Chromium-free semi-organic insulating paint for electrical steel and coating method thereof

A technology for insulating coatings and electrical steels, which is applied in polyester coatings, coatings, devices for coating liquids on surfaces, etc. Complete, beautiful appearance, easy to spread and level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

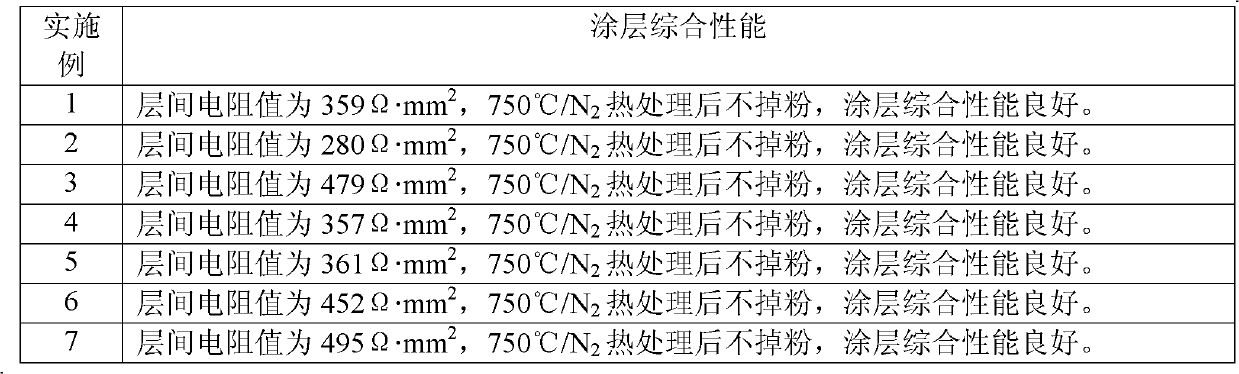

Examples

Embodiment Construction

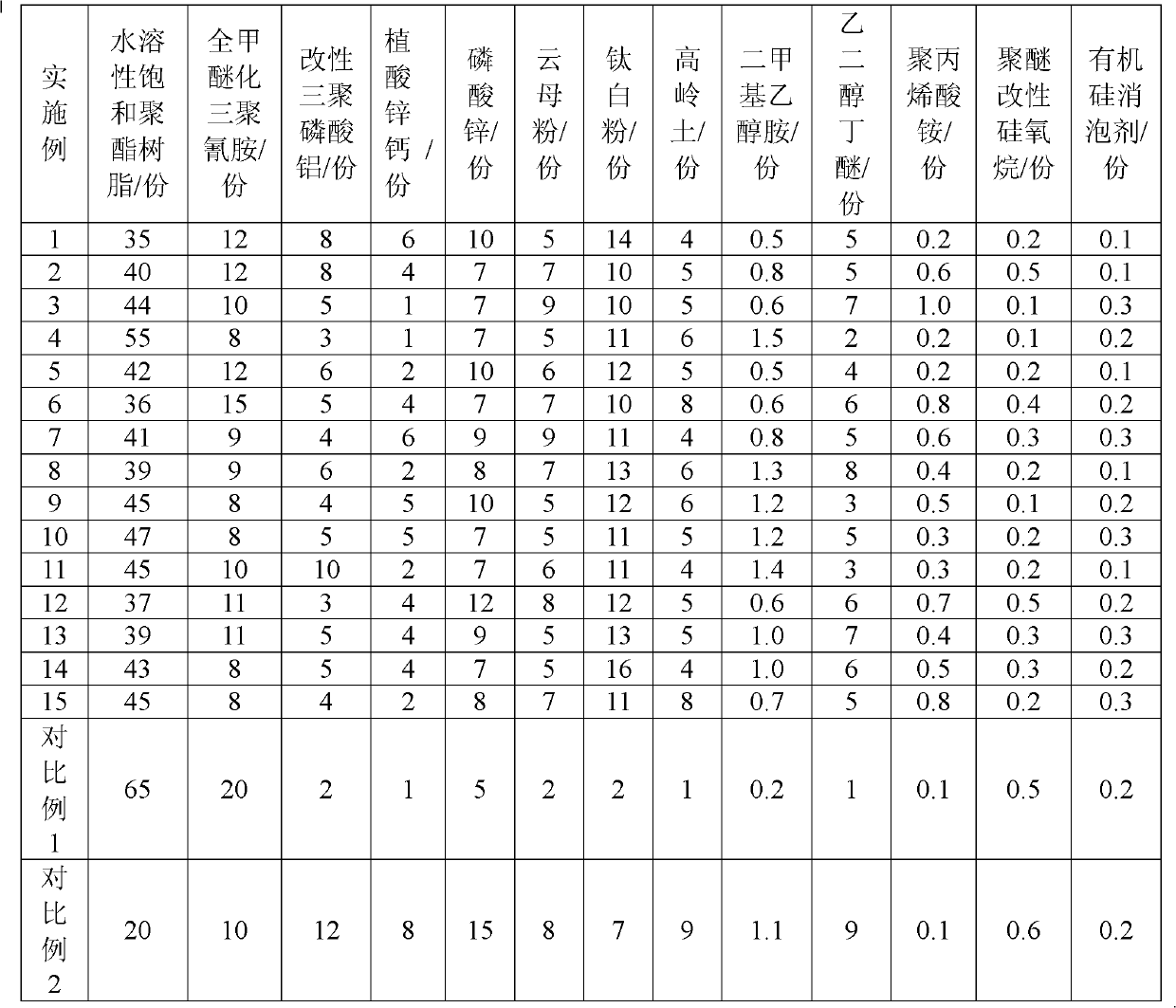

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Table 1 shows the contents by weight of the coating components (excluding water) in Examples 1-15 and Comparative Examples 1-2 of the semi-organic electrical steel insulation coating with good overall performance and no chromium according to the present invention. Adding water to the paint and dissolving it to the required concentration of common electric steel insulating paint can be used for production.

[0014] The content of each component of coating in the embodiment and comparative example of table 1

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com