Set-right structure with function of preventing guide needles from being fractured

A technology of baffles and workbenches, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc. It can solve problems such as easy breakage of lead pins, and achieve the effect of avoiding direct contact and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

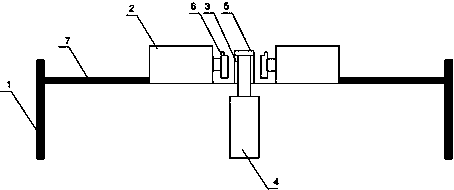

[0018] Such as figure 1 As shown, the present embodiment includes a workbench 1, a baffle 3 and two cylinders 2 are arranged on the workbench 1, the telescopic end of the cylinder 2 is connected with a splint 6, the baffle 3 is fixedly installed in the middle of the two splints 6, and the splint The upper end portion of 6 is stepped, also comprises top mechanism, and top mechanism 4 is arranged on the below of baffle plate, and top mechanism comprises top plate 5 and top cylinder 4, and top plate 5 is arranged on baffle plate 3, and top cylinder 4 The telescoping end runs through the baffle plate 3 and is connected with the bottom of the top plate 5 . When the present invention is working, the network transformer is placed on the workbench 1, and then the guide pin of the network transformer is placed in the gap between the stepped splint 6 and the baffle 5 at the upper end, the baffle 5 and the splint 6 A guide groove is formed between them. The guide groove provides accurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com