow and construction method of green fixing device

A technology of vertical formwork and fixing device, which is applied in the direction of formwork/formwork/work frame, connection of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem that the rigidity and bending strength are not as good as those of steel. , Unfavorable material turnover and recycling, damage to square wood, wall and column formwork, etc., to achieve the effect of high residual value, forest protection, not easy to deform and dislocate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

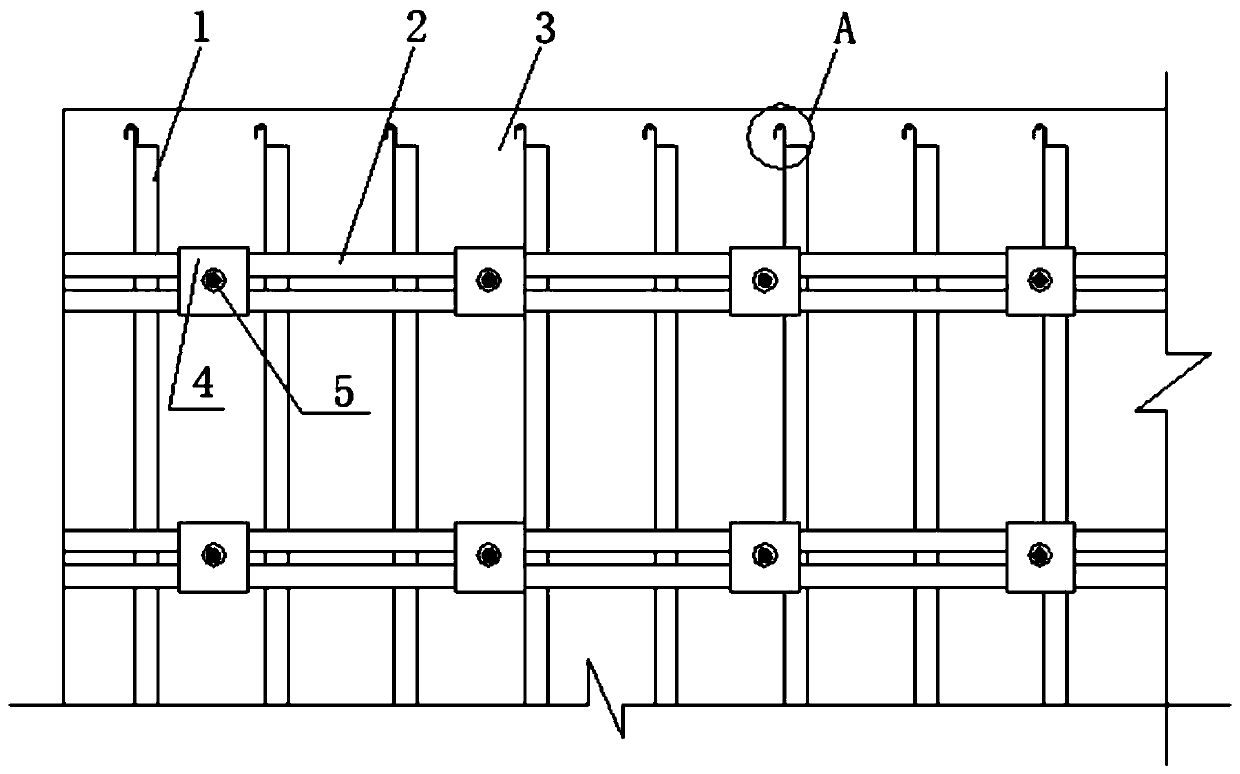

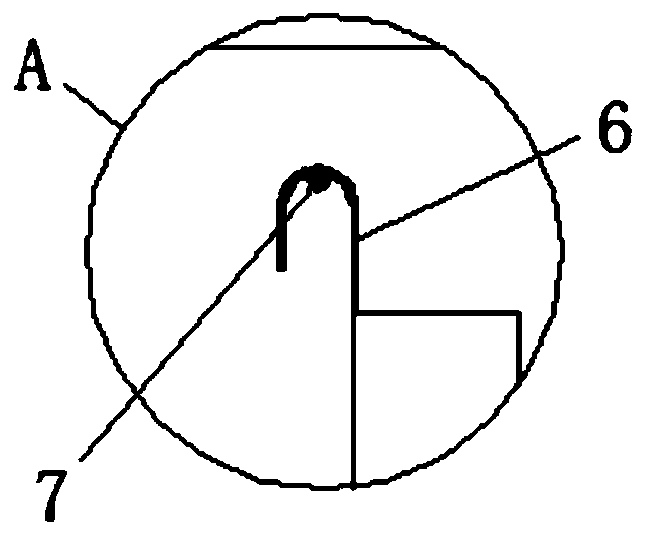

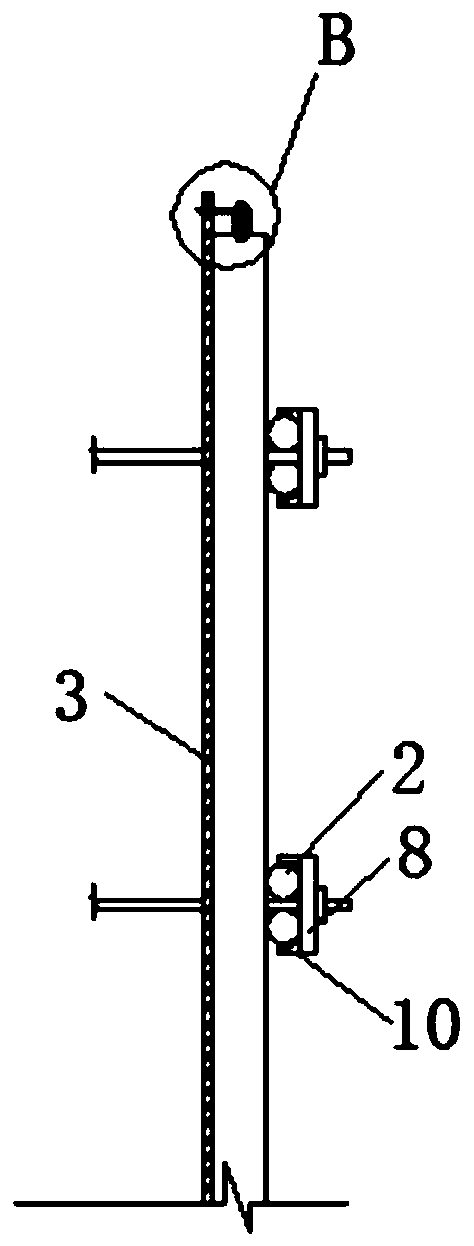

[0030] Such as Figure 1-4 As shown, the present invention provides a technical solution: a green fixing device for welding elbow vertical formwork square steel, comprising a square steel keel 1, the front of the square steel keel 1 is lapped with secondary keels 2, and the number of secondary keels 2 is Four, the number of square steel keels 1 is several, and the number of fasteners 4 is eight. Because square steel keels 1 are provided, when the staff needs to fix the formwork 3, they can use square steel keels 1 instead of wooden strips , and the square steel keel 1 has superior rigidity and bending resistance, is safe and reliable, and eliminates the disadvantages of mold explosion and mold expansion. The back of the keel is overlapped with the front of the template 3, and the fronts of the two sub-keels 2 are overlapped with the back of the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com