Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Carbon free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

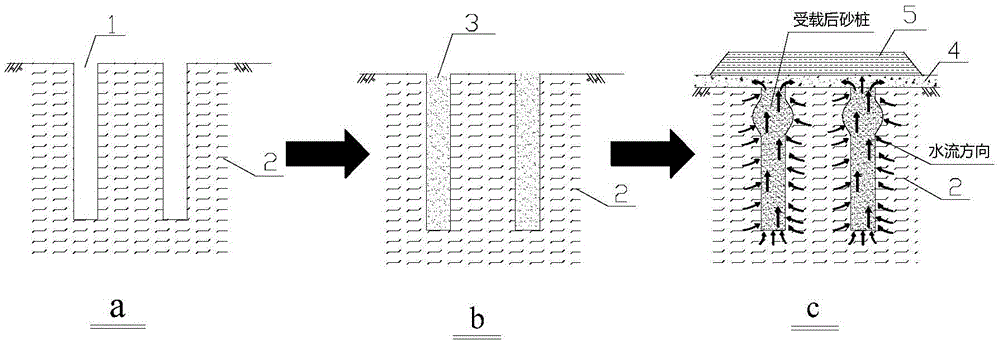

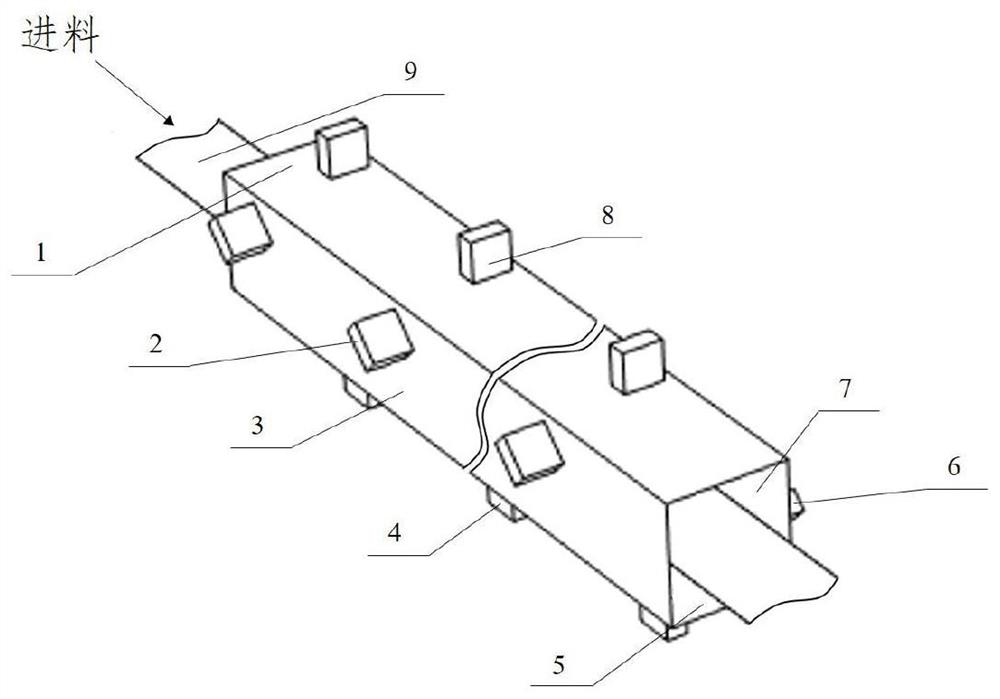

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

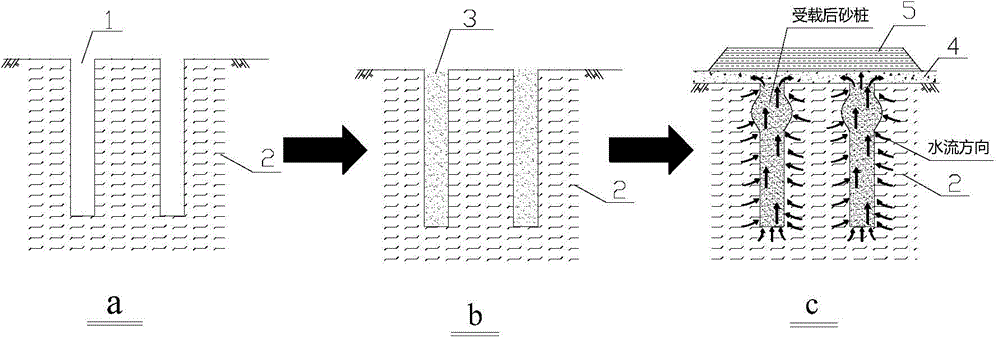

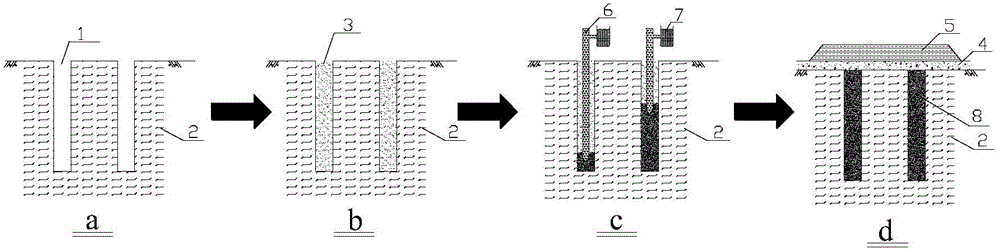

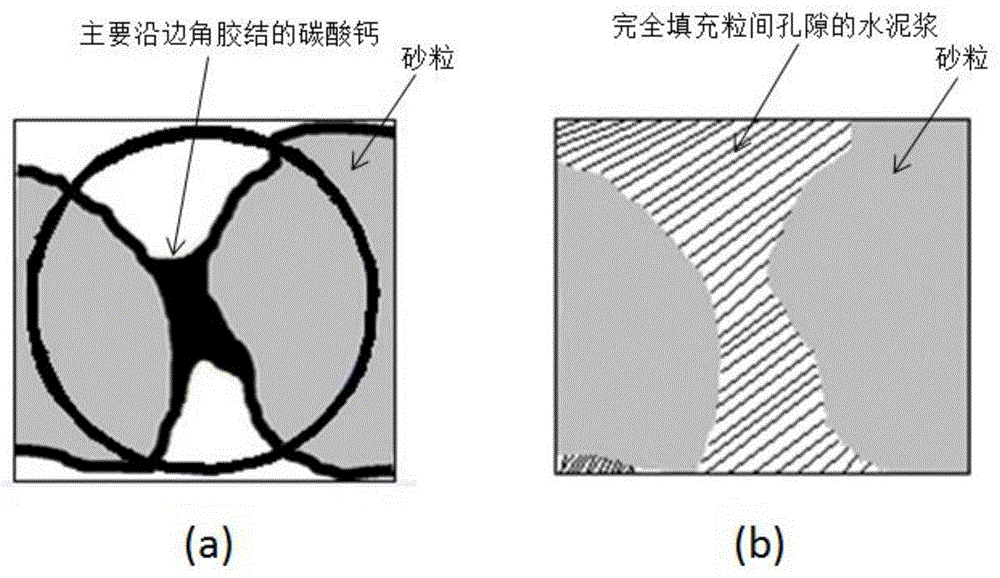

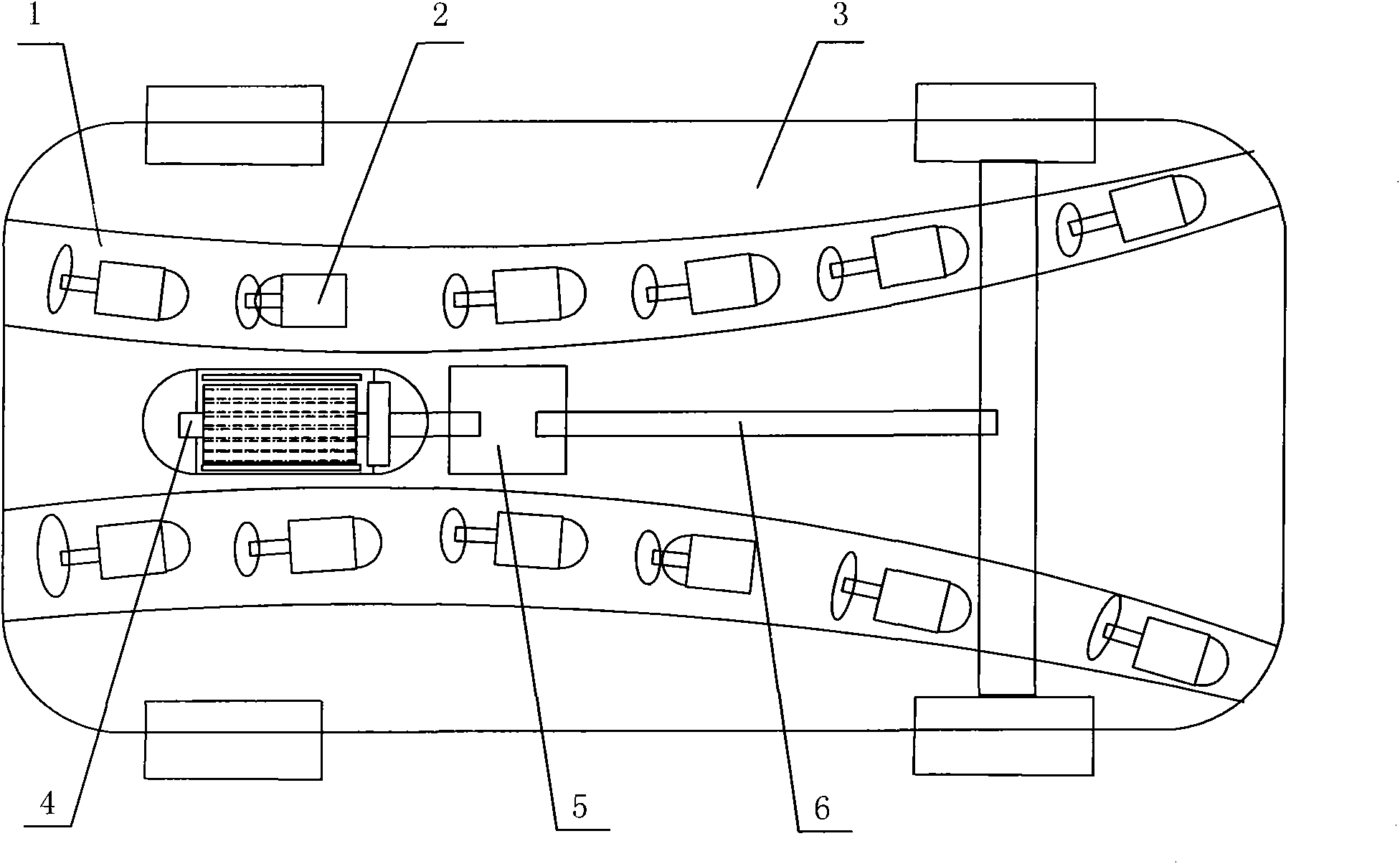

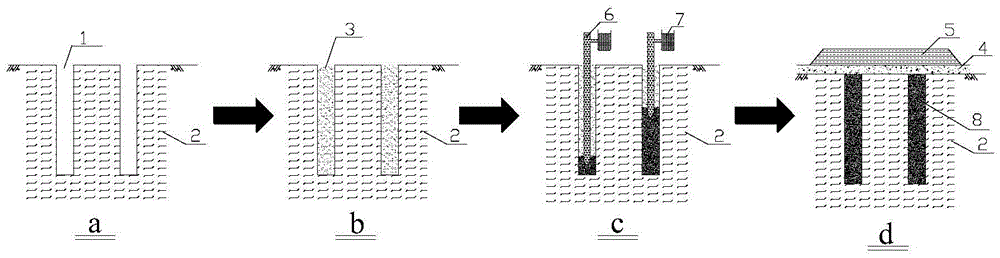

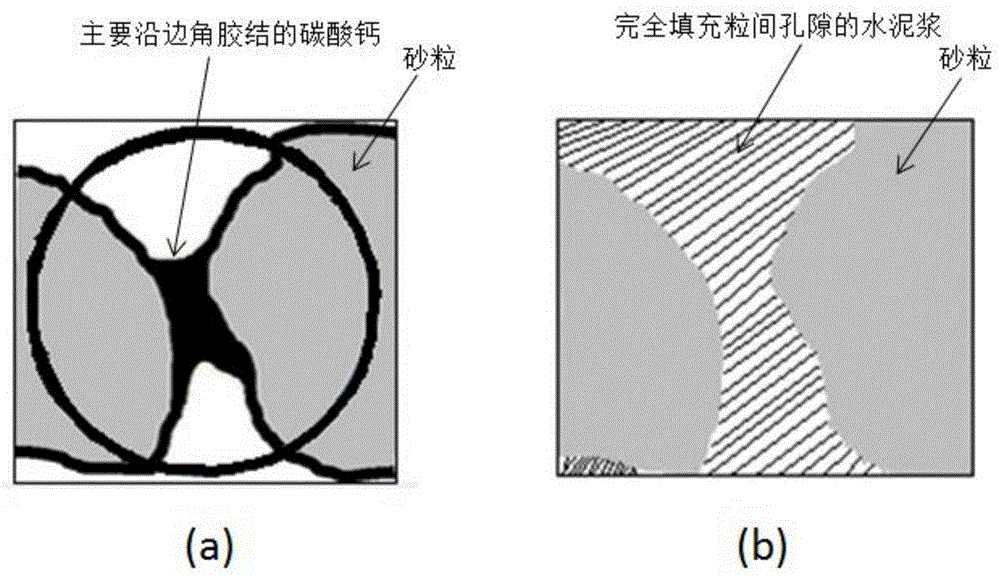

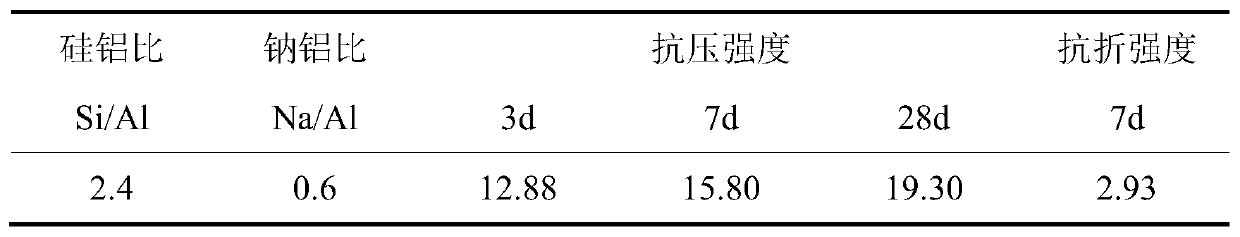

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

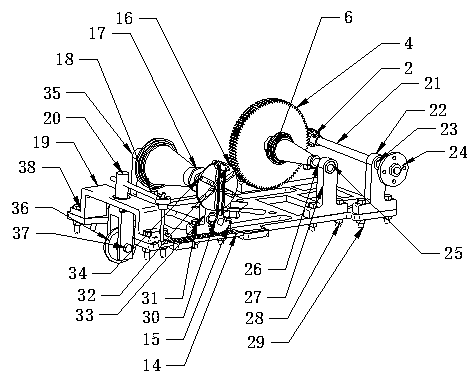

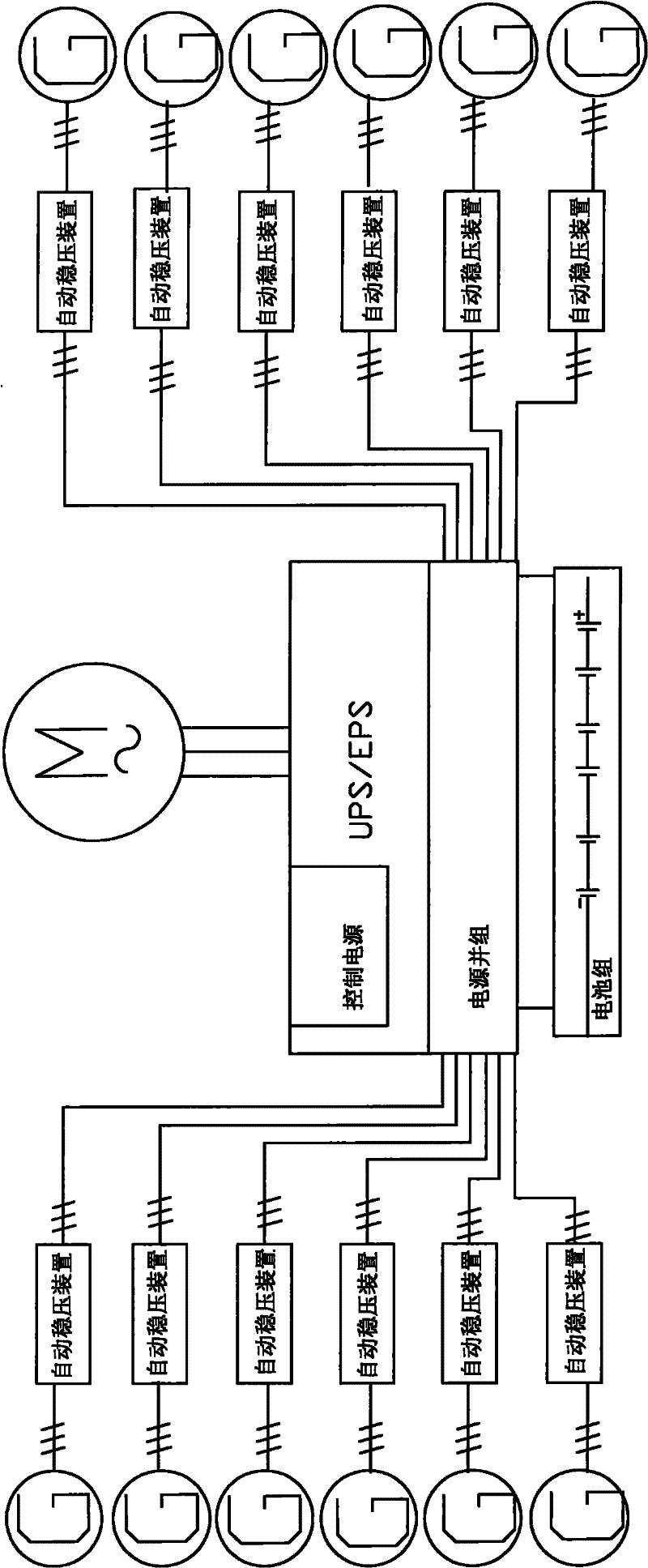

Wind energy electricity generating and supplying system of electromobile

InactiveCN101830178AReasonable designCompact structureWind energy with electric storageEnergy storageBattery chargerWind power generation

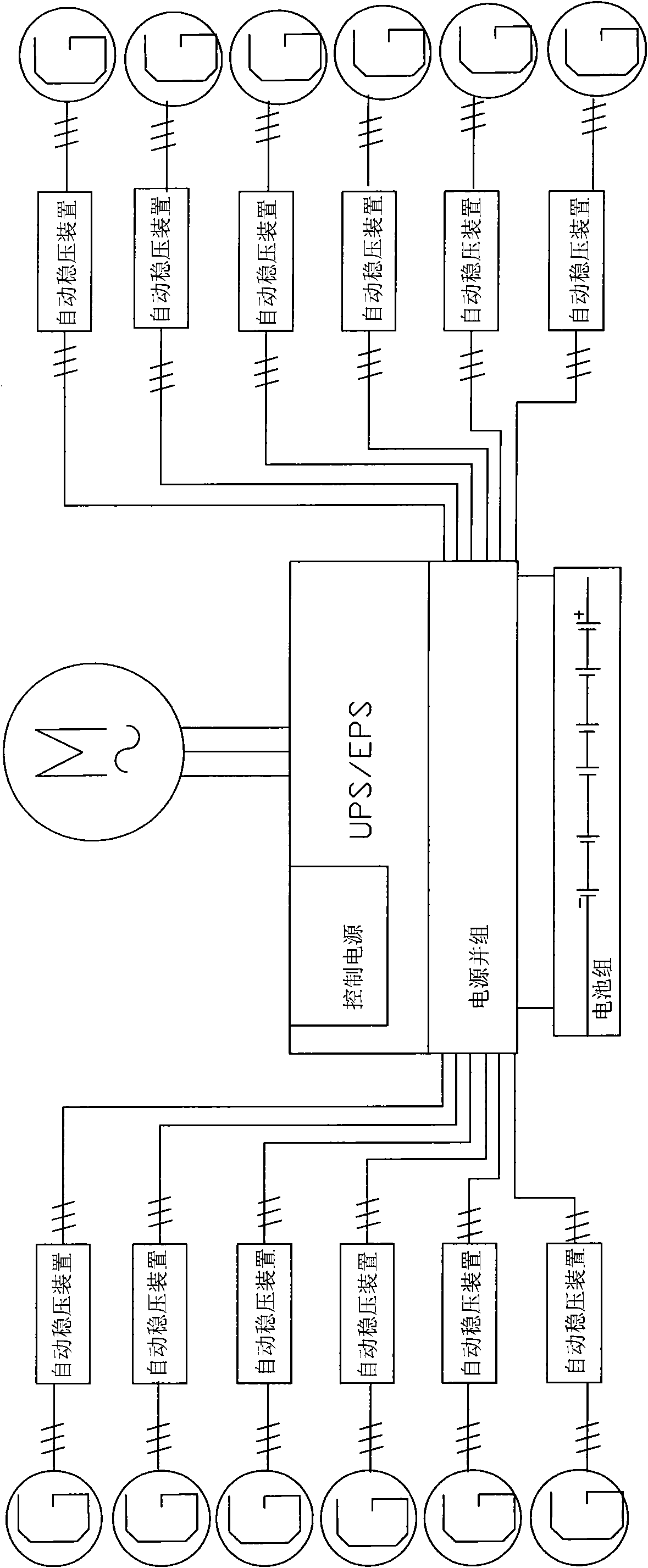

The invention relates to a wind energy electricity generating and supplying system of an electromobile, relating to a wind power generation system, in particular to a wind energy electricity generating and supplying system provided for the electromobile. The wind energy electricity generating and supplying system comprises a ventilating duct, a wind speed flow-limiting valve, a plurality of wind energy generators, an automatic voltage regulator of a generator set, a power supply device and a power supply combination box, wherein the ventilating duct is arranged at the bottom of the electromoible, the wind energy generator is arranged in the ventilating duct, and the wind speed flow-limiting valve is installed at the wind inlet of the ventilating duct. A rectification voltage stabilizer comprises a rectifying diode and a voltage stabilizing diode, and a plurality of groups of line banks are installed in the power supply combination box. The power supply device comprises a control power supply transformer and a power supplying and standby power supply, wherein the input end of the control power supply transformer is connected with the output end of a standby power supply, and the power supplying and standby power supply comprises a solid contactor, a bypass switch, a maintenance bypass switch, a bypass static switch, an output switch, a charger, an inverter, an inverting static switch, a battery pack, a standby battery pack and a filter.

Owner:太谷县晋海通电子科技有限公司

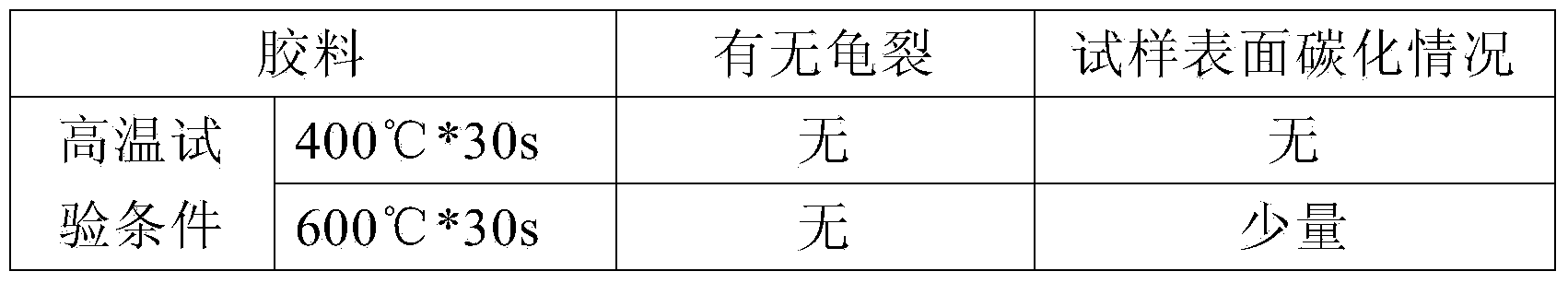

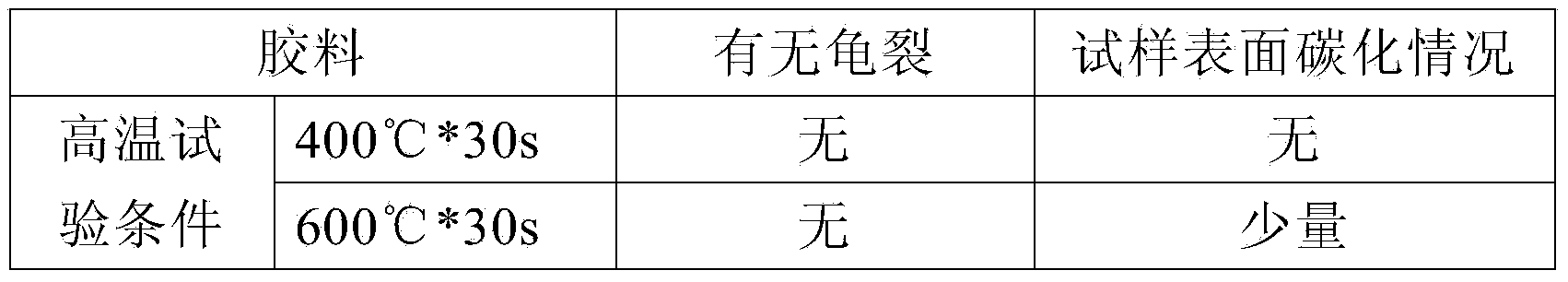

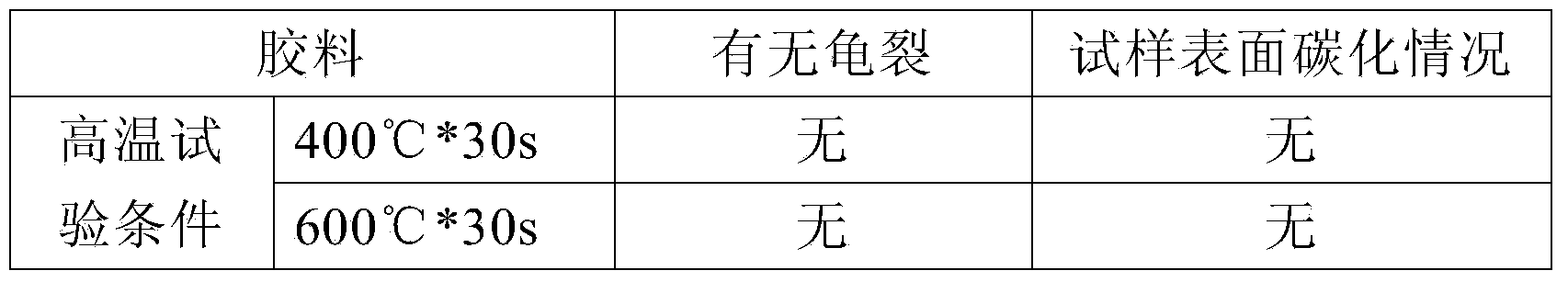

Firing resistant conveyer belt cover plastic and preparation method thereof

The invention discloses firing resistant conveyer belt cover plastic and a preparation method thereof. The firing resistant conveyer belt cover plastic comprises the following components in parts by weight: 100 parts of vulcanizing silicone rubber, 20-70 parts of reinforcing filler, 0.5-5 parts of vulcanizing agent, 8-20 parts of vulcanizing activator, 10-35 parts of plasticizer, 3-6 parts of antiager and 15-45 parts of fire retardant. The preparation method comprises the following steps: first segment mixing, primary cooling, second segment mixing and secondary cooling. The firing resistant conveyer belt cover plastic disclosed by the invention can be used for a long time under an environment of 250-400 DEG C and can be instantly used at 600 DEG C for a short time, and can be used for preventing the phenomenon that a high temperature material cannot be normally transported induced by surface cracking, corrosion or carbonization of the cover plastic due to over high temperature and greatly prolonging the service life of the conveying belt at a high temperature to achieve a good economic benefit. The preparation method disclosed by the invention has the characteristics of simple steps and easiness in operation, and the like.

Owner:WUXI BOTON TECH CO LTD

Graphite electronic heat radiation material as well as preparation method and application of graphite electronic heat radiation material

InactiveCN103281889AGuaranteed thermal conductivityStable temperature fieldPoint-like light sourceGraphiteInduction fieldGraphite

The invention relates to a graphite electronic heat radiation material as well as a preparation method and application of the graphite electronic heat radiation material. The preparation method comprises the following steps that 1) expandable graphite is sent into pulses in a high-temperature furnace and a high-frequency electric induction field to be expanded into graphite worms; 2) the graphite worms are subjected to solid-gas separation; 3) the graphite worms directly pass through carbon nanometer tubes or are added into the carbon nanometer tubes after being cooled, then, the graphite worms pass through a conveying belt, electrodes are arranged under the conveying belt, calendar rollers are arranged above the conveying belt, and the pure graphite worms subjected to primary compression or the graphite worms containing the carbon nanometer tubes are obtained; and 4) the graphite worms are pressed into flexible graphite films, plates or coiled materials in a molding pressing or multi-section rolling modes. The graphite electronic heat radiation material has the beneficial effects that 1) the expansion is very sufficient, and substances inserted into positions between layers are basically volatilized at all; 2) the energy is saved, the emission is reduced, and the fuel gas heat source realizes the carbon-free discharge; 3) the heat conductivity index of products is improved; and 4) the vertical surface heat conductivity can reach 10 to 30w / (m.l), and the parallel surface heat conductivity can reach a value higher than 300 to 900w / (m.k).

Owner:WUHAN UNIV OF TECH

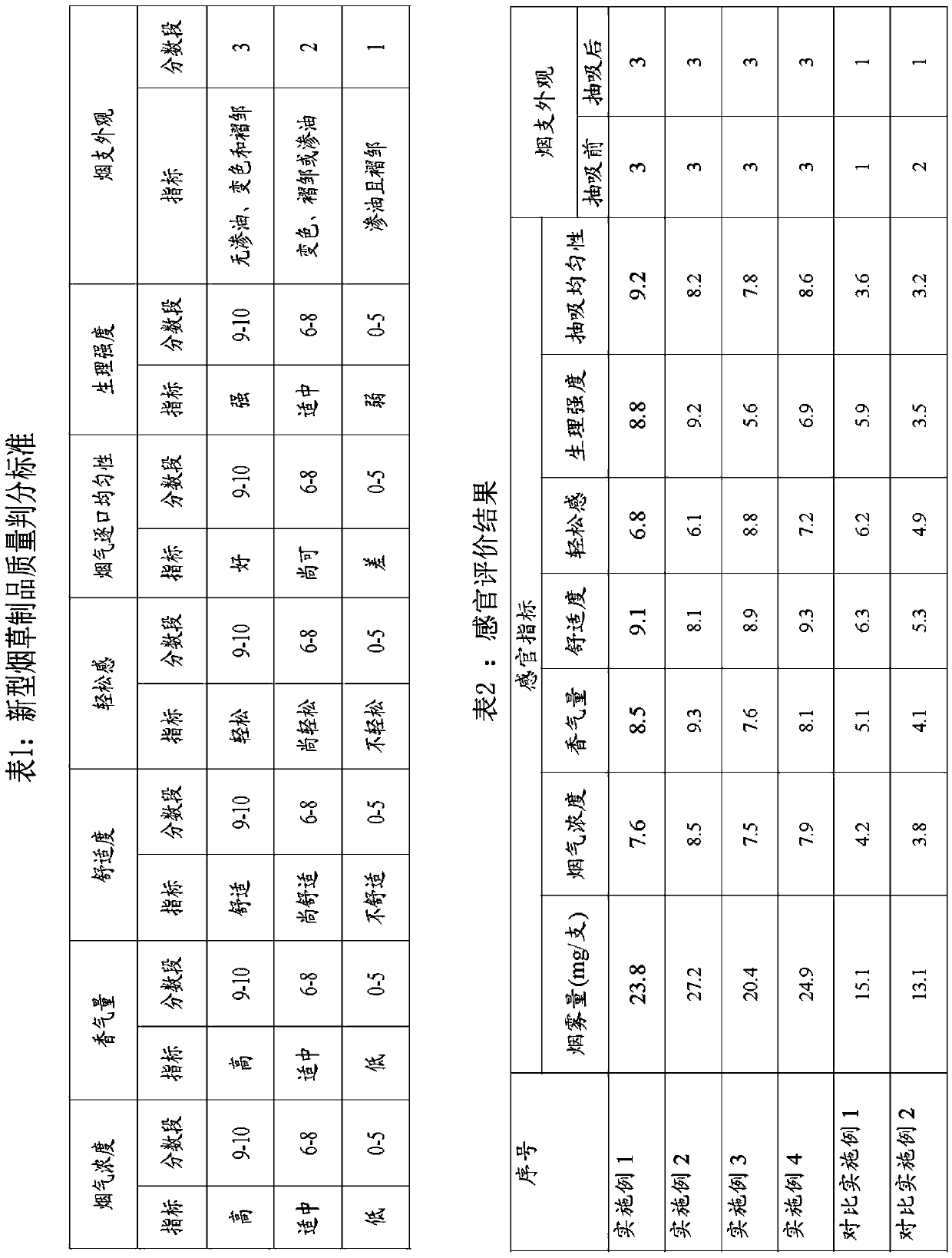

Composite cigarette paper applied to magnetic particle uniform heating type tobacco product

InactiveCN110172868AGood machine adaptabilityBeautiful appearanceNon-macromolecular adhesive additivesSpecial paperFiberEngineering

The invention relates to a composite cigarette paper applied to a magnetic particle uniform heating type tobacco product. The composite cigarette paper is composed of a cigarette fiber paper, a film forming material, and an adhesive layer between the cigarette fiber paper and the film forming material. The composite cigarette paper solves the basic problems of temperature resistance, heat preservation and constant temperature of the cigarette paper applied to the magnetic particle uniform heating type tobacco product; at the same time, by means of the composite cigarette paper, the surface ofthe fiber paper, after a cigarette is sucked, has no discoloration or carbonization or the like, and the appearance of the cigarette is beautiful. The composite cigarette paper not only avoids the overflow of smoke in the uniform heating process of the cigarette, but also effectively improves the feeling of suction and the sensory quality of the smoke.

Owner:CHINA TOBACCO ANHUI IND CO LTD

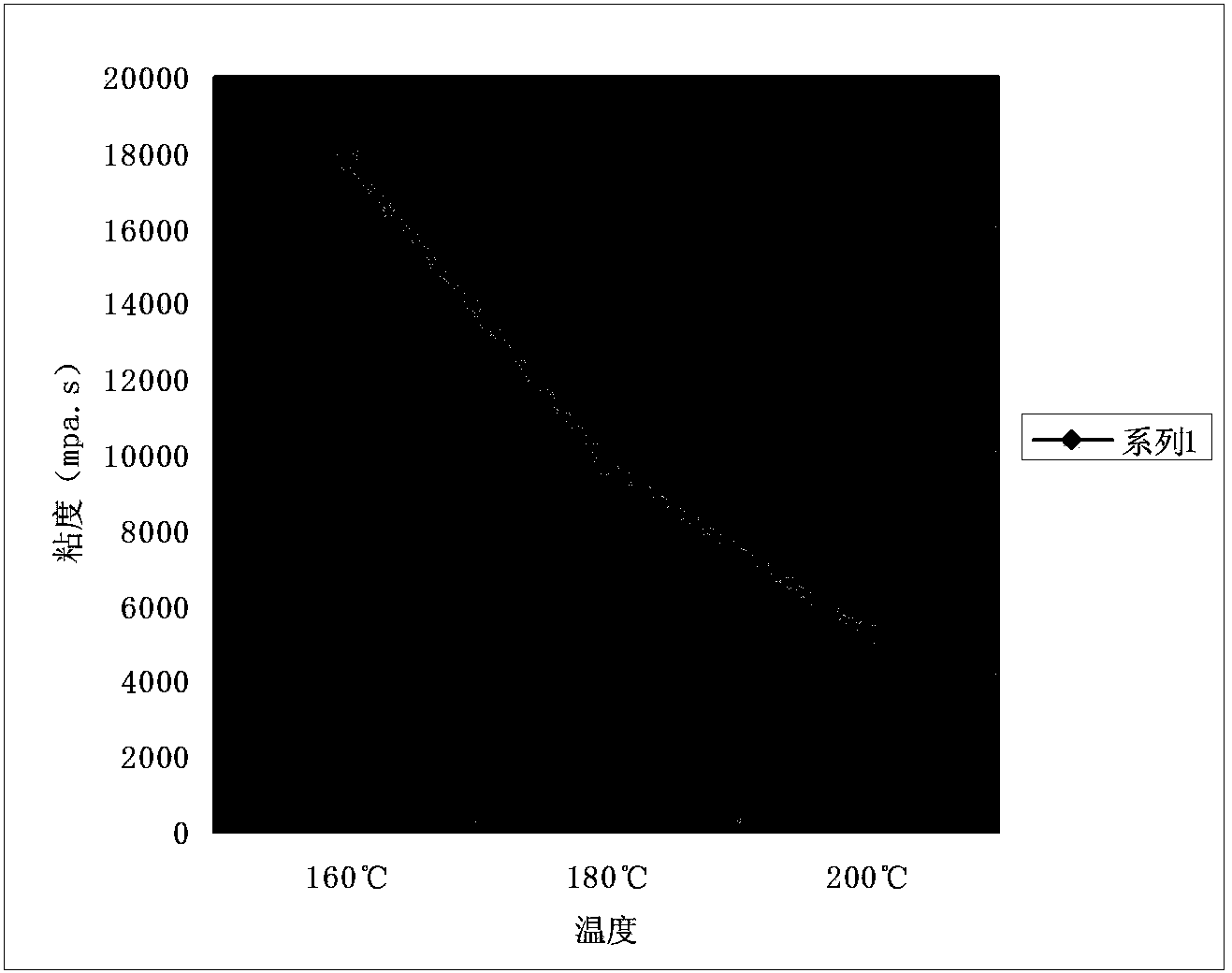

Mobile phone battery aluminum foil packing seal hot melt glue and preparation method thereof

ActiveCN102911624ASimple processGood high and low temperature resistanceMineral oil hydrocarbon copolymer adhesivesGraft polymer adhesivesMaleic anhydrideWax

The invention relates to mobile phone battery aluminum foil packing seal hot melt glue and a preparation method thereof, belonging to the technical field of macromolecular viscose. The method comprises the following steps of: putting sasol wax, tackifying resin C5 hydrocarbon resin and an antioxidant into an electric heating reaction furnace and heating; stirring; adding polyolefin and maleic anhydride modified polyolefin; heating for melting; and vacuumizing, discharging and packing to obtain a mobile phone battery aluminum foil packing seal hot melt glue product. Through the invention, the prepared polyolefin hot melt glue is simple in technology, excellent in high and low-temperature performance, good in initial adhesion and final strength and lower in cost, and prevents carbonization. When in feeding, components with lower viscosity are fed before components with higher viscosity; and the charging order can reduce the rotation load of a stirring paddle in the whole stirring process, reduce the mixing time and save the production cost.

Owner:WUXI WANLI ADHESION MATERIALS

Closed-type liquid-gas conversion engine with internal circulation

The invention discloses a closed-type liquid-gas conversion engine with an internal circulation. The closed-type liquid-gas conversion engine with an internal circulation is a novel low-energy-consumption, high-efficiency and non-emission environment-friendly type engine, wherein high-volatility and low-boiling point solution which is liquid at a normal temperature is used as a steam source, the solution is gasified by virtue of the temperature of hot water and then is pressurized to form a high-pressure gas to drive a machine to rotate.

Owner:沈永培

A method for treating soft ground with microbial grouting drainage sand pile

InactiveCN104631430BImprove deformation resistanceImprove carrying capacityOrganic fertilisersSoil preservationMicroorganismSoil science

A method for treating soft ground with microbial grouting drainage sand piles, the steps comprising: a. making a pile hole 1 on the soft foundation to be treated, and pouring sand into the pile hole 1 to form a sand pile; b. using grouting The tube 6 uniformly injects the urease-producing bacteria liquid 9 and the nutrient salt solution 10 into the sand pile in sequence, and cements the sand grains through the technology of microorganism-induced calcium carbonate crystallization, and controls the concentrations of the urease-producing bacteria liquid 9 and the nutrient salt solution 10 to make the pile The sand in the body forms a specific cementation form to ensure that it has good water permeability; c. After the microbial grouting solidification sand pile is formed, a flexible permeable sand cushion 4 is laid on the top of the foundation composed of the sand pile and the soil between the piles. Apply a preload 5 on the top of the flexible permeable sand cushion 4, so that the pore water in the soil between the piles 2 is discharged along the drainage channel formed by the sand pile and the sand cushion, the soil between the piles is consolidated, and the microbial grouting sand pile, The soft soil after drainage and consolidation and the overlying flexible permeable sand cushion jointly form a composite foundation with high bearing capacity.

Owner:NANJING FORESTRY UNIV

Heavy metal curing agent based on polypropylene fiber and boiler ash and application of heavy metal curing agent

InactiveCN110028973AHigh mechanical strengthGood physical and chemical stabilitySolid waste disposalTransportation and packagingUltimate tensile strengthChemical stability

The invention discloses a heavy metal curing agent based on polypropylene fiber and boiler ash and application of the heavy metal curing agent. The heavy metal curing agent comprises the following component raw materials: boiler ash, an alkali activator, water glass, polypropylene fiber and water; the heavy metal curing agent can be polymerized by excitation to form a cured body with high mechanical strength and good physical and chemical stability, and has a good curing effect when being used for solidifying and stabilizing solids contaminated by heavy metal such as Pb, Cd and the like; a leaching value of heavy metals meets the standard of groundwater class IV water body (GB / T14848-2017), and the raw materials of the heavy metal curing agent comes from industrial waste, therefore, the cost is low, waste control by waste is realized and the heavy metal curing agent has great application prospects.

Owner:WUHAN UNIV

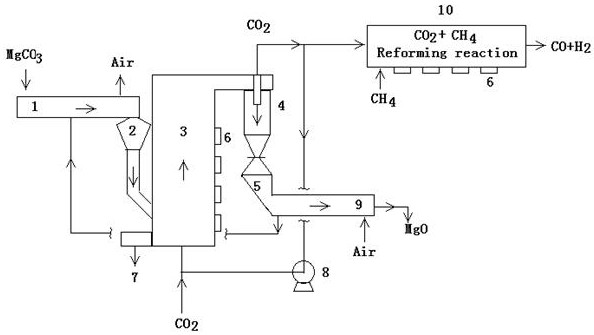

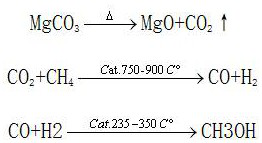

Method for preparing light-burned magnesium oxide by magnesite cracking method

The invention discloses a method for preparing light-burned magnesia by a magnesite cracking method, and relates to a method for preparing light-burned magnesia. The method comprises the following steps: the first step, magnesite powder (200 meshes) is preheated by a rotary preheater, and then uniformly enters into a fluidized bed through a feeding bin and a material leg; the second step, the magnesite powder is suspended (a residence time is 5 s-9 s) in a high-temperature (900 DEG C-1200 DEG C) carbon dioxide gas stream, and cracking is carried out to generate magnesium oxide powder and carbon dioxide gas; the third step, the generated magnesium oxide powder and carbon dioxide gas enter into a cyclone separator to realize separation of the magnesium oxide powder and carbon dioxide; the fourth step, the high-temperature magnesium oxide powder is settled to a material bin, and cooling is carried out by a rotary heat exchanger to obtain the light-burned magnesium oxide powder; the fifthstep, a part of the high-temperature and high-purity carbon dioxide is circulated as a fluidized gas, and mainly a coupling reforming reaction with methane is carried out to generate synthesis gas andfurther generate methanol; and the sixth step, air is subjected to heat exchange with the high-temperature magnesium oxide powder by a rotary jacketed heat exchanger, and then is used for preheatingthe magnesite powder to realize waste heat utilization.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

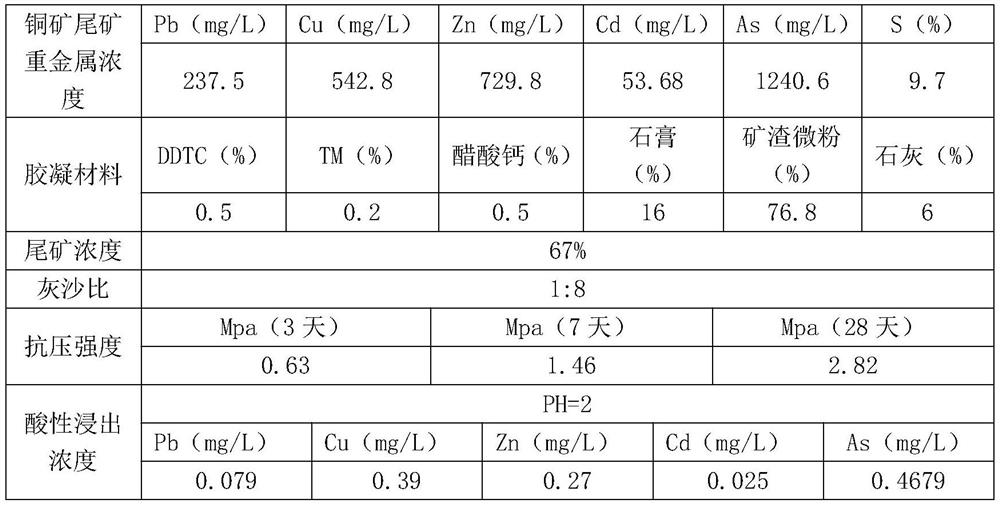

Gelling agent for curing heavy metal ions in tailings and use method thereof

PendingCN112851282AMeet strength requirementsFast curingSolid waste managementHydration reactionSlag

The invention discloses a gelling agent for solidifying heavy metal ions in tailings and a use method of the gelling agent. The gelling agent is prepared from the following raw materials in percentage by mass: 0.25-0.7% of a chelating trapping agent, 0.15-0.3% of a chelating accelerant, 0.2-0.6% of a complexing early strength agent, 1-7% of lime, 0-10% of cement, 8-20% of gypsum, 0-20% of steel slag micro powder and 50-82% of slag micro powder. The chelating trapping agent, the chelating accelerant and the complexing early strength agent are uniformly mixed, and then are uniformly mixed with other components. The gelling agent prepared by the invention not only can be used for cementing full tailings through hydration reaction to realize filling mining, but also can be used for synergistically curing heavy metal ions in the tailings through various effects of leaching, chelating, wrapping, chemical adsorption, chemical passivation, ion substitution and the like to keep the curing stability for a long time, and is especially suitable for cementing filling of full tailings with high heavy metal ion content, and the environmental risk of high content of heavy metal ions in the filling body after tailing filling is obviously reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

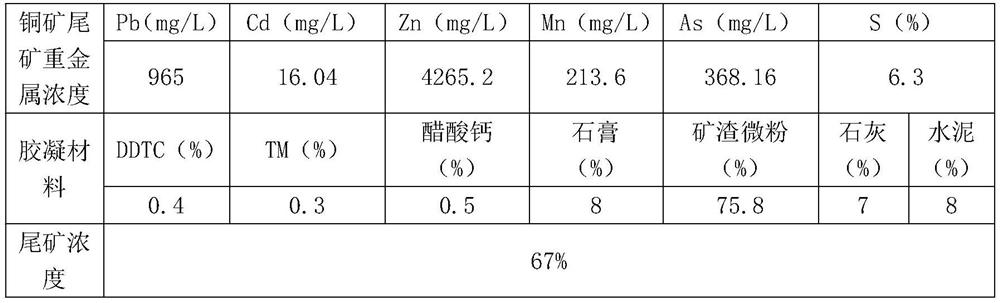

Method for dezincification of zinc-containing dust through microwave hydrogen reduction

PendingCN114525401AHigh carbon contentImprove absorbing performanceProcess efficiency improvementMixed materialsZinc

The invention discloses a method for dezincification of zinc-containing dust through microwave hydrogen reduction, which belongs to the technical field of ferrous metallurgy and comprises the following steps: S1, carrying out optimized ore blending on different types of zinc-containing dust in a steel plant to obtain an ore-blended zinc-containing dust material; s2, a binder is added into the zinc-containing dust material obtained after ore blending, powerful mixing treatment is conducted, then high-pressure roller milling and wet milling combined treatment is conducted, and a uniformly-mixed material is obtained; s3, pelletizing the uniformly mixed material to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls are put into a microwave reduction furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and reduced dezincified balls are obtained. Aiming at the characteristics of high carbon content and excellent wave-absorbing performance in the zinc-containing dust of the iron and steel plant and the characteristics of high heating speed, small heat loss, strong penetrating power, convenience in operation and the like of microwave heating, the defects of high energy consumption and serious pollution of traditional heating can be obviously improved when the zinc-containing dust is heated.

Owner:CENT SOUTH UNIV

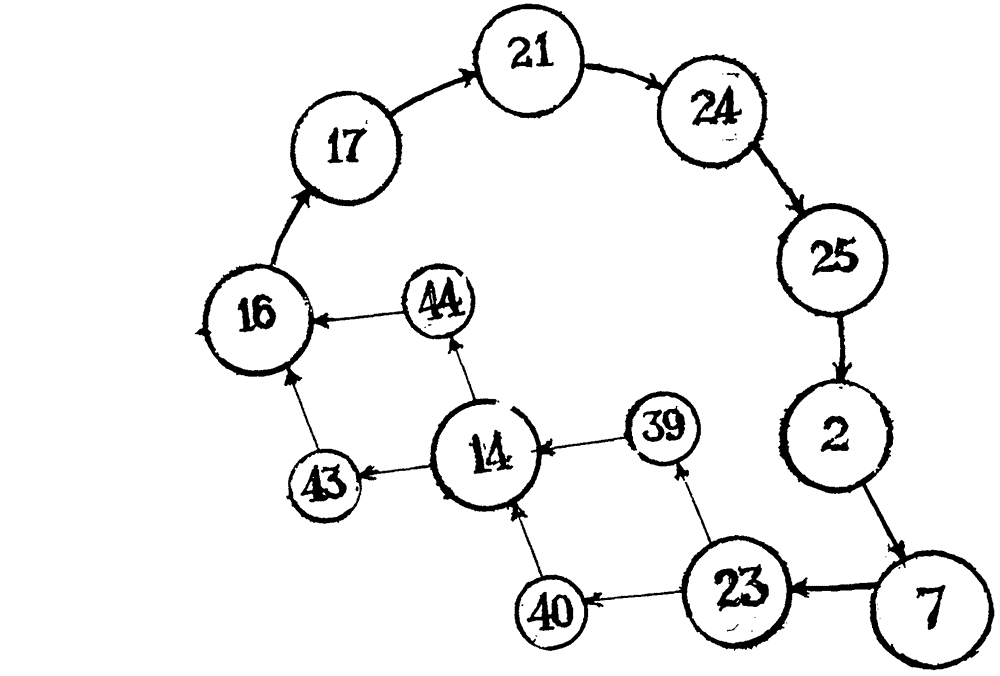

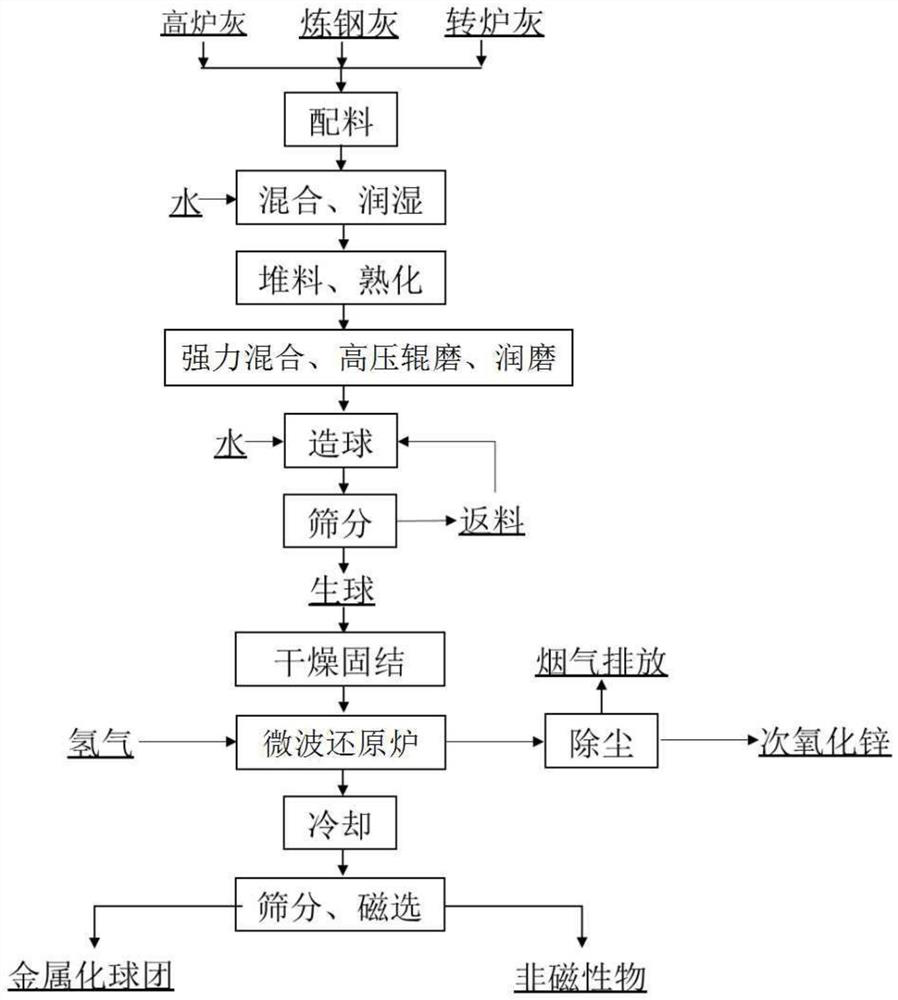

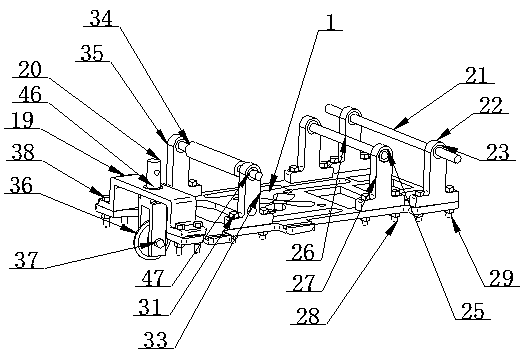

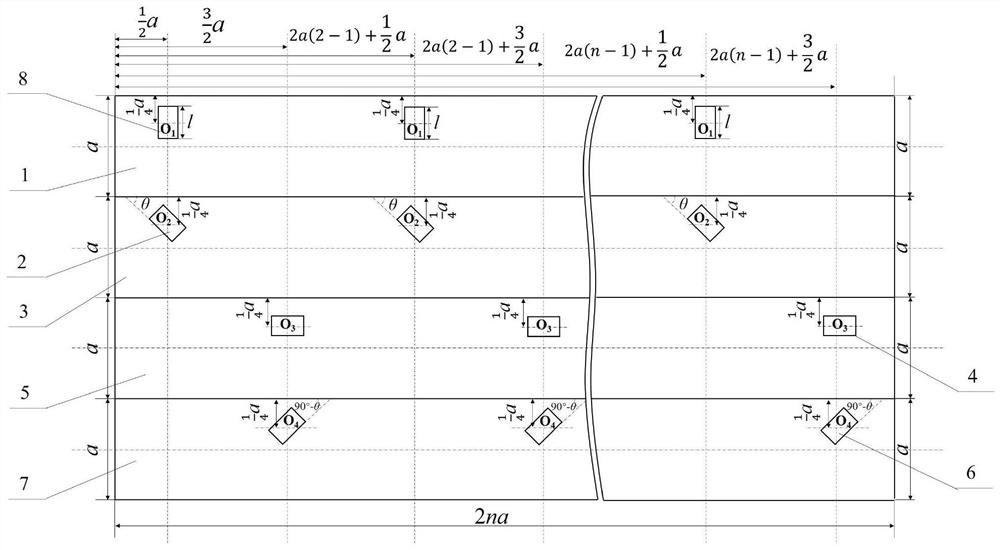

Double-reel S-type carbon-free cart

The invention relates to a double-reel S-type carbon-free cart, and belongs to the technical field of mechanical designing. The cart comprises a bottom plate, a small gear, a driven wheel, a large gear, a driving wheel, a reel wheel I, a fixed pulley supporting plate, a supporting rod, a fixed pulley II, a fixed pulley I, a fixed pulley supporting seat, weights, a supporting plate, a fine-tuning flat gear, a fine-tuning sector structure gear, a steering plate, a reel II, fish-eye holes, a front pulley supporting plate, a rear wheel shaft, a rear wheel supporting seat, a rear wheel shaft bearing, a driving wheel fixing member, a large gear shaft, a reel I supporting seat, a positioning shaft, a reel II supporting seat I, a reel II shaft, a reel II supporting seat II, front wheels, a fixed pulley shaft, a thin rope I, a thin rope II supporting rod nut, a front wheel supporting plate bearing, and a driven wheel bearing. By adopting a double-reel structure, waste of energy in the structural design of the carbon-free cart can be reduced to achieve real carbon free and energy saving and emission reduction, the structure of the cart is simplified, and the cart is easy to process and assemble.

Owner:KUNMING UNIV OF SCI & TECH

Wind energy electricity generating and supplying system of electromobile

InactiveCN101830178BReasonable designCompact structureWind energy with electric storageEnergy storageEngineeringWind power generation

The invention relates to a wind energy electricity generating and supplying system of an electromobile, relating to a wind power generation system, in particular to a wind energy electricity generating and supplying system provided for the electromobile. The wind energy electricity generating and supplying system comprises a ventilating duct, a wind speed flow-limiting valve, a plurality of wind energy generators, an automatic voltage regulator of a generator set, a power supply device and a power supply combination box, wherein the ventilating duct is arranged at the bottom of the electromoible, the wind energy generator is arranged in the ventilating duct, and the wind speed flow-limiting valve is installed at the wind inlet of the ventilating duct. A rectification voltage stabilizer comprises a rectifying diode and a voltage stabilizing diode, and a plurality of groups of line banks are installed in the power supply combination box. The power supply device comprises a control powersupply transformer and a power supplying and standby power supply, wherein the input end of the control power supply transformer is connected with the output end of a standby power supply, and the power supplying and standby power supply comprises a solid contactor, a bypass switch, a maintenance bypass switch, a bypass static switch, an output switch, a charger, an inverter, an inverting static switch, a battery pack, a standby battery pack and a filter.

Owner:太谷县晋海通电子科技有限公司

Compound pigeon manure traditional Chinese medicinal composition for treating allergic diseases, preparation method and application

InactiveCN105726621ARelieve asthma symptomsReliable anti-inflammatory effectRespiratory disorderImmunological disordersDiseaseCough variant asthma

The invention discloses a compound pigeon manure traditional Chinese medicinal composition for treating allergic diseases, a preparation method and application. The traditional Chinese medicinal composition comprises 10 parts of pigeon manure, 0 to 1 part of impatiens balsamina, and an auxiliary including 0 to 1.5 parts of albizia julibrissin durazz. or 0 to 1 part of nostoc commune; or 10 parts of pigeon manure, 0.8 to 1 part of impatiens balsamina and 1.2 to 1.5 parts of albizia julibrissin durazz.; or 10 parts of pigeon manure, 0.8 to 1 part of impatiens balsamina and 0.1 to 1 part of nostoc commune; or 10 parts of pigeon manure, 0.8 to 1 part of impatiens balsamina, 1.2 to 1.5 parts of albizia julibrissin durazz. and 0.1 to 1 part of nostoc commune. Except the impatiens balsamina, each of the other medicinal materials is independently fried, and then each fried traditional Chinese herbal medicinal material is proportionally mixed and crushed with the impatiens balsamina to finally obtain fine powder; an oral powder or liquid finished product is prepared; or oral capsules are prepared; or a powdery product for a patient to inhale is prepared. The traditional Chinese medicinal composition is mainly used for treating respiratory allergies, comprising bronchial asthma, cough variant asthma and allergic rhinitis, or treating allergic skin diseases, comprising urticaria, anaphylactoid purpura and cutis indurativa tuberculosis. The diseases can be radically treated.

Owner:梁鸿猷

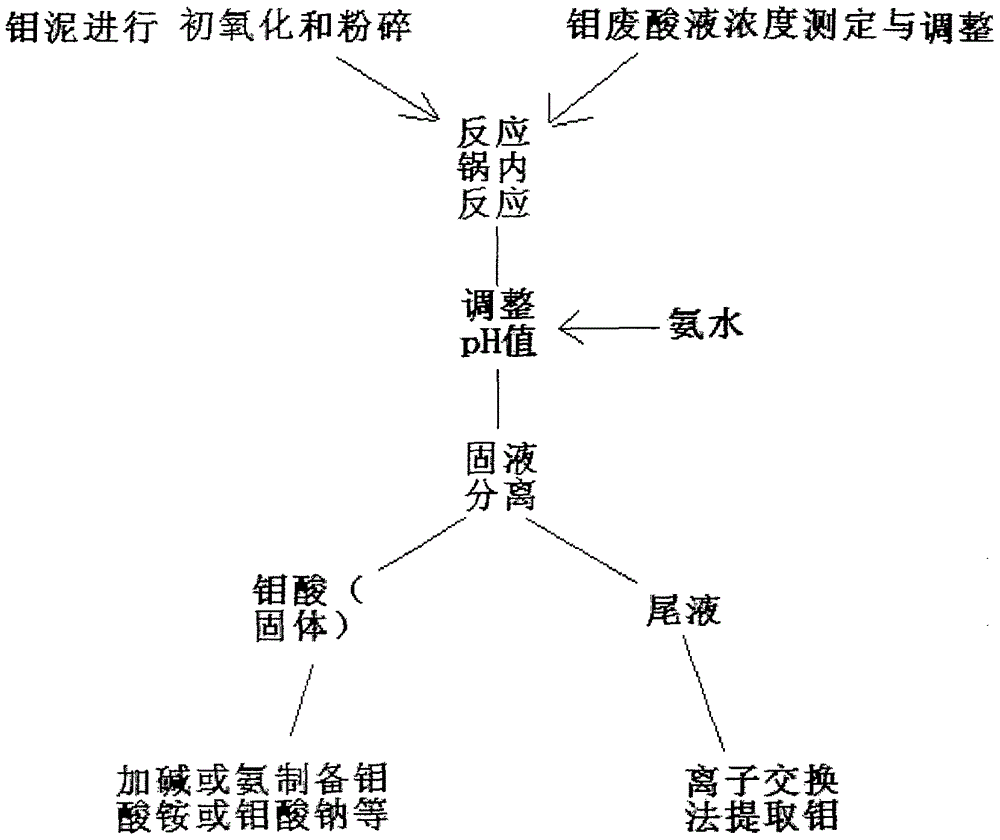

Comprehensive Utilization Method of Molybdenum in Waste Molybdenum

InactiveCN103387264BReduce dosageReduce processing costsMolybdeum compoundsSocial benefitsEconomic benefits

The invention relates to a comprehensive utilization method of molybdenum in waste molybdenum. The comprehensive utilization method comprises the following steps of: (S1) preprocessing the waste molybdenum; (S2) adjusting concentration of molybdenum acid pickle; (S3) adding the molybdenum acid pickle of which the concentration is adjusted into molybdenum mud, stirring for reacting in an enamel or stainless steel reaction vessel for 2 hours under the conditions that the initial temperature is 40-50 DEG C, the pressure is normal pressure and the stirring speed is 110 revolution / minute; (S4) regulating the pH to 1 by utilizing ammonium hydroxide so as to prepare molybdic acid; and (S5) filtering and separating the molybdic acid by utilizing a centrifugal machine or a compressor. By recycling and producing molybdenum products by utilizing the comprehensive utilization method, high economic benefit and remarkable social benefit are obtained.

Owner:高立新

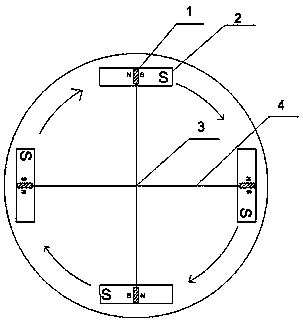

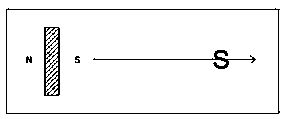

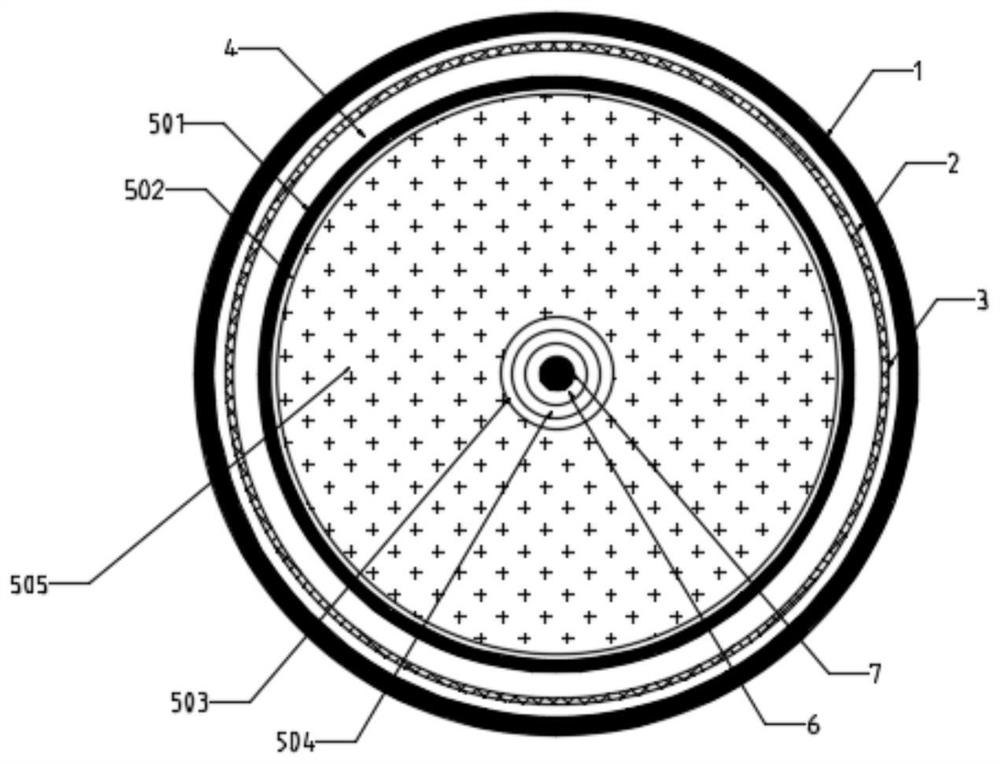

Permanent magnet mutual inductance autorotation machine

InactiveCN111276313AAchieving the goal of clean energySimple structurePermanent magnetsMagnetic polesEngineering

The invention discloses a permanent magnet mutual inductance autorotation machine. Permanent magnets are processed on a plane according to certain intervals, directions and magnetic poles. A movable mechanical rod is arranged in the center of the plane, small magnets are arranged at the two ends of the mechanical rod respectively, the small magnets are bipolar magnets, the large magnets are singlemagnetic poles, and the small magnets and the permanent magnets in the plane drive the mechanical rod to move through the magnetic mutual inductance effect. The problem that large-pollution energy sources such as electric energy and fuel oil are conventionally used in existing mechanical movement is solved, and the effect of clean energy sources is achieved.

Owner:王考

Preparation method of carbon-containing micro-electrolysis material

ActiveCN114574692AImprove adsorption capacityAchieve recyclingWater contaminantsDispersed particle separationElectrolysisMixed materials

The invention discloses a preparation method of a carbon-containing micro-electrolysis material, which comprises the following steps: S1, optimally proportioning a zinc-containing dust material, a carbon source and a binder to obtain a mixture; s2, intensively and uniformly mixing the mixture obtained in the step S1, and then carrying out high-pressure roller milling and wet milling combined treatment to obtain a uniformly mixed material; s3, pelletizing the uniformly mixed material obtained in the step S2 to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls obtained in the step S3 are loaded into a gas-based shaft furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and the carbon-containing micro-electrolysis material is obtained. According to the preparation method of the carbon-containing micro-electrolysis material, Fe and C contained in zinc-containing dust are fully utilized, dezincification of the zinc-containing dust and preparation of the micro-electrolysis material are achieved in one step through a reduction method, the traditional preparation process of the micro-electrolysis material is changed, and short-process and high-value comprehensive utilization of the zinc-containing dust is achieved.

Owner:CENT SOUTH UNIV

Method for enhancing vanadium shale ore grinding and leaching efficiency through microwaves

PendingCN114752761AImprove grindabilityImprove processing effectProcess efficiency improvementLeaching rateMineralogy

The invention relates to a method for enhancing vanadium shale ore grinding and leaching efficiency by utilizing microwaves. According to the technical scheme, the method comprises the following steps: crushing and screening vanadium shale raw ore to obtain vanadium shale raw ore with the particle size of less than 1.5 mm and vanadium shale raw ore with the particle size of 1.5-10.0 mm; starting a continuous microwave treatment device for strengthening vanadium shale ore grinding and leaching efficiency, feeding vanadium shale raw ore with the particle size of 1.5-10.0 mm from a feed port at the speed of 60-150kg / h, and performing water quenching according to the mass ratio of the vanadium shale subjected to microwave treatment to water of 1: (1-3) to obtain water-quenched slurry; and mixing the water-quenched slurry with the vanadium shale raw ore with the particle size of less than 1.5 mm according to the mass ratio of the vanadium shale raw ore with the particle size of less than 1.5 mm to the vanadium shale raw ore with the particle size of 1.5-10.0 mm of 1: (1.5-2), grinding, and leaching the obtained ground product. The method is short in treatment time, low in energy consumption, free of carbon emission, good in vanadium shale grindability and leaching rate strengthening effect, easy to operate, high in treatment efficiency and suitable for microwave strengthening of a vanadium shale all-wet-process vanadium extraction system.

Owner:WUHAN UNIV OF SCI & TECH

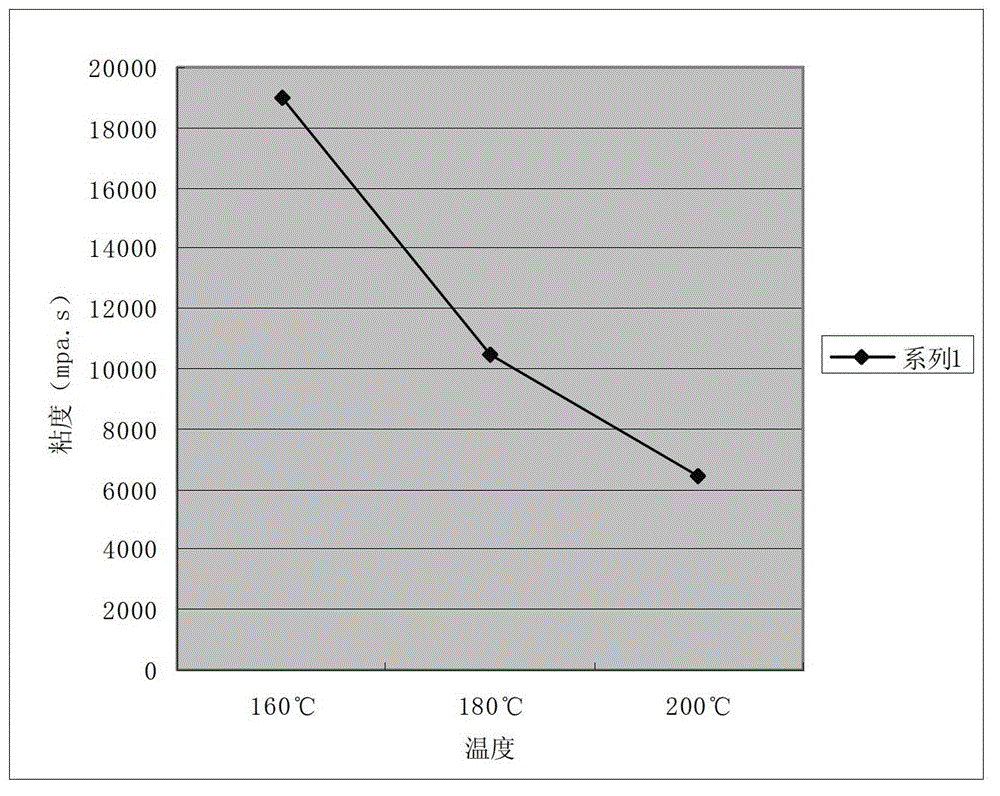

Hot-melt adhesive for transparent PP (polypropylene) boxes and preparation method of hot-melt adhesive

ActiveCN102786895BSimple processGood high and low temperature performanceMineral oil hydrocarbon copolymer adhesivesGraft polymer adhesivesPolymer sciencePolyolefin

The invention relates to a hot-melt adhesive for transparent PP (polypropylene) boxes and a preparation method of the hot-melt adhesive, in particular to a hot-melt pressure-sensitive adhesive of polyolefin and a preparation method of the hot-melt pressure-sensitive adhesive of polyolefin, belonging to the technical field of a macromolecular adhesive. The preparation method comprises the following steps: adding metallocene-catalyzed propylene wax, tackifying resin which is C5 hydrogenated petroleum resin, and antioxidant into an electric-heating reaction furnace for heating; starting stirring, adding amorphous poly alpha olefin (APAO) and maleic anhydride-modified polyolefin, heating and melting; vacuumizing and then packaging to obtain the product hot melt adhesive for transparent PP boxes. The hot-melt adhesive of the polyolefin provided by the invention is characterized by simple preparation process, excellent performance at high temperature and low temperature, no carbonization, good initial adhesion, good final strength and low cost. The components with low viscosity are added firstly and then the components with high viscosity are added in the component adding process; and the rotation load of stirring paddles in the whole stirring process can be reduced, the mixing time can be decreased and the production cost can be saved by the adding sequence of the components.

Owner:WUXI WANLI ADHESION MATERIALS

A kind of graphite electronic heat dissipation material and its preparation method and application

InactiveCN103281889BGuaranteed thermal conductivityStable temperature fieldPoint-like light sourceGraphiteCarbon nanotubeElectron

Owner:WUHAN UNIV OF TECH

Mobile phone battery aluminum foil packing seal hot melt glue and preparation method thereof

ActiveCN102911624BSimple processGood high and low temperature performanceMineral oil hydrocarbon copolymer adhesivesGraft polymer adhesivesPolyolefinPetroleum resin

The invention relates to mobile phone battery aluminum foil packing seal hot melt glue and a preparation method thereof, belonging to the technical field of macromolecular viscose. The method comprises the following steps of: putting sasol wax, tackifying resin C5 hydrocarbon resin and an antioxidant into an electric heating reaction furnace and heating; stirring; adding polyolefin and maleic anhydride modified polyolefin; heating for melting; and vacuumizing, discharging and packing to obtain a mobile phone battery aluminum foil packing seal hot melt glue product. Through the invention, the prepared polyolefin hot melt glue is simple in technology, excellent in high and low-temperature performance, good in initial adhesion and final strength and lower in cost, and prevents carbonization. When in feeding, components with lower viscosity are fed before components with higher viscosity; and the charging order can reduce the rotation load of a stirring paddle in the whole stirring process, reduce the mixing time and save the production cost.

Owner:WUXI WANLI ADHESION MATERIALS

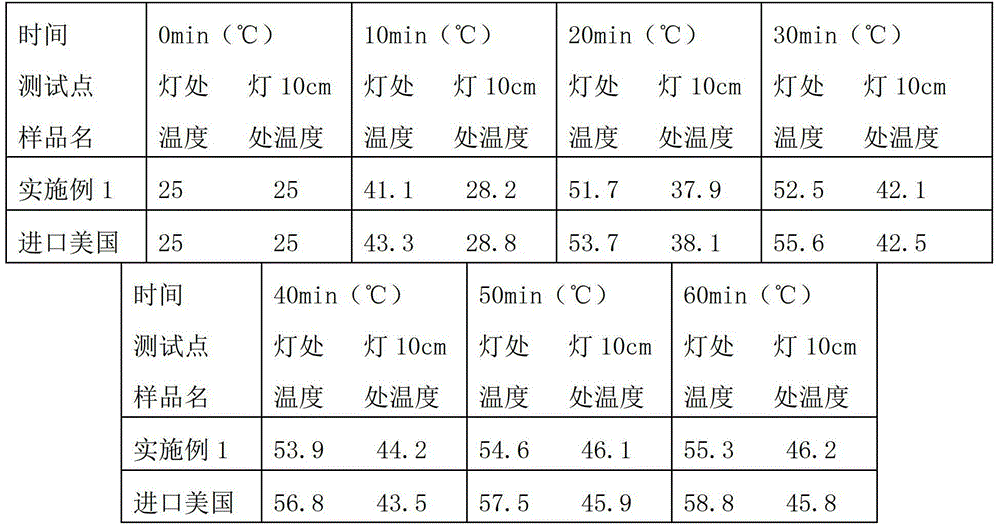

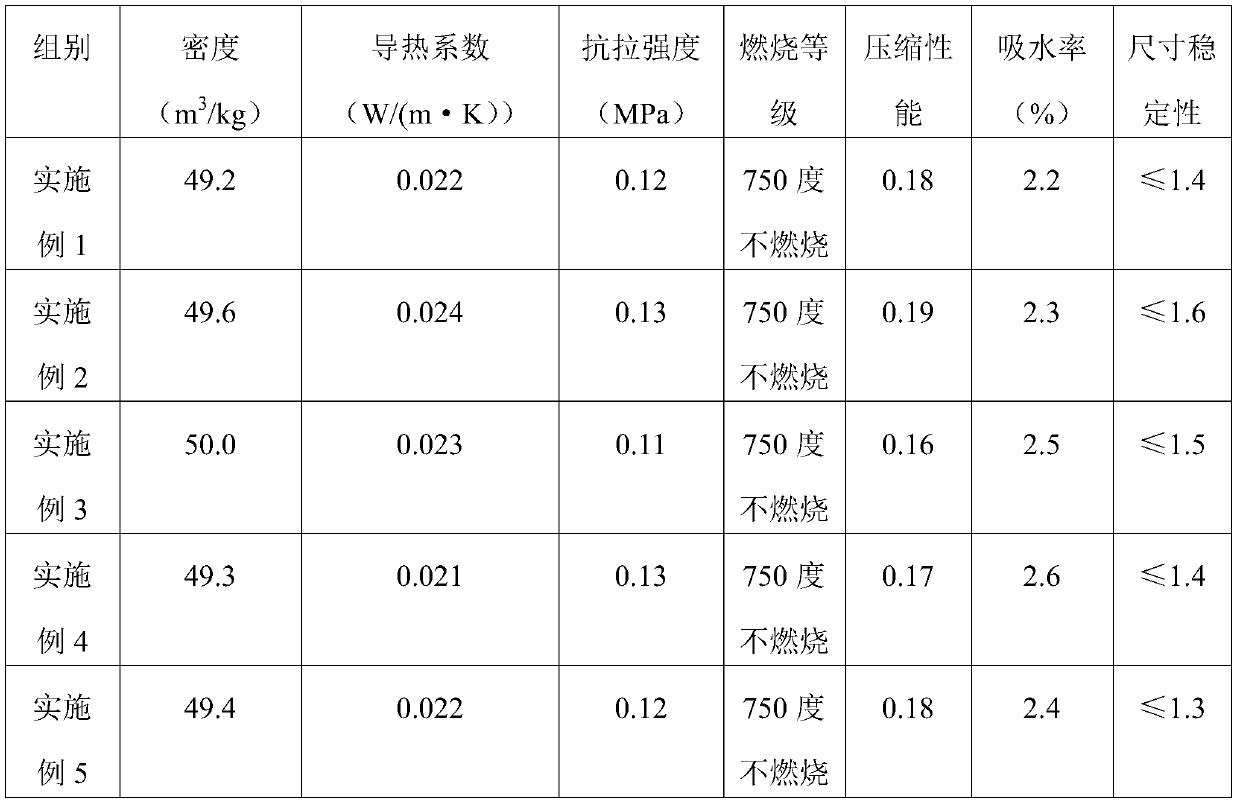

Environment-friendly resin non-combustible thermal insulation material and preparation method thereof

The invention relates to an environment-friendly resin non-combustible thermal insulation material and a preparation method thereof. The environment-friendly resin non-combustible thermal insulation material is prepared from the following raw materials: polyester polyol kR-3550, polyester polyol RP-3940, polyether polyol, clay, silicone oil, a trimerization catalyst, aluminum hypophosphite, melamine cyanurate, urea, tris(2-carboxyethyl) phosphine, purified water and isocyanate. The thermal insulation material is prepared by all-water foaming; the all-water foaming is different from the traditional physical F11 and 141B; water is used as a foaming agent for chemical reactions, and reacts with isocyanate in the foaming process to generate urea and release CO2 at the same time; the released CO2 remains in the foam holes to play a role in foaming, the amount of the released CO2 can be controlled by changing the amount of water in the process of preparing the hard foam so as to obtain foambodies with different densities and hardness, the CO2 is non-combustible and non-toxic, and the potential value ODP of ozone consumption is zero.

Owner:河北首聚新材料科技有限公司

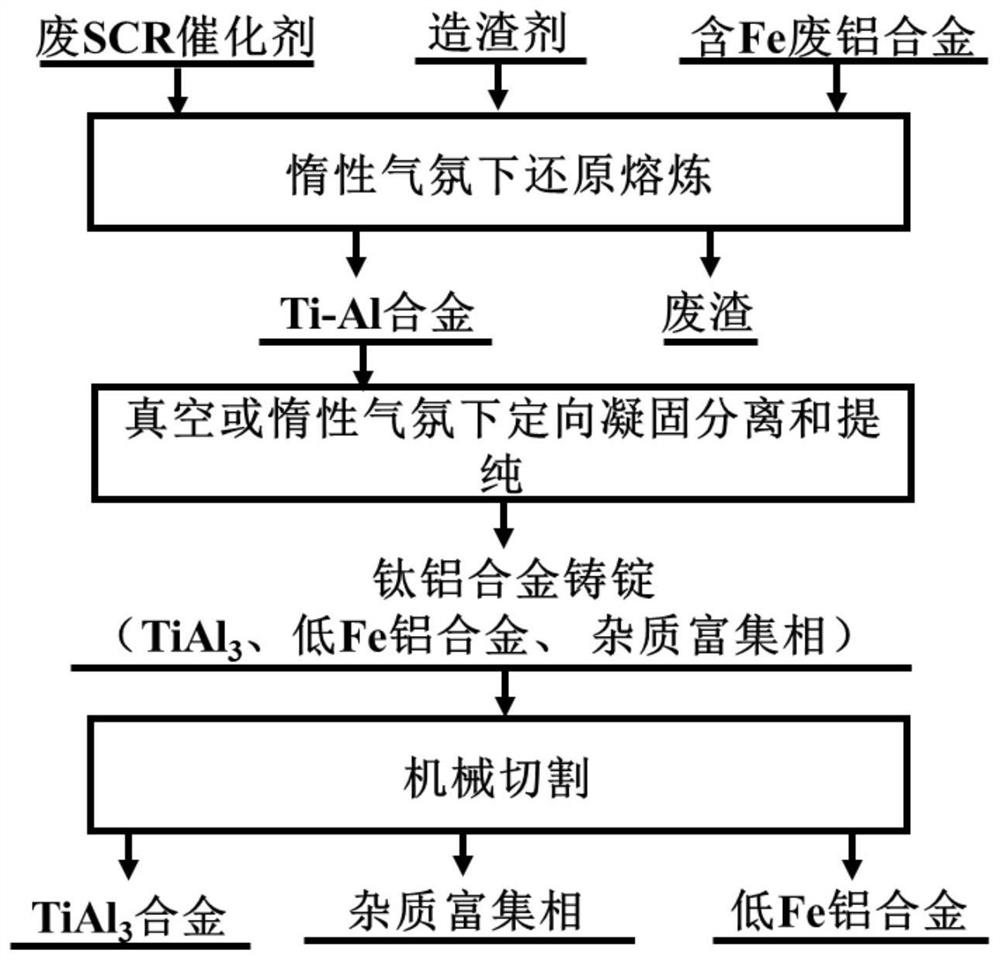

Preparation of tial by using Fe-containing waste aluminum alloy and waste SCR catalyst 3 Methods for Alloys and Low Fe Aluminum Alloys

ActiveCN112981103BEfficient removalFriendly resource utilizationProcess efficiency improvementPtru catalystSlag

Owner:KUNMING UNIV OF SCI & TECH

A method for preparing light-burned magnesia by a magnesite cracking method

ActiveCN110526597BRealize dual utilizationEmission reductionHydrogenEnergy inputEngineeringMagnesite

A method for preparing light-burned magnesia by cracking magnesite, relates to a method for preparing light-burned magnesia. In the first step of the method, magnesite powder (200 mesh) is preheated by a rotary preheater, and then processed The silo and material legs evenly enter the fluidized bed; the second step is that the magnesite powder is suspended in the high temperature (900°C-1200°C) carbon dioxide gas flow (residence time 5s-9s) and cracked to generate magnesium oxide powder and carbon dioxide gas; the second step The magnesium oxide powder and carbon dioxide gas generated in the three steps enter the cyclone separator to realize the separation of magnesium oxide powder and carbon dioxide; in the fourth step, the high temperature magnesium oxide powder settles to the silo, and is cooled by a heat exchanger to obtain lightly burned magnesium oxide powder; In the fifth step, part of the high-temperature and high-purity carbon dioxide is circulated as a fluidized gas, which is mainly coupled with methane to generate synthesis gas and methanol; in the sixth step, air and high-temperature magnesium oxide powder are exchanged through a rotary jacket heat exchanger. After heating, it is used for preheating magnesite powder to realize waste heat utilization.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

External wall heat-insulation and fire-retardant material and preparation method thereof

The invention discloses an external wall heat-insulation and fire-retardant material and a preparation method thereof. The external wall heat-insulation and fire-retardant material is characterized by being prepared from 60-70 parts of foamable thermoset phenolic resin, 30-40 parts of thermoset linear urea resin, 3-8 parts of Tween 80, 10-30 parts of quartz powder, 10-15 parts of micro powder aluminium hydroxide, 10-20 parts of 4A zeolite, 5-12 parts of n-pentane and 2-6 parts of concentrated sulfuric acid. The external wall heat-insulation and fire-retardant material product disclosed by the invention is characterized in that the oxygen index is more than or equal to 55%, the water absorption is less than or equal to 2% (soaked for 24 hours), the heat conductivity coefficient is 0.02-0.029w / mk, the stability and weather resistance of the product are good, and the external wall heat-insulation and fire-retardant material product is non-toxic, odourless and environmentally-friendly. The external wall heat-insulation and fire-retardant material product is ideal fireproof, heat-insulation, energy-saving and beautiful environmentally-friendly decorative material. Detections carried out by national fireproof construction material quality supervision and inspection center show that the combustion performance of the external wall heat-insulation and fire-retardant material product disclosed by the invention is up to the grade A of the standard GB8624-2006 classification for burning behaviour of building materials and products.

Owner:南充春飞纳米晶硅技术有限公司

Environmental protection low discharging device capable of controlling exhaust noise and black smoke for diesel engine vehicles

InactiveCN1570360AFull combustion exhaustLower smoke temperatureExhaust apparatusSilencing apparatusEngineeringFuel oil

May control the diesel engine vehicle to discharge noise black smoke natural environmental protection lowly discharging, design environmental protection exhaust noise black smoke control device domain. This invention goal is for overcome the solution above diesel engine, in the vehicle existing exhaust technology the deficiency, but provided one kind to adapt each diesel engine, the vehicle may arrange the noise elimination noise reduction, might control the fuel oil to discharge the ink smoke, did not need any existing traditional exhaust pipe and so on the appurtenance. And can achieve the environmental protection arranges the noise elimination noise reduction to reduce smoke, lowly exhausts the request to be possible to control diesel engine vehicle exhaust noise black smoke natural environmental protection lowly discharging. This invention goal is realizes like this; It takes a breath the burner body by the exhaust, first burning discharges fume the tube body, first burning discharges fume the tube, the lukewarm water air jacket, the purification burning carbon, the exhaust trades the trachea, the ear listens airless the sound examination to measure listens to part constitution and so on the exhaust pipe.

Owner:吴义贵 +1

Low-carbon high-efficiency nano-zirconium silicate manufacturing method and manufacturing device

ActiveCN105032578BLow-carbon production and sales methodsGreen production and sales methodsGrain treatmentsNano manufacturingHigh energy

The invention relates to a method and device for manufacturing low-carbon and high-efficiency nano-zirconium silicate, comprising: a high-energy drum-type ultra-fine ball mill, a high-efficiency stirring nano-ball mill and a nano-material slurry water separation device. The low-carbon high-efficiency nano-zirconium silicate manufacturing method of the present invention improves the traditional ball mill into a high-energy drum-type ultra-fine ball mill, improves the traditional agitating ball mill into a high-efficiency agitating nano-ball mill, and newly invents a nano-material slurry water separation unit, Make zirconium silicate products enter the era of high-efficiency nano-scale processing and production from the micron-scale era. It is the first time to use liquid packaging technology in the zirconium silicate industry, which saves the drying process, reduces costs, and has no carbon emissions. It realizes the low-carbon, green, and circular production and sales methods of nano-zirconium silicate production.

Owner:唐山市康陶新材料有限公司

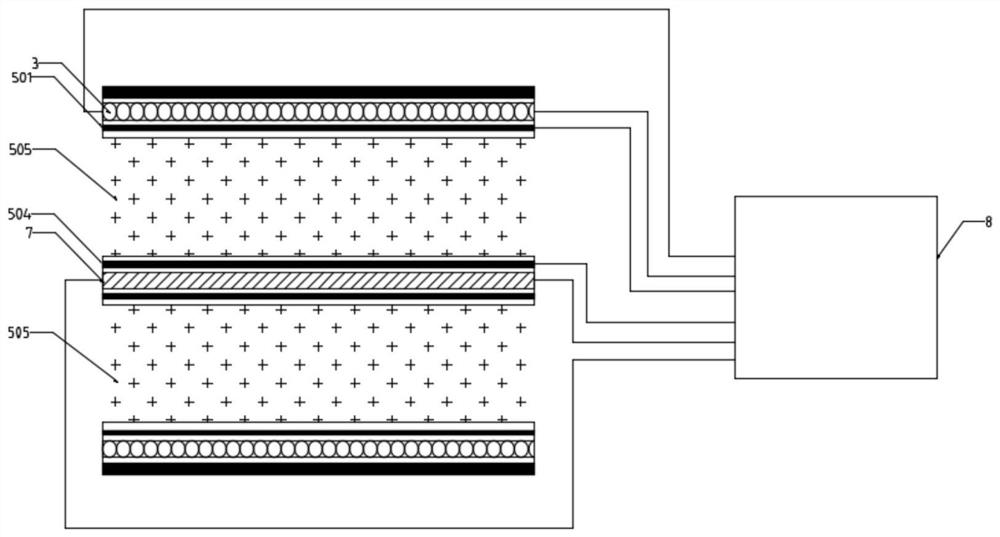

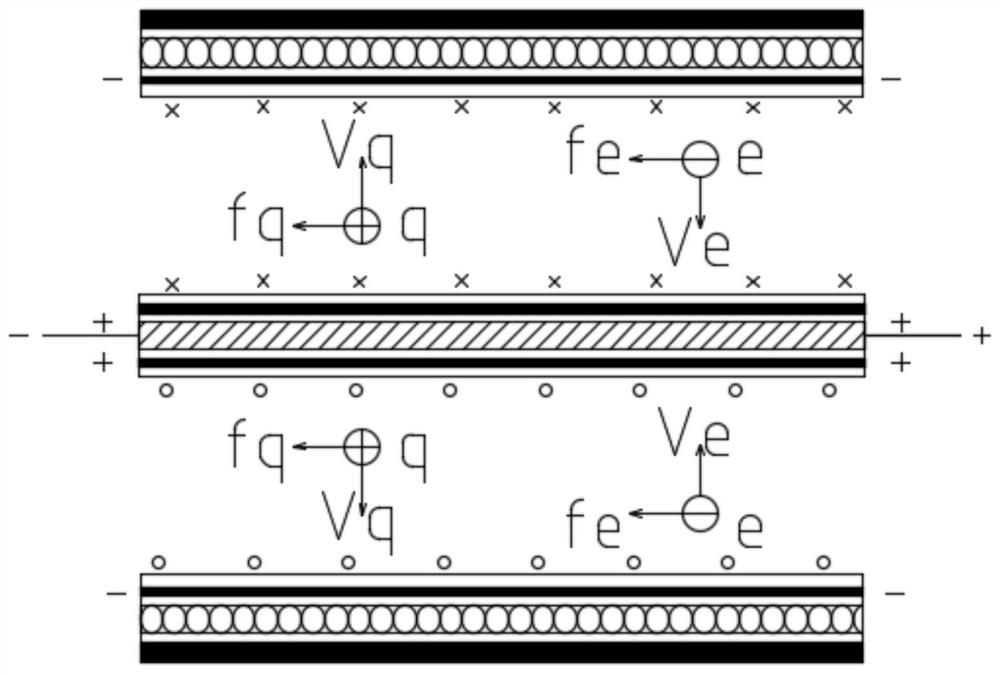

Spiral waveform vibration ion engine

The invention discloses a spiral waveform vibration ion engine. A shell, an insulation heat insulation layer, a coil heating layer, a first insulation layer, an electrode cavity, a second insulation layer and a magnetic field generation rod are sequentially arranged from the outermost layer to the innermost layer of the ion engine. The electrode cavity sequentially comprises an electrode cavity outer ring, a third insulating layer, a fourth insulating layer and an electrode cavity inner ring from outside to inside; a propellant is filled between the third insulating layer and the fourth insulating layer; and two poles of the coil heating layer, the outer ring of the electrode cavity, the inner ring of the electrode cavity and two poles of the magnetic field generating rod are electrically connected with an alternating current power supply. The spiral waveform vibration ion engine has the beneficial effects of high efficiency and large thrust-weight ratio; cleanness and no carbon emission are realized; according to different properties of the carrier, the engine can select different metals, liquid metals or strong electrolytes as propellants; the engine can be designed to be cylindrical, disc-shaped or ring-shaped according to different shapes of carriers; and energy is saved, and long-time use can be achieved by one-time propellant filling.

Owner:孙克

Preparation method and application of environment-friendly hot melt adhesive having low initial adhesion and no compression sensitivity after curing and used for disposable sanitary material

InactiveCN109233708AWon't happenImprove adhesionMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesProduction lineWax

The invention discloses a preparation method and an application of an environment-friendly hot melt adhesive having low initial adhesion and no compression sensitivity after curing and used for a disposable sanitary material. The hot melt adhesive is prepared from 10%-25% of naphthenic oil, 15%-35% of a macromolecular polymer, 1%-10% of synthetic wax and 0.1%-1.0% of an antioxidant. The inventionmainly aims to provide the environment-friendly hot melt adhesive which is used at four end seal parts of the disposable sanitary material, is not carbonized, has excellent bonding property, low initial adhesion, no compression sensitivity and low odors, continuous production of a production line can be guaranteed, the repair and maintenance costs of equipment can be reduced, and 10%-30% of production cost can be saved as compared with a traditional SBC formula hot melt adhesive. The hot melt adhesive overcomes the defects of high initial adhesion and high compression sensitivity of hot melt adhesives after curing in the prior art. The hot melt adhesive reduces initial adhesion and compression sensitivity of the hot melt adhesive after curing by use of a novel host material at four end seal parts of the disposable sanitary material.

Owner:GUANGDONG RURGA NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com