Method for synthesizing 4A molecular sieve by double crystallization

A chemical synthesis and molecular sieve technology, applied in the direction of molecular sieve compounds, chemical instruments and methods, molecular sieve characteristic silicates, etc., can solve the problems of long synthesis time, long activation time, and complicated steps, so as to reduce synthesis cost and reduce the degree of agglomeration , the effect of improving yield and synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

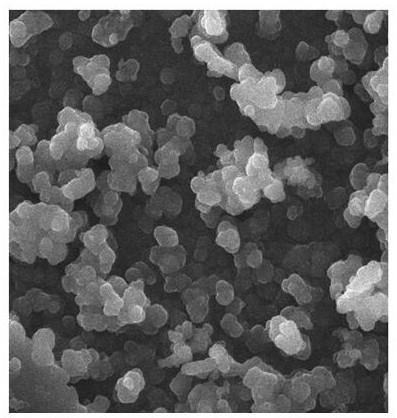

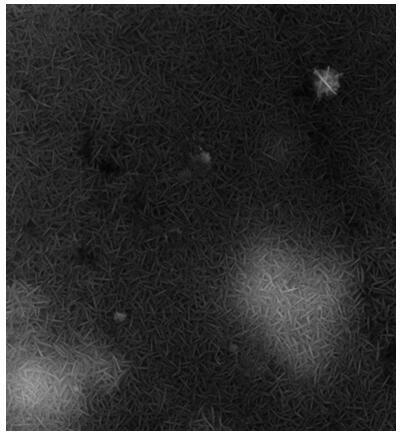

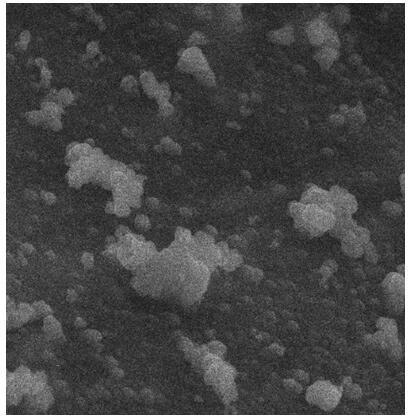

Image

Examples

Embodiment 1

[0020] A method for synthesizing 4A molecular sieves by twin crystallization, the specific steps are as follows:

[0021] (1) First pretreat the coal gangue. The pretreatment method is as follows: heat preservation at 1000°C for 9 hours, pickle the calcined product with 1mol / L hydrochloric acid, and then dry it naturally. Then, according to the mass volume ratio g:mL of 1:6 Ratio, mix the pretreated coal gangue with NaOH solution with a concentration of 0.1mol / L, stir at a constant speed of 250r / min for 600min, vacuum filter and separate to obtain the supernatant;

[0022] (2) Mix Al powder and NaOH solution with a concentration of 0.1mol / L according to the molar ratio of Al and NaOH of 1:5, and stir until the aluminum powder is completely dissolved to obtain a mixed solution;

[0023] (3) Mix the supernatant obtained in step (1) with the mixed solution obtained in step (2) at a volume ratio of 1:1, and place the mixture in an oil bath at 70°C for 5 hours, remove the white flo...

Embodiment 2

[0027] A method for synthesizing 4A molecular sieves by twin crystallization, the specific steps are as follows:

[0028] (1) First pretreat the coal gangue. The pretreatment method is: heat preservation at 900°C for 12 hours, pickle the calcined product with 1mol / L hydrochloric acid and then dry it naturally, and then according to the mass volume ratio g:mL of 1:12 Ratio, mix the pretreated coal gangue with NaOH solution with a concentration of 1mol / L, stir at a constant speed of 350r / min for 40min, vacuum filter and separate to obtain the supernatant;

[0029] (2) Mix Al powder and NaOH solution with a concentration of 1mol / L according to the molar ratio of Al and NaOH of 1:10, and stir until the aluminum powder is completely dissolved to obtain a mixed solution;

[0030] (3) Mix the supernatant obtained in step (1) with the mixed solution obtained in step (2) at a volume ratio of 1:2, and place the mixture in an oil bath at 100°C for 3 hours, remove the white flocs The sup...

Embodiment 3

[0033] A method for synthesizing 4A molecular sieves by twin crystallization, the specific steps are as follows:

[0034] (1) First pretreat the coal gangue. The pretreatment method is: heat preservation at 950°C for 10 hours, pickle the calcined product with 1mol / L hydrochloric acid and then dry it naturally, and then according to the mass volume ratio g:mL of 1:10 Ratio, mix the pretreated gangue with NaOH solution with a concentration of 2mol / L, stir at a constant speed of 300r / min for 400min, vacuum filter and separate to obtain the supernatant;

[0035] (2) Mix Al powder and NaOH solution with a concentration of 2mol / L according to the molar ratio of Al and NaOH of 1:6, and stir until the aluminum powder is completely dissolved to obtain a mixed solution;

[0036] (3) Mix the supernatant obtained in step (1) with the mixed solution obtained in step (2) at a ratio of 1:3 by volume, and place the mixed solution in an oil bath at 140°C for 2 hours, remove the white flocs Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com