Photonic crystal coating equipment for surface of ultrathin flexible base material

A technology of flexible substrates and photonic crystals, which is applied in the direction of winding strips, thin material processing, metal material coating technology, etc., can solve the problem that the edge cannot be coated, the edge of the flexible material is easy to warp, and the flexible material is inconvenient to collect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

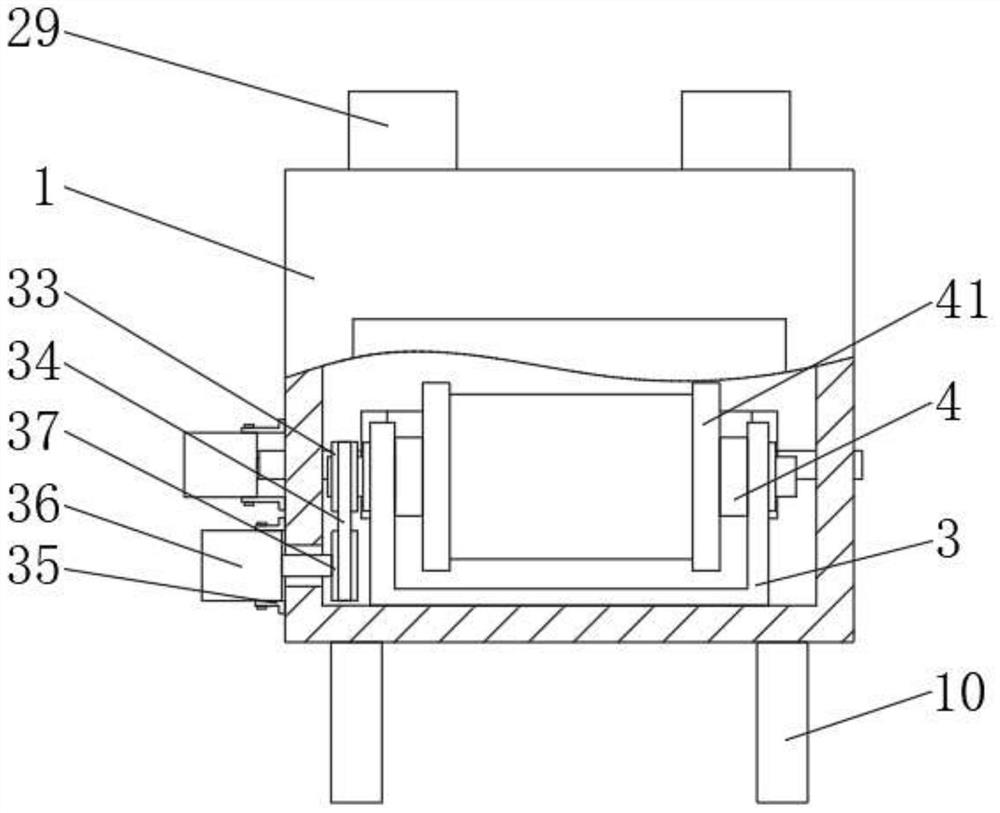

[0028] A photonic crystal coating device on the surface of an ultra-thin flexible substrate, including a box body 1, a partition plate 2, a bracket 3, a connecting block 4, a drive shaft 5, a roller 6, a conveyor belt 7, a motor frame 1 8, a servo motor 9, and support legs 10 and a coating machine 11, the inside of the box 1 is fixedly connected with a partition 2, the inside of the box 1 is fixedly connected with a bracket 3, and the inside of the bracket 3 is rotatably connected with two symmetrically distributed connecting blocks 4 , the inside of the box 1 is rotationally connected with two symmetrically distributed drive shafts 5, the outer side of the drive shaft 5 is fixedly connected with a roller 6, and the outer side of the roller 6 is sleeved with a conveyor belt 7, and the box 1 Two symmetrically distributed motor frames one 8 are fixedly connected to the outer side of the motor frame one 8, and a servo motor 9 is connected to the inner sides of the two motor frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com