Support device for guiding vane full flowpath face vapour deposition and application method thereof

A guide vane and vapor deposition technology, which is applied in the field of support devices for vapor deposition on the full flow channel surface of guide vanes, can solve the problems of inability to meet design requirements, uneven coating of the blade body, and coating on the shielded area, and achieves improved durability. Thermal temperature and working stability, easy product processing and disassembly, the effect of less accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in further detail below in conjunction with accompanying drawing:

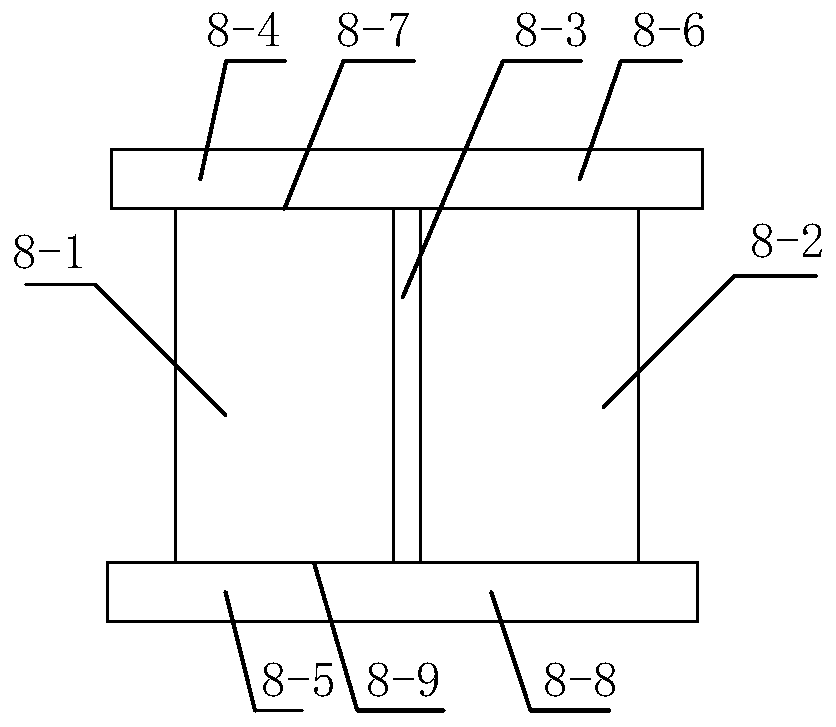

[0054] The invention discloses a supporting device for gas phase deposition on the full channel surface of a guide vane and its application method; the device comprises: a connecting rod 1, a through hole 2, an L-shaped connecting plate 3, a self-rotating bearing device 4, and a protective box for an outer edge plate 5. Support nut 6, inner edge plate protection box 7, guide vane 8 and connecting screw rod 9.

[0055] like figure 1 As shown, one end of the connecting rod 1 is provided with a through hole 2 for connecting with the equipment rotating shaft 11, and the other end uses a nut to fix the connecting rod 1 and the L-shaped connecting plate 3; the L-shaped connecting plate 3 is provided with a self-rotation bearing device 4. The rotation bearing device 4 is connected with the protective box 5 of the outer edge plate, and the protective box 5 of the outer edge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com