Nano-modified water-based weather-resistant sound isolation adhesive and preparation method thereof

A technology of nano-modification and manufacturing method, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of complex process, limited sound insulation effect, uneven actual performance, etc., achieve broad application prospects, improve Sound insulation effect, high use value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

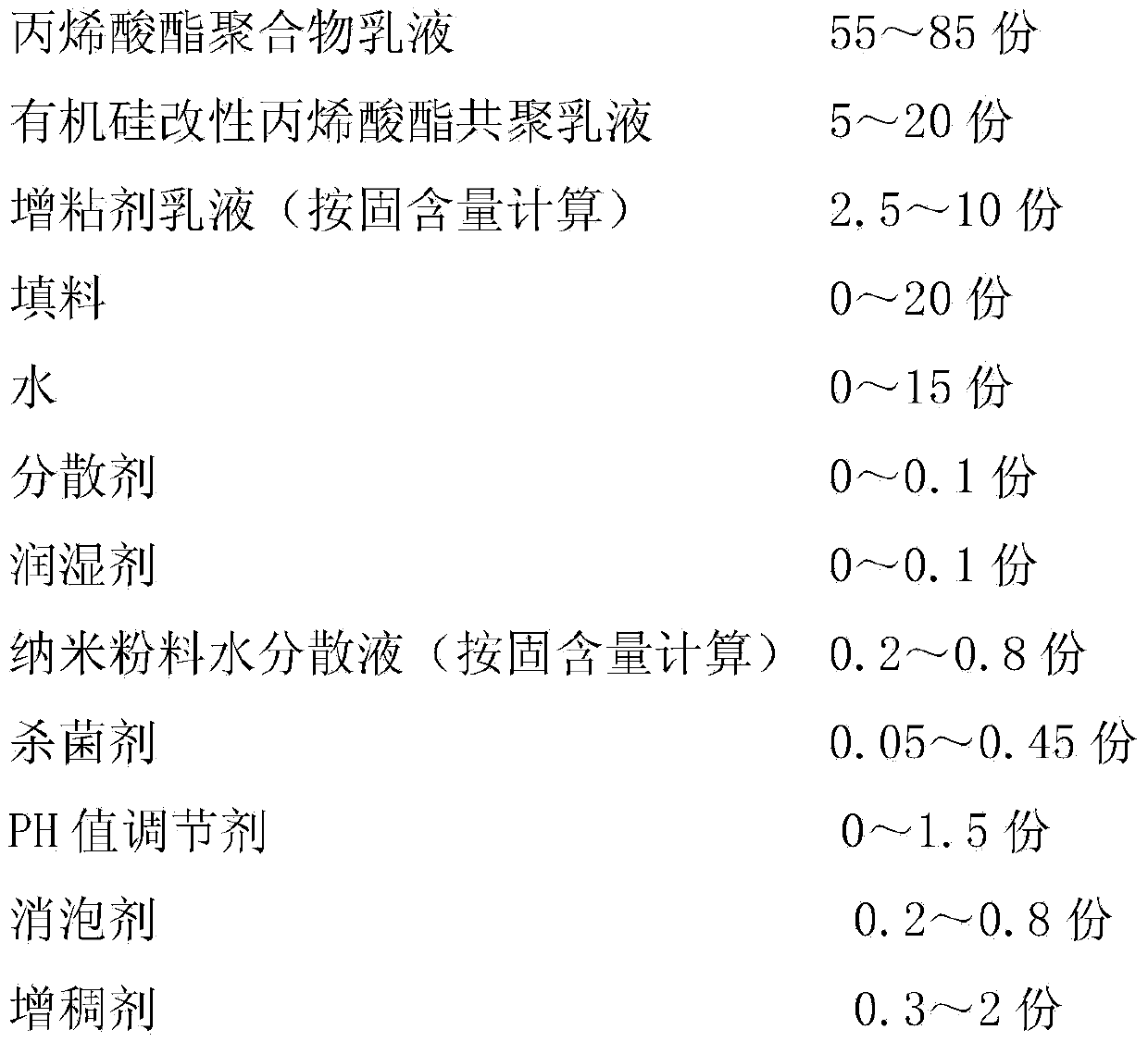

[0047] Ingredients as follows:

[0048]

[0049] The formulation amounts of the above formulation components are calculated in parts by mass, and the parts by mass specifically refer to the reference quantities calculated by weight of each component under the same unit of measurement, the same below.

[0050] The preparation process is as follows:

[0051] 1) Mix and stir the acrylate polymer emulsion and the silicone-modified acrylate copolymer emulsion according to the specified number, and add all the tackifier emulsion, 50% dispersant, 50% wetting agent, and all bactericides at the beginning of stirring, 50% defoamer, stirring and blending for 20-40 minutes to prepare blend emulsion C.

[0052] 2) Put all the water into the empty mixing container, add the remaining dispersant, wetting agent and defoamer at the beginning of stirring at 100-300r / min, stir for about 10 minutes and start to sift in the formula filler at a uniform speed. Disperse at high speed for 40-60 mi...

Embodiment 2

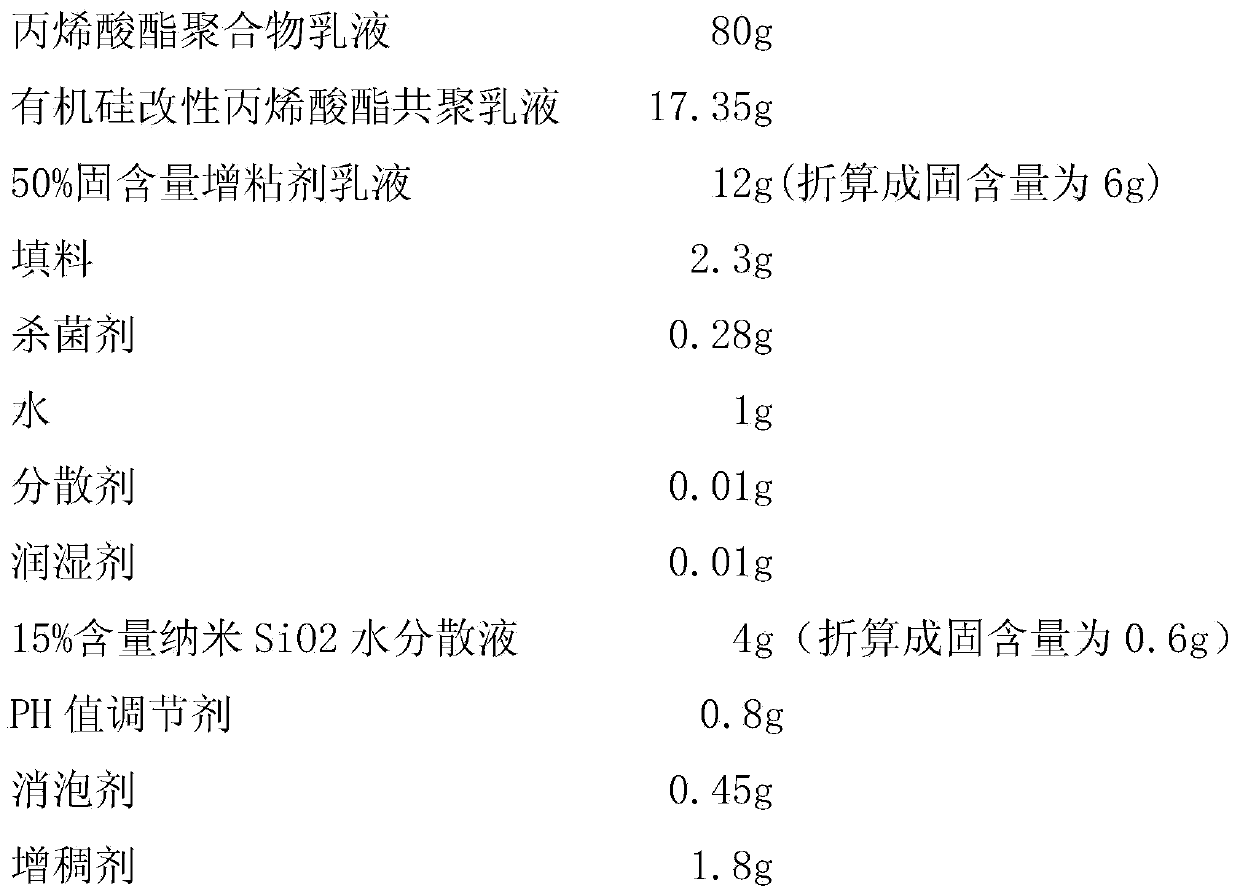

[0057] Ingredients as follows:

[0058]

[0059]

[0060] The preparation process is the same as in Example 1.

[0061] According to the GB / T18258-2000 standard test, the nano-modified water-based weather-resistant sound-insulating adhesive obtained in this example has a damping platform with a damping value greater than 0.9 in the temperature range of -5°C to 115°C.

[0062] According to the standard test of GB / T2791-1995, the arithmetic mean value of the peel strength of the nano-modified water-based weather-resistant sound-insulating adhesive obtained in this example is σT=4.7KN / m.

Embodiment 3

[0064] Ingredients as follows:

[0065]

[0066] The preparation process is the same as in Example 1.

[0067] According to the GB / T18258-2000 standard test, the nano-modified water-based weather-resistant sound-insulating adhesive obtained in this example has a damping platform with a damping value greater than 0.9 in the temperature range of 5°C to 135°C.

[0068] According to the standard test of GB / T2791-1995, the arithmetic mean value of the peel strength of the nano-modified water-based weather-resistant sound-insulating adhesive obtained in this example is σT=3.6KN / m.

[0069] The acrylate polymer emulsion and silicone-modified acrylate copolymer emulsion in the formula components are characterized in that at least one of the emulsions is an acrylate emulsion with a LIPN interpenetrating network type core-shell structure, and at least one of them is an acrylic emulsion that has undergone Silicone modified acrylic polymer emulsion. Among them, preferably, the acryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com