Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Complete coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

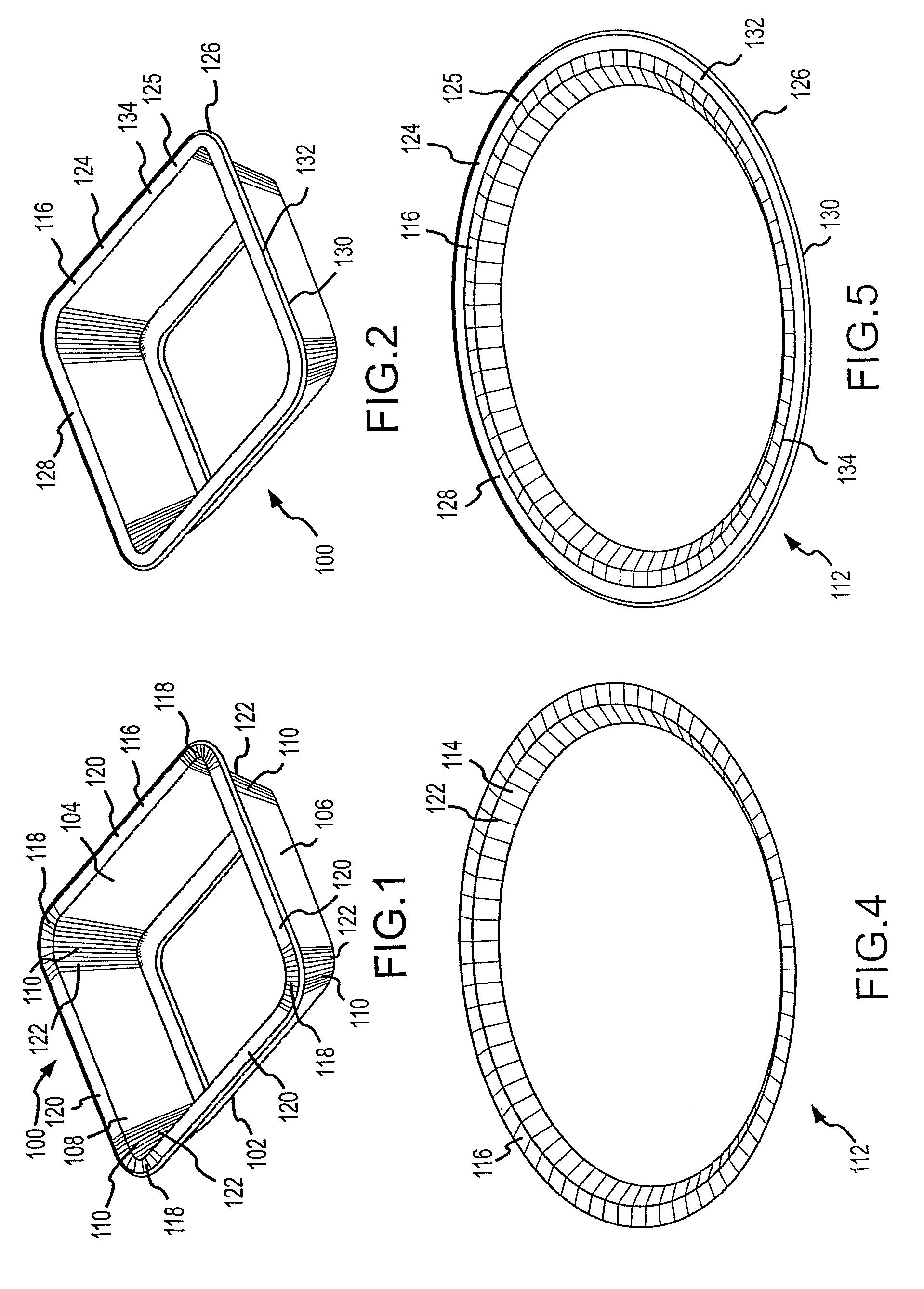

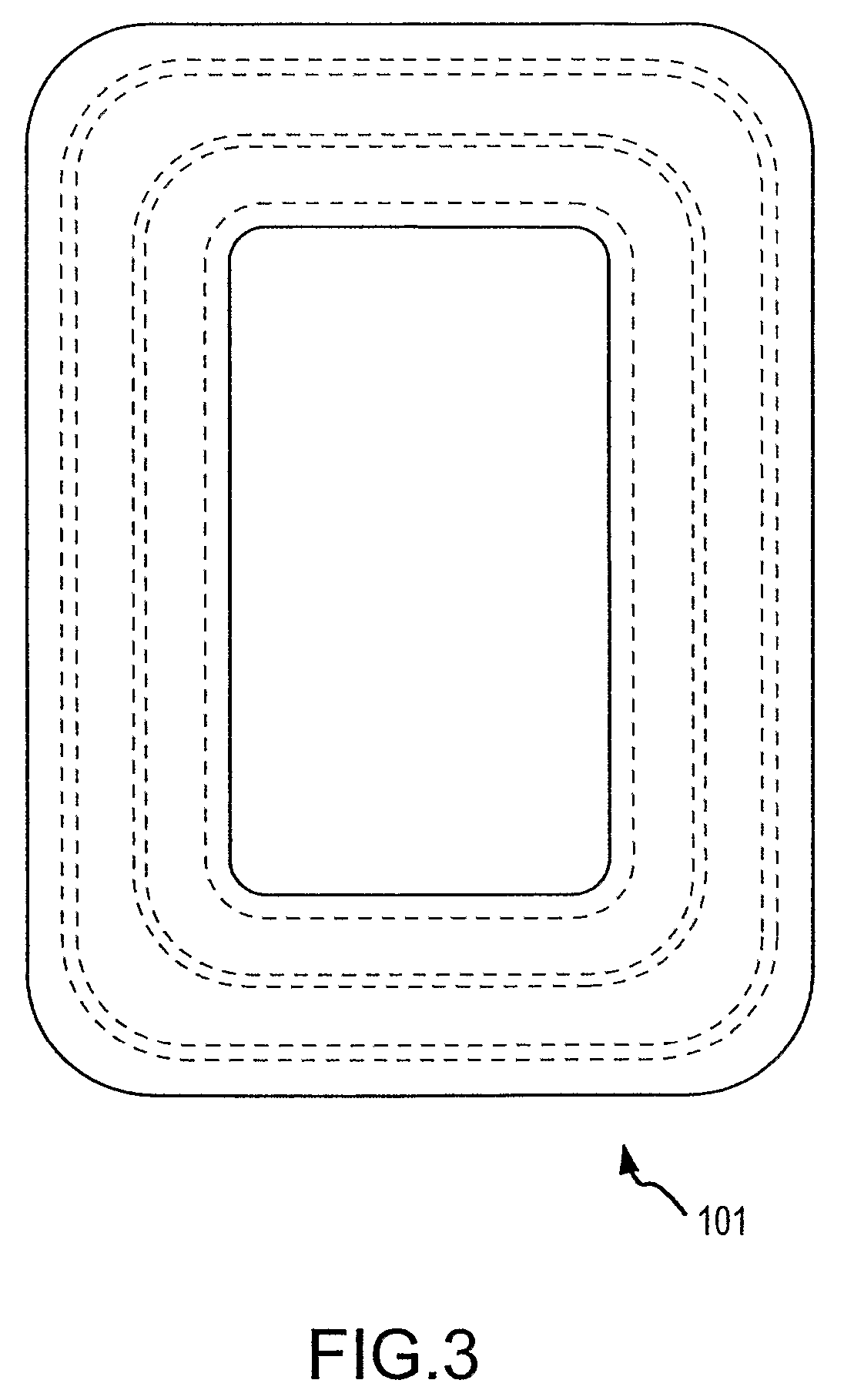

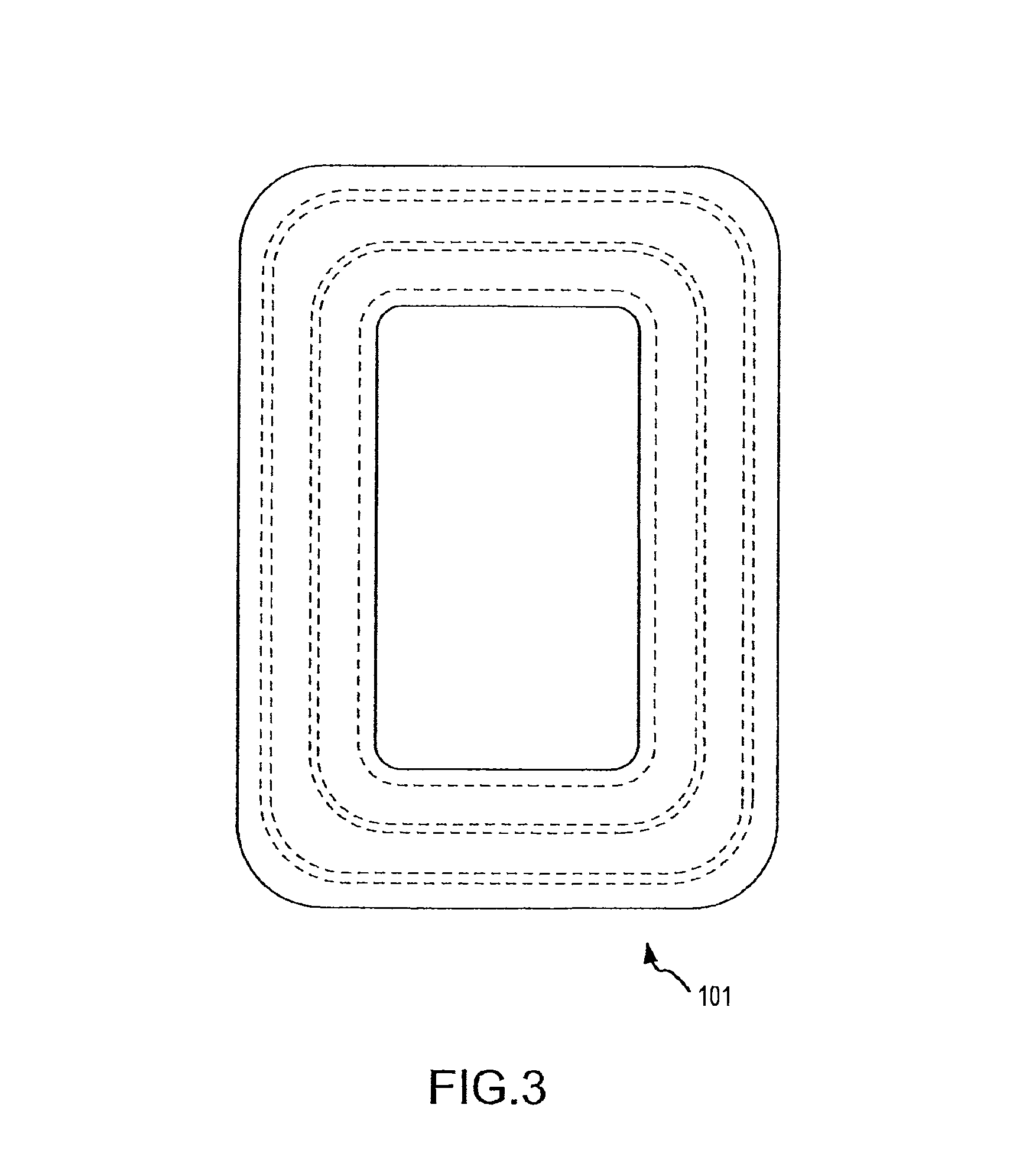

Container having a rim or other feature encapsulated by or formed from injection-molded material

ActiveUS7862318B2Strengthen and stabilize traySimplify carryingClosure lidsTurning machine accessoriesEngineeringFlange

Owner:GRAPHIC PACKAGING INT

Container having a rim or other feature encapsulated by or formed from injection-molded material

InactiveUS20110012291A1Strengthen and stabilize traySimplify carryingConfectionerySweetmeatsEngineeringMechanical engineering

Owner:GRAPHIC PACKAGING INT

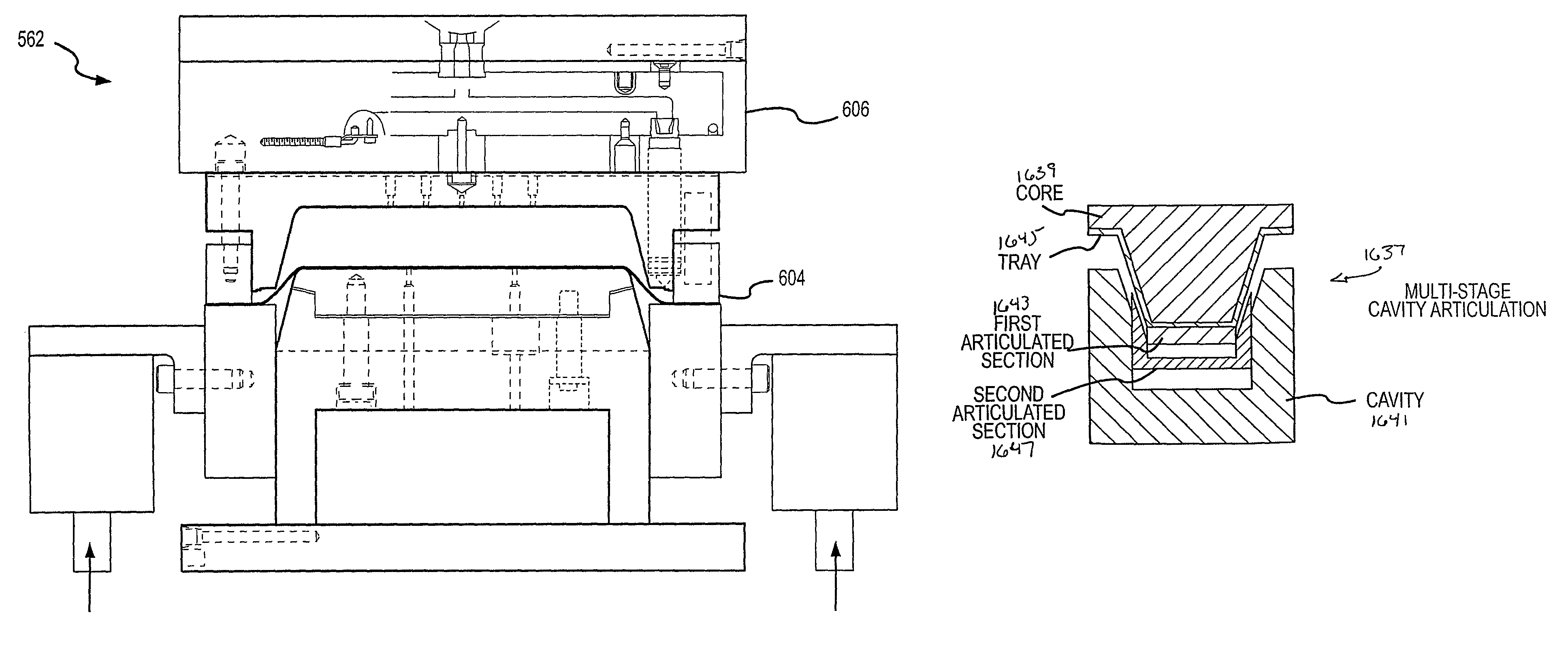

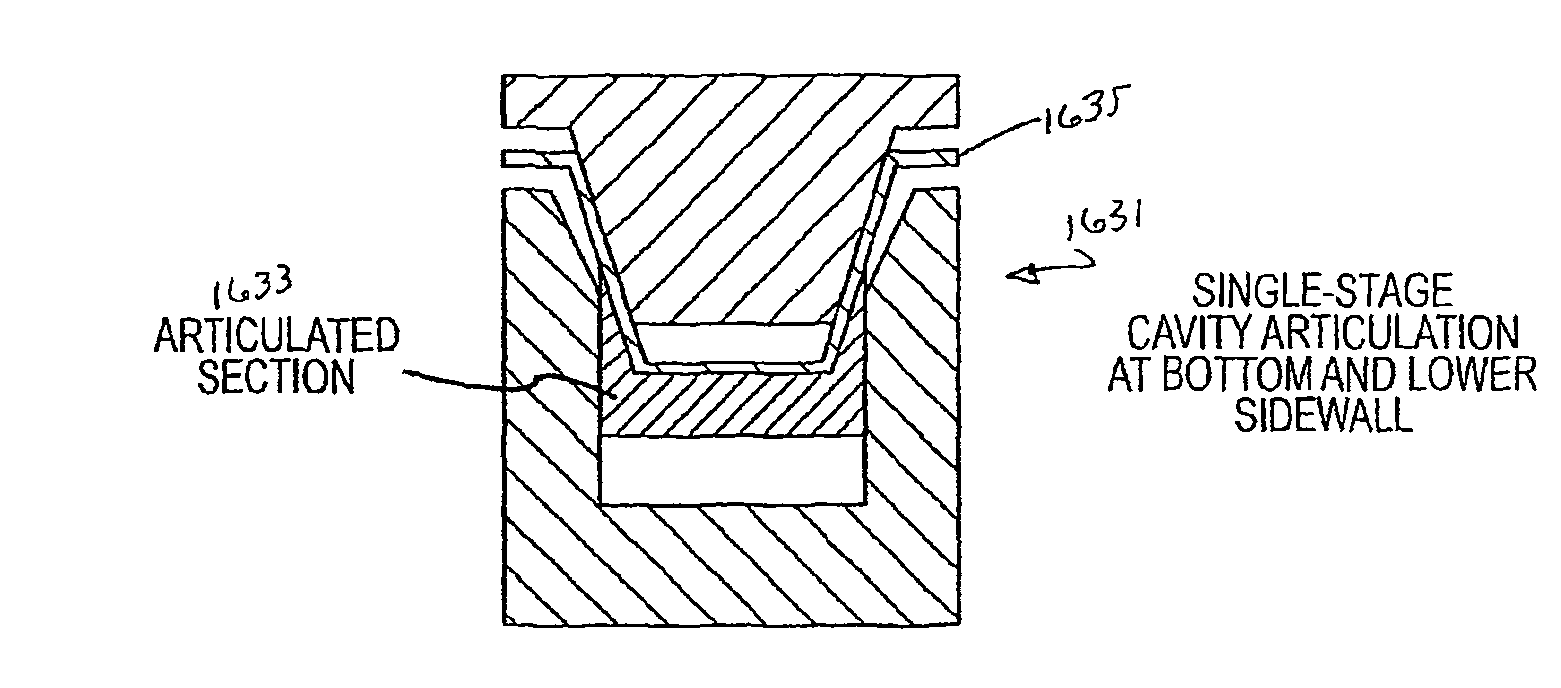

Method of forming container with a tool having an articulated section

InactiveUS8858858B2Strengthen and stabilize traySimplify carryingClosure lidsTurning machine accessoriesMechanical engineeringEngineering

Owner:GRAPHIC PACKAGING INT

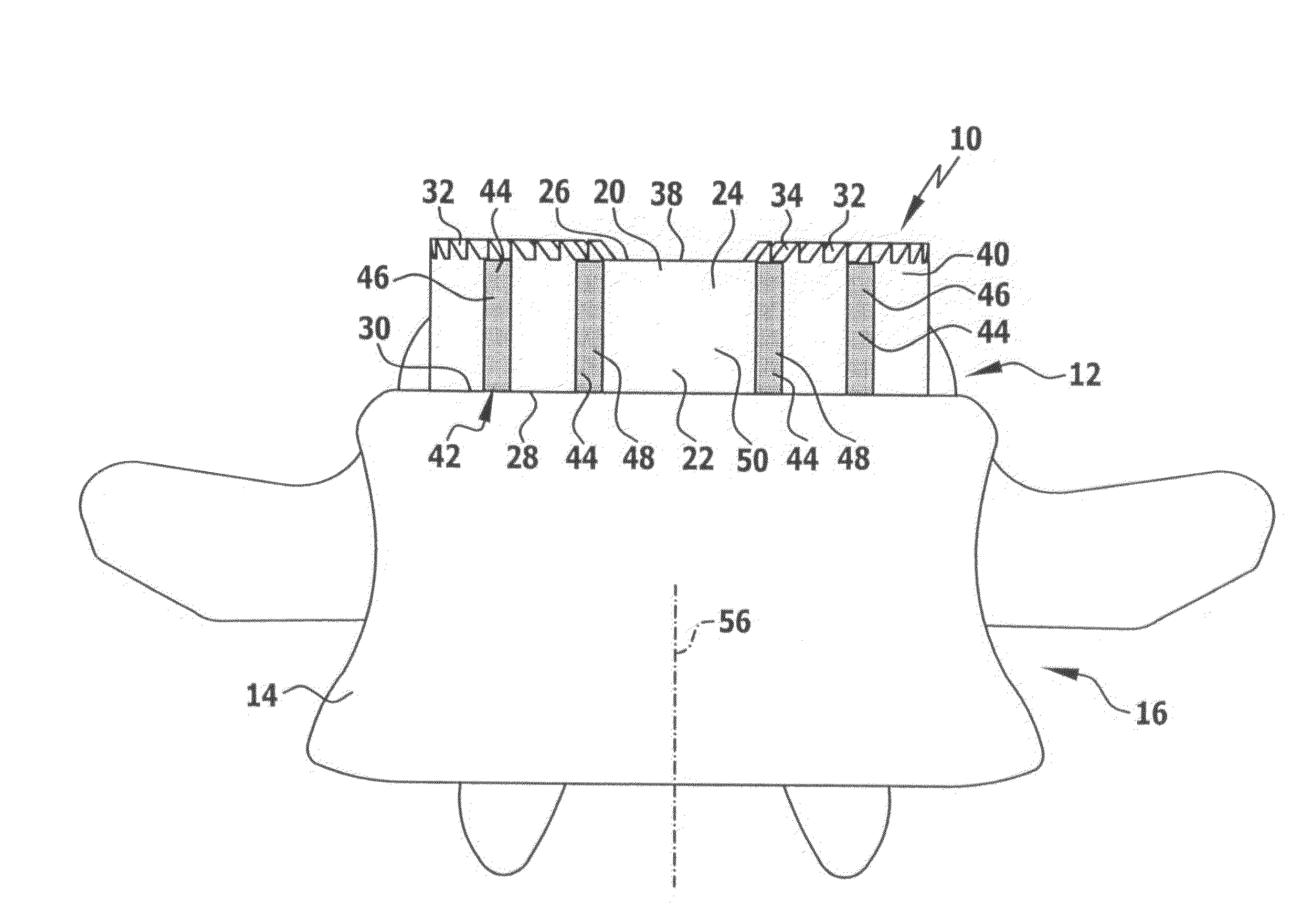

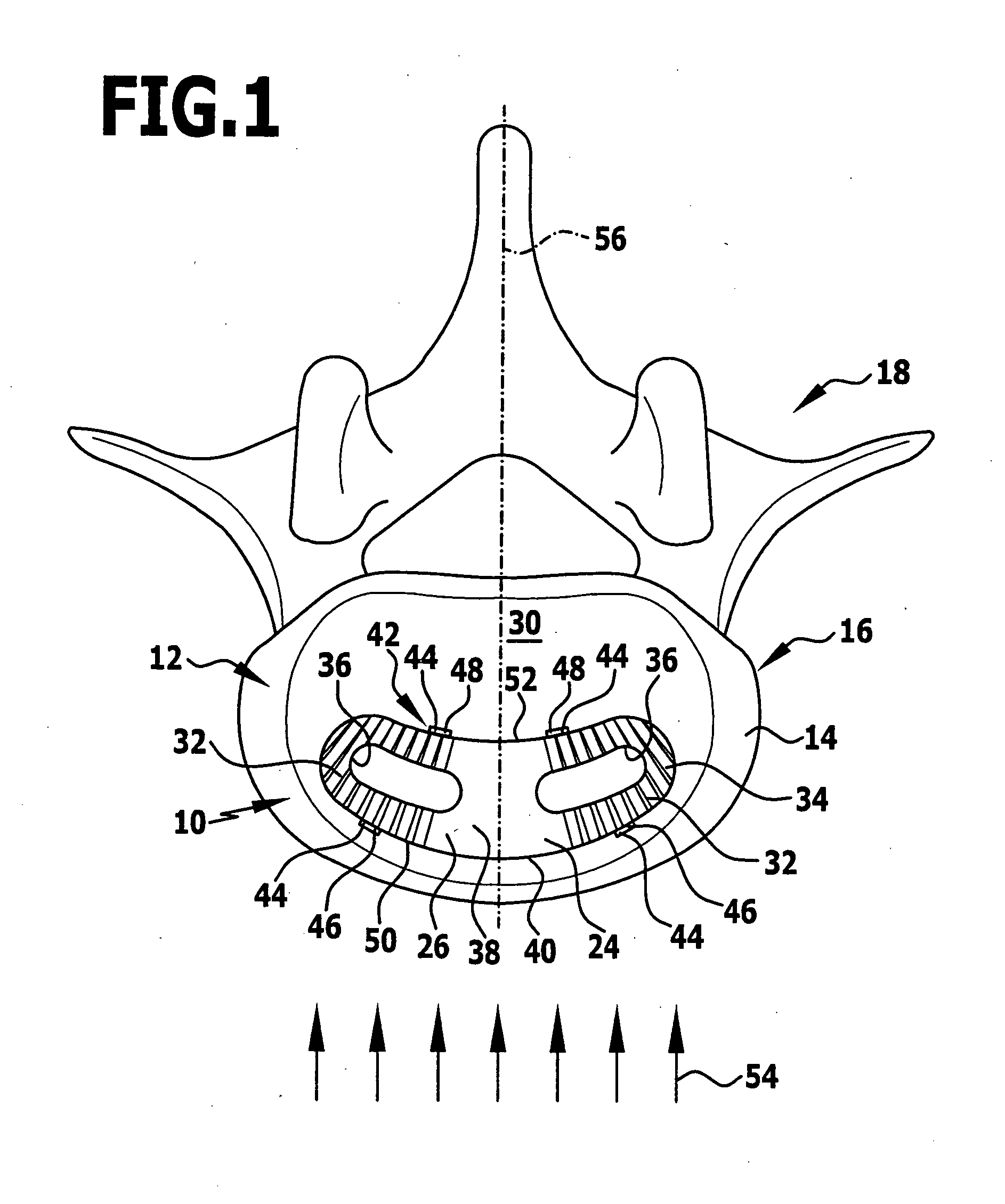

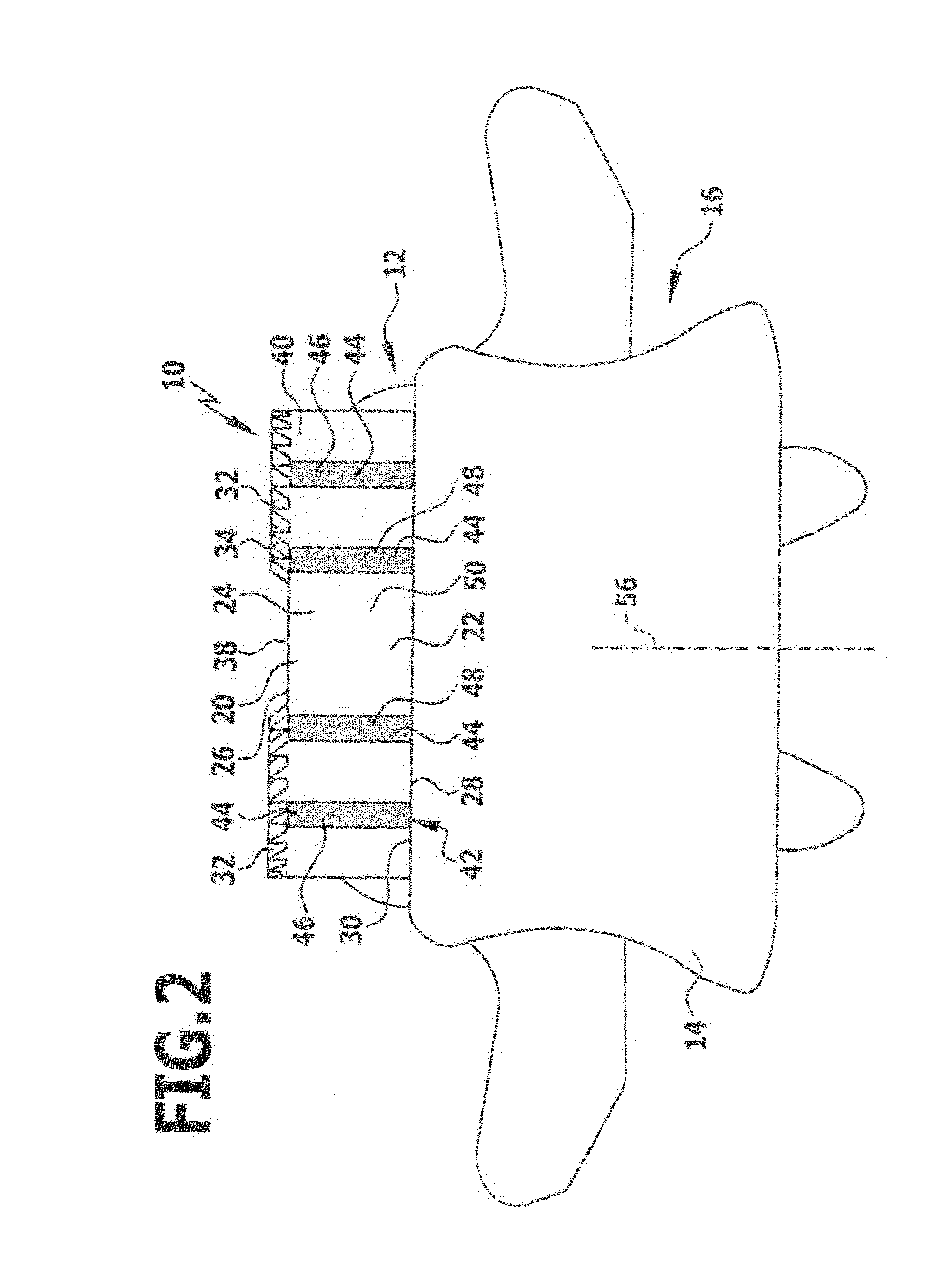

Implant

InactiveUS20080234828A1Avoid rejectionMaintain good propertiesSpinal implantsCoatingsSpinal columnMedicine

In order to improve an implant for replacing a vertebral body or for insertion into an intervertebral cavity between adjacent vertebral bodies of a human or animal spinal column, with a first contact face for resting on a joint face of a first vertebral body and with a second contact face for resting on a joint face of a second vertebral body, the implant being at least partially produced from an X-ray transparent material and comprising at least one X-ray marker in such a way that it can be produced more simply, it is proposed that the at least one X-ray marker is configured in the form of an at least partial marker coating, which contains metal as the marker material, of a side face of the implant, which is inclined relative to the first and / or the second contact face by an angle of inclination.

Owner:AESCULAP AG

Ice making machine evaporator with joined partition intersections

InactiveUS9389009B2Complete coatingLighting and heating apparatusIce productionEngineeringCapillary action

Owner:PENTAIR FLOW SERVICES

Method for preparing water-based ceramic functional coating by taking high-entropy oxide as functional pigment

ActiveCN113372088AComplete coatingNo peelingPigment physical treatmentOxide ceramicEnhanced heat transfer

The invention discloses a method for preparing a water-based ceramic functional coating by taking a high-entropy oxide as a functional pigment, the water-based ceramic functional coating is prepared by taking a high-entropy oxide (A) 3O4 as the functional pigment and mixing with a filler, a binder, a solvent, a dispersing agent, a wetting agent, a defoaming agent and a flatting agent. A in the functional pigment high-entropy oxide (A) 3O4 is at least four kinds of metal elements including Cu, Cr, Co, Mn, Fe, Ni, Al, Zn, Ti and Mg, and in the high-entropy oxide ceramic, all the metal elements are equal in molar ratio. The functional coating prepared from the coating has a good solar spectrum selection characteristic within the wave band of 0.3-25 microns, has a good infrared radiation characteristic within the wave band of 3-12 microns, and has excellent thermal shock resistance and high temperature resistance (greater than or equal to 800 DEG C). Based on the regulation and utilization characteristics of electromagnetic waves, the method has important application value in the fields of solar photo-thermal utilization, infrared enhanced heat transfer, heat dissipation, energy conservation and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

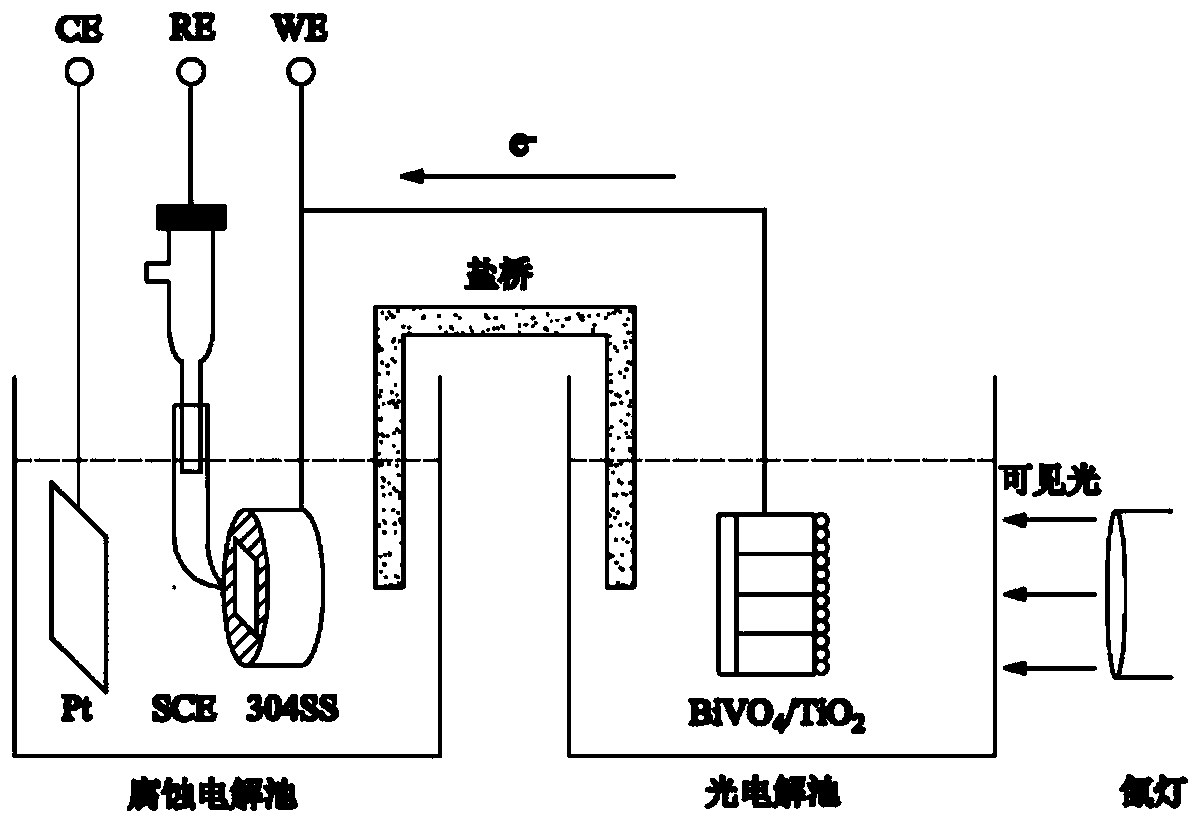

Photo anode material and preparation and application thereof

ActiveCN107557789AExpand the scope of absorptionIncrease profitMaterial nanotechnologySurface reaction electrolytic coatingCorrosion resistantAnodic oxidation

The invention relates to a nanotube array photo anode, in particular to a BiVO4 / TiO2 nanotube array photo anode material which is stably used for photo-induced cathodic protection and preparation andapplication thereof. A preparation method of the material comprises the steps that firstly, an anodic oxidation method is adopted, Pt serves as a counter electrode, a titanium sheet substrate serves as a working electrode, and an NH4F and ethylene glycol solution serves as electrolyte; then, a titanium sheet is calcinated, so that a TiO2 nanotube array thin film is prepared on the surface of the titanium sheet; then, a hydrothermal method is adopted, and reaction solutions with Bi(NO)3 and NH4VO3 as a bismuth source and a vanadium source correspondingly are compounded; the TiO2 nanotube arraythin film is completely immersed into the reaction solutions; and after the TiO2 nanotube array thin film is put into a drying box to be subjected to constant-temperature hydrothermal treatment, calcination treatment is conducted, so that a BiVO4 / TiO2 composite film is obtained. The BiVO4 / TiO2 composite film serves as the photo anode for photo-induced cathodic protection, the utilization rate of visible light can be increased; the corrosion potential of 304 stainless steel is obviously lowered; and the good cathodic protection corrosion-resistant effect can still be achieved in the dark state.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Connector with two piece shells

InactiveUS7837507B1Good shielding functionComplete coatingCoupling protective earth/shielding arrangementsAerospace engineering

Owner:CHENG UEI PRECISION IND CO LTD

Container having a rim or other feature encapsulated by or formed from injection-molded material

InactiveUS20110278762A1Strengthen and stabilize traySimplify carryingClosure lidsTurning machine accessoriesEngineeringMechanical engineering

A tool and method for forming a container from a construct. The tool comprising a cavity for receiving a construct, a core operatively associated with the cavity and being operable to move into the cavity, an injection cavity for receiving injection-molding material and directing injection-molding material around at least a portion of the perimeter of the construct, and a clamping feature. The clamping feature is operatively connected to at least one of the cavity and the core and is for clamping a peripheral portion of the construct as the core moves into the cavity to form the construct into the container.

Owner:TECHNOLOGICAL RES UK +1

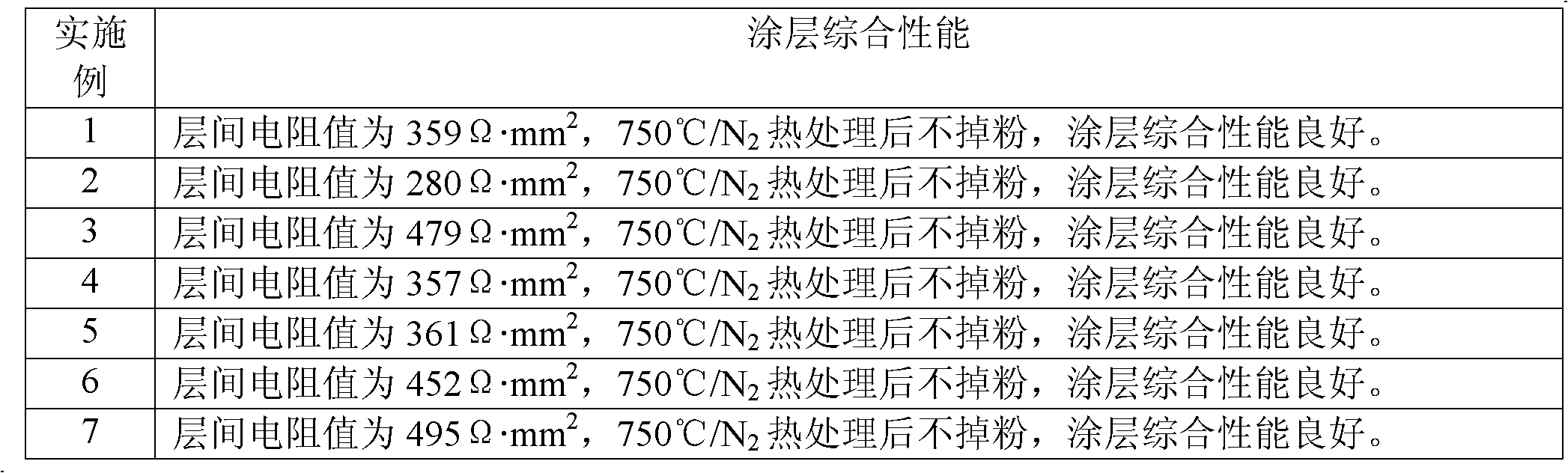

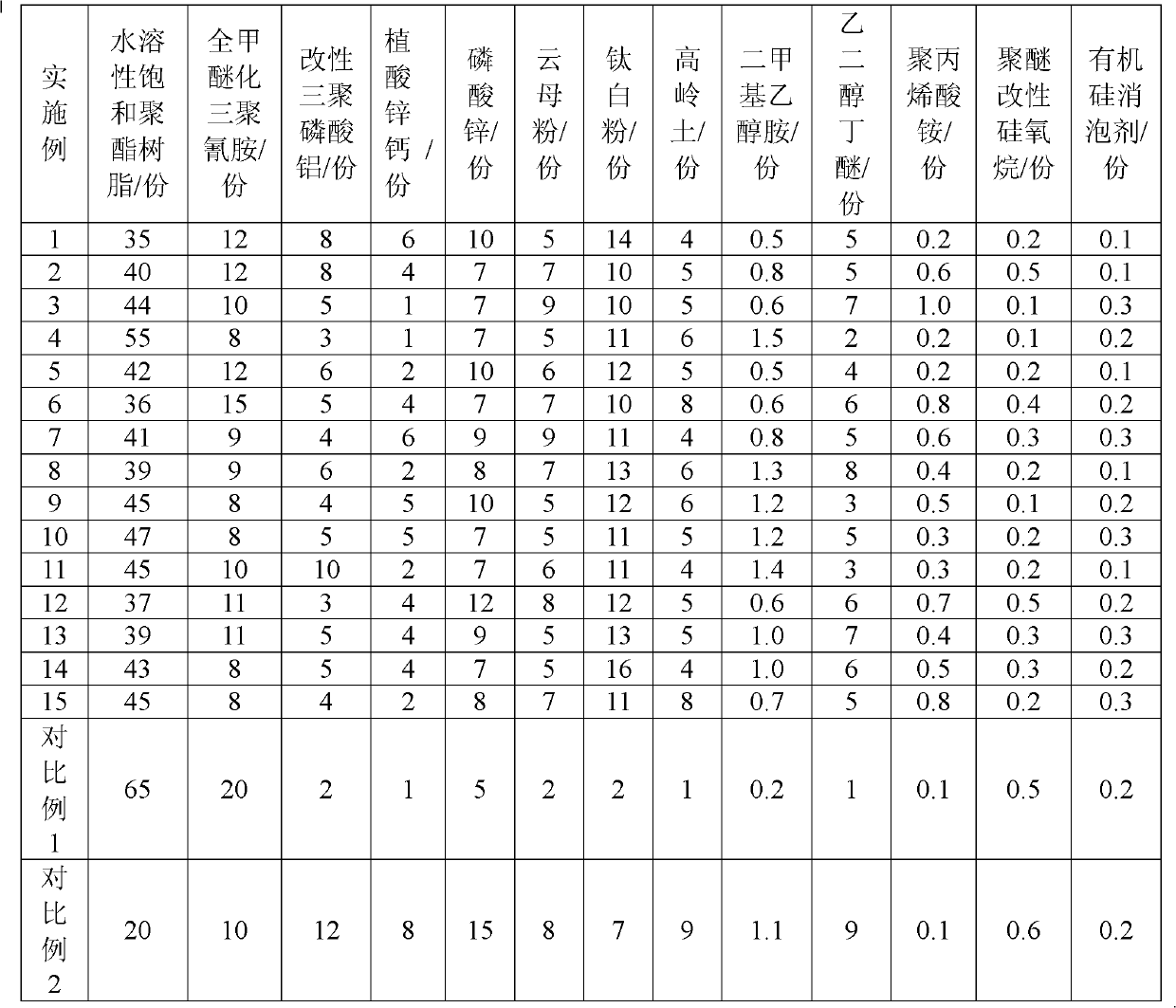

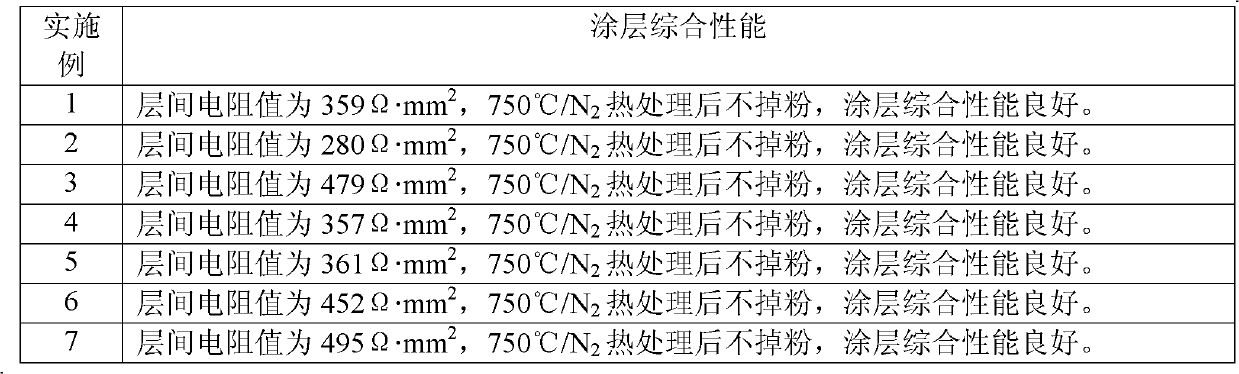

Chromium-free semi-organic insulating paint for electrical steel and coating method thereof

ActiveCN102220073ABeautiful appearanceComplete coatingLiquid surface applicatorsPolyester coatingsWater solubleMelamine resin

The present invention discloses a chromium-free semi-organic insulating paint, which includes the following components: 35-55 parts of water-soluble saturated polyester resin, 8-15 parts of full-methylated melamine resin, 3-10 parts of modified aluminium tripolyphosphate, 1-6 parts of zinc calcium phytate, 7-12 parts of zinc phosphate, 5-9 parts of mica powder, 10-16 parts of titanium dioxide, 4-8 parts of kaolin, 0.5-1.5 parts of dimethylethanolamine, 2-8 parts of ethylene glycol butyl ether, 0.2-1.0 part of ammonium polyacrylate, 0.1-0.5 part of polyether-modified siloxane and 0.1-0.3 part of an organic silicon defoamer. The coating made of the paint disclosed by the invention has the advantages of good insulativity, adhesiveness, heat resistance, stamping capability and weldability, no defects of streak, bubble, color difference and other defects, and long storage life.

Owner:MAANSHAN IRON & STEEL CO LTD

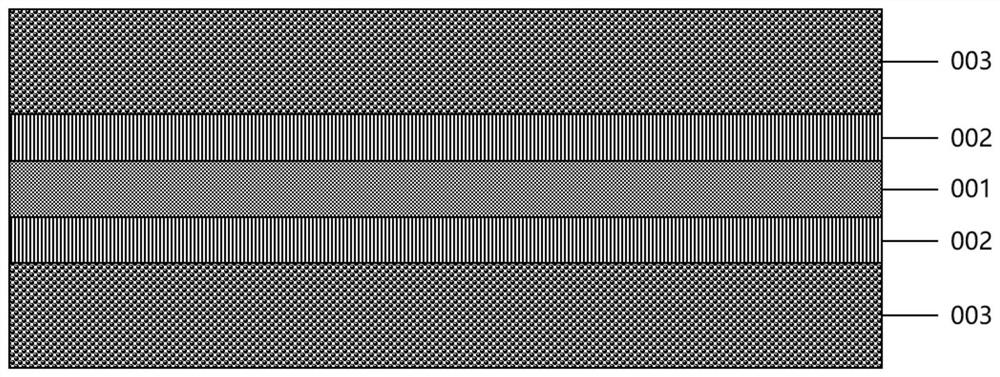

Lithium ion battery positive pole piece with safety coating and preparation method of lithium ion battery positive pole piece

PendingCN114464779APerformance impactAvoid mixingSecondary cellsPositive electrodesPhysical chemistryPole piece

The invention relates to a lithium ion battery positive pole piece with a safe coating and a preparation method thereof, and the method comprises the following steps: preparation of safe coating slurry: adding a matrix material aerogel material, a high-stability positive pole material, a conductive agent and a binder into a dispersant, and dispersing to obtain the safe coating slurry; preparing positive electrode active material slurry: mixing and stirring raw materials of the positive electrode active material to obtain the positive electrode active material slurry; multi-layer extrusion coating: coating a positive electrode current collector (001) with the safe coating slurry and the positive electrode active material slurry; and cold pressing: carrying out cold pressing on the coated positive current collector (001) to obtain the lithium ion battery positive pole piece with the safety coating. Compared with the prior art, the method has the advantages that the influence on the electrical performance of the battery cell is avoided, the production period is shortened, the production cost is reduced and the like.

Owner:BATTERO TECH CORP LTD

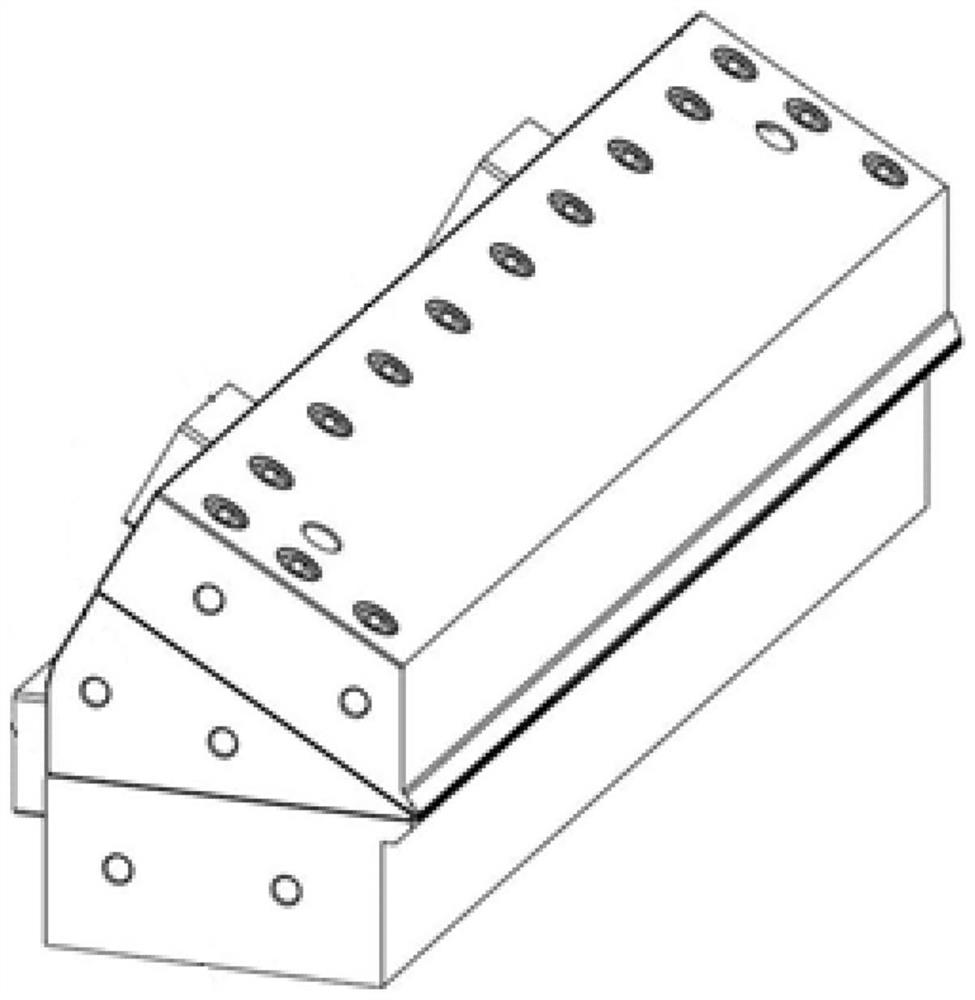

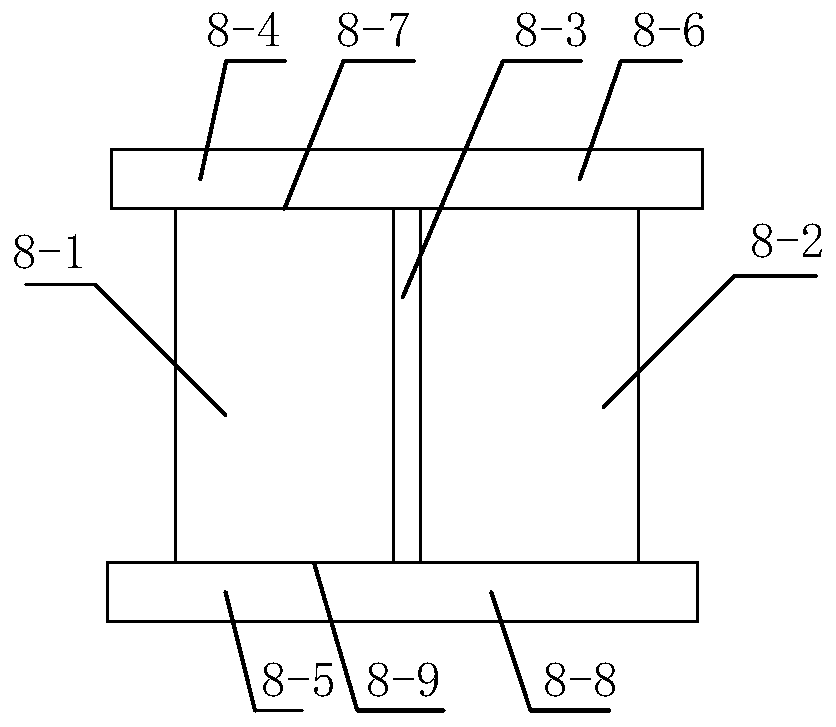

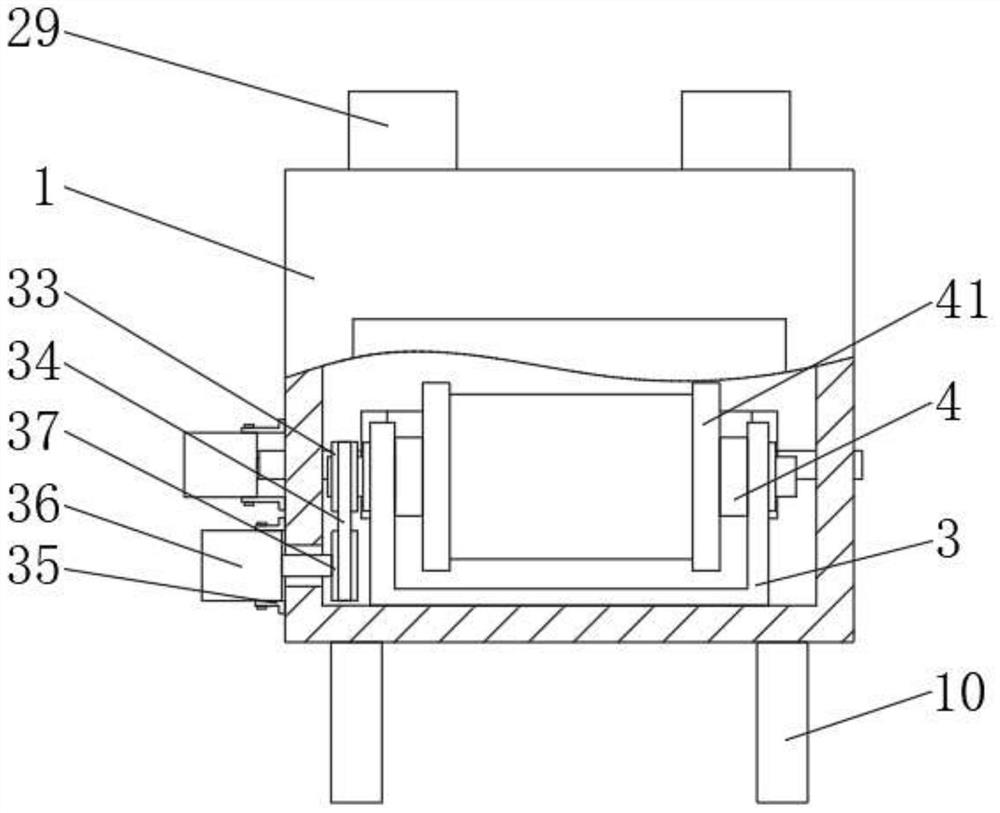

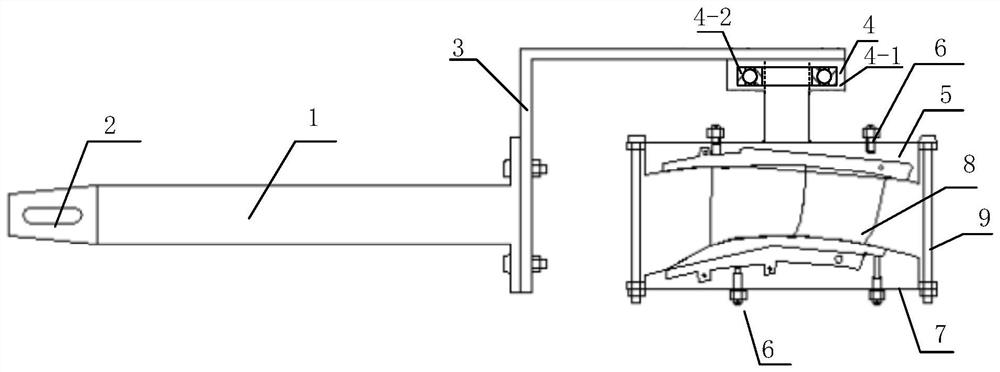

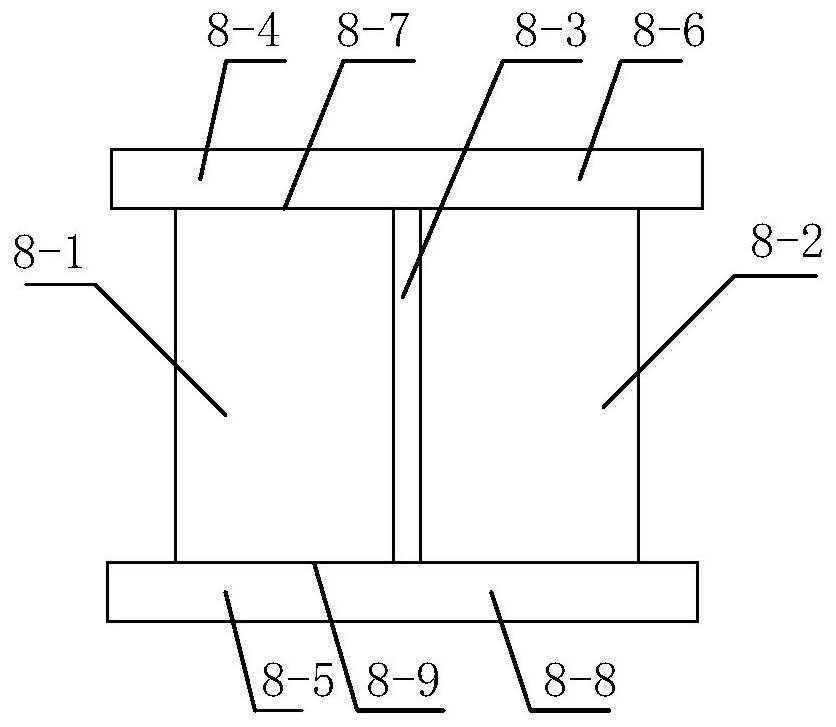

Support device for guiding vane full flowpath face vapour deposition and application method thereof

ActiveCN110158047AImprove temperature stabilityImprove job stabilityVacuum evaporation coatingSputtering coatingGas phaseHeat resistance

The invention discloses a support device for guiding vane full flowpath face vapour deposition and an application method thereof. A clamping device is connected with a rotating shaft through a connecting plate and an L-shaped connecting plate. A guiding vane is mounted inside the clamping device in a clamping manner. The L-shaped is in an L shape, thus, the axis direction of the guiding vane is perpendicular to the axis direction of the rotating shaft; in the coating process, the guiding vane can substantially rotate around the axis direction of the rotating shaft; on the premise that the vanebody surface ceramic coating bonding strength and the columnar crystal structure are guaranteed, the listrium surface bonding strength is greatly improved; an uniform columnar crystal structure is formed; thus, the guiding vane full flowpath face is coated with thermal barrier coating; the heat-resistance temperature of the guiding vane and working stability are greatly improved. The support device is simple in structure; the number of the components is small; product is easy to machine and dismount and mount; and matching design can be conducted on a tool according to the guiding vane structure.

Owner:AECC AVIATION POWER CO LTD

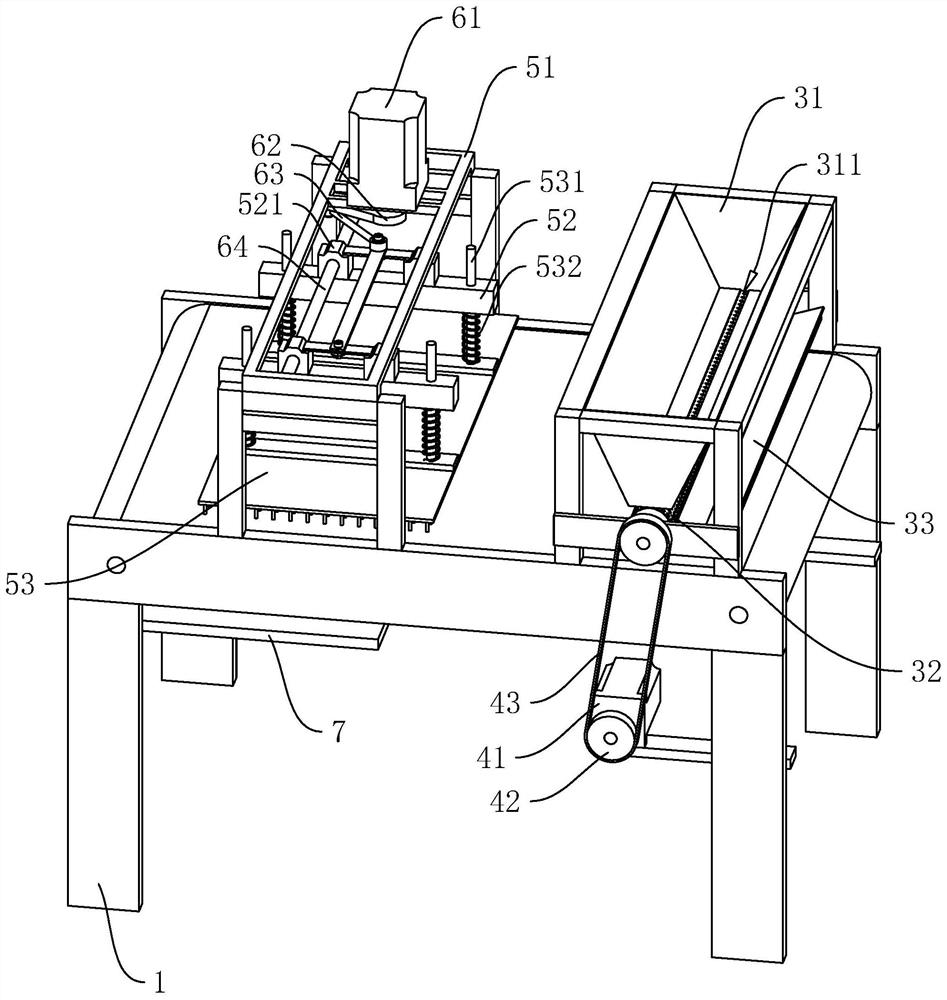

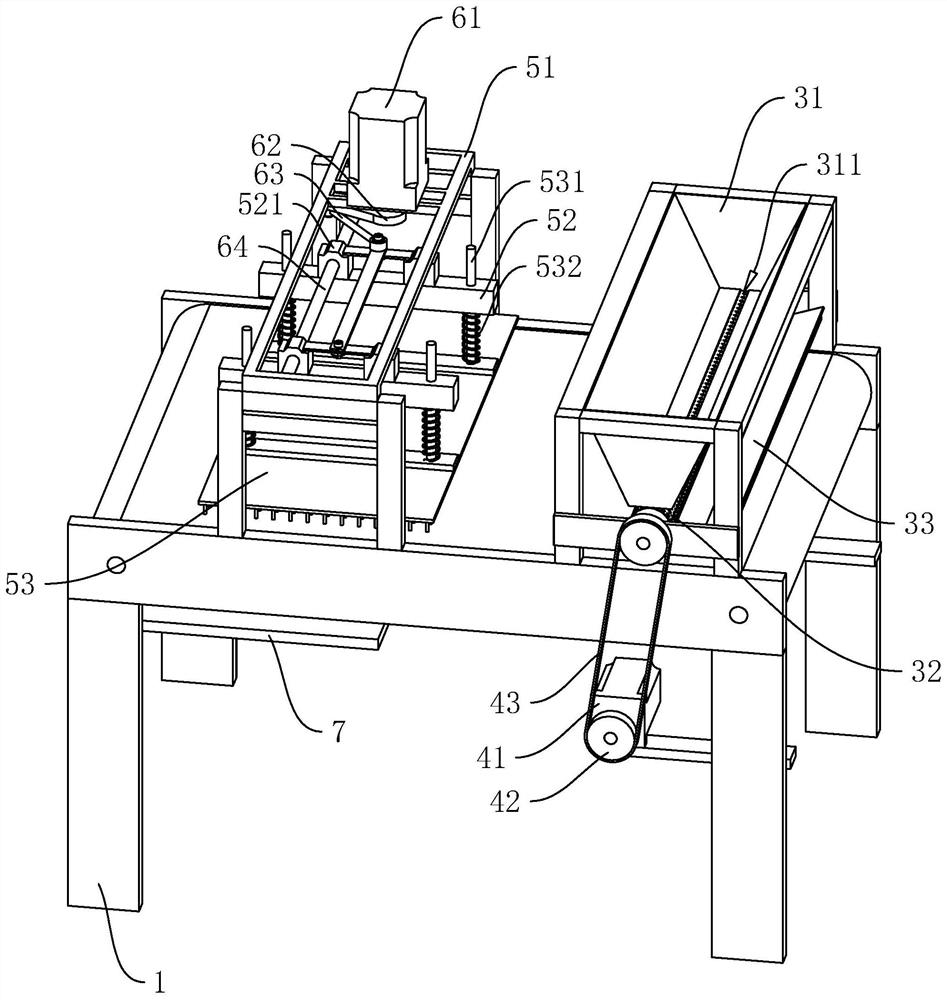

Automatic powder scattering machine for heat-conducting silica gel cloth

ActiveCN112808546AComplete coatingFully contactedLiquid surface applicatorsCoatingsManufacturing engineeringMechanical engineering

The invention relates to an automatic powder scattering machine for a heat-conducting silica gel cloth. The machine comprises a rack, a transmission mechanism arranged on the rack and used for conveying the heat-conducting silica gel cloth and a powder scattering mechanism arranged on the rack and positioned above the transmission mechanism. The powder scattering mechanism comprises a powder box arranged on the rack, a coating roller arranged below the powder box and a driving assembly used for driving the coating roller to rotate, a powder outlet is formed in the bottom of the powder box, the two ends of the coating roller are rotatably connected to the rack, and the top of the coating roller is in clearance fit with the powder outlet. According to the machine, mica powder coating can be automatically conducted on the heat-conducting silica gel cloth, manpower and time are saved, and the production efficiency is greatly improved.

Owner:SHENZHEN LAIMEISI SILICON IND CO LTD

Preparation method of special paint for dust-free writing board

ActiveCN106318202ANot easy to scratchIntegrity guaranteedEpoxy resin coatingsPolyester coatingsWeather resistanceButanone

The invention discloses a preparation method of a special paint for a dust-free writing board. The special paint comprises an upper layer paint and a lower layer paint. The method comprises the following steps: 1, preparation of the lower layer colored paint: preparing No.1 resin, preparing No.2 resin, preparing a color paste, blending the paint, etc.; and 2, preparation of the upper layer transparent matt paint: preparing No.3 resin, preparing No.4 resin, blending the paint, etc.. After being used for a writing board, the paint disclosed by the invention has the following advantages: the hardness is high (not lower than 6H), the painted surface is difficult to scratch in the writing process, and the completeness of the writing surface is kept; and in contrast, the board on the market generally only has a hardness of 1-3H, and the board surface is very easy to scratch in the long-term writing process and is unbeneficial to writing. Besides, the paint has high chemical corrosion resistance (the detected hardness can still be up to 3H after soaking in butanone solvent for 72 hours even when the butanone is not volatilized completely, while the hardness of the writing board on the market is only 2B after soaking in butanone for 2 hours), excellent weather resistance and favorable wear resistance.

Owner:CHONGQING SHUOAO TEACHING EQUIP

Rumen Protected Glucose and Method of Preparation

ActiveUS20180169026A1Reduce weight lossIncrease milk productionAccessory food factorsWorking-up animal fodderRumenMilk yield

The present disclosure provides a preparation method of rumen protected glucose, comprising the following steps: (1) preparing glucose into a pellet and drying; (2) fluidizing the pellet in a fluidized bed after drying; and (3) coating melted aliphatic alcohol and / or saturated fatty acid onto the surface of the pellet located in the fluidized bed to obtain a rumen protected bypass glucose particle. The prepared rumen-protected glucose could go through the rumen of ruminant effectively; and the availability of coating layer in ruminant increases, making the coated glucose be released completely and fully utilized by ruminant, so ketosis or subclinical ketosis and fatty liver disease of the ruminants in perinatal stage could be prevented and reduced effectively, the postpartum weight loss could be reduced, and the cycle conception rate and the milk yield could be increased.

Owner:BEIJING YAHE NUTRITIVE HIGH TECH CO LTD

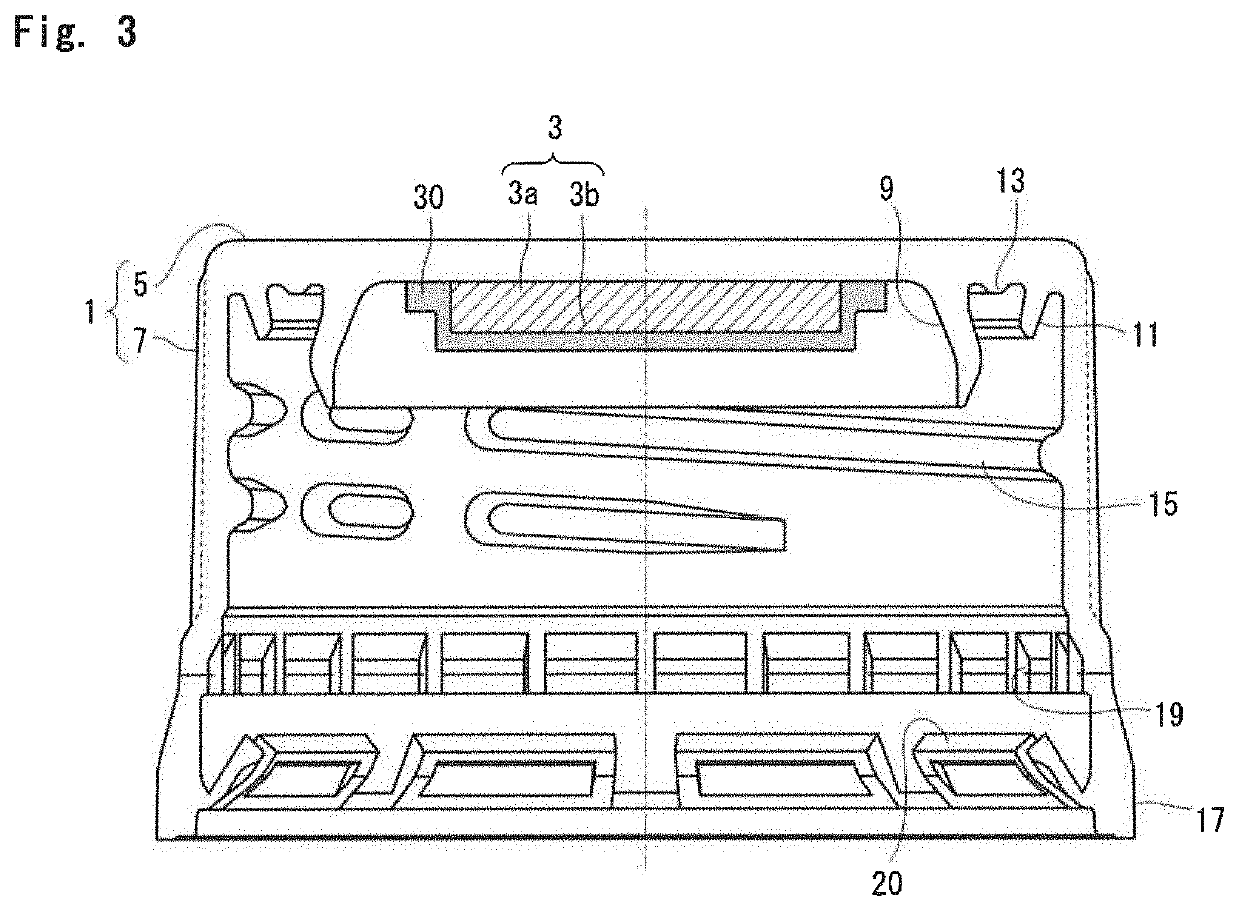

Container lid having oxygen shielding properties

PendingUS20210086954A1Reduce functionSuppress exhaustionClosures with oxygen absorbersCapsLow-density polyethyleneLinear low-density polyethylene

An oxygen-shielding container lid according to the present invention comprises a high density polyethylene cap shell 1 having a skirt section 7 and a top plate section 5 provided with an inner ring 9 for intimate contact with an inner surface of a container mouth; and an in-shell molded body 3 provided in a portion of an inner surface of the top plate section which is surrounded with the inner ring 9. The in-shell molded body 3 is composed of a primary molded body 3a which has been formed by in-shell molding on the inner surface of the top plate section and which has an oxygen shielding function; and a secondary molded body 3b which has been formed on the primary molded body 3a by in-shell molding so as to cover the primary molded body 3a and to be fused and fixed to the inner surface of the top plate section at the peripheral edge of the primary molded body. A resin composition used for formation of the secondary molded body 3b contains linear low density polyethylene, and has a melt flow rate at 190° C. of 1 to 10 g / 10 minutes, a density of 0.900 to 0.920 g / cm3, and a nominal tensile strain at break, as defined by JIS K-6922-2, of 400% or more.

Owner:SUNTORY HLDG LTD +1

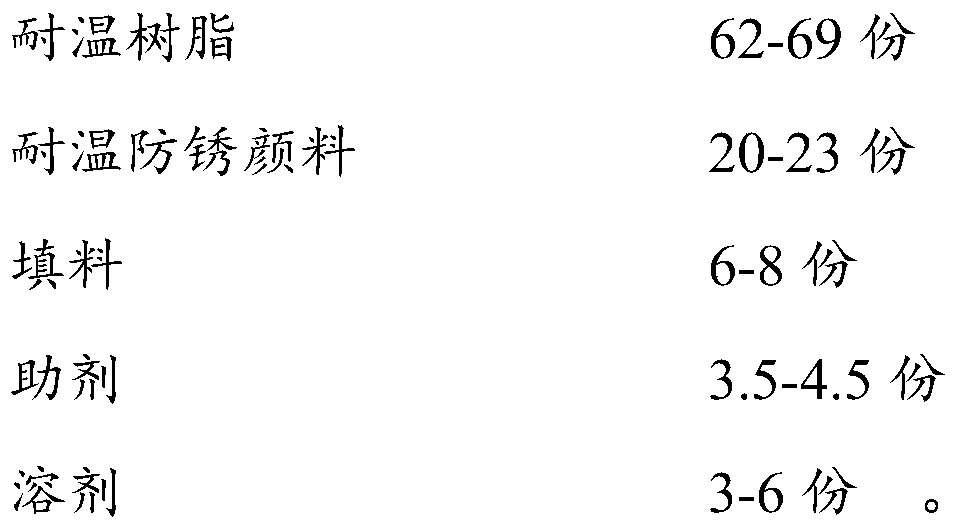

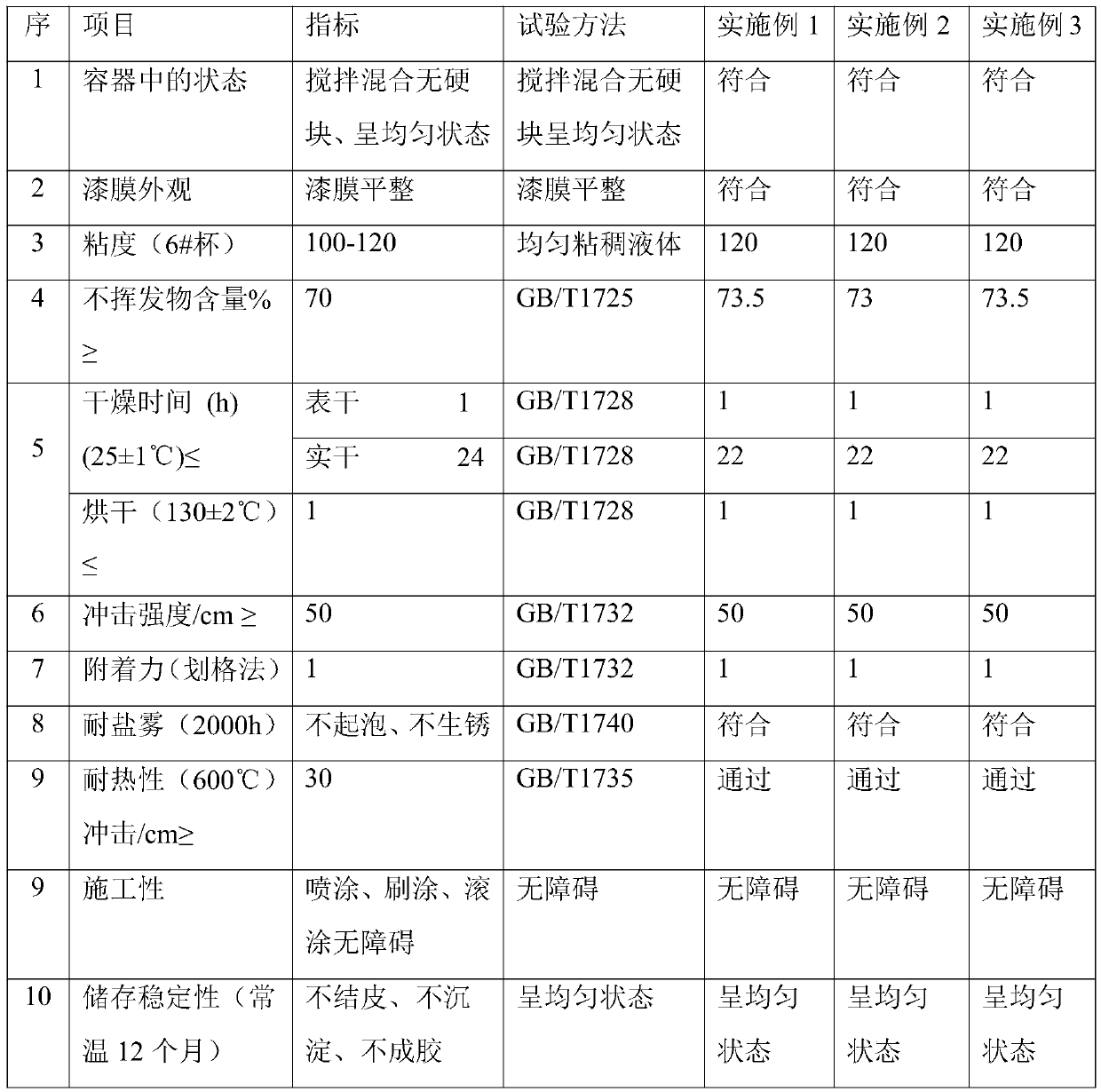

High-temperature-resistant anticorrosive primer for surface of metal structure and preparation method thereof

PendingCN111154397AExtended service lifeLong-term anti-rust and anti-corrosion effectFireproof paintsAnti-corrosive paintsSolid contentHigh heat

The invention discloses a high-temperature-resistant anticorrosive primer for a metal structure surface. The high-temperature-resistant anticorrosive primer is prepared from the following components in parts by weight: 62 to 69 parts of temperature-resistant resin, 20 to 23 parts of a temperature-resistant antirust pigment, 6 to 8 parts of a filler, 3.5 to 4.5 parts of an auxiliary agent and 3 to6 parts of a solvent. The invention also discloses a preparation method for preparing the high-temperature-resistant anticorrosive primer from the components mentioned above. The high-temperature-resistant anticorrosive primer is matched with an organic silicon high-temperature finish paint for coating construction; the formed coating has good physical and chemical properties and corrosion resistance, the service life of a coated object is prolonged within a certain high temperature range, the preparation method is simple and convenient, the primer has a high solid content and low VOC emission, and thus is environmentally friendly, the energy is saved, and the cost is low.

Owner:浙江钱浪涂料科技有限公司

Diaphragm gluing machine for laminated battery pack and super-capacitor pack

InactiveCN104785406ACoated evenlyComplete coatingLiquid surface applicatorsCoatingsSupercapacitorDrive motor

The invention provides a diaphragm gluing machine for a laminated battery pack and a super-capacitor pack. The diaphragm gluing machine comprises a drive motor, wherein the drive motor drives a sizing roller, the sizing roller drives a rubber covered roller through a belt pulley, a gluing groove is formed in the lower part of the sizing roller, a paper placing platform is arranged on one sides of the sizing roller and the rubber covered roller, a material receiving panel is arranged on the other sides of the sizing roller and the rubber covered roller, the tangent line of the sizing roller and the rubber covered roller corresponds to a plane of the paper placing platform; a paper feed roller is arranged between the plane of the paper placing platform and the sizing roller, and another feed roller is arranged between the plane of the paper placing platform and the rubber covered roller. According to the invention, a hot melt glue is printed on a diaphragm of a laminated super-capacitor by using the sizing roller and the rubber covered roller, the tangent line of the sizing roller and the rubber covered roller corresponds to the plane of the paper placing platform to keep the diaphragm flat and intact, the advantages of uniform and smooth coating, high speed and the like are achieved, the mass production of the super-capacitor is implemented, the printed diaphragm is smooth and has no pores, cracks or patterns, the paper does not crease in printing, and the problem of insulation of the diaphragm is better and more economically solved.

Owner:HUBEI SHENGRONG TECH CO LTD

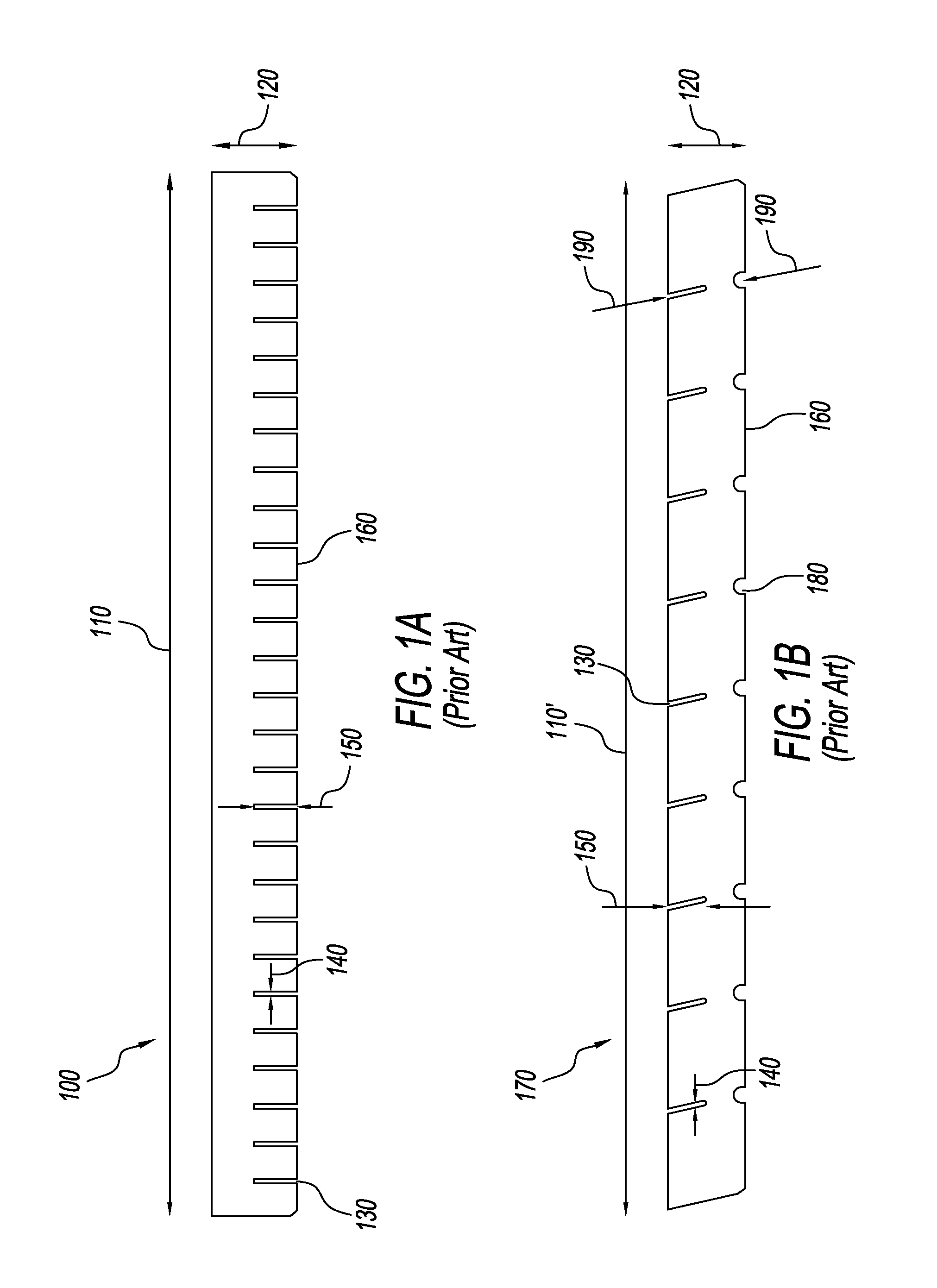

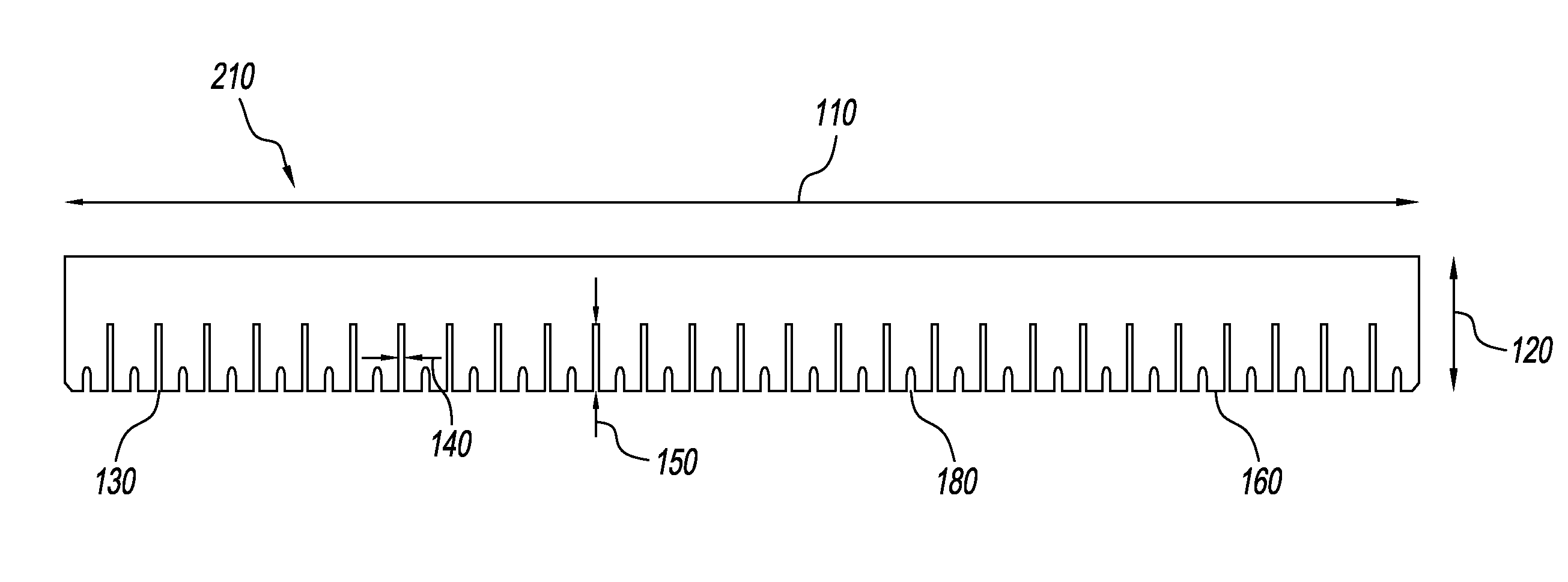

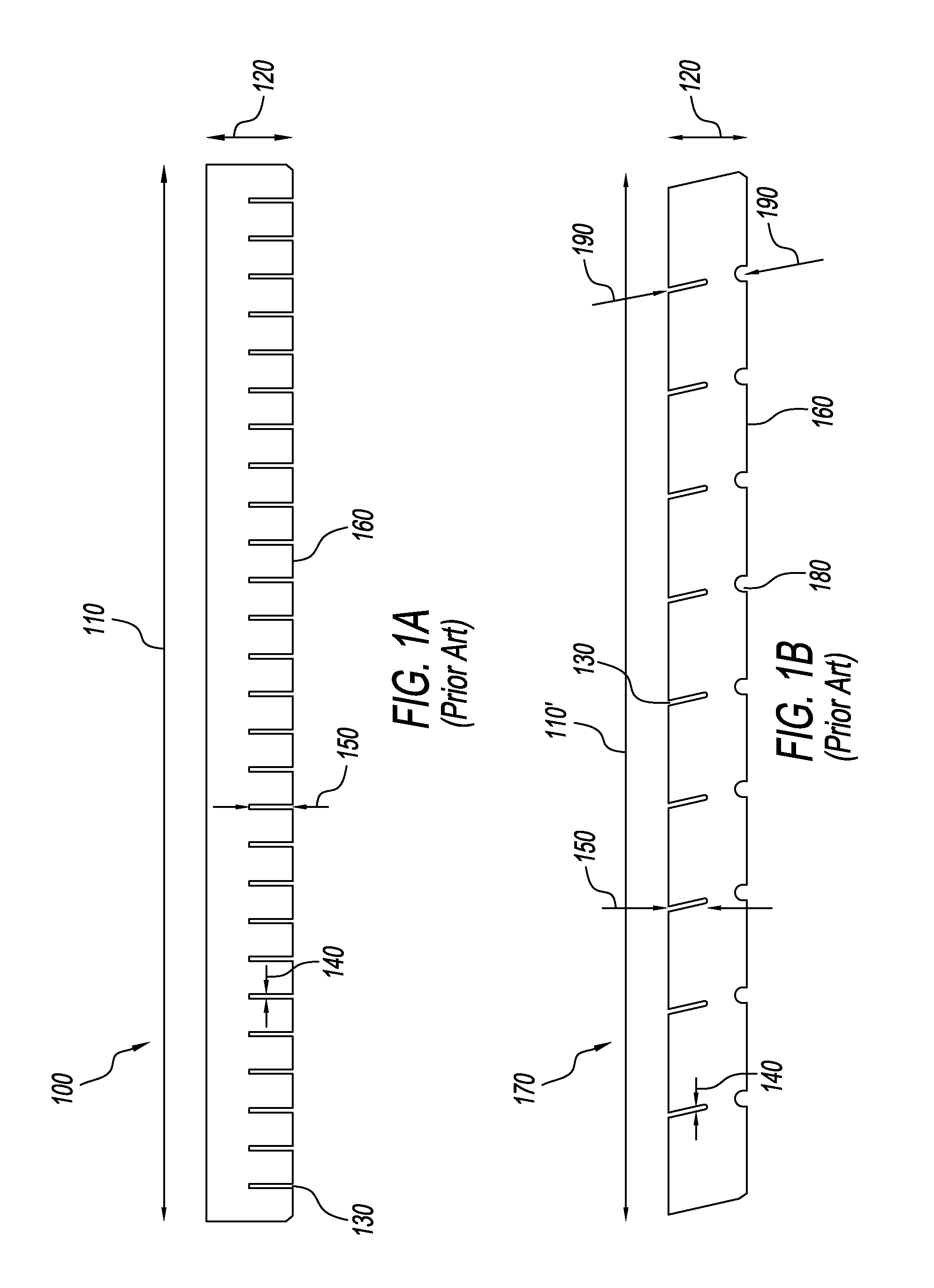

Ice making machine evaporator with joined partition intersections

Disclosed are methods and apparatuses for overcoming known plating deficiencies in evaporator assemblies in ice making machine. One embodiment joins the vertical and horizontal partitions together at their intersections so that all surfaces are susceptible for increased soldering / brazing by eliminating the “voids” by changing the location and design of the “weep holes” in the vertical and / or horizontal partitions. This provides more complete capillary path at the joint between the vertical and horizontal partitions and the evaporator pan allowing improved flow via capillary action of solder / brazing alloy during the joining of the assembled vertical and horizontal partition grid to the evaporator pan. Another embodiment increases the clearance between the partitions at their intersections to allow the post-joining plating treatment to penetrate and coat all the partition surfaces by widening the intersection slots in the partitions, but including “stand-off” features to center the mating partition in the widened intersection slot.

Owner:PENTAIR FLOW SERVICES

Photonic crystal coating equipment for surface of ultrathin flexible base material

PendingCN112678589AEasy to collectAvoid curlMetallic material coating processesWebs handlingPhotonic crystalElectric machine

The invention discloses photonic crystal coating equipment for the surface of an ultrathin flexible base material. The photonic crystal coating equipment comprises a box body, a partition plate, a support, connecting blocks, driving shafts, rollers, a conveying belt, first motor frames, a servo motor, supporting legs and a coating machine, wherein the partition plate is fixedly connected into the box body, and the support is fixedly connected into the box body; the two symmetrically-distributed connecting blocks are rotatably connected to the interior of the support, the two symmetrically-distributed driving shafts are rotatably connected to the interior of the box body, the rollers are fixedly connected to the outer sides of the driving shafts, the outer sides of the rollers are sleeved with the conveying belt, and the two symmetrically-distributed first motor frames are fixedly connected to the outer side of the box body; and the inner sides of the two first motor frames are jointly connected with the servo motor. The invention relates to the photonic crystal coating equipment for the surface of the ultrathin flexible base material. The photonic crystal coating equipment has the characteristics of being capable of preventing edge curling and facilitating material collection.

Owner:YANCHENG INST OF TECH

Chromium-free semi-organic insulating paint for electrical steel and coating method thereof

ActiveCN102220073BBeautiful appearanceWon't fall offLiquid surface applicatorsPolyester coatingsChromium freeGlycol synthesis

Owner:MAANSHAN IRON & STEEL CO LTD

Rumen protected glucose and method of preparation

ActiveUS10058512B2Efficient releaseComplete coatingAccessory food factorsPill deliveryFatty liverFluidized bed

The present disclosure provides a preparation method of rumen protected glucose, comprising the following steps: (1) preparing glucose into a pellet and drying; (2) fluidizing the pellet in a fluidized bed after drying; and (3) coating melted aliphatic alcohol and / or saturated fatty acid onto the surface of the pellet located in the fluidized bed to obtain a rumen protected bypass glucose particle. The prepared rumen-protected glucose could go through the rumen of ruminant effectively; and the availability of coating layer in ruminant increases, making the coated glucose be released completely and fully utilized by ruminant, so ketosis or subclinical ketosis and fatty liver disease of the ruminants in perinatal stage could be prevented and reduced effectively, the postpartum weight loss could be reduced, and the cycle conception rate and the milk yield could be increased.

Owner:BEIJING YAHE NUTRITIVE HIGH TECH CO LTD

A support device for vapor deposition on the full channel surface of a guide vane and its application method

ActiveCN110158047BImprove temperature stabilityImprove job stabilityVacuum evaporation coatingSputtering coatingRotational axisCeramic coating

Owner:AECC AVIATION POWER CO LTD

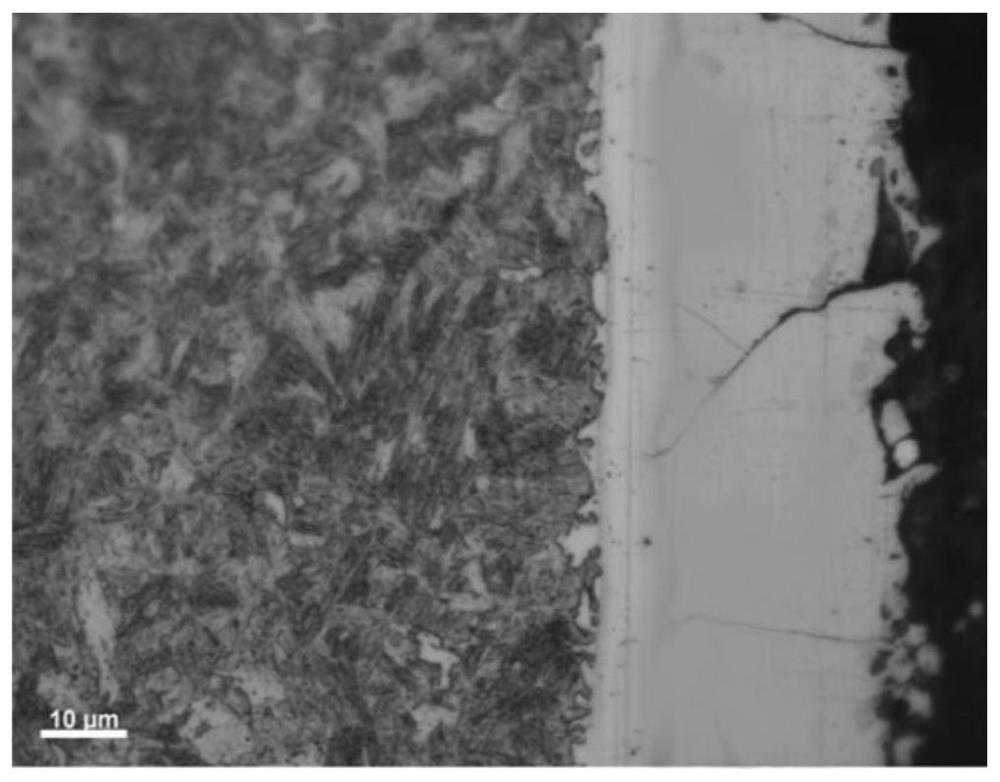

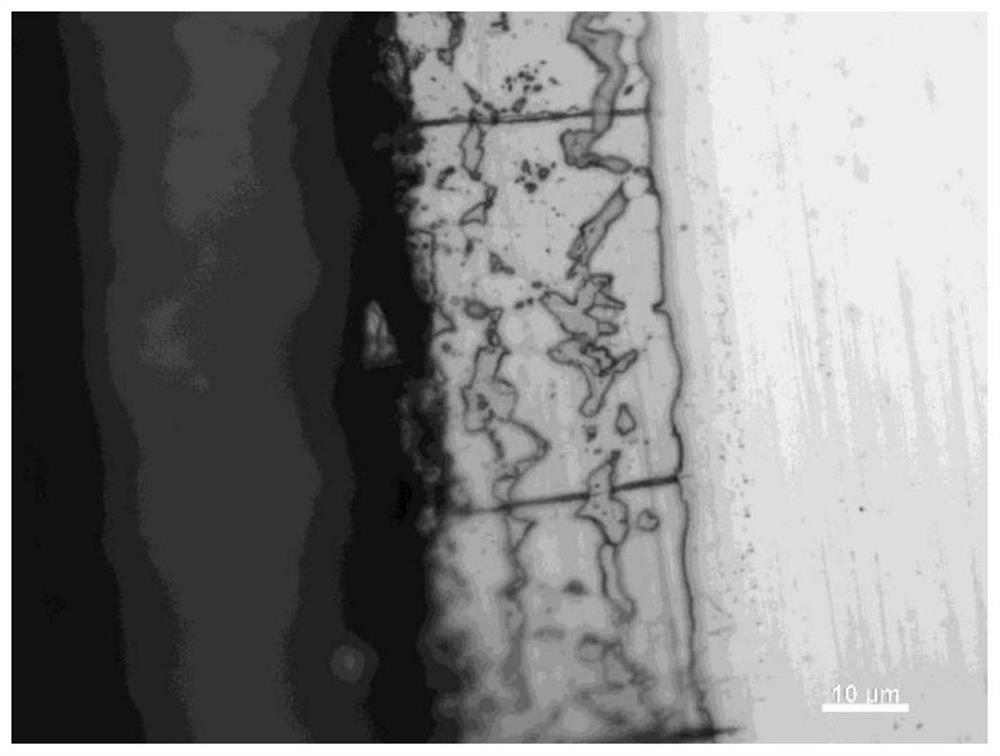

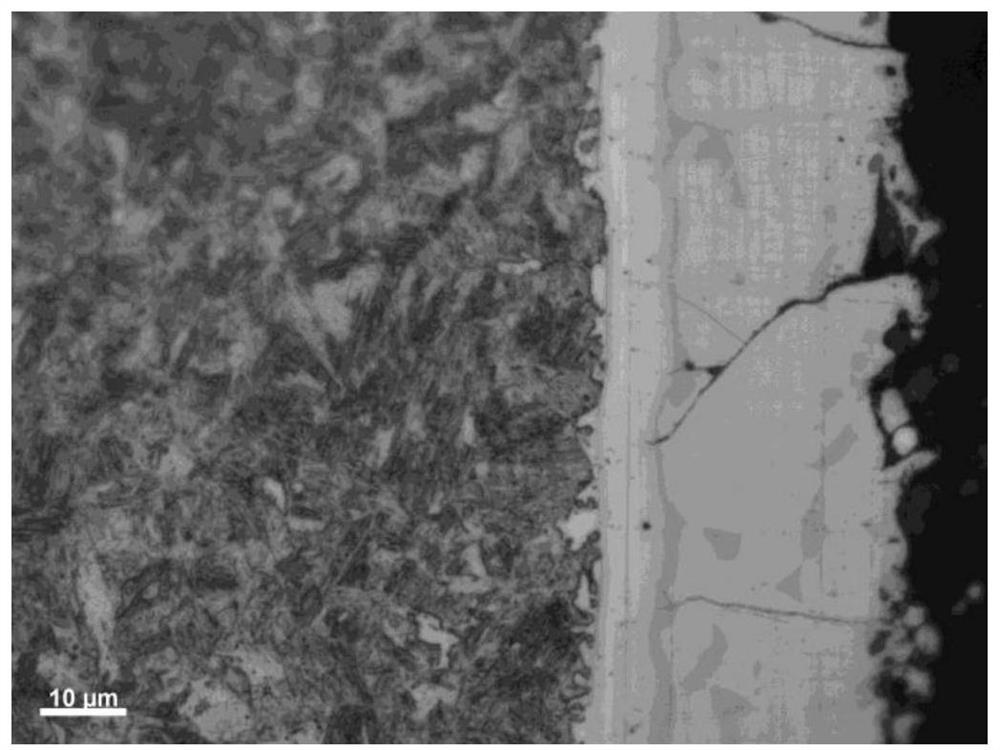

Metallographic sample preparation and display method for iron-aluminum-silicon layer of aluminum-silicon coated steel plate

PendingCN113588363AComplete coatingLow detection and analysis costPreparing sample for investigationMaterial analysis by optical meansWire cuttingAluminium

The invention discloses a metallographic sample preparation and display method of an iron-aluminum-silicon layer after hot stamping forming of an aluminum-silicon coated steel plate, which comprises the following steps: (1) sample preparation: taking the aluminum-silicon coated steel plate, blade-coating a layer of finish paint on the surface of the steel plate by using an RDS20-50# scraper bar, placing the steel plate in a box-type drying furnace for drying, preserving heat, cooling with water, and then blow-drying with cold air, wherein the thickness of the film is 20-50[mu]m, cutting the sample by using wire cutting, and putting the sample into an embedding machine for embedding; then performing grinding and polishing; (2) chemical corrosion: the sample prepared in the step (1) is sequentially subjected to chemical corrosion in a test solution a and a test solution b, the test solution a is a 0.1% nitric acid methanol solution, and the test solution b is 0.1% nitric acid +0.1% HF aqueous solution; and (3) microscope observation: after chemical corrosion is completed, washing the sample with absolute ethyl alcohol, blow-drying the sample with a blower, and observing the sample under a ZISS metallographic microscope. According to the method provided by the invention, a complete coating structure can be obtained, the morphology and distribution state of each phase in the coating can be clearly displayed in the structure observation process, and the method has the characteristics of low detection and analysis cost, rapidness and simplicity.

Owner:TANGSHAN IRON & STEEL GROUP +1

Notebook computer shell vacuum sputtering method

PendingCN112663007AReasonable designImprove wear resistance and corrosion resistanceDigital data processing detailsVacuum evaporation coatingSputteringSand blasting

The invention provides a notebook computer shell vacuum sputtering method, which comprises the following steps of clamping a notebook computer shell to fix the position of the notebook computer shell by a clamp; carrying out corresponding polishing and degreasing treatment on the fixed notebook computer shell; performing automatic dust removal and static electricity removal on the degreased notebook computer shell through a negative ion dust removal gun and dust removal gauze; carrying out sand blasting treatment on the surface of the plastic shell base material through emery for the shell subjected to dust removal treatment in the previous step; cleaning the surface of the plastic shell base material subjected to sand blasting treatment through ultrasonic waves; performing vacuum coating on the the notebook computer shell, wherein the surface of the shell is coated with a layer of copper film, the surface of the shell is coated with a layer of silver film, and then the surface of the shell is coated with a layer of copper film, so that a'copper-silver-copper 'sandwich type coating structure is formed; and spraying finishing varnish, drying, cooling and inspecting. In the coating spraying process, completeness of the coating is guaranteed, the abrasion resistance and the corrosion resistance of the shell are improved, the quality of the notebook computer shell coated with the coating is high, and high popularization value is achieved.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

A diaphragm glue coating machine for a stacked battery pack or a supercapacitor pack

InactiveCN104785406BCoated evenlyComplete coatingLiquid surface applicatorsCoatingsCapacitanceSupercapacitor

The invention provides a diaphragm gluing machine for a laminated battery pack and a super-capacitor pack. The diaphragm gluing machine comprises a drive motor, wherein the drive motor drives a sizing roller, the sizing roller drives a rubber covered roller through a belt pulley, a gluing groove is formed in the lower part of the sizing roller, a paper placing platform is arranged on one sides of the sizing roller and the rubber covered roller, a material receiving panel is arranged on the other sides of the sizing roller and the rubber covered roller, the tangent line of the sizing roller and the rubber covered roller corresponds to a plane of the paper placing platform; a paper feed roller is arranged between the plane of the paper placing platform and the sizing roller, and another feed roller is arranged between the plane of the paper placing platform and the rubber covered roller. According to the invention, a hot melt glue is printed on a diaphragm of a laminated super-capacitor by using the sizing roller and the rubber covered roller, the tangent line of the sizing roller and the rubber covered roller corresponds to the plane of the paper placing platform to keep the diaphragm flat and intact, the advantages of uniform and smooth coating, high speed and the like are achieved, the mass production of the super-capacitor is implemented, the printed diaphragm is smooth and has no pores, cracks or patterns, the paper does not crease in printing, and the problem of insulation of the diaphragm is better and more economically solved.

Owner:HUBEI SHENGRONG TECH CO LTD

A kind of preparation method of diamond surface coating resin film

ActiveCN104762592BCoating stabilitySolid coatingVacuum evaporation coatingSputtering coatingPower flowSurface cleaning

The invention relates to the technical field of diamond surface treatment, particularly a manufacturing method of a resin film plated on a diamond surface, which is performed in a diamond vacuum plating machine. The method comprises the following steps: a. vacuumizing: putting diamond in a plating chamber of a vacuum ion plating machine, and vacuumizing the plating chamber to 2*10<-3>Pa; b. diamond surface cleaning: carrying out cleaning treatment on the diamond for 30 minutes by using a 5KV ion source; and c. diamond surface plating: treating the diamond powder treated by the step b in the following technique: the target cathode uses an ABS (acrylonitrile-butadiene-styrene) resin sheet target, the voltage is 400V, the direct current is 1.0-1.2A, the deflecting voltage is 140-160V, and the like. The method can easily plate a resin film on the diamond, and has the advantages of high plating stability and high plating compactness. Besides, the plating technique also has the advantage of complete and uniform plating.

Owner:HENAN HUANGHE WHIRLWIND CO LTD

Automatic duster for thermally conductive silicone cloth

ActiveCN112808546BComplete coatingFully contactedLiquid surface applicatorsCoatingsEngineeringSilica gel

The present application relates to an automatic dusting machine for thermally conductive silicone cloth, which comprises a frame, a transmission mechanism arranged on the frame for conveying the thermally conductive silicone cloth, and a duster arranged on the frame and located above the transmission mechanism The powder-spraying mechanism includes a powder box arranged on the frame, a coating roller arranged below the powder box, and a drive assembly for driving the rotation of the coating roller. The bottom of the powder box is provided with a powder outlet, and the coating roller The two ends of the roller are rotatably connected to the frame, and the top of the coating roller is gap-fitted with the powder outlet. The application can automatically coat the thermal conductive silica gel cloth with mica powder, save manpower and time, and greatly improve the production efficiency.

Owner:SHENZHEN LAIMEISI SILICON IND CO LTD

A kind of photoanode material and its preparation and application

ActiveCN107557789BExpand the scope of absorptionIncrease profitMaterial nanotechnologySurface reaction electrolytic coatingTio2 nanotubeComposite film

The invention relates to a nanotube array photo anode, in particular to a BiVO4 / TiO2 nanotube array photo anode material which is stably used for photo-induced cathodic protection and preparation andapplication thereof. A preparation method of the material comprises the steps that firstly, an anodic oxidation method is adopted, Pt serves as a counter electrode, a titanium sheet substrate serves as a working electrode, and an NH4F and ethylene glycol solution serves as electrolyte; then, a titanium sheet is calcinated, so that a TiO2 nanotube array thin film is prepared on the surface of the titanium sheet; then, a hydrothermal method is adopted, and reaction solutions with Bi(NO)3 and NH4VO3 as a bismuth source and a vanadium source correspondingly are compounded; the TiO2 nanotube arraythin film is completely immersed into the reaction solutions; and after the TiO2 nanotube array thin film is put into a drying box to be subjected to constant-temperature hydrothermal treatment, calcination treatment is conducted, so that a BiVO4 / TiO2 composite film is obtained. The BiVO4 / TiO2 composite film serves as the photo anode for photo-induced cathodic protection, the utilization rate of visible light can be increased; the corrosion potential of 304 stainless steel is obviously lowered; and the good cathodic protection corrosion-resistant effect can still be achieved in the dark state.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

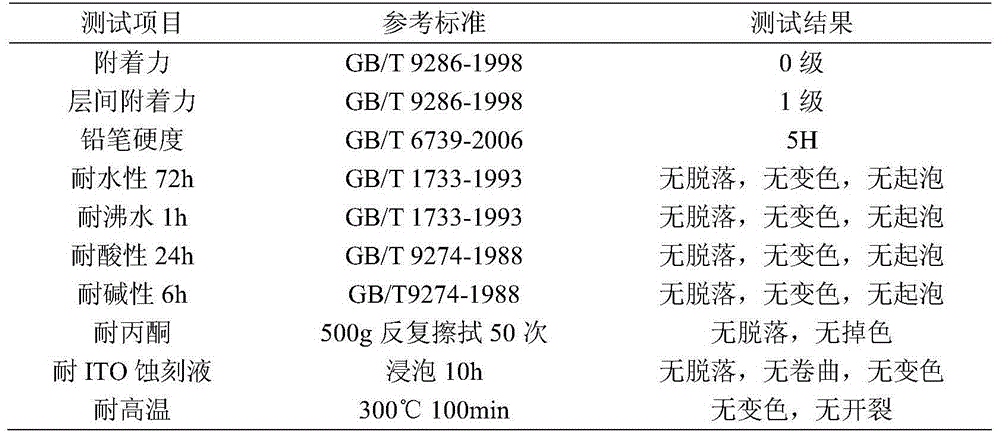

A kind of thermosetting high temperature resistant touch screen ink and preparation method thereof

The invention discloses thermosetting high temperature resisting printing ink for a touch screen as well as a preparation method of the printing ink. The formula of the printing ink comprises the following raw materials in parts by weight: 55-65 parts of modified organic silicon resin, 20-30 parts of titanium dioxide, 5-15 parts of powder packing, 3-8 parts of a diluent, 0.5-1.4 parts of a dispersant, 0.1-0.3 part of a leveling agent, 0.05-0.1 part of a defoamer, 1-2 parts of a silane coupling agent and 2-5 parts of a curing agent. The preparation method comprises the following steps: mixing the modified organic silicon resin, a pigment, the powder packing, 0.35-0.95 part of the dispersant, 0.05-0.15 part of the leveling agent and 2-5.4 parts of the diluent to obtain a main agent; and adding the curing agent, the defoamer, the silane coupling agent as well as remaining leveling agent, dispersant and diluent into the main agent, and dispersing, filtering and discharging. The printing ink coating is high temperature- resisting in coating, excellent in color retention at a high temperature of 300 DEG C, good in adhesion to a base material, high in hardness, resistant to acetone wiping and resistant to ITO (Indium Tin Oxides) etching liquids.

Owner:深圳市卓联电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com