Spiral waveform vibration ion engine

A technology of ion engine and waveform vibration, applied in electromechanical devices, electrical components, etc., can solve problems that cannot be effectively solved, bulky, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

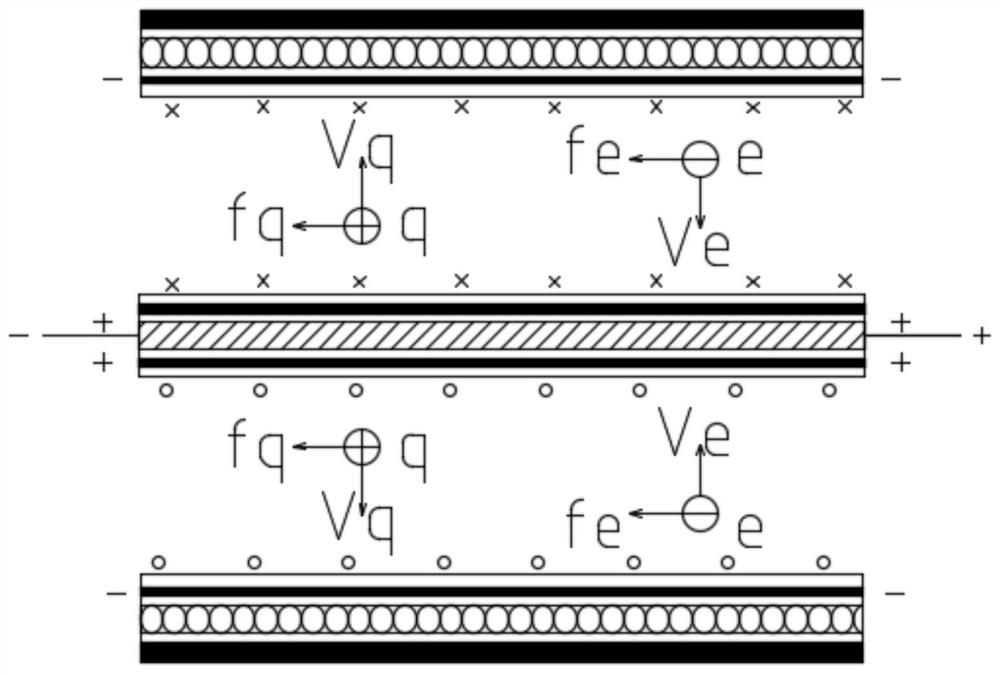

[0024] Specific embodiment 1, a kind of helical waveform vibrating ion engine, is power source with metal, liquid metal or strong electrolyte;

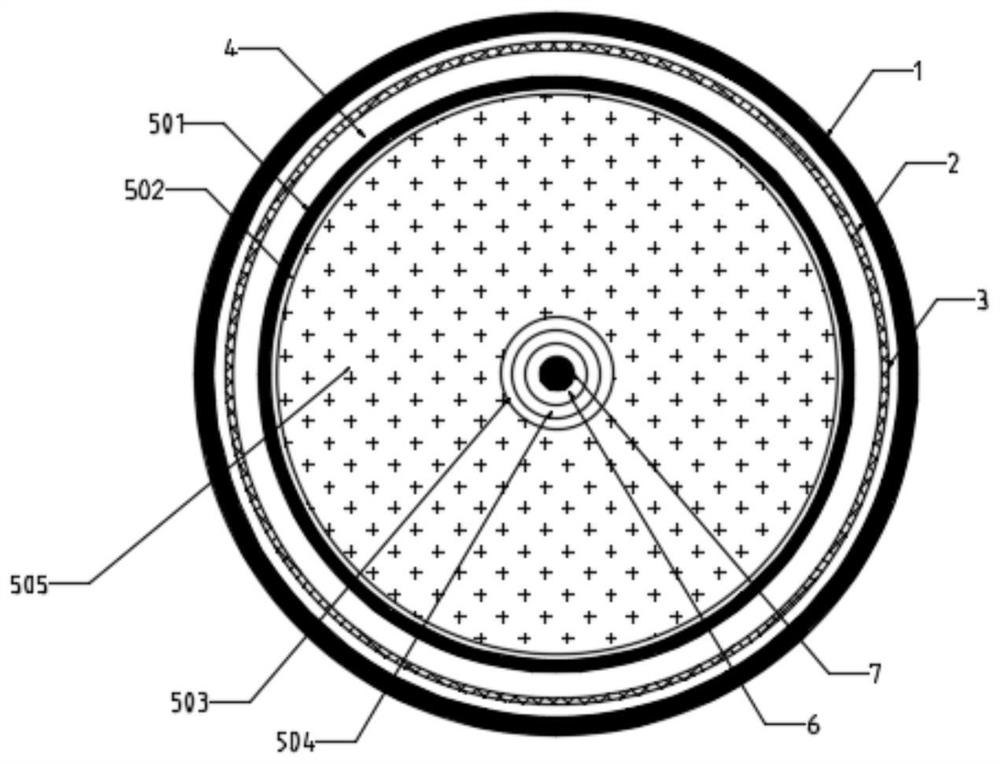

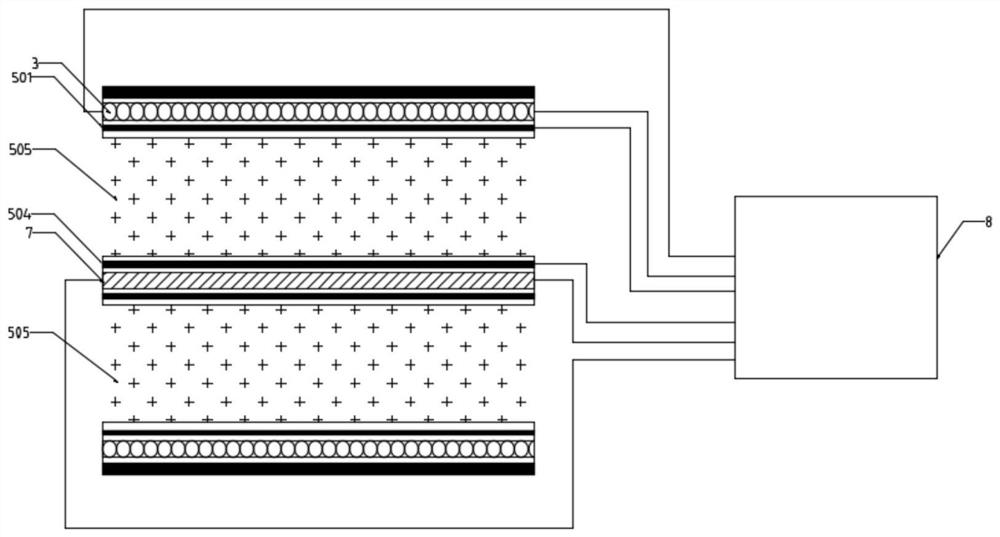

[0025] From the outermost layer to the innermost axis of the ion engine, there are sequentially provided shells 1, insulation and heat insulation layers 2, coil heating layers 3, first insulation layers 4, electrode chambers, second insulation layers 6, and magnetic field generators. stick 7;

[0026] The electrode cavity includes an outer ring 501 of the electrode cavity, a third insulating layer 502, a fourth insulating layer 503 and an inner ring 504 of the electrode cavity from the outside to the inside. Propellant 505, in the present embodiment 1, propellant 505 is metal, liquid metal;

[0027] Wherein, the two poles of the coil heating layer 3 , the outer ring 501 of the electrode cavity, the inner ring 504 of the electrode cavity and the two poles of the magnetic field generating rod 7 are all electrically connected to the AC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com