Semi-dry desulfurization ash-based enhanced-temperature-adjusted-flame-retardant interior wall putty powder and preparation method thereof

A semi-dry method of desulfurization and interior wall putty powder technology, applied in the direction of filling slurry, etc., can solve the problems of poor cleaning and safety, low added value, cracking of building materials, etc., and achieve the effect of promoting enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

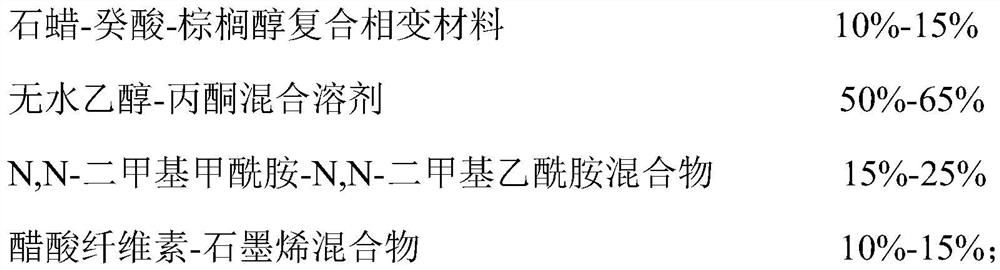

Method used

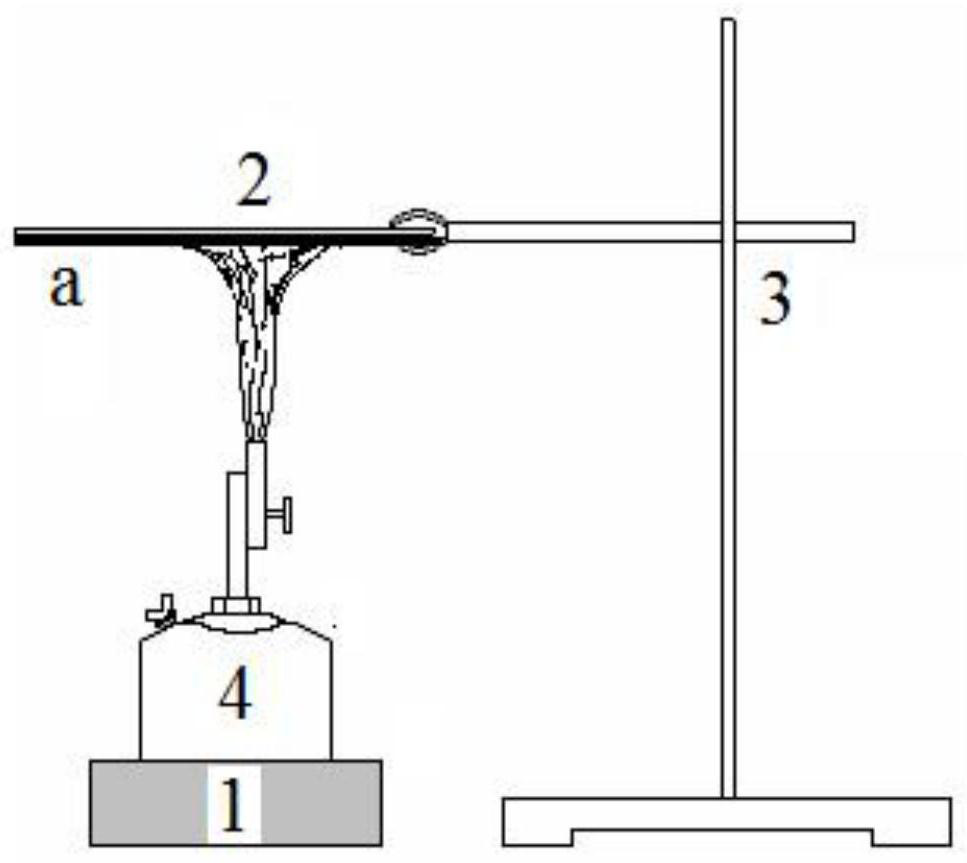

Image

Examples

Embodiment 1

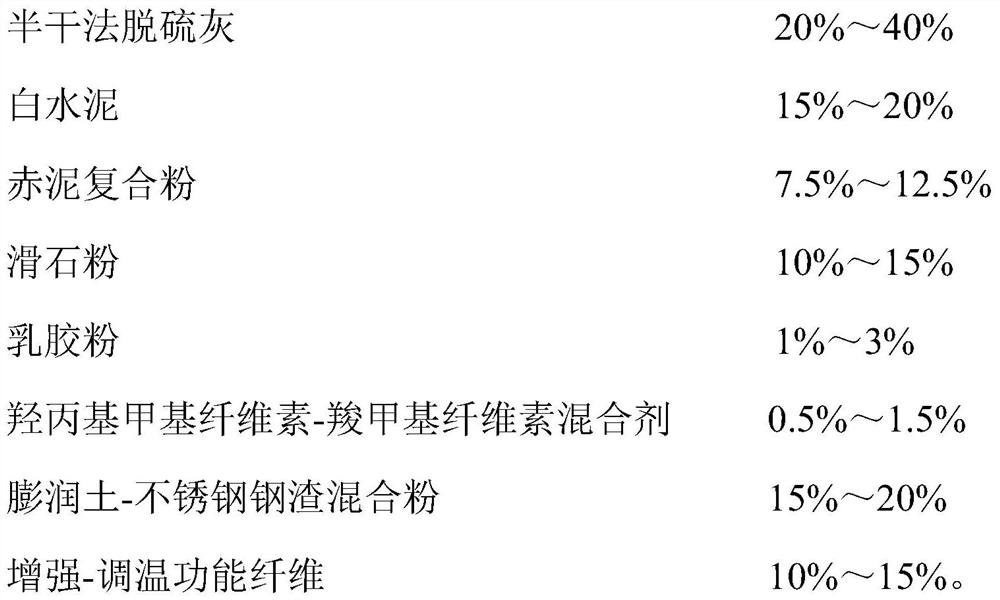

[0029] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0030]

[0031] The chemical composition (mass percentage) of the semi-dry desulfurization ash is CaO (59.2%), SO 3 (32.1%), Cl (3.2%), Fe 2 o 3 (1.8%), K 2 O (1.3%), Na 2 O (0.6%), SiO 2 (0.5%), MgO (0.4%), Al 2 o 3 (0.3%), others (0.6%), the fineness is 400 mesh.

[0032] The white cement is white Portland cement with a grade of P·W 32.5.

[0033] The red mud composite powder is a mixture of Bayer red mud and sintering red mud, the mass ratio of Bayer red mud to sintering red mud is 3:1, and its chemical composition (mass percentage) is SiO 2 (20.5%), Al 2 o 3 (17.6%), CaO (36.4%), Fe 2 o 3 (8.9%), MgO (1.5%), Na 2 O (6.8%), others (8.3%), the fineness is 500 mesh.

[0034] The fineness of the talc powder is 400 mesh; the minimum film-forming temperature of the latex powder is 0°C-5°C.

[0035] In the hydroxypropyl meth...

Embodiment 2

[0041] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0042]

[0043] The chemical composition (mass percentage) of the semi-dry desulfurization ash is CaO (59.2%), SO 3 (32.1%), Cl (3.2%), Fe 2 o 3 (1.8%), K 2 O (1.3%), Na 2 O (0.6%), SiO 2 (0.5%), MgO (0.4%), Al 2 o 3 (0.3%), others (0.6%), the fineness is 400 mesh.

[0044] The white cement is white Portland cement with a grade of P·W 32.5.

[0045] The red mud composite powder is a mixture of Bayer red mud and sintering red mud, the mass ratio of Bayer red mud to sintering red mud is 1:3, and its chemical composition (mass percentage) is SiO 2 (19.2%), Al 2 o 3 (16.9%), CaO (32.7%), Fe 2 o 3 (9.3%), MgO (1.7%), Na 2 O (10.3%), others (9.9%), the fineness is 500 mesh.

[0046] The fineness of the talc powder is 400 mesh; the minimum film-forming temperature of the latex powder is 0°C-5°C.

[0047] In the hydroxypropyl met...

Embodiment 3

[0053] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0054]

[0055] The chemical composition (mass percentage) of the semi-dry desulfurization ash is CaO (59.2%), SO 3 (32.1%), Cl (3.2%), Fe 2 o 3 (1.8%), K 2 O (1.3%), Na 2 O (0.6%), SiO 2 (0.5%), MgO (0.4%), Al 2 o 3 (0.3%), others (0.6%), the fineness is 400 mesh.

[0056] The white cement is white Portland cement with a grade of P·W 32.5.

[0057] The red mud composite powder is a mixture of Bayer process red mud and sintering process red mud, the mass ratio of Bayer process red mud to sintering process red mud is 1:1, and its chemical composition (mass percentage) is SiO 2 (18.8%), Al 2 o 3 (20.1%), CaO (27.7%), Fe 2 o 3 (12.3%), MgO (1.4%), Na 2 O (9.5%), others (10.2%), the fineness is 500 mesh.

[0058] The fineness of the talc powder is 400 mesh; the minimum film-forming temperature of the latex powder is 0°C-5°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com