Integral heald wire for jacquard loom and its making process

A technology of jacquard loom and manufacturing method, which is applied in healds, textiles, papermaking, textiles, etc., can solve the problems of easy corrosion of healds, poor fabric quality, complicated manufacturing, etc., and achieve the goal of wide application, few processes, and short process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

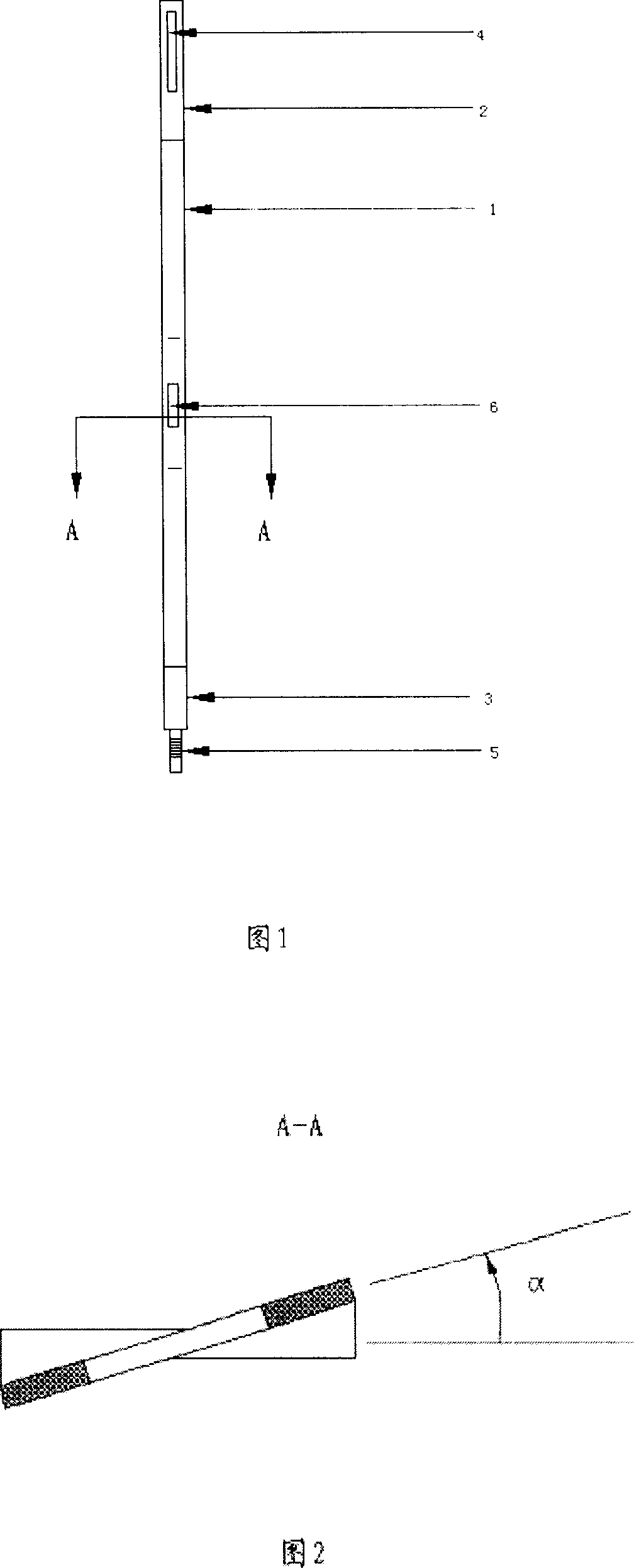

[0026] In Fig. 1: a kind of integrated heddle that is used for jacquard loom of invention, is a strip-shaped yarn guiding device 1, is stainless steel material, has the macromolecular material component associated with other parts at both ends, wherein one end The connecting member 2 has a small hole 4, and the connecting member 3 at the other end is provided with a thread 5, and the center of the yarn guide device 1 has a geometrically shaped small hole, which is the heddle eye 6, and the warp yarn passes through the heald eye 6. With the lifting and lowering of the heald, a space is formed, which is called the opening. The weft yarn is introduced into the opening in a direction perpendicular to the warp yarn, and intersects with the warp yarn. In Figure 2, the heald eye section and the heald yarn There is a torsion angle α of 15° in the non-heald eye, the total length of the heddle is 360.0mm, the width is 2.0mm, and the thickness is 0.3mm. The length of the heald eye is 5.0m...

Embodiment 2

[0029] The integrated heald of the jacquard loom of the present implementation, the heald eye section of the heddle and the heald no heald eye portion form 45 . The torsion angle, the total length of the heddle is 660.0mm, the width is 4.0mm, the thickness is 0.4mm, the length of the heald eye is 3.0mm, and the width is 2.5mm.

[0030] Its manufacturing method, in the calendering process, the process line speed of the calender is 50 m / min; the calendering pressure is 1.5 million Newton; in the punching process, the speed of the punching machine is 100 rpm; Min, injection volume 50 g / time; in polishing process, rotating speed 200 rev / min / .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com