Mobile phone battery aluminum foil packing seal hot melt glue and preparation method thereof

A mobile phone battery and hot-melt adhesive technology, which is applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve the problems of inability to achieve low-temperature adhesive strength at -20°C, demanding technical requirements, and long curing time, etc. problem, to achieve the effect of good final strength, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

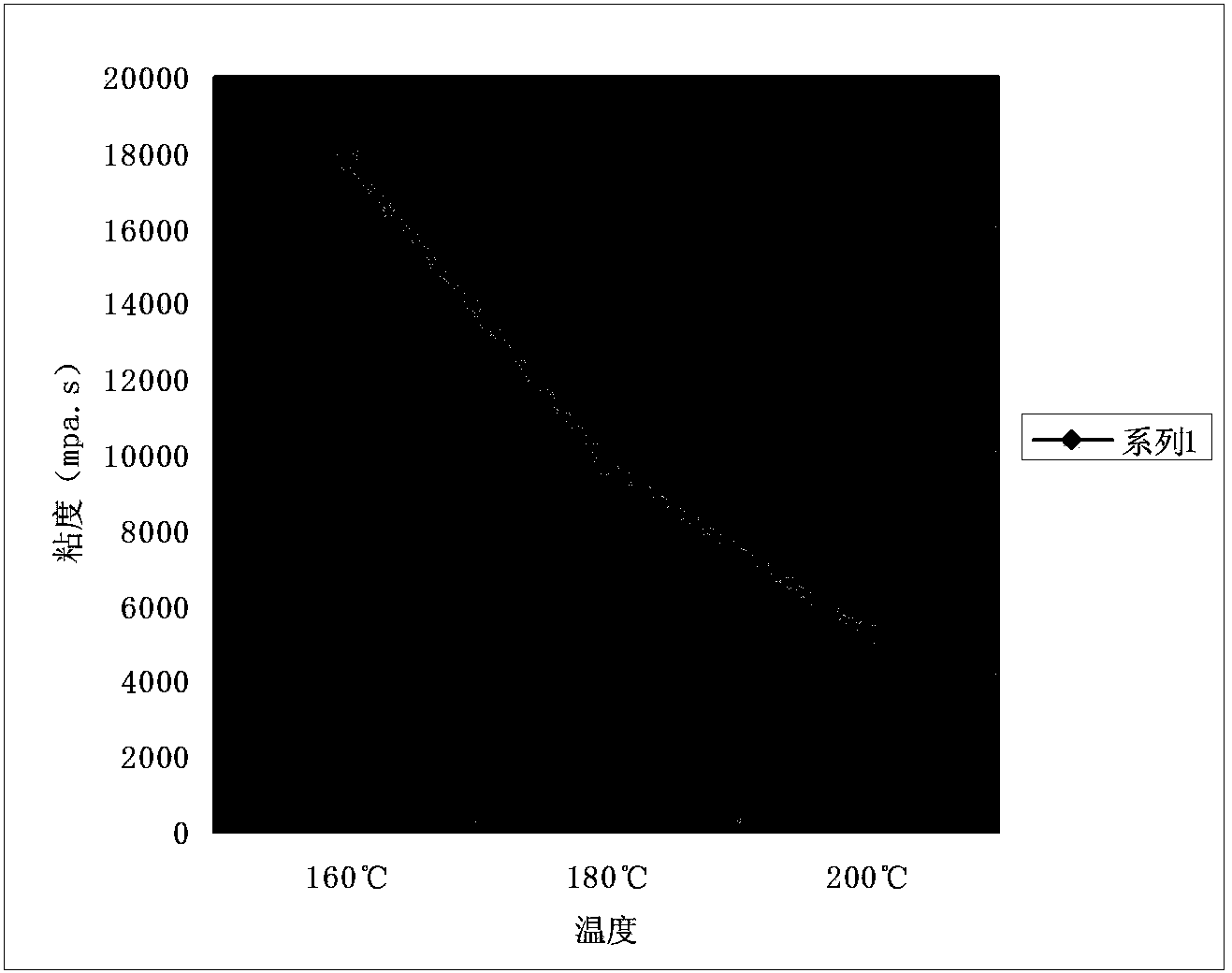

Image

Examples

Embodiment 1

[0021] Hot melt adhesive formula for aluminum foil packaging sealing of mobile phone battery:

[0022] Polyolefin POP: 15kg, Polyolefin POE: 15 kg, C5 Hydrogenated Petroleum Resin: 35 kg, Sasol Wax: 5 kg, Maleic Anhydride Modified Polyolefin: 30 kg, Antioxidant 1010: 0.15 kg, Antioxidant Oxygen 168: 0.15 kg.

[0023] Preparation method of hot melt adhesive for aluminum foil packaging of mobile phone battery

[0024] (1) Heating: put Sasol wax, tackifying resin C5 hydrogenated petroleum resin and 100% antioxidant into an electric heating reaction furnace, raise the temperature to 130°C, and heat for 40 minutes to obtain a mixture;

[0025] (2) Melting: Start stirring, stir the mixture obtained in step (1) at a stirring speed of 80~120r / min, put in polyolefin POP, polyolefin POE and maleic anhydride modified polyolefin, heat up to 160°C until the reactant all melted;

[0026] (3) Vacuumizing and discharging: Seal the electric heating reaction furnace, turn on the vacuum pump,...

Embodiment 2

[0033] Hot melt adhesive formula for aluminum foil packaging sealing of mobile phone battery:

[0034] Polyolefin POP: 13kg, Polyolefin POE: 12kg, C5 Hydrogenated Petroleum Resin: 30 kg, Sasol Wax: 10 kg, Maleic Anhydride Modified Polyolefin: 35 kg, Antioxidant 1010: 0.15 kg, Antioxidant Dosage 168: 0.15 kg.

[0035] Preparation method of hot melt adhesive for aluminum foil packaging of mobile phone battery

[0036] (1) Heating: put Sasol wax, tackifying resin C5 hydrogenated petroleum resin and 100% antioxidant into an electric heating reaction furnace, raise the temperature to 130°C, and heat for 40 minutes to obtain a mixture;

[0037] (2) Melting: Start stirring, stir the mixture obtained in step (1) at a stirring speed of 80~120r / min, put in polyolefin POP, polyolefin POE and maleic anhydride modified polyolefin, heat up to 160°C until the reactant all melted;

[0038] (3) Vacuumizing and discharging: Seal the electric heating reaction furnace, turn on the vacuum pump,...

Embodiment 3

[0044] Hot melt adhesive formula for aluminum foil packaging sealing of mobile phone battery:

[0045] Polyolefin POP: 10kg, Polyolefin POE: 10kg, C5 Hydrogenated Petroleum Resin: 33kg, Sasol Wax: 8kg, Maleic Anhydride Modified Polyolefin: 32kg, Antioxidant 1010: 0.2kg, Antioxidant 168: 0.2kg.

[0046] The preparation method of the sealing hot-melt adhesive for aluminum foil packaging of mobile phone batteries is as follows in parts by weight:

[0047] (1) Heating: put Sasol wax, tackifying resin C5 hydrogenated petroleum resin and antioxidant into an electric heating reaction furnace, raise the temperature to 170°C, and heat for 30 minutes to obtain a mixture;

[0048] (2) Melting: Start stirring, stir the mixture obtained in step (1) at a stirring speed of 100r / min, put in polyolefin POP, polyolefin POE and maleic anhydride modified polyolefin, heat up to 180°C until the reactants are completely melted ;

[0049] (3) Vacuumizing and discharging: Seal the electric heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com